2

Table Of Contents

Identication of Machine ...................................................................... 2

Specications............................................................................................. 2

Introduction ............................................................................................... 3

Safety ............................................................................................................ 3

Signal Words.................................................................................... 3

General Guidelines........................................................................ 4

Before Operation ........................................................................... 5

During Operation .......................................................................... 5

Following Operation .................................................................... 5

Pump Safety Precautions............................................................ 5

Installation .................................................................................................. 6

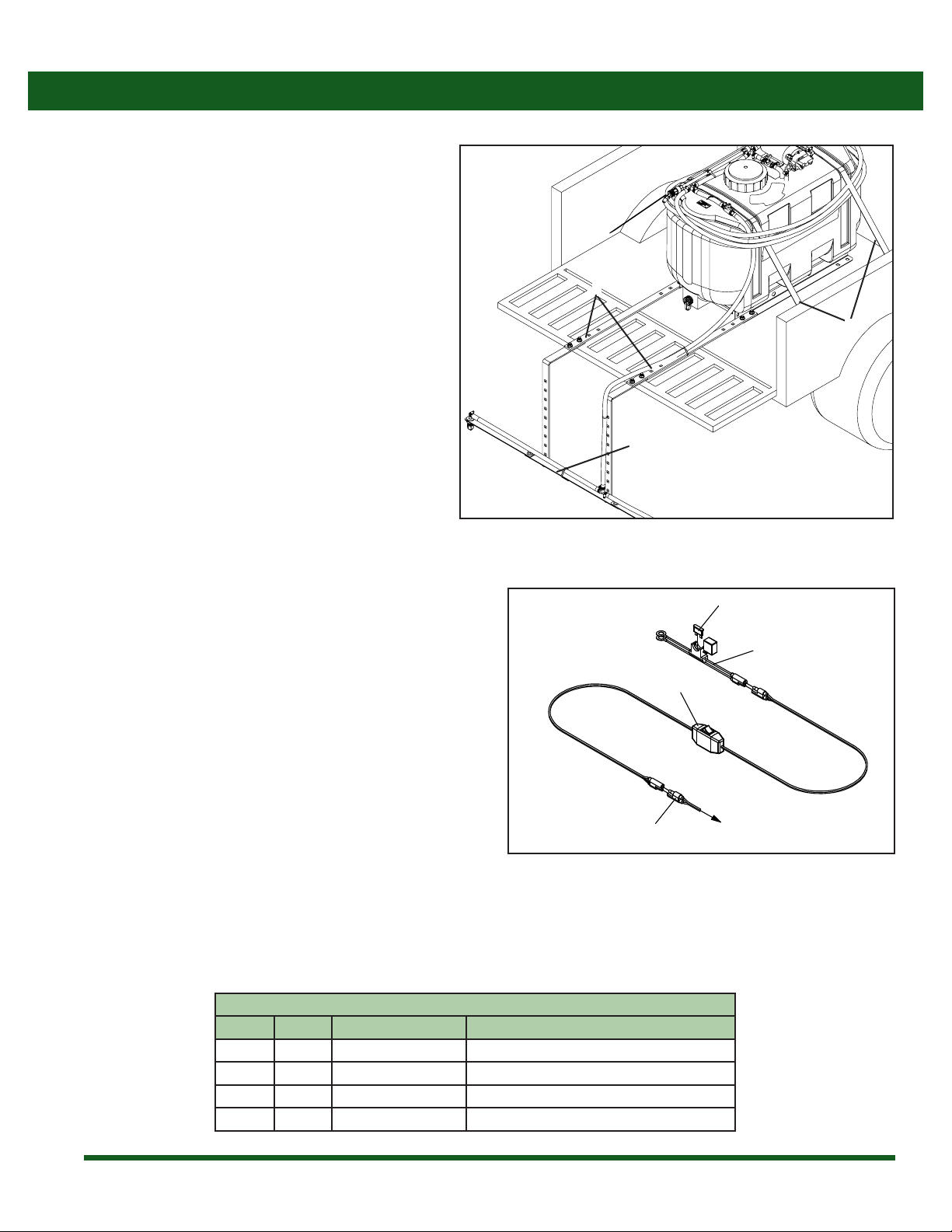

Mounting the Skid Sprayer........................................................ 6

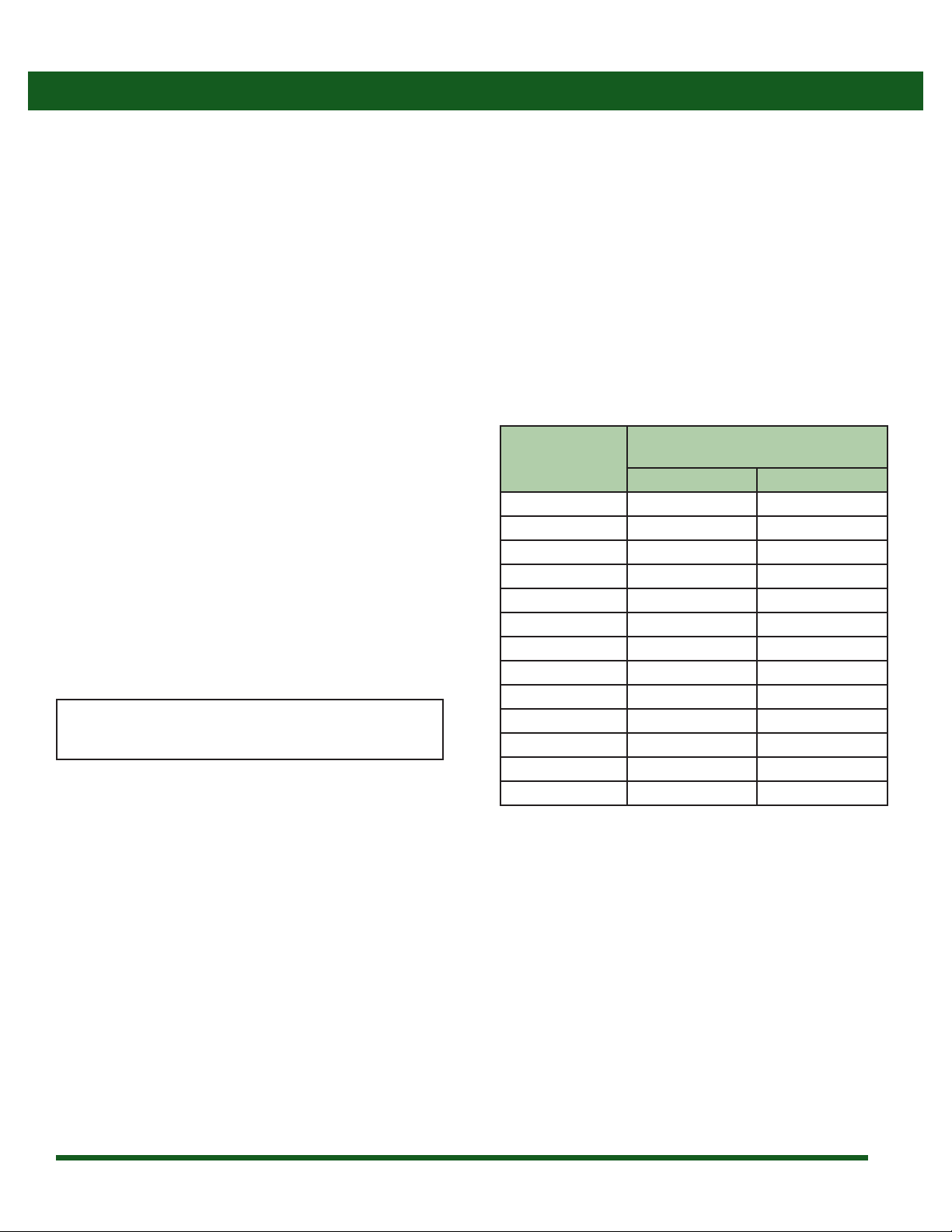

Wiring Harness ............................................................................... 6

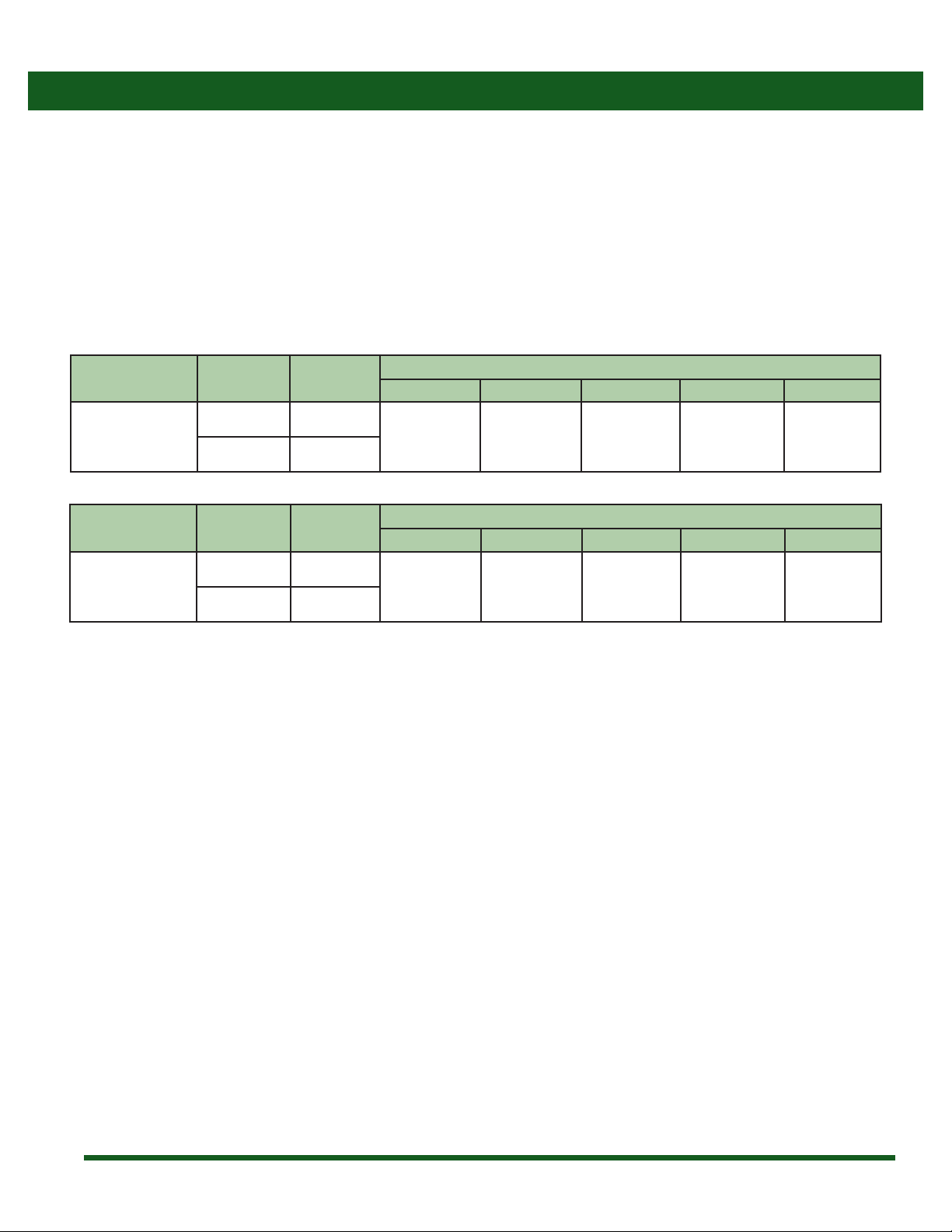

Calibrating the Sprayer........................................................................... 7

1. Calculating the Speed............................................................. 7

2. Application Rate Charts.......................................................... 8

Boom Application Rate Chart ................................................... 8

Operating Instructions ........................................................................... 9

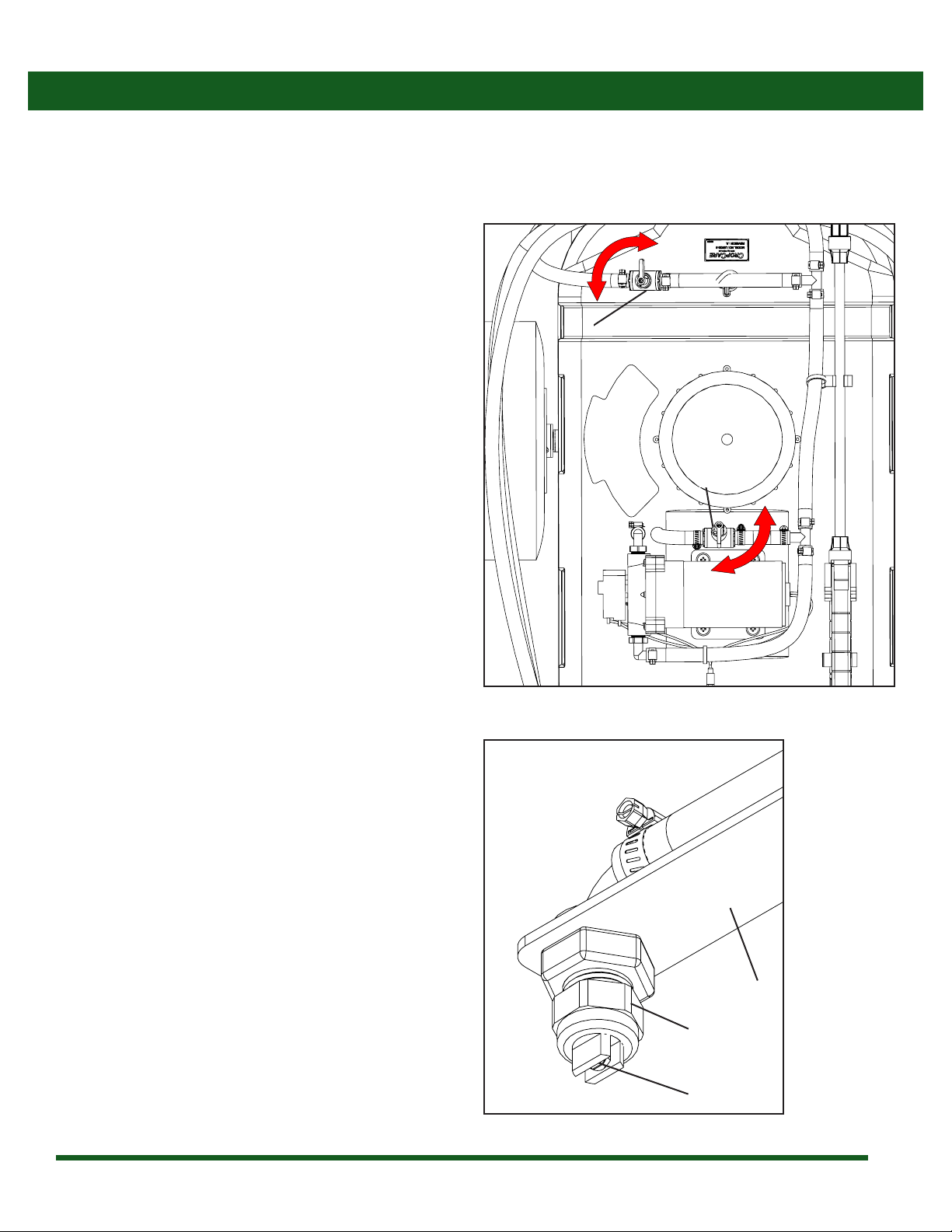

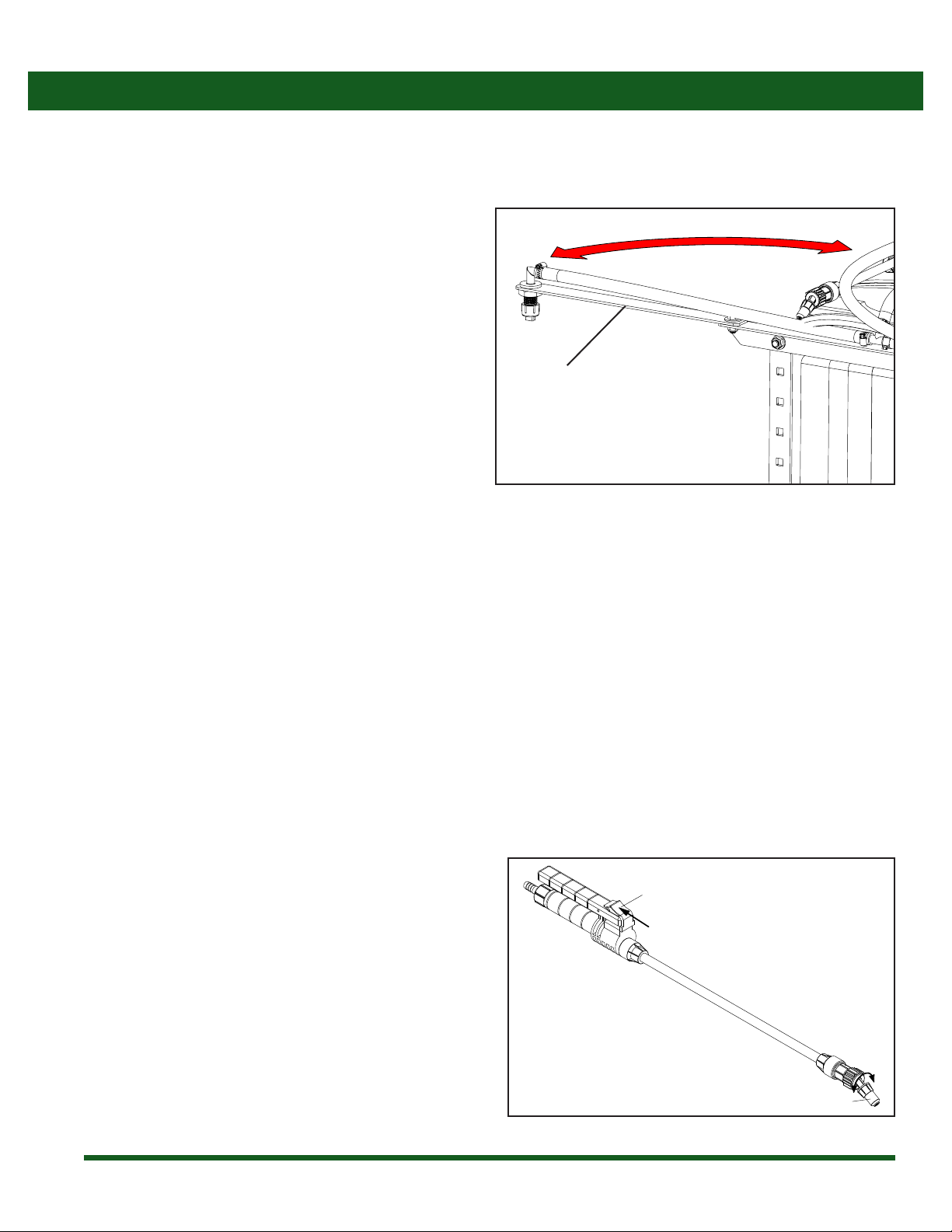

Spraying with the Boom .......................................................9-10

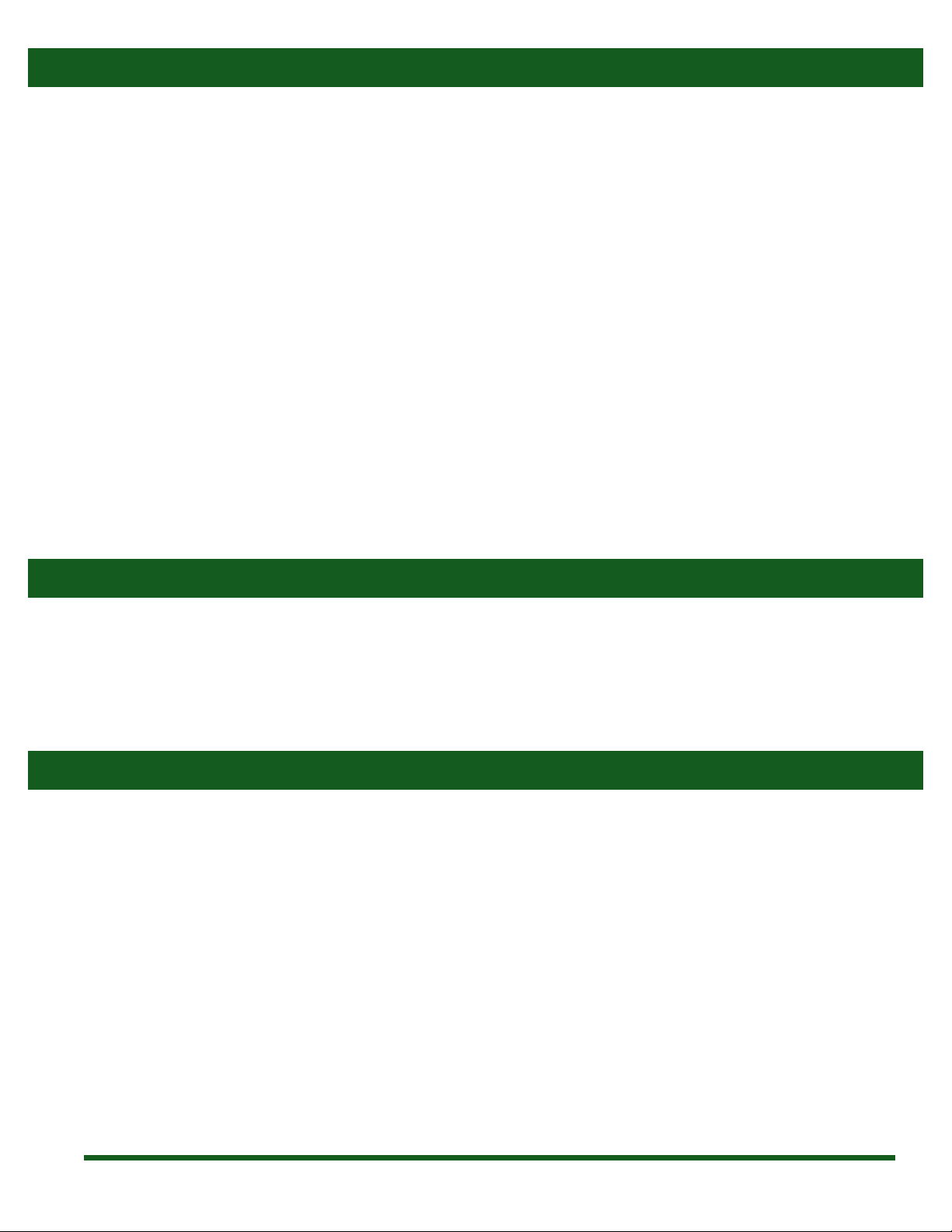

Spraying with the Spray Gun ..................................................10

Following Operation ..................................................................11

Maintenance Instructions ............................................................ 11-12

Routine Maintenance.......................................................... 11-12

Winterizing your Sprayer..........................................................12

Troubleshooting .....................................................................................13

Breakdowns and Parts Lists ......................................................... 14-16

Base Unit Breakdown.................................................................14

Base Unit Parts List......................................................................15

Pump Breakdown & Parts List.................................................16

CropCare® Limited Warranty ..............................................................17

Ordering Parts .........................................................................................17

Specications

Tank capacity ................................................................................ 25 gal

Min power supply ..................................................... 12 volt / 8 amp

Wiring harness length ........................................................................ 8’

Pump:

Type...........................................................................Diaphragm pump

Manufacturer .............................................................................Remco®

Max pressure..................................................................................60 psi

Max ow rate ............................................................................2.2 gpm

Sprayer:

Spraying width (Boom) ...................................................................90”

Hose length (Handgun) ...................................................................15’

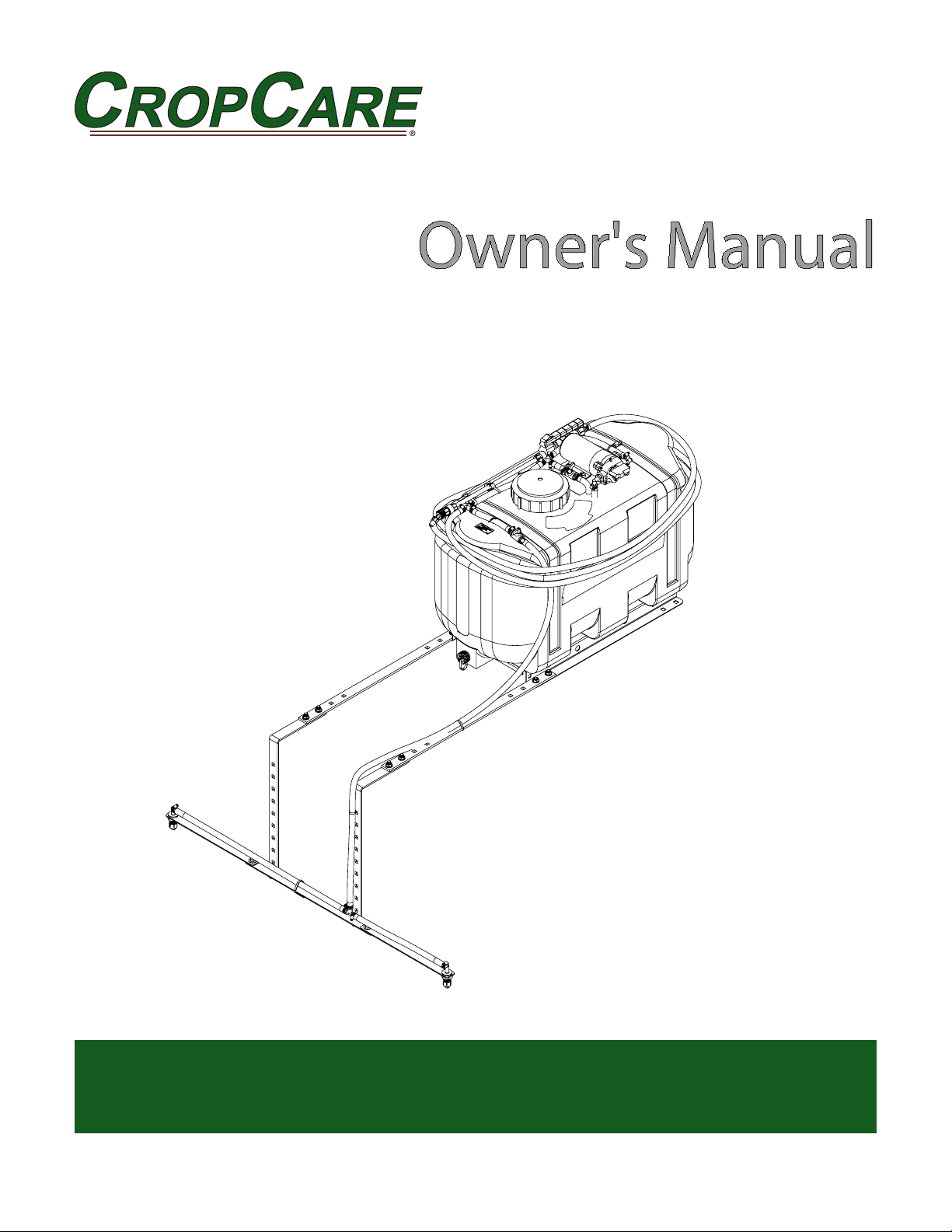

25 gallon LGX Skid Sprayer

Weight:

Base unit (empty) .........................................................................40 lbs

Base unit (full).............................................................................250 lbs

Identication of Machine

• Model #’s: LGX25-2

• The model number and revision identication decal is located on top of the tank .