ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian) ENGLISH (Translated from Italian)

TABLE OF CONTENTS

A CONFORMITY

A.1

DECLARATION OF CONFORMITY (94/9/CE, Annex X, le. B)

A.2 DECLARATION OF CONFORMITY (2004/108/EC)

A.3 DECLARATION OF CONFORMITY IECEX

B MACHINE AND MANUFACTURER IDENTIFICATION

C GENERAL WARNINGS

D SAFETY INSTRUCTIONS

D.1 SAFETY WARNINGS

D.2 DEFINITION OF CLASSIFIED ZONES

D.3 INTENDED USE

D.4 FIRST AID RULES

D.5 GENERAL SAFETY RULES

D.6 PACKAGING

D.7

PACKAGE CONTENTS/PRE-INSPECTION

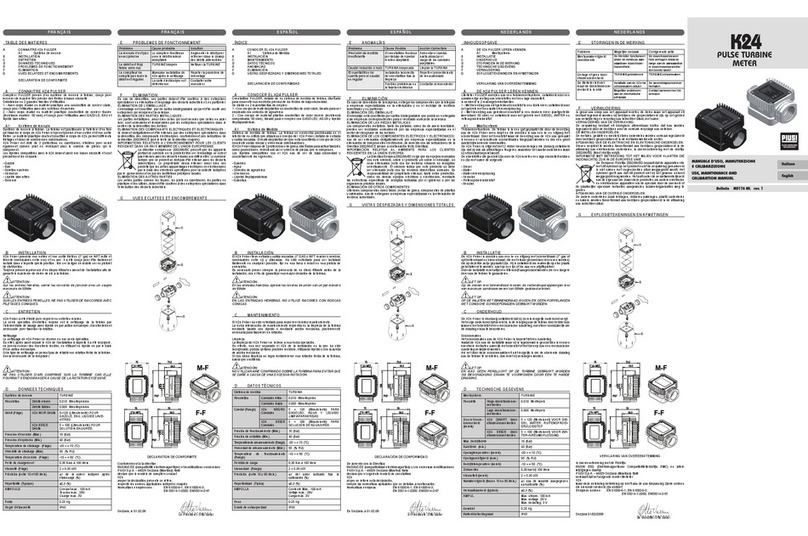

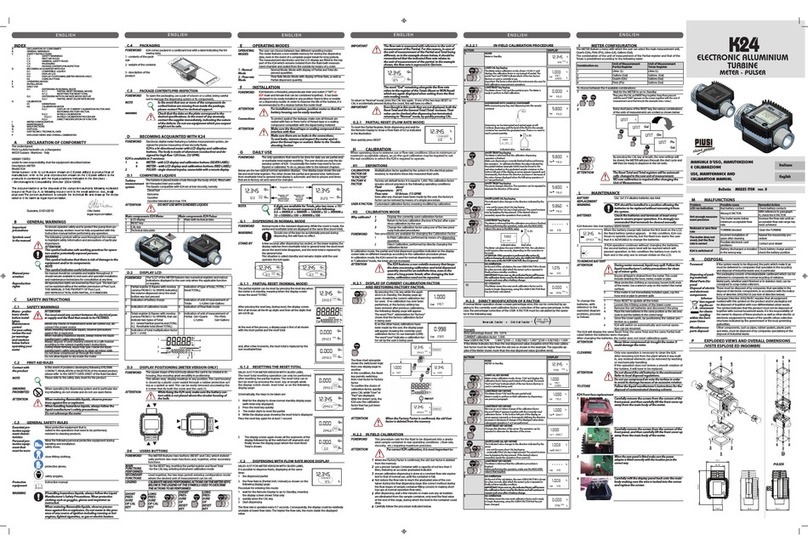

E BECOMING ACQUAINTED WITH K24

E.1 COMPATIBLE LIQUIDS

E.2 DISPLAY LCD

E.3 DISPLAY POSITIONING (METER VERSION ONLY)

E.4 USERS BUTTONS

F OPERATING MODES

G INSTALLATION

H DAILY USE

H.1 DISPENSING IN NORMAL MODE

H.1.1 PARTIAL RESET (NORMAL MODE)

H.1.2 RESETTING THE RESET TOTAL

H.2 DISPENSING WITH FLOW RATE MODE DISPLAY

H.2.1 PARTIAL RESET (FLOW RATE MODE)

I CALIBRATION

I1 DEFINITIONS

I2 CALIBRATION MODE

I.2.1 DISPLAY OF CURRENT CALIBRATION FAC-

TOR

AND RESTORING FACTORY FACTOR.

I.2.2 IN FIELD CALIBRATION

I.2.2.1

IN-FIELD CALIBRATION PROCEDURE

I.2.3 DIRECT MODIFICATION OF K FACTOR

L METER CONFIGURATION

M MAINTENANCE

N MALFUNCTIONS

O DISPOSAL

P TECHNICAL DATA

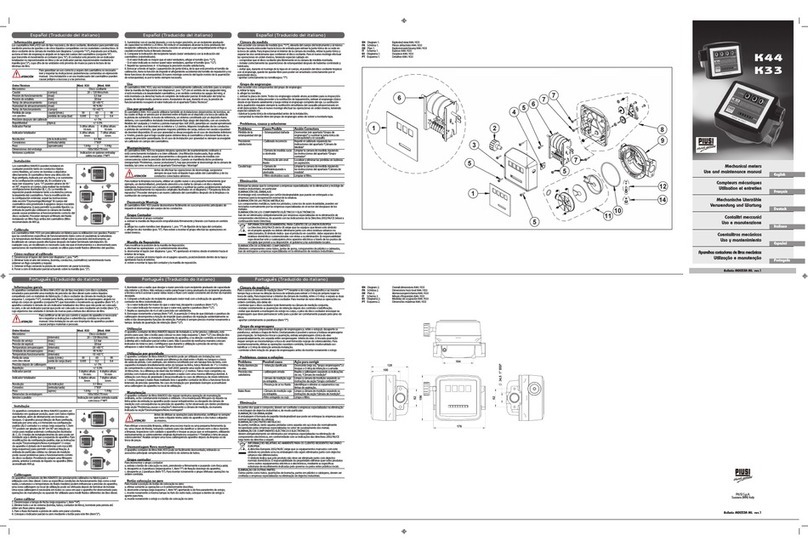

Q EXPLODED VIEWS AND OVERALL DIMENSIONS

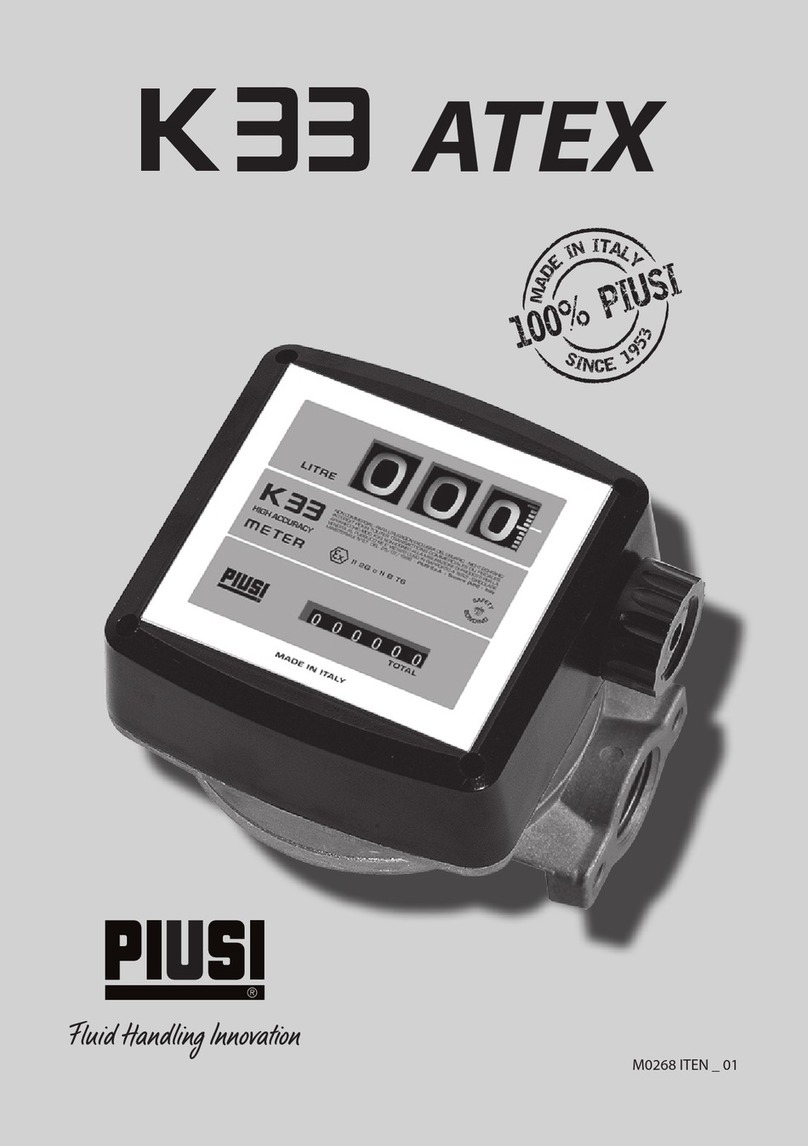

A CONFORMITY

A.1 DECLARATION OF CONFORMITY

(2014/34/UE, Annex X)

The manufacturer: PIUSI S.p.A.

Via Pacinoi, 16/A z.i. Rangavino

46029 Suzzara (MN) Italy

Declares under its own and sole responsibility that the machine:

Type: K24

Model: F00408N*nn

(*N = X : Meter version ; N = Y : Pulser version)

Year of manufacture: refer to the year of production shown on the CE plate affixed to

the product.

comply with all relevant provisions of the following directives:

- 2014/34/UE

and the following harmonized standards, applied standards and/or technical specifica-

tions:

EN 60079-0:2012 ; IEC 60079-0:2011

EN 6007911-0:2012 / A11:2013 ; IEC 60079-11:2011

Notified body data: name, identification number and address

· 1 Name: CESI S.p.A.

· 2 Identification number: 0722

· 3 Address: Via Rubaino, 134 - 20134 - Milano

Number of the EC type-examination certificate: CESI 13 ATEX 049 X

This equipment is classified as follows:

II 2 G Ex ia IIB T4 (135°C) Gb

Read the Use and Maintenance manual before using the meter.

Suzzara, 20/04/2016 Oo Varini

Legal Representative

A.2 EC DECLARATION OF CONFORMITY (2014/30/EU)

The undersigned: PIUSI S.p.A.

Via Pacinoi, 16/A z.i. Rangavino

46029 Suzzara (MN) Italy

HEREBY STATES

under its own responsibility, that the equipment described below:

Descriprion: METER

Model: K24

Serial number: refer to Lot Number shown on CE label affixed to product Year of manu-

facture: refer to the year of production shown on the CE label affixed to the product is

in conformity with the legal provisions indicated in the directives :

- Electromagnetic Compatibility Directive 2014/30/EU

The documentation is at the disposal of the competent authority following motivated

request

at

Piusi

S.p.A.

or

following

request

sent

to

the

email

address:

doc_t

[email protected].

The person authorised to compile the technical file and draw up the declaration is Oo

Varini as legal representative.

Suzzara, 20/04/2016 Oo Varini

legal representative.

A.3 DECLARATION OF CONFORMITY IECEX

The manufacturer:: PIUSI S.p.A.

Via Pacinoi, 16/A z.i. Rangavino

46029 Suzzara (MN) Italy

Declares under its own and sole responsibility that the machine:

Type: K24

Model: F00408N*nn

(*N = X : Meter version ; N = Y : Pulser version)

Year of manufacture: refer to the year of production shown on the CE plate affixed to

the product.

comply with all the following harmonized standards, applied standards and/or technical

specifications:

IEC 60079-0:2011; IEC 6 0079-11:20 11

Notified body data: name, identification Number and address

· 1 Name: CESI S.p.A.

· 2 Identification number: 0722

· 3 Address: Via Rubaino, 134 - 20134 - Milan

CoC Certificate Number: IECEX CES 13.0021X

The equipment is classified as follows:

Ex ia IIB T4 (135°C) Gb

Read the Use and Maintenance manual before using the pump.

Suzzara, 20/04/2016 Oo Varini

Legal Representative

B MACHINE AND MANUFACTURER

IDENTIFICATION

AVAILABLEMODELS: K24

MANUFACTURER: PIUSI S.p.A. ,

Via Pacinotti 16/A – z.i. Rangavino

46029 Suzzara - Mantova (Italy)

C GENERAL WARNINGS

Important pre-

cautions To ensure operator safety and to protect the meter from po-

tential damage, workers must be fully acquainted with this

instruction manual before performing any operation.

Symbols used

in the manual The following symbols will be used throughout the manual

to highlight safety information and precautions of particular

importance:

WARNING

WARNINGindicates a hazardou s situation which, if not

avoided, could result in death or serious injury

NOTICE

NOTICE is used to address pratices not related to per-

sonal injury

Manual pres-

ervation

This manual should be complete and legible throughout. It

should remain available to end users and specialist installa-

tion and maintenance technicians for consultation at any

time.

Reproduction

rights

This manual belongs to Piusi S.p.A., which is the sole propri-

etor of all rights indicated by applicable laws, including, by

way of example, laws on copyrights. All the rights deriving

from such laws are reservedto Piusi S.p.A.: the reproduction,

including partial, of this manual, its publication, change, tran-

scription and notification to the public, transmission, includ-

ing using remote communication media, placing at disposal

of the public, distribution, marketing in any form, translation

and/or processing, loan and any other activity reserved by

the law to Piusi S.p.A..

WARNING

Installation, assembly and maintenance operations of

the K24, must onlybe performed by personnel qualified

to operate in HAZARDOUS LOCATIONS ZONE1.

BEFORE PROCEEDING WITH THE REFUELLING

OF THE AIRCRAFT, ENSURE THAT THE SYSTEM IN-

TENDED FOR SUCH ACTION COMPLIES WITH THE

REGULATIONS IN FORCE IN THE COUNTRYOF USE

Stop operation immediately if static sparking occurs

or if you feel a shock. Do not use equipment until you

identify and correct the problem.

Keep a working fire extinguisherin the work area.

Do not operate the unit when fatigued or under the in-

fluence of drugs or alcohol.

Do not alter or modify equipment. Alterations or modi-

fications may void agency approvals and create safety

hazards.

Keep children and animals away from work area.

Comply with all applicable safety regulations.

D SAFETY INSTRUCTIONS

D.1 SAFETY WARNINGS

WARNING

Mains - preliminary checks before installation

You must avoid any contact between the electrical

power supply and the fluid that needs to be FILTERED.

MAINTENANCE CONTROL

Before any checks or maintenance work are carried

out, disconnect the power source.

FOR YOUR SAFETY, REVIEW THE MAJOR WARNINGS AND CAUTIONS BE-

LOW BEFORE OPERATING YOUR METER

When metering flammable liquids, observe precau-

tions against fire or explosion

When handling hazardous liquids, always follow the

liquid manifacturer’s safety precautions

Always dispose of used cleaning solvents in a safe

manner according to the solvent manifacturer’s in-

structions.

During meter removal, liquid may spill. Follow the

liquid manifacturer’s safety precautions to clean up

minor spills

Do not blow compressed air through the meter

Do not allow liquids to dry inside the meter

Use only liquids permied

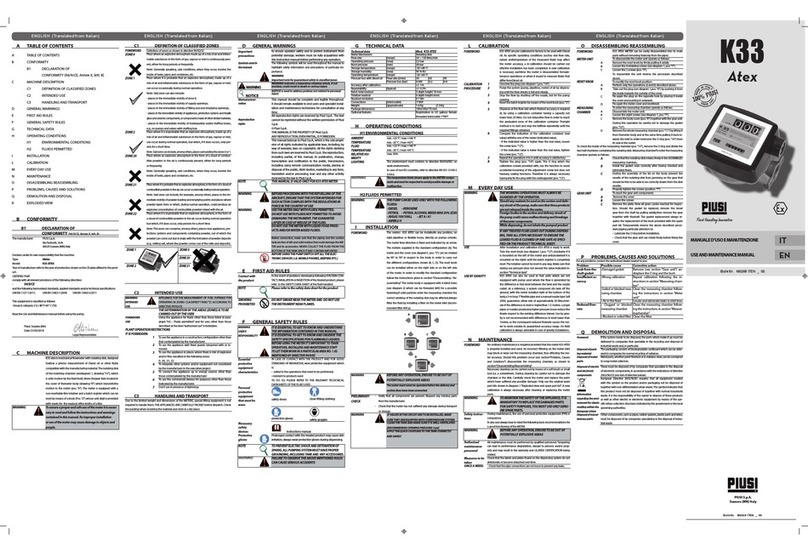

D.2 DEFINITION OF CLASSIFIED ZONES (EN60079-10-1)

FOREWORD Definition of zones as shown in directive 99/92/CE

ZONE 0

Place where an explosive atmosphere made up of a mix of air and in-

flammable substances in the form of gas, vapour or mist is continuously

present, either for long periods or frequently.

Note: Generally speaking, said conditions, when they occur, involve the

inside of tanks, pipes and containers, etc.

ZONE 1

Place where it is probable that an explosive atmosphere, made up of

a mix of air and inflammable substances in the form of gas, vapour or

mist, can occur occasionally during normal operation.

Note: Said zone can also include:

- places in the immediate vicinity of zone 0;

- places in the immediate vicinity of supply openings;

- places in the immediate vicinity of filling and and emptying openings;

-

places in the immediate vicinity of appliances, protection systems and

fragile glass and ceramic components, or components made of other simi-

lar materials;

- places in the immediate vicinity of inadequately sealed stuffing boxes,

e.g., on pumps and valves with stuffing box.

ZONE 2

Place where it is improbable that an explosive atmosphere, made up

of a mix of air and inflammable substances in the form of gas, vapour

or mist, can occur during normal operation, but which, if it does occurs,

only persists for a short time.

Note: Said zone can include, among others, places surrounding the zones

0 or 1.

ZONE 20

Place where an explosive atmosphere in the form of a cloud of com-

bustible powders in the air is continuously present, either for long pe-

riods or frequently.

Note: Generally speaking, said conditions, when they occur, involve the

inside of tanks, pipes and containers, etc.

ZONE 21

Place where it is probable that an explosive atmosphere, in the form of a

cloud of combustible powders in the air, can occur occasionally during nor-

mal operation.

Note: Said zone can include, for example, among others, places in the

immediate vicinity of powder loading and emptying points and places

where powder layers form or which, during normal operation, could

produce an explosive concentration of combustible powders mixed

with the air.

ZONE 22

Place where it is improbable that an explosive atmosphere, in the form

of a cloud of combustible powders in the air, occur during normal op-

eration but which, if it does occur, only persists for a short time.

Note: This zone can comprise, among others, places near appliances,

protections systems and components containing powder, out of which

the powder can come out due to leaks with the formation of powder

deposits (e.g., milling salt, where the powder comes out ofthe mills and

deposits).

ZONE 1 ZONE 0

ZONE

20

ZONE 2

ZONE 21

ZONE 22

D.3 INTENDED USE

WARNING

INTENDED USE

METER FOR TRANFERRING FUEL SUITABLE FOR

OPERATING IN ZONES CLASSIFIED“1”AND “2”, AC-

CORDING TO DIRECTIVE 99/92/CE

THE DETERMINATION OFTHE AREAS (ZONES) IS TO

BE CARRIED OUT BYTHE USER

FORBIDDEN USE Using the appliance for fluids other than those listed

at paragraph “COMPATIBLE LIQUIDS” and for uses

other than thosedescribed at the item “authorisedu se”

is forbidden.

PLANT OPERATION RESTRICTIONS IT IS FORBIDDEN:

1To use the appliance in a construction configuration

other than that contemplated by the manufacturer

2To use the appliance with fixed guards tampered with

or removed.

3To use the appliance in places where there is risk of

explosion and/or fires classified in the following zones:

0; 20; 21; 22

4To integrate other systems and/or equipment not con-

sidered by the manufacturer in the executive project.

5To connect the appliance up to energy sources other

than those contemplated by the manufacturer

6To use the commercial devices for purposes other than

those indicated by the manufacturer.

7Do not use in case of lightnings

D.4 FIRST AID RULES

Contact with

the product

In the event of problems developing following EYE/SKIN

CONTACT, INHALATION or INGESTION of the treated

product, please refer to the SAFETY DATA SHEET of the

fluid handled.

NOTICE

Please refer to the safety data sheet for the product

SMOKING

PROHIBITED When operating the dispensing system and in particular dur-

ing refuelling, do not smoke and do not use open flame.

WARNING

When metering flammable liquids, observe precau-

tions against fire or explosion

When handling hazardous liquids, always follow the

liquid manifacturer’s safety precautions.

Do not submerge the meter

D.5 GENERAL SAFETY RULES

Essential pro-

tective equip-

ment charac-

teristics

Wear protective equipment that is:

suited to the operations that need to be performed;

resistant to cleaning products.

Personal pro-

tective equip-

ment that must

be worn

Wear the following personal protective equipment during

handling and installation:

safety shoes;

close-fiing clothing;

protective gloves;

safety goggles;

instruction manual

Protective

equipment

WARNING

If handling hazardous liquids, always follow the Liquid

Manifacturer’s Safety Precautions. Wear protective

clothing such as goggles, gloves and respirator as in-

structed.

When metering flammable liquids, observe precautions

against fire or explosion. Do not meter in the presence

of any source of ignition including running or hot en-

gines, lighted cigarees, or gas or electric heaters

D.6 PACKAGING

FOREWORD K24 comes packed in a cardboard box with a label indicating the

following data:

1 - contents of the

package

2 - weight of the

contents

3 - description of the

product

D.7

PACKAGE CONTENTS/PRE-INSPECTION

NOTICE

In the event that one or more of the components de-

scribed below are missing from inside the package,

please contact Piusi S.p.A. technical support.

Check that the data on the plate correspond to the de-

sired specifications. In the event of any anomaly, con-

tact the supplier immediately, indicating the nature of

the defects. Do not use equipment which you suspect

might not be safe.

E BECOMING ACQUAINTED WITH K24

FOREWORD Electronic digital meter featuring a turbine measurement system, de-

signed for precise measuring of low viscosity uids.

K24 is a bi-directional meter with LCD display and calibration

buons. The body is made of aluminum (conductive) and de-

signed for high flow 120 l/min. (32 GPM).

WARNING

Do not use K24 for purposes other than those intended.

E.1 COMPATIBLE LIQUIDS

Turbine

measurement

system

The turbine is placed inside a hole through the body of k24, fied with

M-f threaded inlet and outlet.

The liquids compatible with k24 are at low viscosity, namely:

COMPATIBLE

LIQUIDS - DIESEL - KEROSENE

- PETROL - PETROL ALCOHOL MIXED MAX 20% (E20)

- AVGAS 100/100LL - JET A / A1

- ASPEN 2/ 4

WARNING

DO NOT USE WITH SUNDRIES LIQUIDS

INTENDED USE The K24 ow meter has been designed and made for

the precise measurement of pumped liquids, including

under high pressure. Use only the liquids listed under the

item «Compatible liquids».

UNINTENDED USE Using the system for purposes other than those intend-

ed and indicated under “Intended use” is strictly forbid-

den.

All other uses excepting those for which the litre coun-

ter was designed and described in this manual shall be

deemed “MISUSE”, and consequently Piusi S.p.A. dis-

claims all liability for any injury caused to persons of

animals or damage to things or the system itself.

NOT COMPATIBLE

LIQUIDS

The K24 flow meter IS NOT compatible with the follow-

ing fluids :

All fluids of group IIC , IC (definition like IEC60079-0)

Not suitable with explosive dust (IIIC)

All fluids not suitable with alluminum, PA (polyammide) ,

PBT (Polybutylene terephthalate).

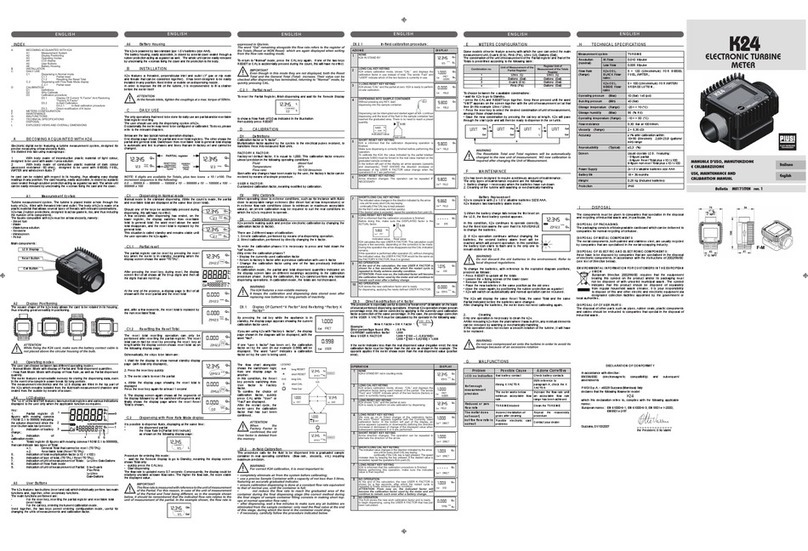

Main components K24

1LCD display 3CAL key

2RESET key 4Technical data plate

5Marking

METER PULSER

E.2 DISPLAY LCD (METER VERSION ONLY)

FOREWORD The “LCD” of the METER features two numerical registers and vari-

ous indications displayed to the user only when the applicable func-

tion so requires.

1Partial register (5 figures with moving

comma FROM 0.1 to 99999) indicating

the volume dispensed since the reset

buon was last pressed

6Indication of type of total, (TOTAL /

Reset TOTAL);

2Indication of baery charge 7Indication of unit of measurement of

Totals: L=Litres Gal=Gallons

3Indication of calibration mode 8Indication of Flow Rate mode

4Totals register (6 figures with moving

comma FROM 0.1 to 999999), that

can indicate two types of Total:

4.1.

General Total that cannot be reset

(TOTAL)

4.2. Reseable total (Reset TOTAL)

9Indication of unit of measurement of

Partial: Qts=Quarts Pts=Pints

L=Litres Gal=Gallons

5Indication of total multiplication factor

(x10 / x100)

456

9

7

1

2

3

8

E.3 DISPLAY POSITIONING (METER VERSION ONLY)

FOREWORD The square shape of the k24 body allows the card to be rotated in its

housing, thus ensuring great versatility in positioning

This allows easy display readings in any position. The card housing is

closed by a plastic cover sealed through a rubber protection acting as

a gasket as well. This can be easily removed unscrewing the 4 screws

that fix both the cover and the card (1).

NOTICE

While fixing the K24 card, make sure the baery con-

tact cable is not placed above the circular housing of

the bulb.

E.4 USERS BUTTONS

FOREWORD The METER features two buons (RESET and CAL) which individu-

ally perform two main functions and, together, other secondary func-

tions

.

MAIN

FUNCTIONS

PERFORMED

- for the RESET key, reseing the partial register and Reset Total

- for the CAL key, entering instrument calibration mode

SECONDARY

FUNCTIONS Used together, the two keys permit entering configuration mode

where the desired unit of measurement can be set.

LEGEND CALIBRATE MEANS PERFORMINGACTIONS ONTHE METER

KEYS. BELOW IS THE LEGEND OF THE SYMBOLS USED TO

DESCRIBE THE ACTIONS TO BE PERFORMED

SHORT

PRES

SURE

OFCAL

KEY

CAL LONG

PRES

SURE

OFCAL

KEY

CALCAL

CAL

SHORT

PRES

SURE

OF

RESET

KEY

RESET

LONG

PRES

SURE

OF

RESET

KEY

RESET

RESET

RESET

F OPERATING MODES

OPERATING

MODES The user can choose between two different operating modes:

The meter features a non-volatile memory for storing the dispensing

data, even in the event of a complete power break for long periods.

The measurement electronics and the LCD display arefied in the top

part of the K24 which remains isolated from the fluid-bath measure-

ment chamber and sealed from the outside by means of a cover.

1 - Normal

Mode Normal Mode: Mode with display of Partial and Total dispensed quanti-

ties

2 - Flow rate

Mode Flow Rate Mode: Mode with display of Flow Rate, as well as Partial dis-

pensed quantity.

G INSTALLATION

WARNING

Installation, assembly and maintenance operations of

the K24 , must only be performed by personnel quali-

fied to operate in HAZARDOUS LOCATIONS ZONE1.

K24featuresa threaded,perpendicularinletand outlet

(1” NPT or BSP male and female that can be combined

together). It has been designed to be easily installed

in any position: fixed in-line or mobile on a dispensing

nozzle. In order to improve the life of the turbine, it is

recommended to fit a strainer before the meter itself

For installations on system, position meter so that the

baery housing can be easily reached.

CONNECTIONS To protect against the leakage, make sure all threads

are sealed with two or three turns of thread tape or a

sealing compound compatible with the liquid being

metered

Make sure the thread tape or sealing compound does

interfere with flow

Make sure there are no leaks in the connections.

To seal leaks, remove and inspect the meter and replace

the thread tape or sealant. Refer to the Troubleshooting

Section

To minimize static electricity build up,use only static

conductive hose R<1MΩm when metering flammable

fluids, and keep the fill nozzle in contact with the con-

tainer being filled during the filling process.

All parts of our system must be incontinuity and

grounded.

DO NOT exceed 145 psi - 20 bar line pressure.

DO NOT install additional foot valve or check valve

without a pressure relief valve; otherwise the meter

may rapture.

PULSER

CONNECTIONS The electrical signal between K24 PULSER and the

control unit device must be protected by intrinsically

safe barrier.

The electrical limits of signal are the follows :

Ui = 12 V

Ii = 100 mA

Pi = 0.3 W

The barier must be properly connected to an earth

grounded.

Improper installation of this meter and barier could re-

sult in death or serious injury.

H DAILY USE

FOREWORD The only operations that need to be done for daily use are partial

and/or reseable total register reseing. The user should use only

the dispensing system of K24. Occasionally the meter may need to

be configured or calibrated. To do so, please refer to the relevant

chapters.

Below are the two typical normal operation displays. One display page shows the partial

and reset total registers. The other shows the partial and general total. Switchover from

reseable total to general total display is automatic and tied tophases and times that are

in factory set and cannot be changed.

NOTICE

6 digits are available for Totals, plus two icons x 10 /

x100. The increment sequence is the following:

0.0 -> 99999.9 -> 999999 -> 100000 x 10 -> 999999 x 10

->100000 x 100 -> 999999 x 100

H.1 DISPENSING IN NORMAL MODE

FOREWORD Normal mode is the standard dispensing. While the count is made,

the partial and reseable total are displayed at the same time (reset

total).

NOTICE

Should one ofthe keys be accidentally pressedduring

dispensing, this will have no effect.

stand by A few seconds aer dispensing has ended, on the lowerregister, the

display switches from reseable total to generaltotal: the word reset

above the word total disappears, and the reset total is replaced by

the general total. This situation is called standby and remains stable

until the user operates the k24 again.

H.1.1 PARTIAL RESET (NORMAL MODE)

The partial register can be reset by pressing the reset key

when the meter is in standby,meaning when the display screen

shows the word “TOTAL”.

Aer pressing the reset key, during reset, the display screen

first of all shows all the lit-up digits and then all the digits that

are not lit up.

At the end of the process, a display page is first of all shown

with the reset partial and the reset total

and, aer a few moments, the reset total is replaced bythe non

reseableTotal.

H.1.2 RESETTING THE RESET TOTAL

The reset total reseing operation can only be performed

aer reseing the partial register. The reset total can in fact

be reset by pressing the reset key at length while the display

screen shows reset total as on the following display page:

Schematically, the steps to be taken are:

1Wait for the display to show normal standby display page

(with total only displayed)

2Press the reset key quickly

3The meter starts to reset the partial

4While the display page showing the reset total is displayed

Press the reset key again for at least 1 second

The display screen again shows all the segments of the

display followed by all the switched-off segments and fi-

nally shows the display page where the reset Reset Total

is shown.

H.2 DISPENSING WITH FLOW RATE MODE DISPLAY

It is possible to dispense fluids, displaying at the same time::

1the dispensed partial

2the Flow Rate in [Partial Unit / minute] as shown on the

following display page:

Procedure for entering this mode:

1wait for the Remote Display to go to Standby, meaning the

display screen shows Total only

2quickly press the CAL key.

3Start dispensing

The flow rate is updated every 0.7 seconds. Consequently, the display could be relatively

unstable at lower flow rates. The higher the flow rate, the more stable the displayed

value.

NOTICE

The flow rate is measured with reference to the unit of

measurement of the Partial. For this reason, in case of

the unit of measurement of the Partial and Total be-

ing different, as in the example shown below, it should

be remembered that the indicated flow rate relates to

the unit of measurement of the partial. In the example

shown, the flow rate is expressed in Qts/min.

The word “Gal” remaining alongside the flow rate re-

fers to the register of the Totals (Reset or NON Reset)

which are again displayed when exiting from the flow

rate reading mode.

To return to “Normal” mode, press the CAL key again. If one of the two keys RESET or

CAL is accidentally pressed during the count, this will have no effect.

NOTICE

Even though in this mode they are not displayed, both

the Reset Total and the General Total (Total) increase.

Their value can be checked aer dispensing has termi-

nated, returning to “Normal” mode, by quickly pressing

CAL.

H.2.1 PARTIAL RESET (FLOW RATE MODE)

To reset the Partial Register, finish dispensing and wait for

the Remote Display to show a FlowRate of 0.0 as indicated

in the illustration

then quickly press RESET

I CALIBRATION

When operating close to extreme use or flow rate conditions (close to minimum or maxi-

mum acceptable values), an on-the-spot calibration maybe required to suit the real condi-

tions in which the K24 is required to operate.

I.1 DEFINITIONS

CALIBRATION

FACTOR OR

“K FACTOR”

Multiplication factor applied by the system to the electrical pulses

received, to transform these into measured fluid units.

FACTORY K

FACTOR

Factory-set default factor. It is equal to 1,000. This calibration factor

ensures utmost precision in the following operating conditions:

Fluid Diesel

Temperature: 20°C - 68°F

Flow rate: 50 lit/min (13 GPM)

Even aer any changes have been made by the user, the factory k

factor can be restored by means of a simple procedure.

USER K FAC-

TOR: Customized calibration factor, meaning modified by calibration.

I.2 CALIBRATION MODE

Why calibrate? 1Display the currently used calibration factor:

2Return to factory calibration (FactoryK Factor) aer a pre-

vious calibration by the user

3Change the calibration factor using one of the two previ-

ously indicated procedures

FOREWORD Two procedures are available for changing the Calibration

Factor:

1

In-Field Calibration, performed by means of a dispensing operation

2

Direct Calibration, performed by directly changing the calibration

factor

In calibration mode, the partial and total dispensed quantities indicated on the display screen

take on different meanings according to the calibration procedure phase. In calibration mode,

the K24 cannot be used for normal dispensing operations. In “Calibration” mode, the totals

are not increased

NOTICE

The K24 features a non-volatile memory that keeps

the data concerning calibration and total dispensed

quantity stored for an indefinite time, even in the

case of a long power break; aer changing the bat-

teries, calibration need not be repeated.

II 2 G

Atex

CES 13.0021X

K24

ELECTRONIC

ALLUMINIUM

TURBINE

METER

Use, maintenance and Calibration manual

En

Bulletin M0320 A EN_00