Table of Contents

II

4 Machine specifications 27

4.1 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2 Description of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.1 Basic machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.2 Blower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.3 Metering units and air duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.4 Boom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.3 Technical data of basic equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Special equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.1 Universal drive shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.2 Metering shaft for fine seeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.3 Metering shaft for weed remover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.4.4 Distance-Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.5 Section control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.6 D-GPS receiver A100 EGNOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.7 Bracket set for CCI and joystick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4.8 Other special equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 Transport without tractor 39

5.1 General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Loading and unloading, parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6 Commissioning 41

6.1 Accepting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Operating licence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.1 Germany . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2.2 EAC countries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2.3 France. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2.4 Other countries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3 Tractor requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4 Checking the height of the pin or ball coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.5 Adjusting the trailer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.6 Installing the universal drive shaft on the machine. . . . . . . . . . . . . . . . . . . . . . . . . 45

6.6.1 Checking the length of the universal drive shaft . . . . . . . . . . . . . . . . . . . . . . . . 45

6.6.2 Installing/removing the universal drive shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.7 Installing the machine to the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.8 Connecting the ball coupling (variant A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.9 Connecting the pin coupling (variant B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.10 Installing the universal drive shaft on the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.11 Brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.12 Connecting the lighting system and camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.13 Connecting the ISOBUS terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.14 Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.14.1 Connection overview of the control block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.15 Filling the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.16 Checking the level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.17 Rear view camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

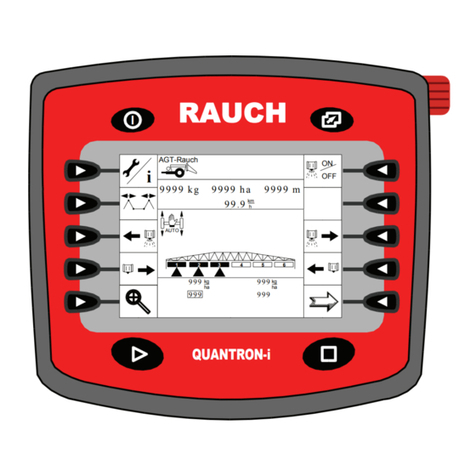

6.18 Starting the machine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63