Bulletin M0092d EN_00

PIUSI S.p.A.

EN This document has been drawn with great care about the accuracy of the data

contained therein. However, PIUSI S.p.A. takes no responsibility for any mistakes

and omissions.

ENGLISH (Translation of the original language) ENGLISH (Translation of the original language) ENGLISH (Translation of the original language) ENGLISH (Translation of the original language) ENGLISH (Translation of the original language) ENGLISH (Translation of the original language) ENGLISH (Translation of the original language)

1 INDEX

1 INDEX

2 CE DECLARATION OF CONFOR ITY

3 GENERAL PRECAUTIONS

3.1 SAFETY WARNINGS

4 GETTING TO KNOW THE ETER

4 DETAILED INFOR ATION ON THE ETER

4 ANUAL AND AUTO OPERATION

5 INSTALLING THE ETER

5.1 SYSTE REQUIRE ENTS

5 LINE PRESSURE RELIEF

5.3 FLUSHING THE LINES

5.4 PRELI INARY CHECKS ON THE ETER

5.5 OUNTING THE EXTENSION ON THE ETER

5.6 ASSE BLING THE ETER

5.7 AIR PURGING FRO THE LINES

5.8 CHECKING THE FLOW-RATE

6 USING THE ETER

6.1 DISPENSING IN ANUAL ODE

6.2 DISPENSING IN AUTO ODE

7 CUSTO IZING THE ETER

7.1 CUSTO IZING ENU

7.2 FREQUENTLY USED PRESET VALUES

7.3 UNIT OF EASURE ENT

7.4 DECI AL DIGITS

7.5 AUTO RESET

7.6 STOP PRECISION IN AUTO ODE

7.7 CALIBRATION

8 AINTENANCE OF THE ETER

8.1 BATTERY REPLACE ENT

8.2 FILTER CLEANING

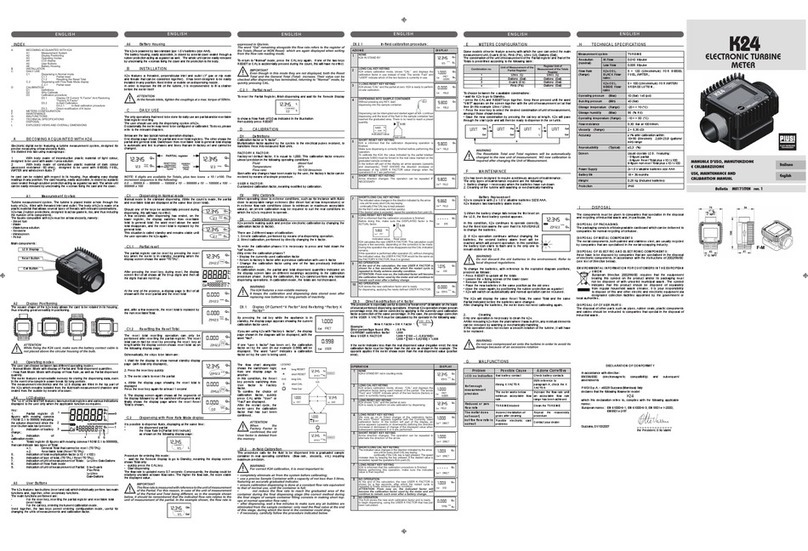

9 PRODUCT IDENTIFICATION

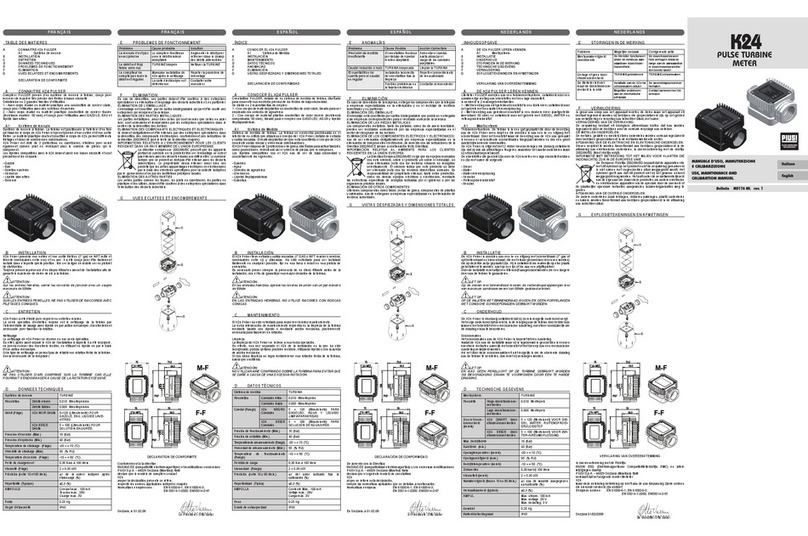

10 CONSTRUCTION DATA

10.1 TECHNICAL DATA

10.2 DI ENSIONS

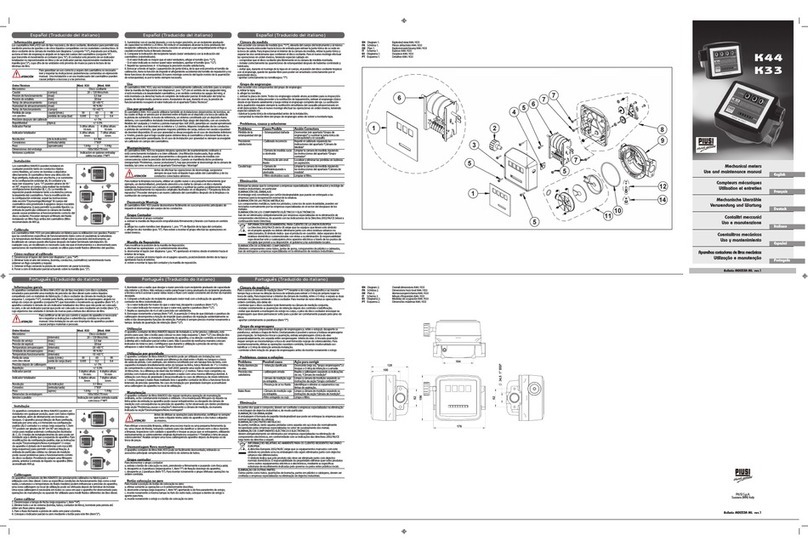

10.3 SPARE PARTS EXPLODED VIEW

10.4 TROUBLESHOOTING

11 DISPOSAL

2 CE DECLARATION OF CONFORMITY

The undersigned:

PIUSI S.p.A

Via Pacinotti 16/A z.i. Rangavino

46029 Suzzara - Mantua - Italy

DECLARES

on its own responsibility, that the machine described below:

Description: Dispensing nozzle for oil.

odel: K500

is in compliance with the legislative regulations which transpose directives:

- 2014/30/EEC (electromagnetic compatibility directive) and subsequent amendments.

Documents are made available to the appropriate authority on request at Piusi S.p.A.

The person in charge of writing both the technical file and the conformity statement is Otto

Varini as the legal representative.

Suzzara 20/04/2016

Otto Varini

The legal representative

3 GENERAL PRECAUTIONS

Important

warnings

In order to protect workers' safety, to avoid damaging and before

performing any operation, please read and familiarize with the

whole instruction manual.

Symbols used

in the manual

In order to signal particularly important instructions or warnings,

the following symbols are used:

This symbol highlights important aspects as to SAFETY.

This symbol highlights important aspects as to the CORRECT

USE of the ETER.

This symbol highlights important aspects as to avoid

POLLUTION HAZARDS.

The instructions provided by this manual satisfy both the

Installer's and the Users' requirements ( anager and Operators)

of the ETER.

In the Table of Contents a symbol alongside each paragraph

indicates the person this information is intended for.

Operator

All paragraphs marked with this symbol concern the Operator.

The operator is the person who uses the ETER to carry out

dispensing operations.

Therefore the Operator is not expected to read paragraphs

other than those marked with this symbol.

Manager

All paragraphs marked with this symbol concern the anager.

The ETER offers several options (selection of the unit of

measurement, selection of the Number of Decimal Digits,

Calibration, etc.). At least one skilled Operator (hereinaer

referred to as the anager) must know this data in order to allow

the Operators to use the ETER correctly. The anager must

read thoroughly all paragraphs concerning the anager and the

Operator.

Installer

All paragraphs marked with this symbol concern the Installer

only.

He is responsible for installing the ETER and is required to

read the manual thoroughly, no paragraph omied.

Manual storage

This manual must be intact and completely readable. The

final users, as well as the qualified technicians authorised to

installation and maintenance must be able to view it at any time.

Reproduction

rights

Piusi S.p.A. is the exclusive owner of all rights envisaged by

applicable laws, including the rules concerning copyrights.

All rights arising from these standards are reserved to Piusi

S.p.A.: even partial reproduction of this manual, its publication,

edit, transcription, communication to the public, distribution,

marketing in any form, translation and/or processing, lending,

and any other activities are reserved by law to Piusi S.p.A..

This manual is and essential and integral part of the product

and must be handed over to the personnel who carries out the

installation, uses and maintains the ETER.

Read all indications given in this manual as they provide important

instructions as to safe installation, use and maintenance.

Keep this manual safe for future reference.

Do not remove, tear or modify any part of this manual for any

whatsoever reason.

In case of loss or damage, a new copy can be requested to the

manufacturer, provided the relevant code is indicated.

The manufacturer is not liable for any damage to persons, things

or the unit itself, if the latter is installed or used incorrectly.

SAFETYWARNINGS

ATTENTION

ains -

preliminary

checks before

installation

You must avoid any contact between the electrical power supply

and the fluid that needs to be pumped.

Control and

maintenance

operations

Before any checks or maintenance work are carried out,

disconnect the power source.

FIRE AND EX-

PLOSION

When flammable

fluids are present

in the work area,

be aware that

flammable fumes

can ignite or

explode while the

station is oper-

ating.

Tohelp prevent fire and explosion:

Use equipment only in will ventilated area.

Keep work area free of debris, including rags and spilled or open

containers of solvent and gasoline.

Do not plug or unplug power cords or turn lights on or off when

flammable fumes are present.

Ground all equipment in the work area.

Stop operation immediately if static sparking occurs or if you feel

a shock. Do not use

equipment until you identify and correct the

problem.

Keep a working fire extinguisher in the work area.

EQUIPMENT

MISUSE

isuse can

cause death or

serious injury

!

Do not operate the unit when fatigued or under the influence

of drugs or alcohol.

Do not leave the work area while equipment is energized or in op-

eration.

Turn off the equipment when not in use.

Do not alter or modify the equipment. Alterations or modifica-

tions may void agency approvals and create safety hazards.

Route hoses and cables away from traffic areas, sharp edges,

moving parts, and hot surfaces.

Keep children and animals away from the working area.

Respect all safety norms in force.

TOXIC FLUID

OR FUMES

HAZARD

For issues arising from the treated product with eyes, skin, inhalation

and ingestion refer to the safety data sheet of the fluid used.

Store hazardous fluid in approved containers, and dispose of it

according to applicable guidelines.

Prolonged contact with the product may cause skin irritation; during

delivery phases, always wear protective gloves.

4 GETTING TO KNOW THE METER

The ETER is a dispensing nozzle for oils and other fluids, to

be installed as a final shutoff device at the end of pressurized

flexible hoses.

Besides guaranteeing an exact measurement and display of the

fluid amount dispensed, when used as a normal nozzle.

The METER also allows the user to PRESELECT the quantity

to be supplied and automatically stops dispensing when the

preset amount has been reached.

The ETER integrates:

"(#%&!'$

A.

An ergonomic handle.

B.

A swivel, with a rubber cover, which allows the user to rotate the handle

independently from the connected flexible hose.

C.

A flow control valve, activated by a trigger, which is equipped with a protection

against accidental starts.

D.

A meter with oval gears, controlled by an electronic board and equipped with a

battery-powered microprocessor.

E.

A large liquid-crystal display, integrated in the 5-key keypad, for the communication

between the K500 and the Operator.

F.

A motorized valve shutting system, automatically activated by a microprocessor

when dispensing a PRESELECTED amount (AUTO mode).

G.

A multi-position extension to adjust the angle of the valve with respect to the handle.

H.

An automatic no-drip valve, adjustable with respect to the end, to further facilitate

dispensing in confined spaces.

4.1

DETAILEDINFORMATIONONTHEMETER

The handle

An external shock-resistant plastic cover contains all the

components of the ETER and provides an ergonomic handle.

The baeries

The baeries are housed in the upper compartment. The cover

is fixed by means of four cross-head screws. The user can easily

access this compartment to replace the baeries.

Filter

The swivel and filter

The ETER is equipped with a swivel to be connected to the

flexible hose.

The swivel is equipped with a 1/2" female thread (BPS or NPT)

and houses the filter.

The large filtering surface guarantees a reduced pressure loss.

The rubber cover of the swivel

During installation the swivel may be equipped with a rubber

cover to prevent the swivel itself or the metal end of the flexible

hose from damaging the vehicle body.

This cover is available in different colours, which can be used as

a "colour code" to identify the dispensed product easily.

The trigger

The ETER is equipped with a balanced valve, controlled by a

trigger, which can be activated using just one finger.

The trigger, protected against accidental starting, can be:

Released

The valve is in closed position.

Fully pressed

The valve is in maximum open position.

Locked in open position

The valve is in open position for automatic operation.

The liquid-

crystal display

“LCD”

The ETER uses an LCD with the following numeric registers

and indications:

1.

Batch total (4 digits, floating point)

2.

Totals (7 digits).

3.

Indication of the Total type (TOTAL / Resettable TOTAL).

4.

Indication of the Unit of easurement:

QTS = Quarts

PTS = Pints

LIT = Liters

GAL = Gallons

5. Indication of operation in AUTO mode.

The LCD automatically turns off if the ETER is not used for a

certain period.

To reactivate the LCD press the RESET key.

Keypad

The keypad is of membrane type and is equipped with 5 keys.

Numeric keys

to be used to set the PRESET value (automatic dispense stop

value).

AUTO key

to be used to select and confirm the PRESET value.

RESET key

to be used to reset the Batch Total and to display the

Reseable TOTAL.

Liter-counter

meter

To guarantee an accurate measurement of the dispensed amount

the ETER uses the principle of the oval gears.

Multi-position

extension

To guarantee an easy use, the ETER is equipped with a multi-

position extension. It can be positioned by the operator within

a 75° range.

75°

The dripless valve can be rotated by 240°

4.2 MANUALANDAUTOOPERATION

The ETER is a PRESETTABLE dispensing nozzle which can be

used in two operating modes:

MANUAL Mode

In ANUAL mode, dispensing starts as soon as the Operator

operates the trigger.

The only preliminary operation to be carried out by means of

the ETER keys is the possible reseing (RESET) of the value

previously indicated on the Batch total.

The operator must check the dispensing operation personally

and stop it by releasing the trigger when the desired amount is

reached.

The ETER has been designed to ensure maximum safety during

use an avoid oil spillage due to an improper use or operator's

carelessness.

In particolar the ETER does not allow the valve to be locked in

open position during MANUAL mode. This avoids a continuous

dispensing, should the operator be absent or has not preset an

automatic stop value (AUTO mode).

AUTO Mode

To dispense using the PRESELECTION option, before starting

dispensing the operator must:

Select the desired amount by means of the ETER keys as

explained in paragraph 6.2.

Confirm the selected value thus entering the AUTO mode:

The ETER displays the AUTO message and is ready to

dispense automatically without requiring the presence of the

operator.

Start dispensing, by pulling the trigger and seing it to the

locked position.

The operator's presence is no longer needed and he can wait

until the ETER automatically stops once the selected amount

has been dispensed.

In any case the operator must attend to the METER while

dispensing in AUTO mode in order to avoid any oil spillage due

to external factors.

Carefully read the instructions given in paragraph 6.2 before

dispensing in AUTO mode.

The ETER allows the user to lock the trigger in open position

only when the display shows the message AUTO.

To lock the trigger in open position:

pull it completely;

then release it.

If the message AUTO blinks, automatic dispensing cannot

be started; if the trigger is completely pulled and afterwards

released, it does not remain locked in position, but it closes again

thus interrupting the dispensing operation.

The blinking message AUTO indicates that the selecting phase

of the desired value is still in progress, but the AUTO mode has

not yet been entered by confirming the displayed value.

The ETER automatically unlocks the trigger thus stopping the

dispensing when the predetermined value has been reached.

However, while dispensing in AUTO mode, it is possible to stop

dispensing manually before the desired value is reached by

unlocking the trigger.

To unlock the trigger and set it in closed position again:

pull it completely;

then release it.

When the dispensing has been manually stopped, as soon as

the AUTO message is displayed, it is possible to restart the

automatic operation as the trigger can still be locked in open

position.

The ETER automatically exits the AUTO mode after a given

period of time (TI E OUT) without dispensing.

5 INSTALLING THE METER

This paragraph describes the necessary operations to be

carried out when the METER is installed for the first time on a

new system or to replace an existing nozzle with the METER.

5.1 SYSTEMREQUIREMENTS

12

4

3

5

6

The ETER has been designed to be used as a component of

a centralized system for oil distribution and other industrial

fluids, which must bemanufactured and installed by specialized

personnel in compliance with the standards relevant to such a

pressurized system.

To explain the installation and maintenance operations relevant

to the ETER, refer to the following diagram which shows a

typical installation, as regards to the components located

directly upstream any “dispensing outlet” of the ETER.

1.

Distribution system lines.

2.

Shut-off valve.

3.

Flexible hose for reel entry.

4.

Reel.

5.

Flexible hose.

6.

Nozzle.

The presence of the shut-off valve in the system is necessary

to ensure a safe and correct installation and maintenance

of the ETER without requiring to make the whole system

unserviceable.

The structure and complexity of the system upstream the above-

mentioned shut-off valve (rigid or flexible feeding lines, pumps,

tanks, valves, etc.) as well as the possible presence of the flexible

hose reel can be freely chosen by the installer. In fact they do not

affect the maintenance operations of the ETER.

5.2

LINEPRESSURERELIEF

This operation is to be carried out when replacing a pre-existing

nozzle with the ETER nozzle or when dismounting the ETER

for maintenance purposes.

Failure to carry out the line pressure relief procedure may

cause damage to persons or things.

Close the shut-off valve. Otherwise stop the feeding pump

and make it unserviceable to avoid an accidental re-start

during maintenance operations.

Operate the valve of the nozzle to be replaced (or of the

ETER to be disassembled for maintenance purposes)

dispensing into a suitable container in order to release the

line pressure.

If a dripless valve is installed at the end of the nozzle, the

pressure inside the line will not drop to zero, but it may remain

around 0.2 - 0.5 bar, according to the dripless valve used.

Only for ETER dismounting: remove the rubber cover from

its coupling on the swivel and move it along the flexible hose

in order to gain an easy access to the swivel.

By means of two wrenches, unscrew the threaded end of the

flexible hose from the swivel.

Be careful to collect any oil leakage into a suitable container.

5.3 FLUSHINGTHELINES

Flushing the lines means to let a given amount of oil flow inside

them, so as to ensure a proper “ washing” of the whole system,

a correct cleaning and the absence of dirt, contaminated

material or processed waste inside the lines before installing

the nozzle.

The flushing operation must be carried out on all lines upstream

the nozzle and, in case the system is equipped with more than

one nozzle, flush the lines which supply the nozzles farthest away

from the supply pump, then continue with the nozzles situated

near the pump.

The flushing procedure depends on the type and features of

the system and must be carried out by trained and qualified

personnel in compliance with the procedures set down by the

installer.

This operation is absolutely necessary with NEW

INSTALLATIONS or if the lines used are contaminated.

Consequently it may not be necessary to carry out this

procedure when replacing a nozzle already in use.

5.4 PRELIMINARYCHECKSONTHEMETER

ake sure that the threaded end fied on the flexible hose is

suitable for the swivel of the ETER equipped with: Female

thread 1/2” BSP or Female thread 1/2” NPT.

Filter

Check that the ETER nozzle to be installed is complete and

in good condition, making sure that the filter is clean and

correctly installed (see paragraph 8.2).

The METER filter, characterized by a large filtering surface,

has been designed to guarantee a correct filtering and a low

pressure loss.

To remove and re-install the filter, refer to paragraph 8.2.

The absence or improper installation of the filter may block the

METER valve o the liter-counter if dirt is present in the tubes.

This situation may occur especially during new installations. To

solve these problems, consult a qualified Service Centre.

MOUNTINGTHEEXTENSIONONTHEMETER

D

E

B

C

A

Three different types of extensions can be installed on the

ETER nozzle:

SWIVELLING extension;

RIGID extension;

FLEXIBLE extension;

All of them are equipped with an automatic dripless valve.

All extensions on the nozzle side are equipped with a rigid

ending part (external Ø 12 mm, 3/8"G nut) suitable for a quick

connection to the ETER without using any sealant.

Remove the plug from outlet A (3/8”G).

ake sure that gasket B on the swivel is correctly seated.

Lubricate the gasket and its seat.

Tighten end D on ETER by means of two wrenches; while

the first one on outlet A locks the ETER, the second one

tightens nut C on end D. Before locking nut C orientate valve

E.

An improper tightening of the extension may cause it to

become loose thus endangering persons or things. Tighten the

ring nut with a torque wrench setting of 3.5 Kgm

5.6 MOUNTINGTHEMETER

Fit the rubber cover of the swivel into the flexible hose, in

the direction indicated in figure, making it slide over the male

thread of the hose.

Apply a thread sealant to the male thread of the hose.

Tighten the swivel completely by means of two wrenches.

Slide the rubber cover towards the valve until it fits into the

seat, located on the swivel.

5.7 AIRPURGINGFROMTHELINES

After the installation of the nozzle, a certain quantity of air will

be inevitably present both inside the flexible hose downline the

shut-off valve and in the other system lines. To purge the air

and guarantee a steady flow and a correct calculation of the

amount dispensed, two operators should proceed as follows:

With the shut-off valve still closed, insert the ETER

extension into the opening of a container of suitable capacity,

to avoid spraying or spillage which may occur during the initial

irregular flow.

While the first operator acts on the ETER trigger, the

second must open the shut-off valve; when the flow starts

being steady, the second operator shall set the valve to the

fully open position.

Continue line purging while keeping the ETER valve

completely open, till reaching a steady flow. At this point

release the trigger thus stopping dispensing.

5.8 CHECKINGTHEFLOWRATE

Once carried out the installation and purging operations, it is

advisable to check the dispensing flow-rate which must comply

with the range indicated in paragraph 10.1, to ensure a correct

operation of the valve.

The METER allows the user to check easily and directly the

dispensing flow-rate:

During the operation in ANUAL mode, press and keep

pressed the AUTO key.

The ETER will display the current flow-rate in units per minute.

Batch total dispensed

Current flow-rate

If the flow-rate exceeds the range limits, adjust the system

components (pumps or balancing valves) to comply with them.

6 USING THE METER

The ETER has been designed for professional use and

must be utilized by adult personnel properly trained for the

intended purpose.

The ETER must not be used outside the operating ranges

(see Technical Data in paragraph 10.1) or for fluids other than

lubricants and anti-freeze mixtures.

Do not tamper with or modify the ETER.

Regularly check the good condition of the ETER.

The ETER dispenses high-pressure fluids; do not point the

nozzle to any part of the body.

Use the personal protection equipment recommended by the

national standards relevant to the dispensed products.

Do not carry out any maintenance operation on the ETER

without previously relieving the pressure from the system

lines.

The ETER is designed for indoor use only.

Is used outdoors, make sure it will not be exposed to rain, snow

or direct sunrays.

In case of manual dripless valve, after a daily use it is important

to discharge the overpressure between the chamber (1) and

the manual valve (2) of the spout. Carry out this operation with

the pump switched off. Then unscrew the valve (2). During this

discharging operation, do NOT push the trigger (3).

6.1 DISPENSINGINMANUALMODE

The ETER can be used as a normal dispensing nozzle if the

operator does not preset an automatic stop value.

If the ETER is off, press RESET to restart it.

The ETER displays:

Last amount

dispensed

Non-resettable

Total

The ETER can be programmed to display the last amount

dispensed until the RESET button is pressed or to automatically

reset the Batch Total a few minutes after a dispensing operation

in ANUAL mode (see “Auto RESET” at paragraph 7.5).

If the last dispensing operation has been carried out in AUTO

mode, the dispensed amount is never reset, independently from

the selection of the Auto RESET.

Reseing the

Batch Total

To reset the batch total, press RESET. The ETER will display:

Resettable Batch total

Non-resettable

Total

Reseing the

Total

To reset the resettable Total, press and keep pressed the RESET

key. The ETER will display:

Non-resettable

total

Dispensing

Pull the trigger to dispense.

Release the trigger to stop dispensing.

6.2 DISPENSINGINAUTOMODE

The ETER allows the user to select the automatic stop value -

“PRESET value” - with different procedures:

Direct seing

of a new

PRESET value

The METER allows the user to directly set the PRESET value

by means of the numeric keys.

If the ETER is off, press RESET to restart it.

The ETER will display:

Non-resettable

Total

To select a new PRESET value (for example 12.3) use the numeric

keys.

The ETER will display:

Selected value

AUTO message

Blinking

As long as the AUTO message blinks, it is not yet possible to

start a new automatic dispensing; if the trigger is completely

pulled, when released, it does not remain locked in open position

but closes again thus interrupting the dispensing.

The blinking message AUTO indicates that the selecting phase

of the desired value is still in progress, but the AUTO mode has

not yet been selected by confirming the displayed value.

To confirm the PRESET value, press and keep pressed the

AUTO key until the ETER displays:

Resettable Batch total

Selected value

Indication

AUTO not

Blinking

Selecting a

PRESET

value

The METER allows the operator to use the most frequently

used PRESET values without having to set them by means of

the numeric keys.

In particular, the ETER stores:

The last PRESET value “AUTO LAST”;

Five different PRESET frequent values “AUTO 1 ... AUTO 5”.

The AUTO LAST value is automatically updated each time a new

PRESET value is set by means of the keypad; the last value used

replaces the previous one in memory.

The “AUTO 1 ... AUTO 5” values can be freely set and modified

according to the procedure indicated in paragraph 7.2.

If the ETER is off, press RESET to restart it. The ETER will

display:

Last amount

dispensed

Non-resettable

Total

Press AUTO. The ETER displays the PRESET value stored in

AUTO LAST.

PRESET value

AUTO LAST indication

Blinking

Pressing AUTO again, the ETER displays the PRESET

value stored in AUTO 1:

PRESET value

AUTO 1 indication

Blinking

To display the other stored values, press AUTO as many times as

necessary to reach the desired value.

The blinking message will be:

As long as the AUTO message blinks, it is not yet possible to

start a new automatic dispensing; if the trigger is completely

pulled, when released, it does not remain locked in open position

but closes again thus interrupting the dispensing.

The blinking message AUTO indicates that the selecting phase

of the desired value is still in progress, but the AUTO mode has

not yet been selected by confirming the displayed value.

In this phase it is possible to modify the displayed AUTO value

by means of the numeric keys. The modification of the displayed

AUTO value, however, does not change the stored AUTO value;

to modify the latter, it is necessary to follow the procedure

indicated in paragraph 7.2.

To confirm the PRESET value, press and keep pressed the

AUTO key until the ETER displays:

Batch total zeroed

Selected value

Indication

AUTO not

Blinking

Dispensing in

AUTO mode

To start dispensing:

Pull the trigger fully down and then release it.

The trigger thus remains locked in open position. Now dispensing

can continue even if the Operator is not attending.

To stop manually the dispensing in progress:

Pull again the trigger fully down and then release it.

The dispensing operation can be resumed in AUTO mode

within a given time (TI E OUT) from the stop. Within this

TI E OUT the ETER still allows the locking of the trigger

in open position.

Once expired this TI E OUT, the ETER still allows the user

to continue the dispensing but only in ANUAL mode.

Dispensing automatic stop:

The supply automatically stops when the preset value is reached.

The AUTO message disappears from the LCD.

Manual resumption of the dispensing (TOPPING UP):

Once dispensing has been carried out in AUTO mode, the

ETER allows the user to continue the dispensing operation, if

necessary.

To carry out the TOPPING UP, DO NOT press RESET and pull

the trigger.

The dispensed amount is added to the previous one in AUTO

mode. The PRESET value previously set, displayed in the Total,

starts blinking to indicate that the preset value has been

exceeded.

Blinking value