The square box in the motor type will contain a number representing

the motor length.

20(0.79)

_

_

_

190(42)

210(47)

480(108)

15(0.59)

37(8.3)

52(11.7)

130(29)

130(29)

160(36)

390(87)

10(0.39)

27(6.0)

34(7.6)

89(20)

95(21)

130(29)

340(76)

5(0.2)

21(4.7)

25(5.6)

67(15.0)

75(16.8)

110(24)

290(65)

PH533

PH544

PX53

PX24

PK54

PK24

PK25

PK26

PH554

PH56

PH26

PK56

PH59

PH29

PK59

PK29

Thank you for purchasing an Oriental Motor product.

This Operating Manual describes product handling procedures and

safety precautions.

●

Please read it thoroughly to ensure safe operation.

●

Always keep the manual where it is readily available.

HM-601-17

Introduction

The precautions described below are intended to prevent

danger or injury to the user and other personnel through

safe, correct use of the product. Use the product only after

carefully reading and fully understanding these instructions.

Safety precautions

●

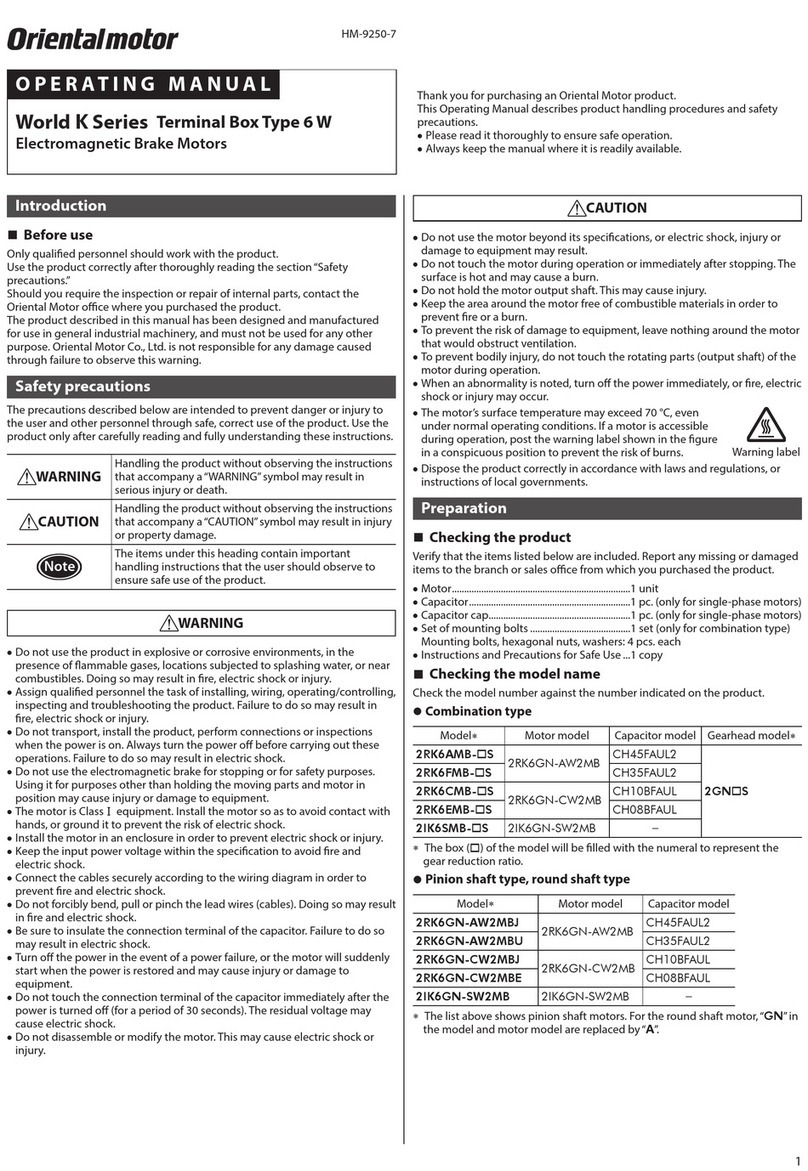

Through hole type

Motor type

Distance from the top of motor’s output shaft [mm (inch)]

0(0)

17(3.8)

20(4.5)

54(12.1)

63(14.1)

96(21)

260(58)

Handling the product without observing the instructions

that accompany a “Warning” symbol may result in serious

injury or death.

●

Do not use the product in explosive or corrosive envi-

ronments, in the presence of flammable gases, loca-

tions subjected to splashing water, or near com-

bustibles. Doing so may result in fire or injury.

●

Assign qualified personnel the task of installing, wiring,

operating/controlling, inspecting and troubleshooting

the product. Failure to do so may result in fire or injury.

●

Provide a means to hold the moving parts in place for ap-

plications involving vertical travel. The motor loses

holding torque when the power is shut off, allowing the

moving parts to fall and possibly causing injury or dam-

age to equipment.

●

Install the motor in an enclosure in order to prevent in-

jury.

●

Keep the input-power voltage within the specified range

to avoid fire.

●

Connect the cables securely according to the wiring di-

agram in order to prevent fire.

●

Do not forcibly bend, pull or pinch the cable. Doing so

may fire.

●

For the power supply use a DC power supply with rein-

forced insulation on its primary and secondary sides.

Failure to do so may result in electric shock.

●

Turn off the power in the event of a power failure, or the

motor will suddenly start when the power is restored

and may cause injury or damage to equipment.

●

Do not disassemble or modify the motor. This may

cause injury. Refer all such internal inspections and re-

pairs to the branch or sales office from which you pur-

chased the product.

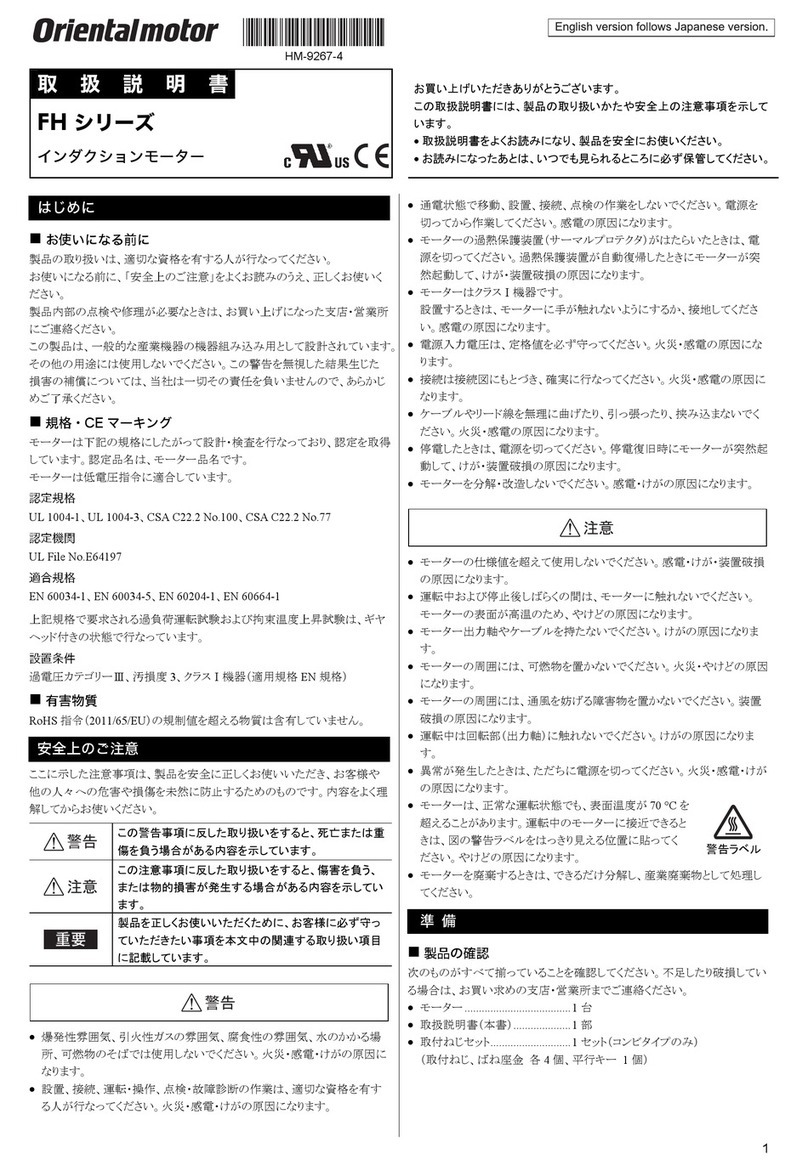

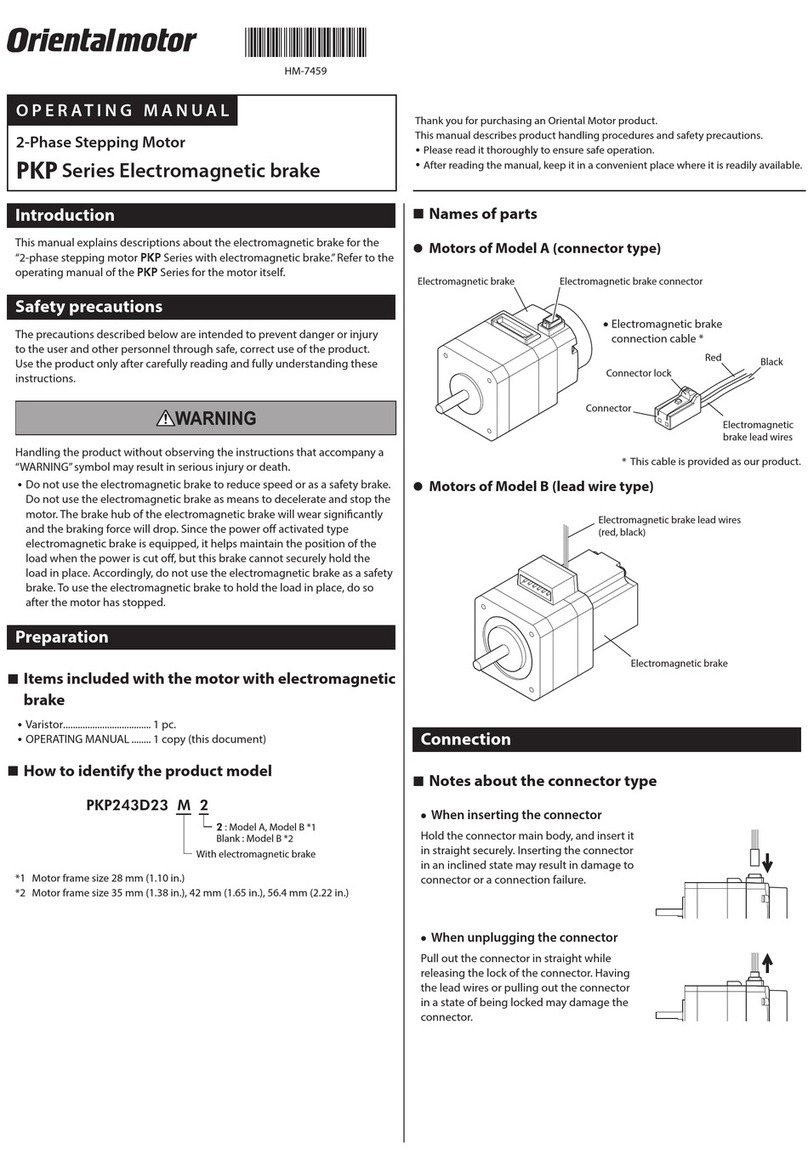

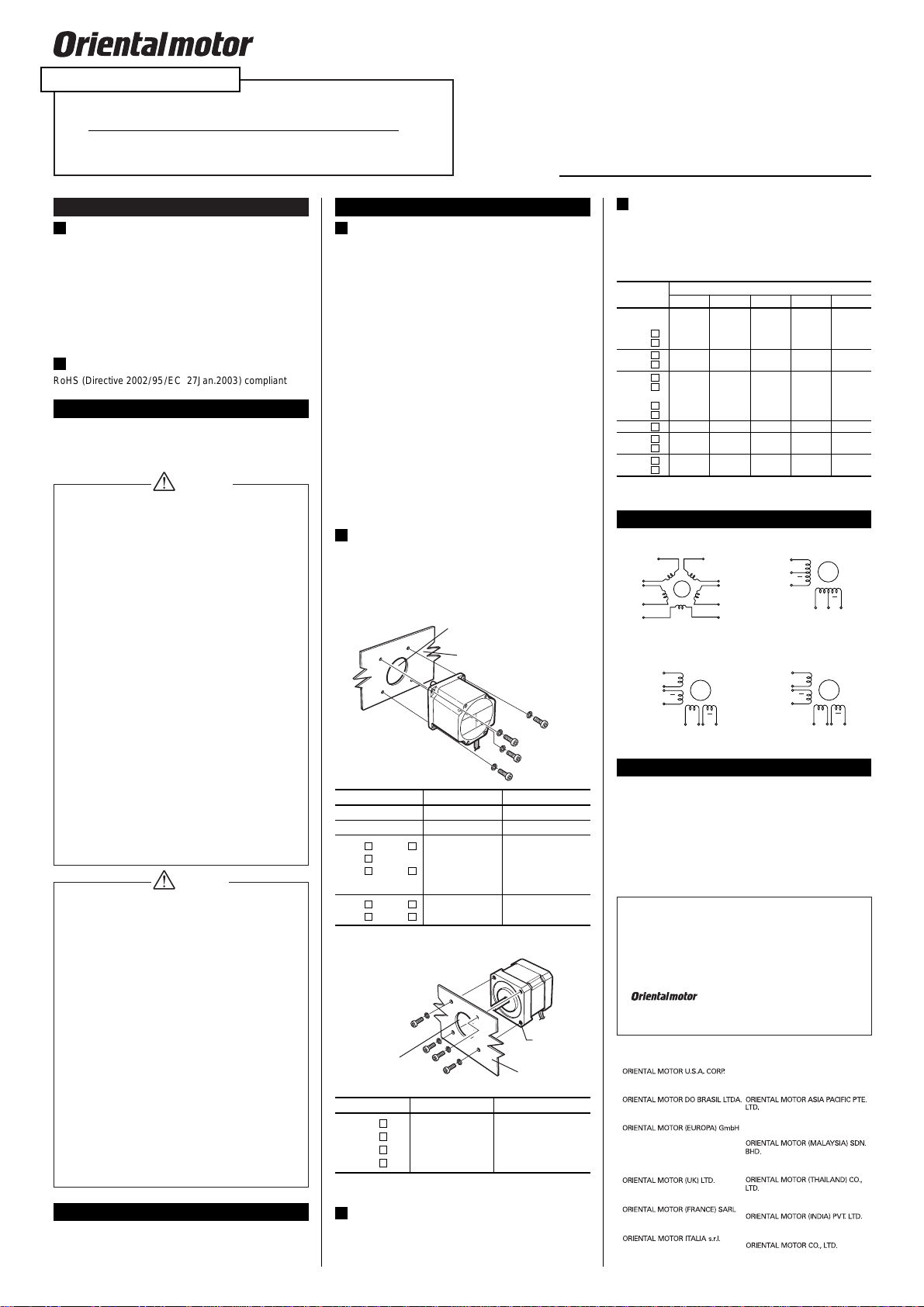

How to install the motor

Install the motor onto an appropriate flat metal plate having

excellent vibration resistance and heat conductivity. When

installing the motor, secure it with four bolts (not supplied)

through the four mounting holes (or tapped holes) provided.

Leave no gap between the motor and plate.

Mounting-pilot holder

(countersunk or

drilled through) Metal plate

4-M3P0.5

(4-No.4-40UNC)

Metal plate

Mounting-pilot holder

(countersunk or drilled through)

Handling the product without observing the instructions

that accompany a “Caution”symbol may result in injury or

property damage.

●

Do not use the motor beyond its specifications, or in-

jury or damage to equipment may result.

●

Do not touch the motor during operation or immediate-

ly after stopping. The surface is hot and may cause a

burn.

●

Do not hold the motor output shaft or motor cable. This

may cause injury.

●

Provide an emergency-stop device or emergency-stop

circuit external to the equipment so that the entire

equipment will operate safely in the event of a system

failure or malfunction. Failure to do so may result in in-

jury.

●

To prevent bodily injury, do not touch the rotating parts

(output shaft) of the motor during operation.

●

Immediately when trouble has occurred, stop running

and turn off the power. Failure to do so may result in fire,

electric shock or injury.

●

Conduct the insulation resistance measurement or with-

stand voltage test separately on the motor and the dri-

ver. Failure to do so may result in equipment damage.

●

To dispose of the motor, disassemble it into parts and

components as much as possible and dispose of indi-

vidual parts/components as industrial waste.

To verify that the unit you’ve purchased is the correct one,

check the model number shown on the identification plate.

Report any incorrect or damaged item to the branch or sales

office from which you purchased the product.

Checking the product

Before using the motor

Only qualified personnel should work with the product.

Use the product correctly after thoroughly reading the section

“Safety precautions”.

The product described in this manual has been designed

and manufactured for use in general industrial machinery,

and must not be used for any other purpose. For the power

supply use a DC power supply with reinforced insulation on

its primary and secondary sides. Oriental Motor Co., Ltd. is

not responsible for any damage caused through failure to

observe this warning.

●

Tapped hole type

The square box in the motor type will contain a number representing

the motor length. (No.4-40UNC): USA model type

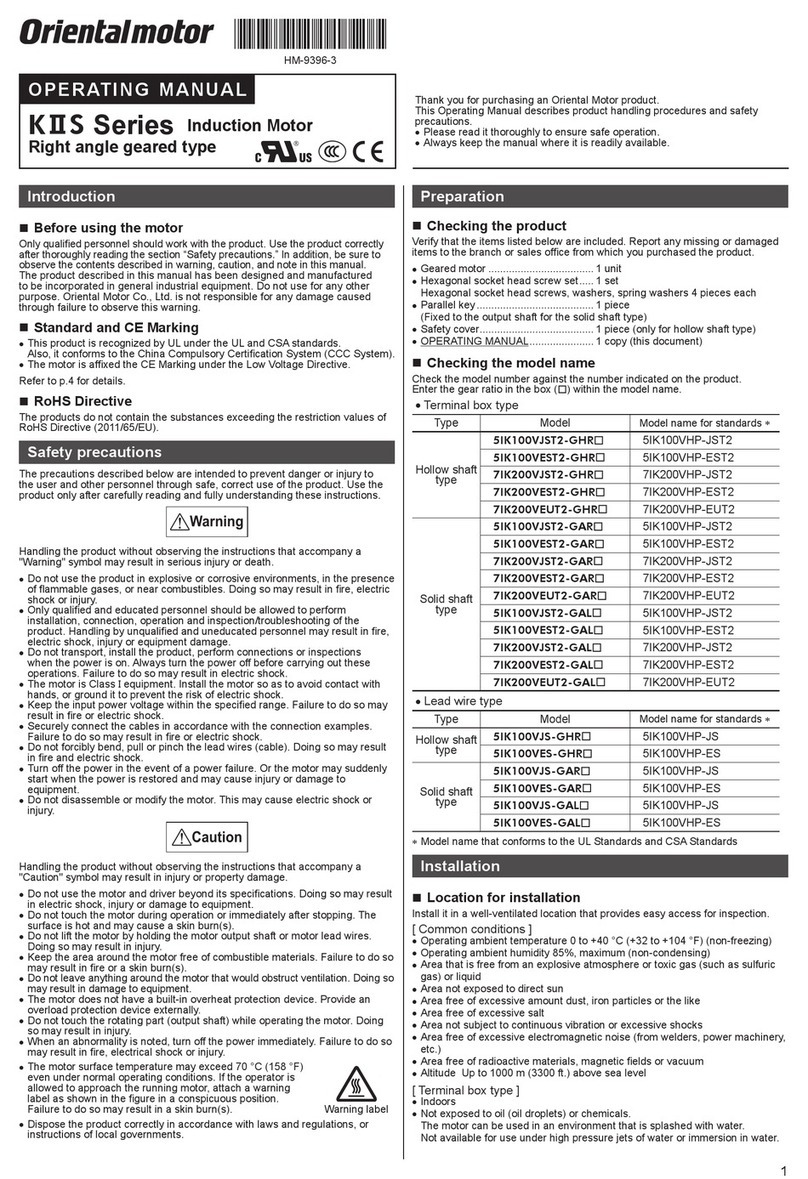

Permissible overhung load

and permissible thrust load

The overhung load on the motor’s output shaft or gear out-

put shaft must be kept within the permissible values listed

below. The thrust load must not exceed the motor’s mass.

It is recommended that periodic inspections be conducted

for the items listed below after each operation of the motor.

If an abnormal condition is noted, discontinue any use and

contact your nearest office.

●

Check for any unusual noises in the motor’s bearings (ball

bearings) or other moving parts.

●

Are there any scratches, signs of stress or loose driver

connections in the motor cable?

●

Are the motor’s output shaft and load shaft out of align-

ment?

Inspection

●

Unauthorized reproduction or copying of all or part of

this Operating Manual is prohibited.

●

Characteristics, specifications and dimensions are sub-

ject to change without notice.

●

While we make every effort to offer accurate informa-

tion in the manual, we welcome your input. Should you

find unclear descriptions, errors or omissions, please

contact the nearest office.

●

is a trademark of Oriental Motor Co.,

Ltd.

© Copyright ORIENTAL MOTOR CO., LTD. 2011

0.5N·m(4.4lb-in)

1.0N·m(8.8lb-in)

2.0N·m(17.7lb-in)

3.0N·m(26lb-in)

Motor type Bolt size Tightening torque

PH533

PH544

PK56 , PH56

PK25

PK26 , PH26

PH554

PK59 , PH59

PK29 , PH29

M2.5 or M2.6

M3(No.4-40UNC)

M4

M5

1.0N·m(8.8lb-in)

Motor type Bolt size Tightening torque

PK54

PK24

PX53

PX24

M3(No.4-40UNC)

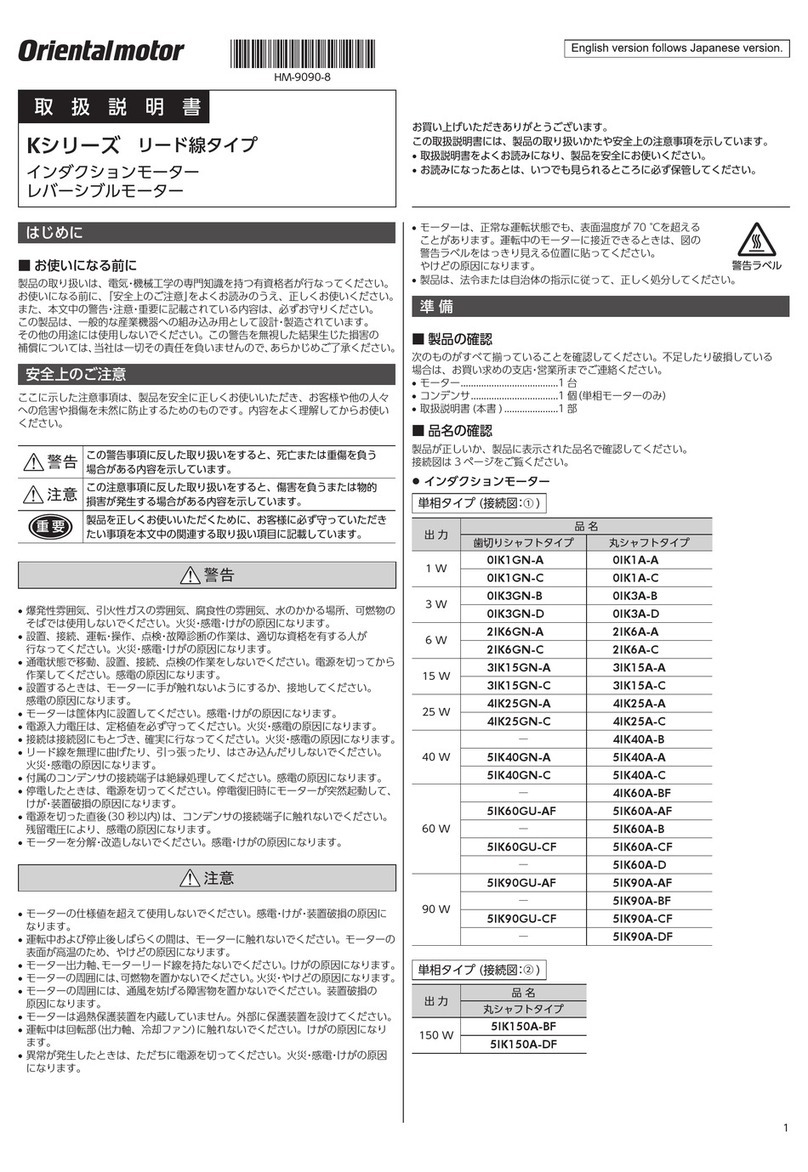

Green Blue

Red

White

Yellow

Brown

Orange

Gray

Black

Purple

AE

B

C

D

Red

Black

Yellow

Green

White Blue

A

A

BB

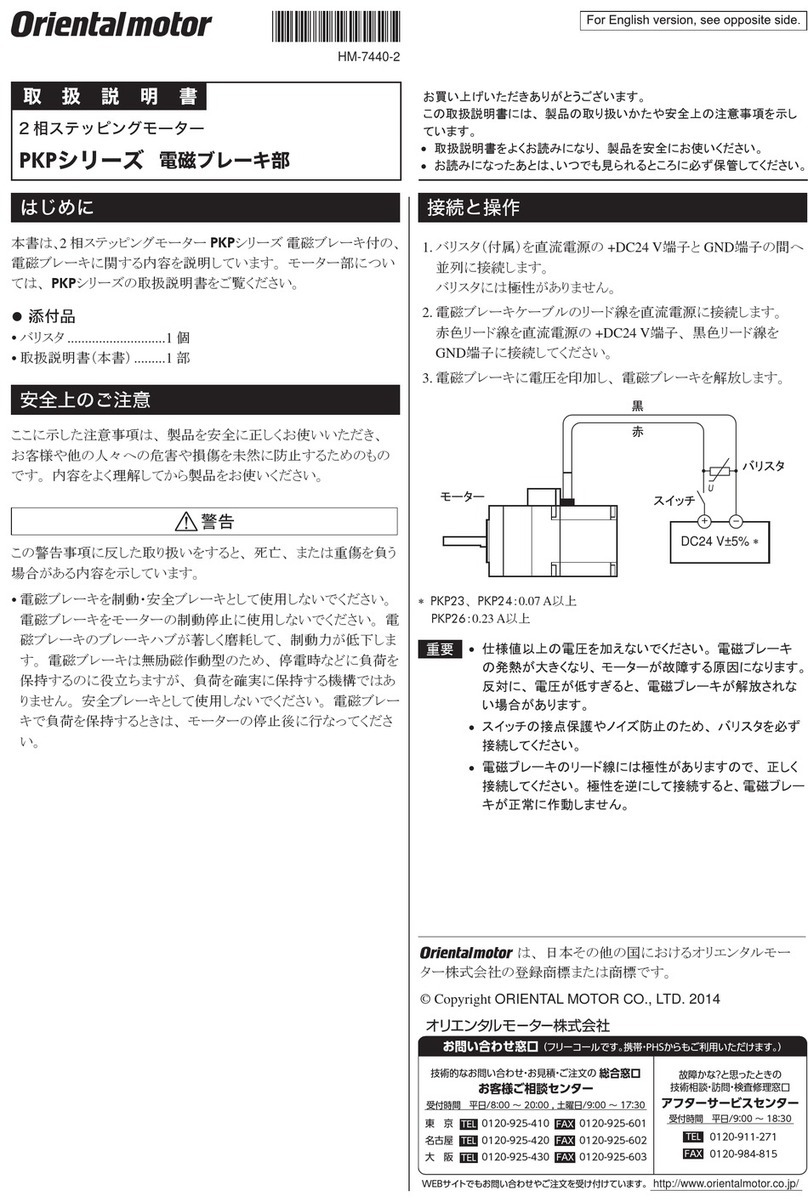

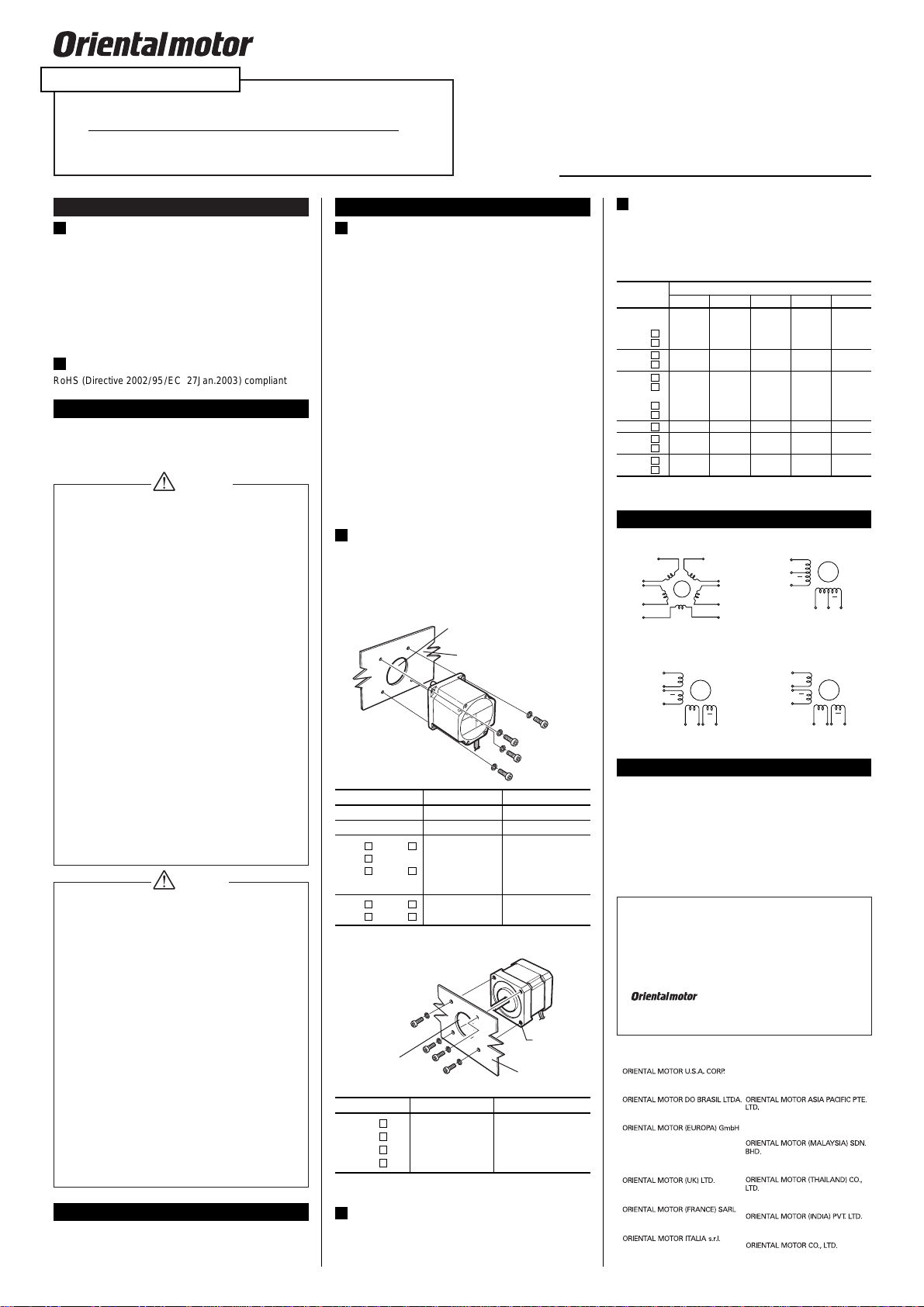

Wiring diagram

●

5-phase

●

2-phase 6-lead wire type

Red Yellow

/White

Red

/White

Black

Black/White

Orange/White

Orange

Yellow

A

A

BB Red Brown

White

Black

Yellow

Orange

Green

Blue

A

A

BB

●

2-phase 8-lead wire type

PH

series

●

2-phase 8-lead wire type

PK

series

The square box in the motor type will contain a number representing

the motor length.

[Unit:N(lb.)]

OPERATING MANUAL

Hazardous substances (PK series only)

RoHS (Directive 2002/95/EC 27Jan.2003) compliant

Location for installation

The motor is designed and manufactured for installation in

equipment. Install it in a well-ventilated location that pro-

vides easy access for inspection. The location must also

satisfy the following conditions:

●

Inside an enclosure that is installed indoors (provide vent

holes)

●

Operating ambient temperature

-

10°C to +50°C (+14°F to +122°F) (non-freezing)

●

Operating ambient humidity 85%, maximum (no conden-

sation)

●

Area that is free from an explosive nature or toxic gas

(such as sulfuric gas) or liquid

●

Area not exposed to direct sun

●

Area free of excessive amount dust, iron particles or the

like

●

Area not subject to splashing water (storms, water droplets),

oil (oil droplets) or other liquids

●

Area free of excessive salt

●

Area not subject to continuous vibration or excessive

shocks

●

Area free of excessive electromagnetic noise (from

welders, power machinery, etc.)

●

Area free of radioactive materials, magnetic fields or vacuum

Installation

Installing a load

When connecting a load to the motor, align the centers of

the motor’s output shaft and load shaft. Be careful not to

damage the output shaft or the bearings when installing a

coupling or pulley to the motor’s output shaft.

Warning

Caution

Stepping Motor

PK

series

,

PH

series

,

PX

series

Technical Support Tel:(800)468-3982 www.orientalmotor.com

8:30 A.M. to 5:00 P.M., P.S.T. (M-F) 7:30 A.M. to 5:00 P.M., C.S.T. (M-F)

Tel:+55-11-3266-6018

www.orientalmotor.com.br

Schiessstraße 44, 40549 Düsseldorf,

Germany

Technical Support

Tel:00 800/22 55 66 22

www.orientalmotor.de

Tel:01256-347090

www.oriental-motor.co.uk

Tel:01 47 86 97 50

www.orientalmotor.fr

Tel:02-93906346

www.orientalmotor.it 4-8-1Higashiueno,Taito-ku,Tokyo

110-8536 Japan

Tel:03-6744-0361

www.orientalmotor.co.jp

Tel:1800-806161

www.orientalmotor.com.my

Tel:1800-888-881

www.orientalmotor.co.th

Tel:+91-80-41125586

www.orientalmotor.co.in

Singapore

Tel:1800-8420280

www.orientalmotor.com.sg

• Please contact your nearest Oriental Motor office for further information.

Published in April 2018

The products do not contain the substances exceeding the

restriction values of RoHS Directive (2011/65/EU).