Pilz PNOZ e3vp User manual

Other Pilz Relay manuals

Pilz

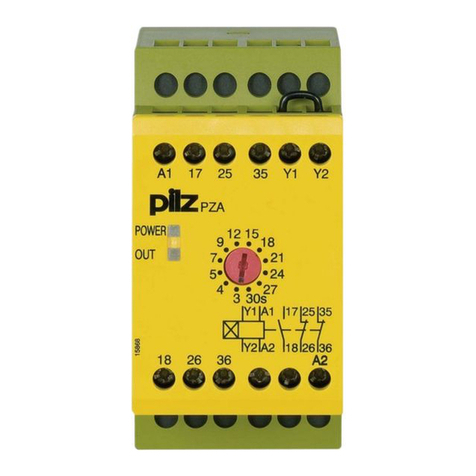

Pilz PZA Series User manual

Pilz

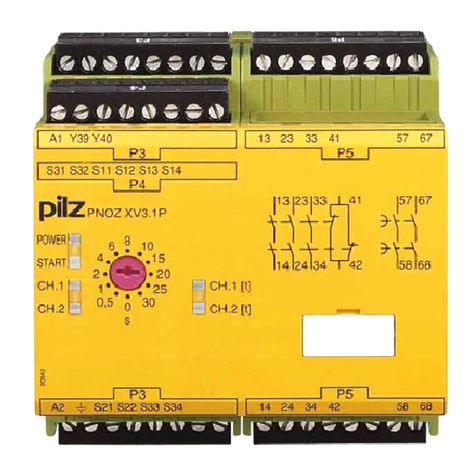

Pilz PNOZ XV3.1P User manual

Pilz

Pilz P2HZ 5 User manual

Pilz

Pilz PZE X4V User manual

Pilz

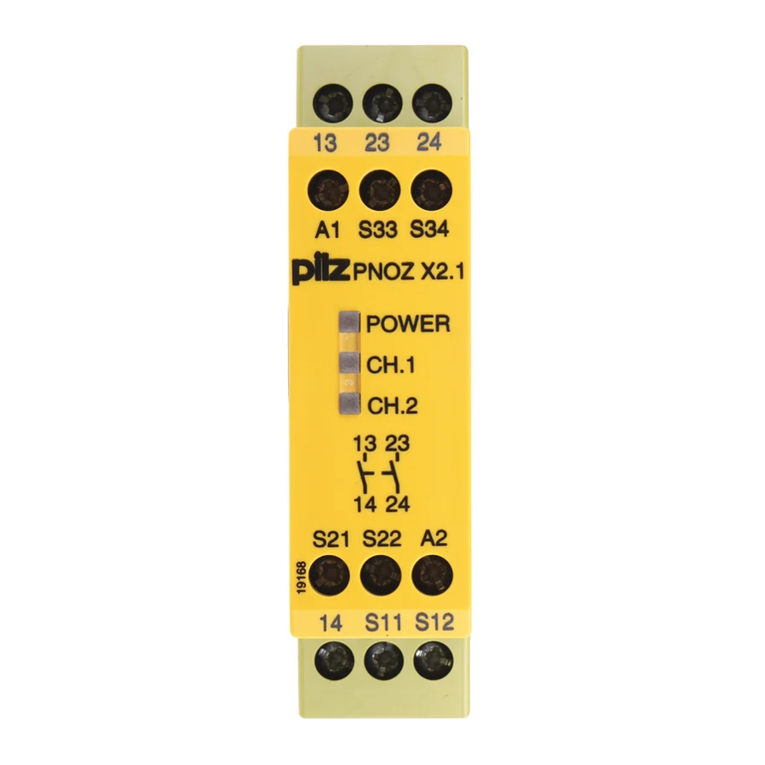

Pilz PNOZ X2 User manual

Pilz

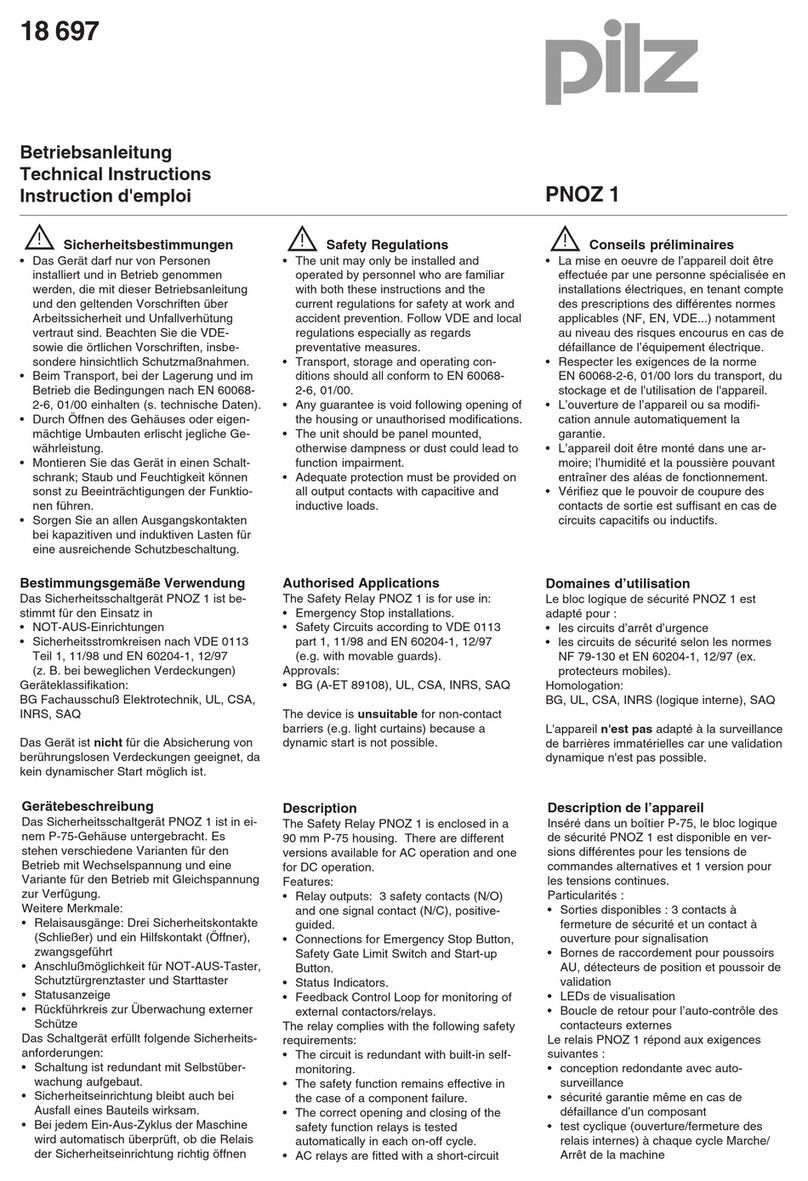

Pilz PNOZ 1 Owner's manual

Pilz

Pilz PNOZ s60 User manual

Pilz

Pilz PSWZ X1P Owner's manual

Pilz

Pilz PNOZ X2.4V Owner's manual

Pilz

Pilz PNOZ XV2.1 User manual

Pilz

Pilz PNOZ X2.7P User manual

Pilz

Pilz PNOZ s7 User manual

Pilz

Pilz PSEN im1 User manual

Pilz

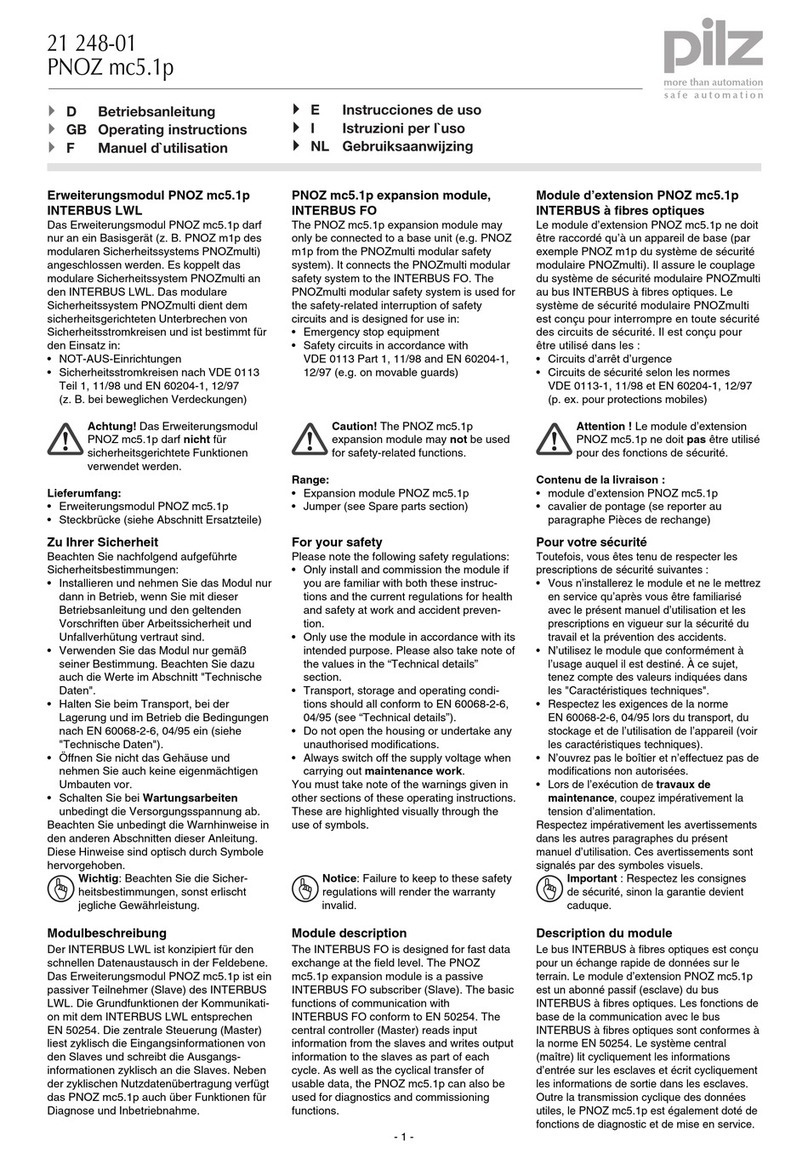

Pilz PNOZ mc5.1p User manual

Pilz

Pilz 20076-6NL-07 User manual

Pilz

Pilz PNOZ c2 User manual

Pilz

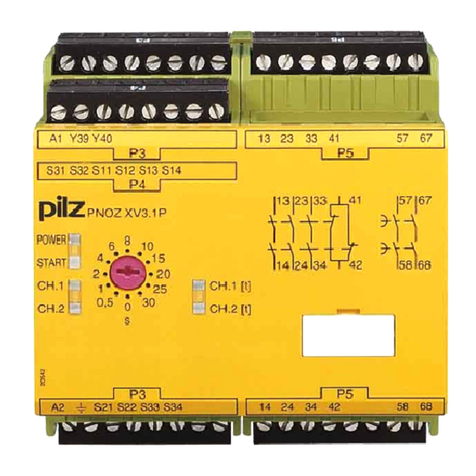

Pilz PNOZ XV3.1P User manual

Pilz

Pilz PNOZ mc0p User manual

Pilz

Pilz PNOZ X7P 24 V DC/AC User manual

Pilz

Pilz PNOZ msi b4 Box User manual

Popular Relay manuals by other brands

CD Automation

CD Automation REVEX 2PH 280A user manual

ABB

ABB SPAJ 142 C User manual and technical description

Ruelco

Ruelco 1S04 Operation manual

Basler

Basler V3E Z1P B2C1F instruction manual

Doepke

Doepke Dupline DSM 2 operating instructions

Siemens

Siemens SIRIUS 3RT1966-4D Original operating instructions