5.

F1FR56-300 Horizontal Sidewall, F1FR56-300 Horizon-

tal Sidewall Recessed & F1FR56-300 Horizontal Side-

wall Concealed

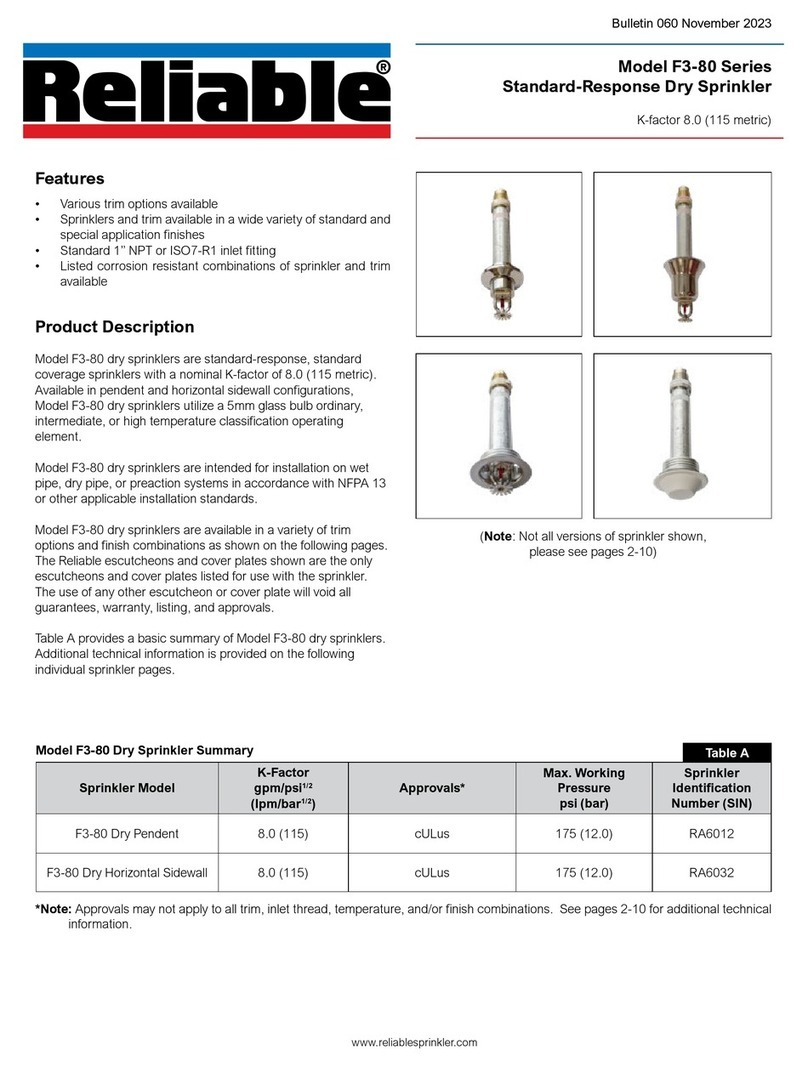

Models F1FR56-300 Horizontal Sidewall, F1FR56-300

Horizontal Sidewall Recessed and SWC56 Concealed are

quick response type sprinklers. Model F1FR56-300 Hori-

zontal Sidewall Recessed and SWC56 assemblies utilize the

push-on / thread-off escutcheon and cover-plate, respec-

tively. These assemblies are shipped with a protective cap.

Remove cap to enable mounting the F1FR56-300 Horizon-

tal Sidewall sprinkler/cup assembly in place and then push

or thread the escutcheon or cover-plate into the installed

sprinkler/cup assembly. When the F1FR56-300 Horizontal

Sidewall is ordered with the F2 escutcheon the sprinkler and

escutcheon assembly are shipped separately. The sprinkler

and collar must be assembled together before the sprinkler

can be installed in a fitting.

The SWC56 sprinkler’s cover is attached to its skirt us-

ing 135°F (57°C) ordinary temperature classification solder.

When the ambient temperature rises, the solder holding the

cover-plate melts, allowing the release of this part and thus

exposing the sprinkler inside to the rising ambient tempera-

ture.

The Model F1FR56-300 Horizontal Sidewall utilizes a

3.0mm frangible glass bulb. This allows quick response

which enables the sprinkler to apply water to a fire sooner

than standard sprinklers of the same temperature rating.

Application and Installation

The most common applications for Model F1FR56-300 Se-

ries Quick Response Sprinklers will be in fire protection sys-

tems for high rise buildings where a quick response rating is

required and the pressure entering the sprinkler system is in

excess of 175 psi (12 bar). The use of these sprinklers will

provide opportunity to reduce or eliminate the need for pres-

sure reducing valves.

The Model F1FR56-300/CCP Concealed Sprinkler Assem-

bly uses a ½” (15mm) orifice, ½” NPT (R½), 135°F (57°C),

155°F (68°C), 175°F (79°C), or 200°F (93°C) rated Model

F1FR56-300 Pendent Sprinkler with a threaded Model CCP

cup, which is factory attached to the sprinkler. The assem-

bly is completed by the installation of an attractive, low pro-

file, 135°F (57°C) or 165°F (74°C) rated Model CCP push

on cover plate assembly. The cover plate and sprinkler cup

assemblies are joined using a cover plate with flexible tabs

for threaded engagement. A choice of two cover plate as-

semblies provide either ½” (13mm) or 5/16” (8mm) of cover

adjustment.

Do not install these sprinklers in ceiling which have positive

pressure in the space above.

After a 25/8” (67mm) diameter hole is cut in the ceiling, the

sprinkler is easily installed with the Model GFR2 Wrench.

A PTFE thread sealant should be applied to the sprinkler

threads only. The Model GFR2 Wrench is then used to en-

gage the sprinkler wrenching surfaces and to install the

sprinkler in the fitting. When inserting or removing the wrench

from the sprinkler/cup assembly, DO NOT WRENCH ON

ANY OTHER PART OF THE SPRINKLER. The cover plate is

then pushed onto the cup. Final adjustment is made by hand

turning the cover plate until the skirt flange makes full contact

with the ceiling. Cover plate removal requires turning in the

counter clockwise direction.

After installation, inspect all sprinklers to ensure that there is

a gap between the cover plate and ceiling and that the four

cup slots are open and free from any air flow impediment to

the space above.

Concealed cover plate/cup assemblies are listed only for

use on specific sprinklers. The use of any other concealed

cover plate/cup assembly with the Model F1FR56-300 Pen-

dent Sprinkler or the use of the Model CCP concealed cover

plate assembly on any sprinkler with which it is not specifi-

cally listed may prevent good fire protection and will void all

guarantees, warranties, listings and approvals.

Quick response sprinklers are intended for installation as

specified in NFPA 13. Quick response sprinklers and stan-

dard response sprinklers should not be intermixed.

The Model F1FR Series Recessed and Concealed Quick

Response Sprinklers are to be installed as shown.

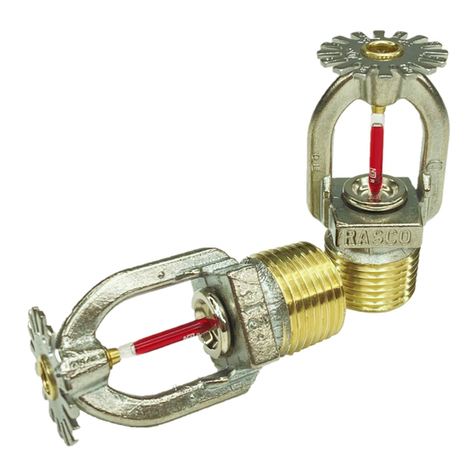

When installing Model F1FR56-300 Upright and Pendent

Sprinklers, use the Model W2 Sprinkler Wrench. Use the

Model GFR2 Wrench for installing F1FR-300 Recessed and

Concealed Pendent Sprinklers. Any other type of wrench

may damage these sprinklers.

Glass bulb sprinklers have orange covers to protect the

bulb during the installation process. REMOVE THIS PRO-

TECTION ONLY AFTER THE SYSTEM HAS BEEN HYDRO-

STATICALLY TESTED AND, WHEN APPLICABLE, THE ES-

CUTCHEONS HAVE BEEN INSTALLED. RASCO wrenches

are designed to install sprinklers when covers are in place.

The Model F1FR56-300 Horizontal Sidewall sprinkler is in-

tended for installation in light & ordinary hazard occupancies

in accordance with NFPA 13. This sprinkler is especially well-

suited for use in student dormitories, hotels, hospitals and

care facilities, and can be used where the pressure entering

the sprinkler system calls for 300 psi (20,7 bar) applications.

Models F1FR56-300 Horizontal Sidewall recessed and

SWC56 concealed sprinklers utilize a threaded cup which

is factory attached to the sprinkler. The assembly is com-

pleted by the installation of the attractive push-on/thread-off

escutcheon and135°F (57°C) rated push-on/thread-off cover,

respectively. When the F1FR56-300 Horizontal Sidewall is or-

dered with the F2 escutcheon the escutcheon assembly is

shipped separately and requires assembly of the collar at the

time of installation (Ref. Figure 5).

Apply a PTFE thread sealant to the sprinkler threads. After

a 25/8” (67mm) diameter hole is cut in the wall, the sprinkler

is easily installed with the Model GFR2 Wrench. To install

the sprinkler, remove the protective cap and then position the

wrench into the sprinkler/cup assembly until the wrench fully

engages the flats of the sprinkler. Then tighten the sprinkler

into the pipe fitting. When inserting or removing the wrench

from the sprinkler/cup assembly, care should be taken to pre-

vent damage to the sprinkler. DO NOT WRENCH ON ANY

OTHER PART OF THE SPRINKLER.