R&G Racing

Unit 1, Shelley’s Lane, East Worldham, Alton, Hampshire, GU34 3AQ

Tel: +44 (0)1420 89007 Fax: +44 (0)1420 87301 www.rg-racing.com Email: info@rg-racing.com

From the kit take one of the cable tie provided and loop it around the two small holes located

in the centre of the licence plate bracket (Item 4). Secure the licence plate illuminator (Item 7)

wiring with the cable tie just fitted as shown in Picture 9.

From the kit, take the cover plate (Item 9) and place it below the licence plate bracket (Item 4).

Ensure that the folded areas of the cover plate are facing upwards. Align all the 5mm and 8mm

holes together.

Take the indicator bracket assembly and position it below the cover plate with both 5mm holes

being aligned as shown in Picture 10. Secure the assembly using M5 bolts (Item 12) with M5

washers (Item 6) and M5 nyloc nuts (Item 5) from the kit. Tighten the nuts to 12Nm.

Apply a thin layer of grease onto the surface of each spacer (Item 3) provided in the kit. Place

each spacer over the 8mm hole on the licence plate bracket (Item 4). Shown in Picture 11. The

grease is used to keep the spacers in place while fitting.

Offer the whole tail tidy assembly towards the subframe of the bike with all the wires being

positioned in the slot provided (shown in Picture 12). Locate the wires around the subframe as

original.

Secure the assembly using the M8 bolts (Item 10) with M8 washers (Item 2) and M8 nyloc

nuts (Item 1) as shown in Picture 13. Tighten the nuts to 20Nm.

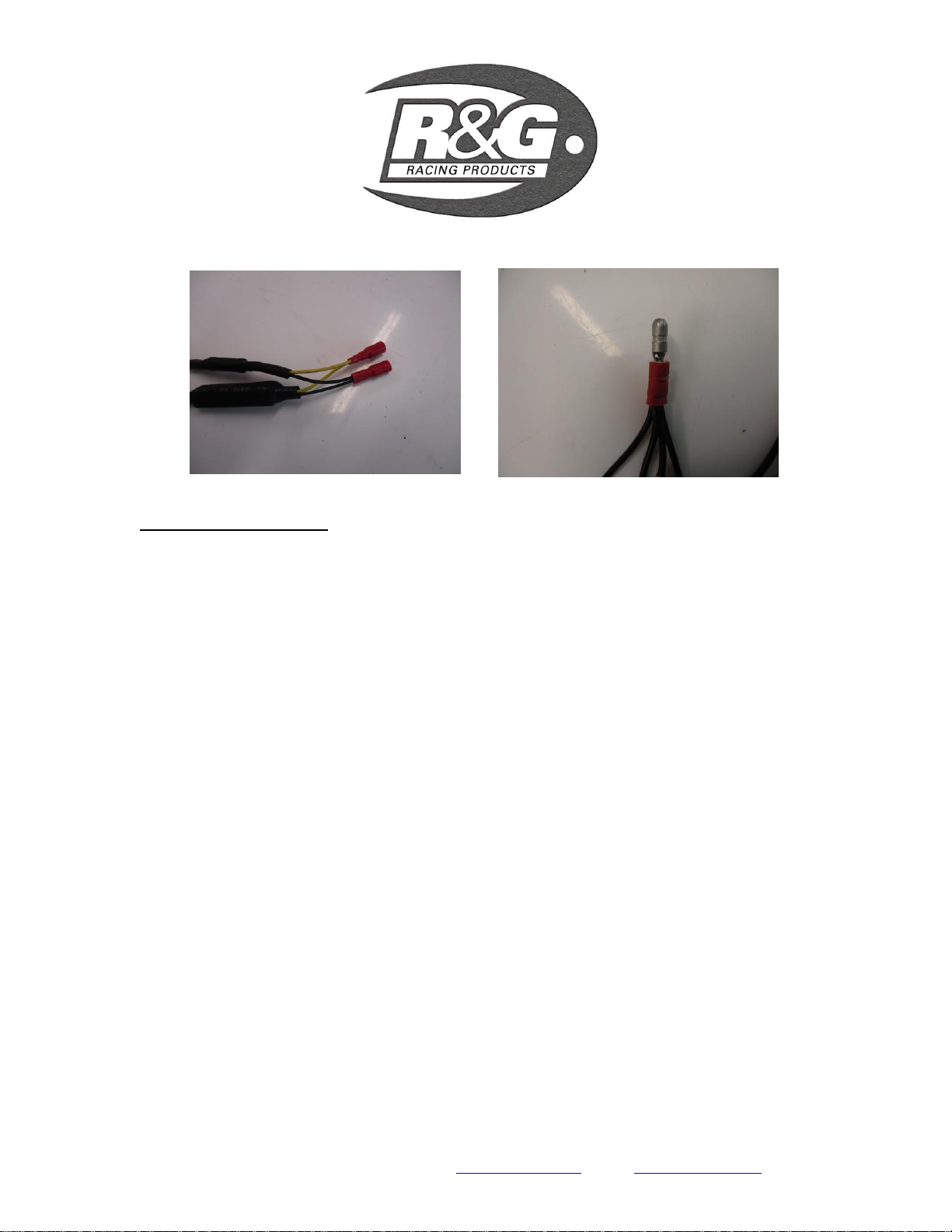

Take the OEM subharness that was removed earlier, in order to install R&G licence plate

illuminator, the OEM wiring needs to be ‘cut and shut’. Cut the OEM licence plate illuminator

wiring at least 20mm away from its bulb holder (Shown in Picture 14). Peel the end of both

wires and crimp female bullet connectors (Item 13) from the kit. Plug in the licence plate

illuminator connectors in this scheme:

Subharness YELLOW ------------Licence Plate Illuminator RED

Subharness GREEN ---------------Licence Plate Illuminator BLACK

If licence plate illuminator fails to illuminate, please swap the connectors over.

If using R&G Mini/ Aero indicators, resistors RGR0001 and RGR0002 are required to be

connected in parallel. Cut the all connectors from both resistors and peel all the wire ends

using an electrical plier. Working from one side of both resistors at a time, join the two yellow

wires together and fit a female bullet connector (Item 13). Ensure that the connector is crimped

correctly. Repeat the procedure to the other two black wires (Shown in picture 15). Connect

the female bullet connectors just fitted to the male indicator connectors in this scheme:

Mini Indicator YELLOW----------------Resistors YELLOW

Mini Indicator BLACK------------------Resistors BLACK

Repeat the procedure for the other mini indicator.

On the other end of both resistors, join the two exposed yellow wires together and crimp using

a male bullet connector (Item 13). Repeat the procedure for the other indicator, to join the

yellow wires together only. Join all four black wires from all four resistors together and crimp

using a male bullet connector (Item 13) as shown in Picture 16.

please connect the indicator resistors in this scheme:

Subharness LIGHT BLUE -----------Resistors YELLOW

Subharness ORANGE-----------------Resistors YELLOW

Subharness GREEN -------------------Resistors BLACK

Reconnect the main square subharness connector to the main OEM harness as original. Tuck

in all the wiring in an appropriated location and tidy up using the cable ties (Item 14) provided.

It is recommended to have the bike running and test all the lights at this stage.

Refit licence plate as original (it may require drilling)

IMPORTANT: IF FITTING A FULL-SIZE LICENCE PLATE AND PLACING IT FAR

DOWN ON THE LICENCE PLATE HANGER, THERE IS A SMALL CHANCE OF THE

LICENCE PLATE HITTING THE BACK WHEEL UNDER HEAVY LOAD AND OVER