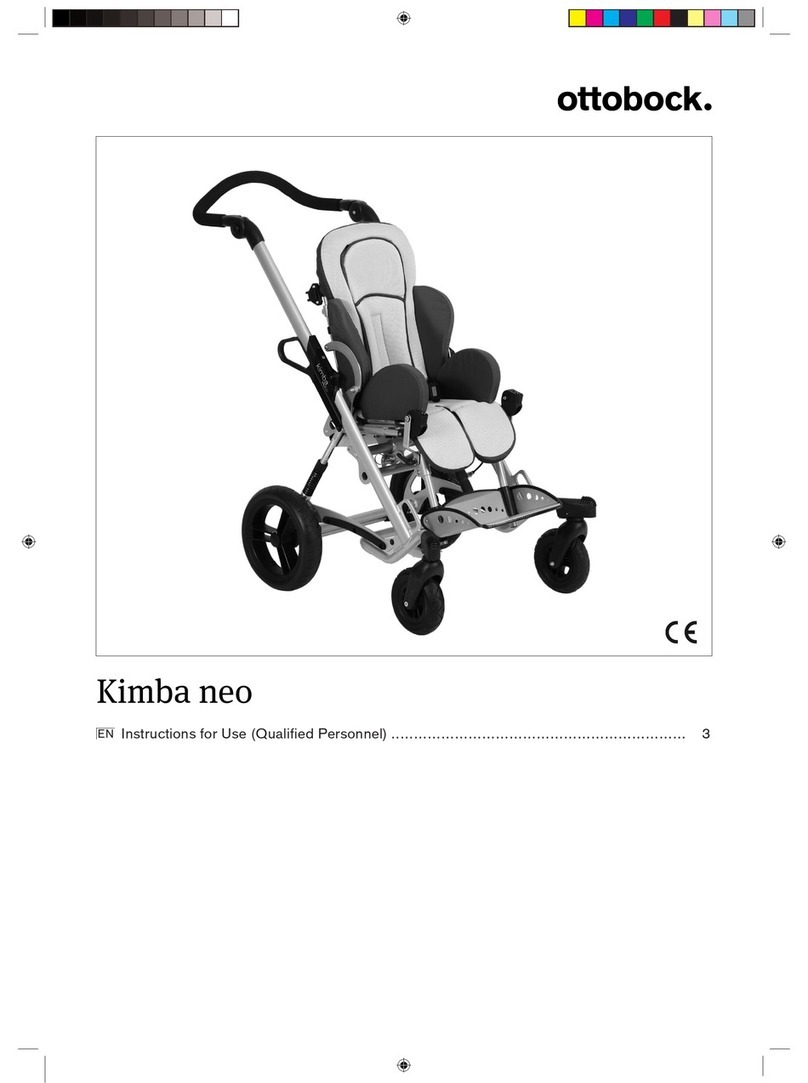

1 Preface

Regular maintenance is important – it increases the safety and service life of the product.

All rehab products should be checked and serviced once a year.

When using a product often, however, or when a product is being used by children or adolescents who are

still growing or by patients whose clinical picture changes, it is recommended to check, readjust and possi-

bly service the product at an interval of 6 months.

For all service and maintenance works use only original spare parts.

The service and maintenance works described in this manual should be performed by skilled specialist staff

only and not by the user of the product.

This service and maintenance manual refers to the respective spare parts catalogues and instructions for

use manuals of the described products; therefore, please use all documents together.

Please use the maintenance schedules (check list) for duplication. Keep the completed maintenance sched-

ules and hand over a copy to the customer.

Instructions for Use Spare Parts Catalogue

Eco-Buggy 647H446 646K44

2 Safety

For all maintenance and repair works, there are a few points you should always observe:

Use appropriate tools (refer to pages 3 & 4).

Wear appropriate clothing as well as gloves and safety glasses, if necessary.

Secure the product to prevent it from tipping over or falling off the workbench, for example.

Study the service and maintenance instructions before beginning your work.

You should become familiar with the functions of the product first. If you do not know the product,

please first study the instructions for use before inspecting the product.

If no instructions for use are available to you, please order them from the manufacturer (refer to

the overview of all Otto Bock Branches "Otto Bock Worldwide" – alternatively you can download

the document from our homepage under www.ottobock.de or www.ottobock.com).

Clean / disinfect the product before starting inspection. Please also refer to the Instructions for

Use Manual regarding any care instructions or specific product inspection information.

Many of the screw fastenings use thread lock or nylock nuts. If you have to undo such screw

fastenings please replace the respective nut or screw with a new thread lock and/or nut. If new

screws or nuts with thread lock are not available use a liquid thread lock substance with medium

strength (e.g. Loctite 241 or Euro Lock A24.20).