Table of contents

108716_en_01 PHOENIX CONTACT 3 / 52

Table of contents

1 For your safety ...........................................................................................................................5

1.1 Identification of warning notes ...............................................................................5

1.2 Qualification of users .............................................................................................5

1.3 Field of application of the product ..........................................................................6

1.4 Safety notes...........................................................................................................6

2 Starting up the printer .................................................................................................................8

2.1 Unpacking and setup.............................................................................................8

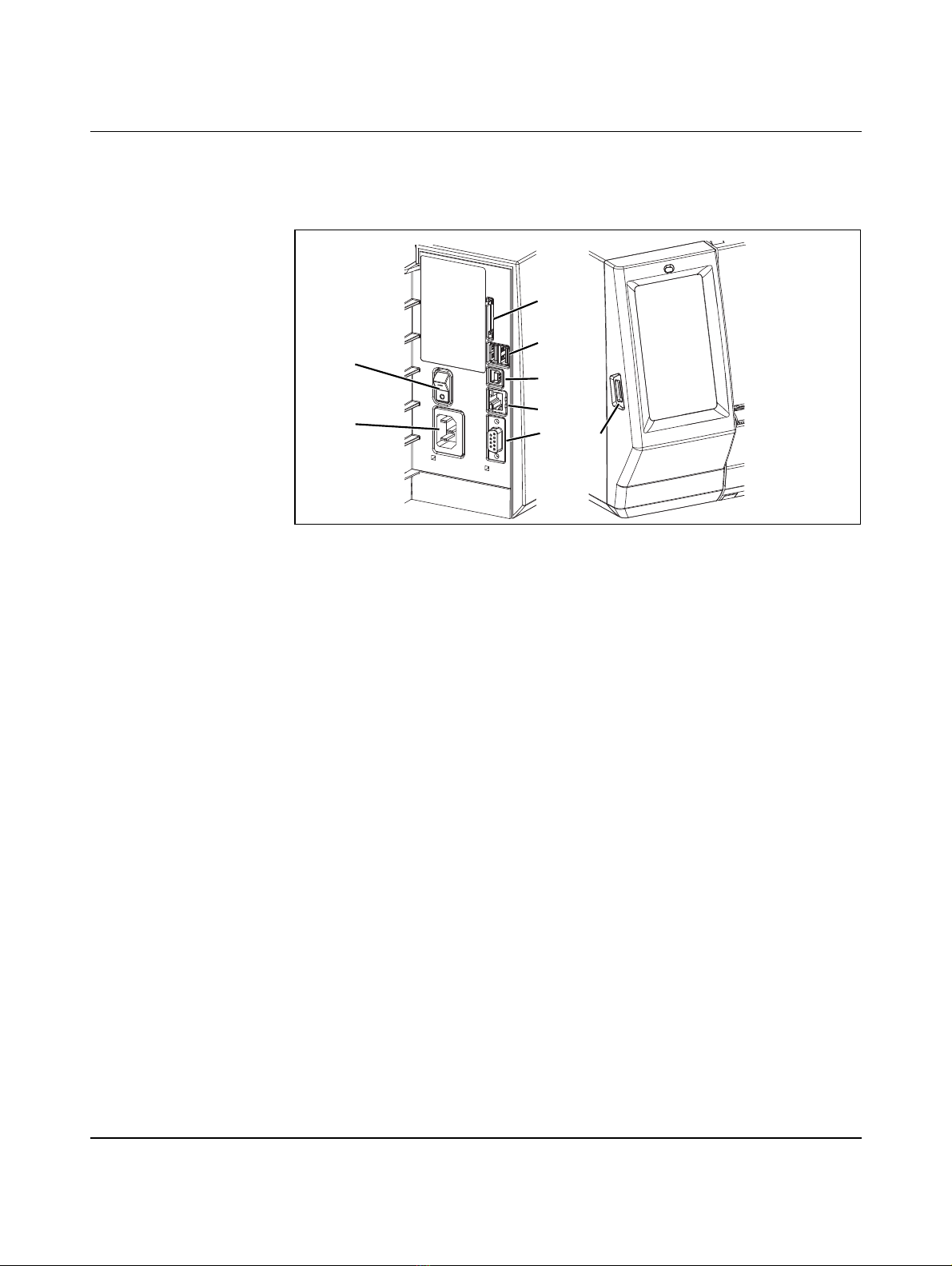

2.2 Overview of the device ..........................................................................................9

2.3 Connecting the device .........................................................................................10

2.3.1 Connecting the mains cable .................................................................10

2.3.2 Connecting the printer via USB ............................................................11

2.3.3 Connecting a printer via WLAN ............................................................12

2.3.4 Connecting a printer via Ethernet .........................................................12

2.4 Inserting the material and printing........................................................................13

2.4.1 Inserting the material ............................................................................13

2.4.2 Inserting Leporello labels .....................................................................14

2.4.3 Inserting the ink ribbon .........................................................................15

2.4.4 Printing .................................................................................................16

2.4.5 Creating print jobs ................................................................................16

3 Operating the printer ................................................................................................................17

3.1 Touch screen display...........................................................................................17

3.1.1 Operating the display ...........................................................................17

3.1.2 Changing the language ........................................................................17

3.1.3 Start page ............................................................................................18

3.2 Operation via the menu........................................................................................19

3.3 Configuration via the website...............................................................................27

3.4 Printing via FTP ...................................................................................................28

3.4.1 FTP login ..............................................................................................28

3.4.2 Sending print data via FTP ...................................................................28

3.4.3 FTP access to storage media ...............................................................29

3.4.4 FTP firmware update ............................................................................29

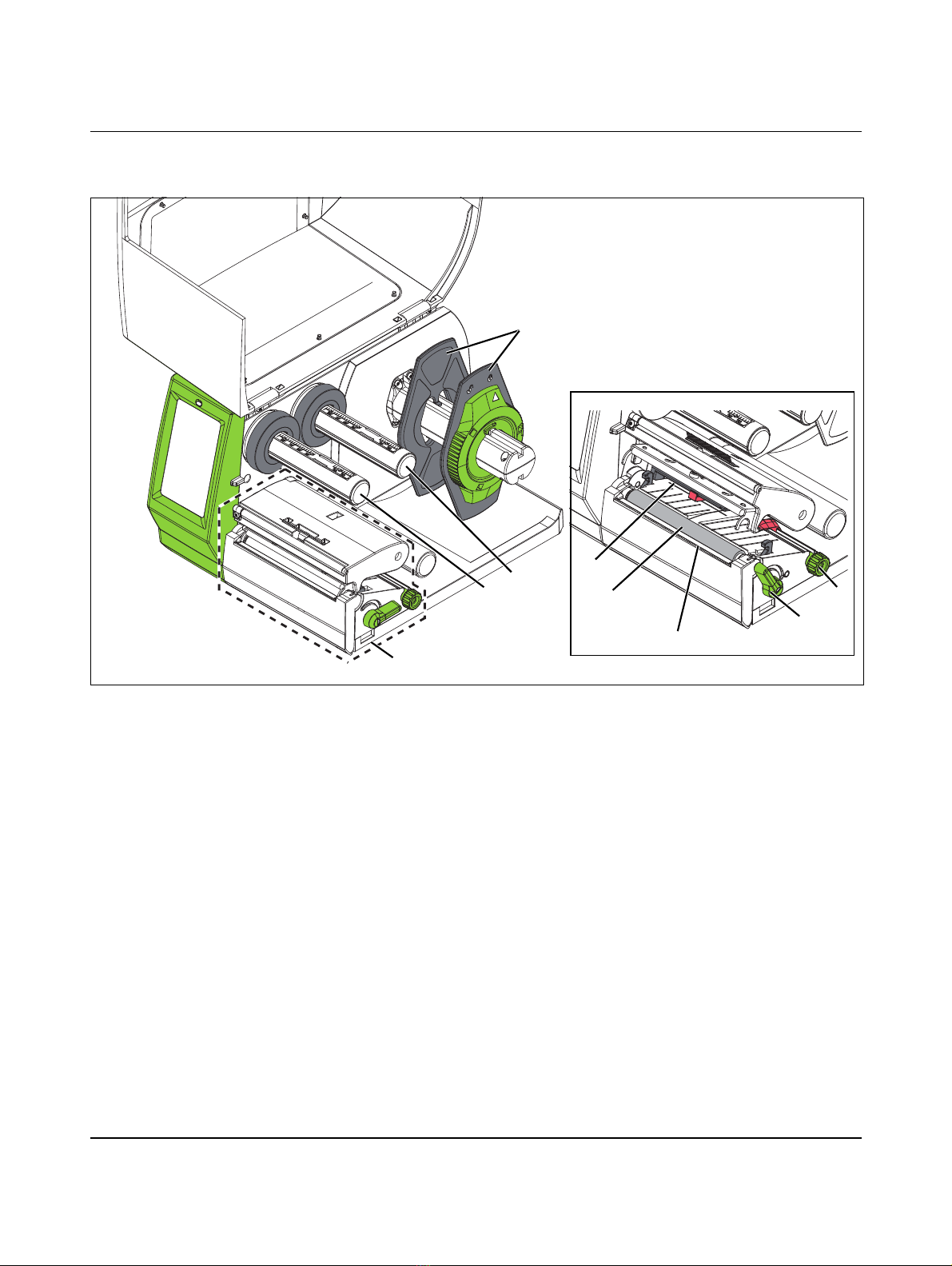

4 Mounting accessories ..............................................................................................................30

4.1 Cutter or perforator ..............................................................................................30

4.2 Mounting the external media hub.........................................................................34