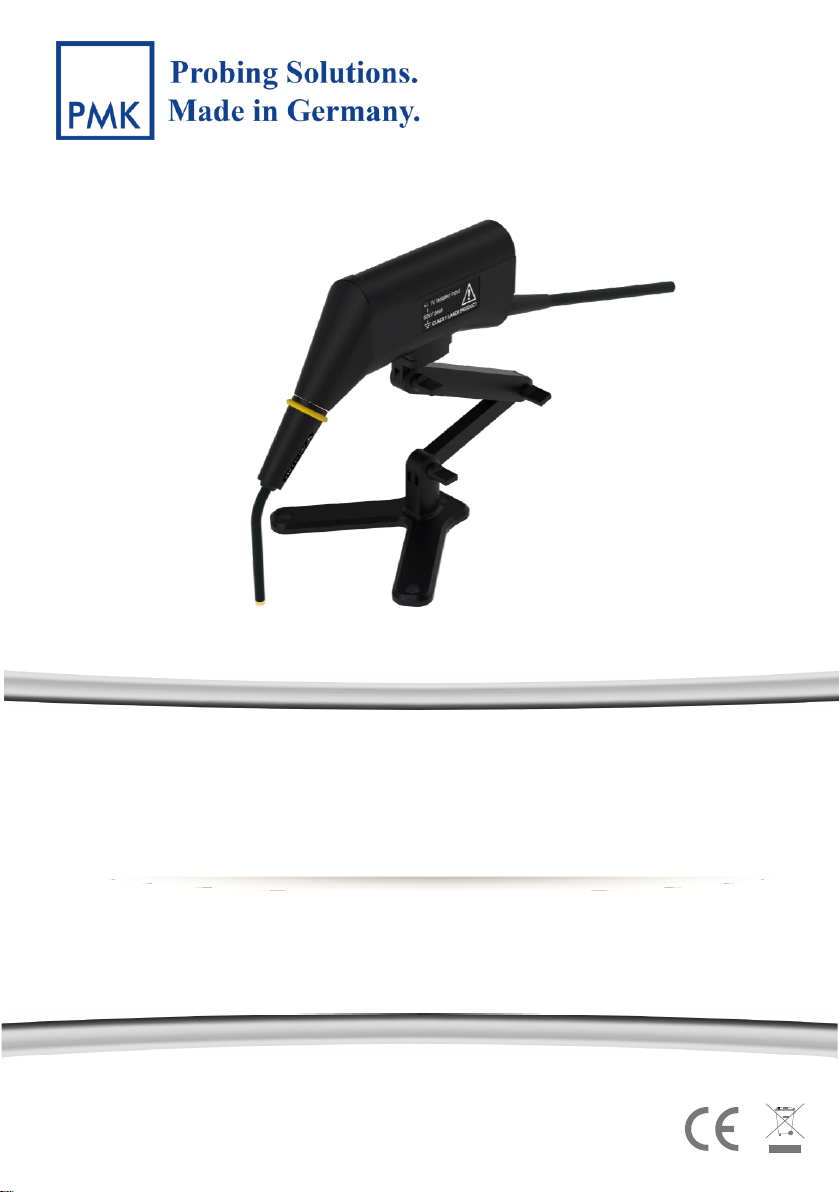

FireFly®Instruction Manual

3

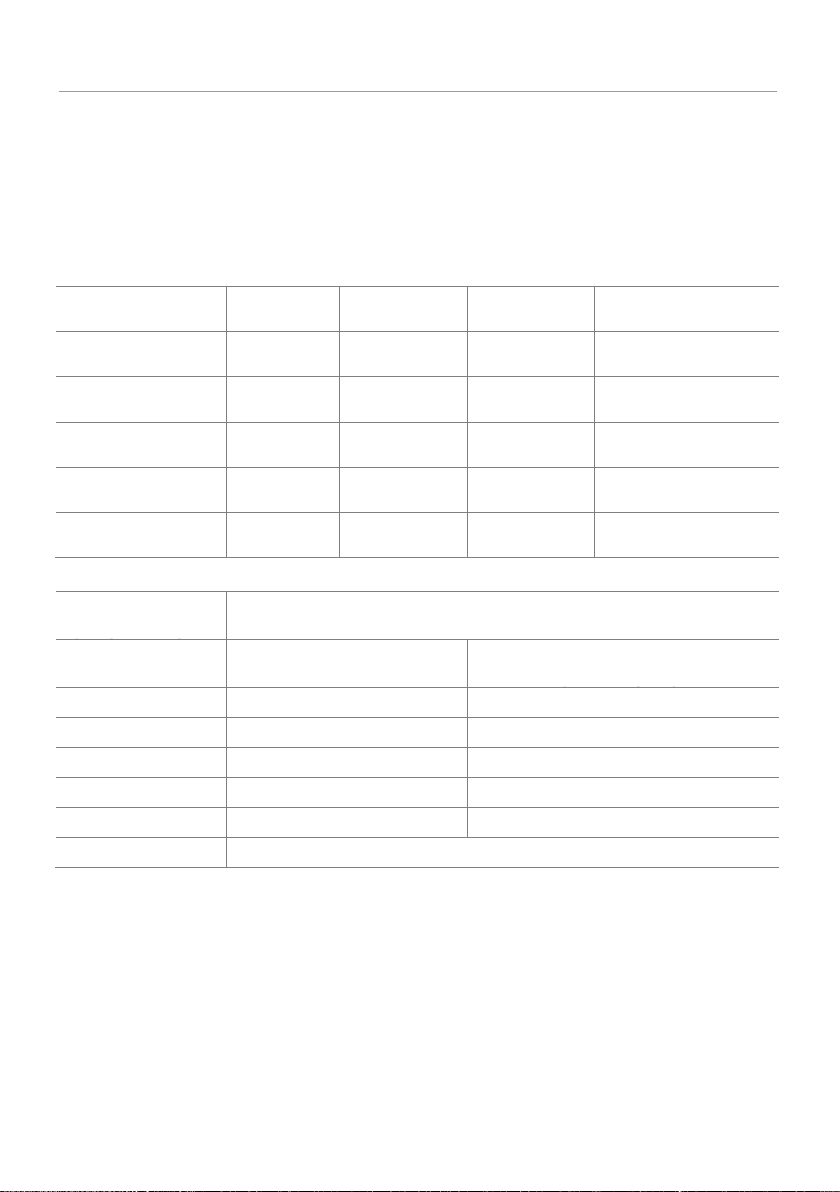

Table of Contents

Manufacturer........................................................................................................................................................ 2

Warranty............................................................................................................................................................... 2

Compliance Information....................................................................................................................................... 4

IEC Pollution Degrees............................................................................................................................................ 5

IEC Safety Symbols................................................................................................................................................ 5

Safety and Handling Information.......................................................................................................................... 6

Safety and Handling Information (Continued)...................................................................................................... 7

Lithium-Ion 18650 Battery Charging and Storage Information........................................................................ 7

Clearance Requirements ................................................................................................................................. 8

About FireFly®....................................................................................................................................................... 9

Factory Calibration ............................................................................................................................................... 9

Specifications...................................................................................................................................................... 10

Electrical Specifications1................................................................................................................................ 10

Electrical Specifications (Continued) ............................................................................................................ 11

Environmental Specifications ........................................................................................................................ 12

Physical Specifications................................................................................................................................... 12

Dimensions.................................................................................................................................................... 12

Typical Common Mode Rejection Ratio (CMRR) ........................................................................................... 13

Typical Maximum Differential Input Voltage (CW)........................................................................................ 13

Typical Frequency Response ......................................................................................................................... 14

Typical Differential Input Impedance ............................................................................................................ 14

User Interface..................................................................................................................................................... 15

Interface Box Controls & Indicators............................................................................................................... 15

Probe Status Indicator................................................................................................................................... 15

Probe Head Battery Level Indicators ............................................................................................................. 15

Probe Head Power ON/OFF Button............................................................................................................... 16

Auto-Zero Button .......................................................................................................................................... 16

Remote Interface................................................................................................................................................ 16

Getting Started ................................................................................................................................................... 16

Cable Selection.............................................................................................................................................. 17

Connection to the Test Points (Circuit-Under-Test)....................................................................................... 17

Making the Measurement............................................................................................................................. 17

Scope of Delivery ................................................................................................................................................ 18

Ordering Information.......................................................................................................................................... 19