Reliable JL-14 Manual

Other Reliable Irrigation System manuals

Reliable

Reliable JL-17 User manual

Reliable

Reliable DH56 HSW-PL Manual

Reliable

Reliable F156 Series Manual

Reliable

Reliable GFR User manual

Reliable

Reliable F1FR56 Manual

Reliable

Reliable F1-300 User manual

Reliable

Reliable F156 EC Series User manual

Reliable

Reliable F1FR-300 User manual

Reliable

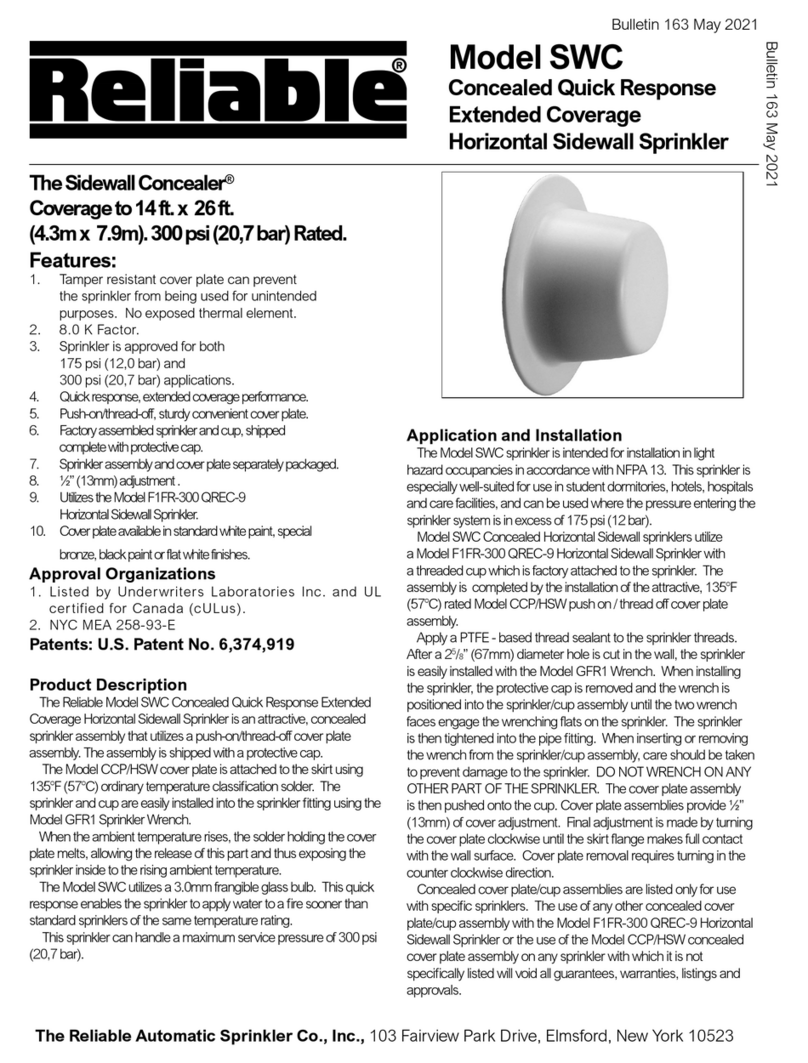

Reliable SWC Manual

Reliable

Reliable XL User manual

Reliable

Reliable G5 Series User manual

Reliable

Reliable F1FR56-300 QREC Series User manual

Reliable

Reliable F1FR-SS Series User manual

Reliable

Reliable DDX PrePaK Maintenance manual

Reliable

Reliable DD56-6 Manual

Reliable

Reliable G5-56 Manual

Reliable

Reliable G6-80 Manual

Reliable

Reliable Sidewall Concealer SWC User manual

Reliable

Reliable F3QR56 User manual

Reliable

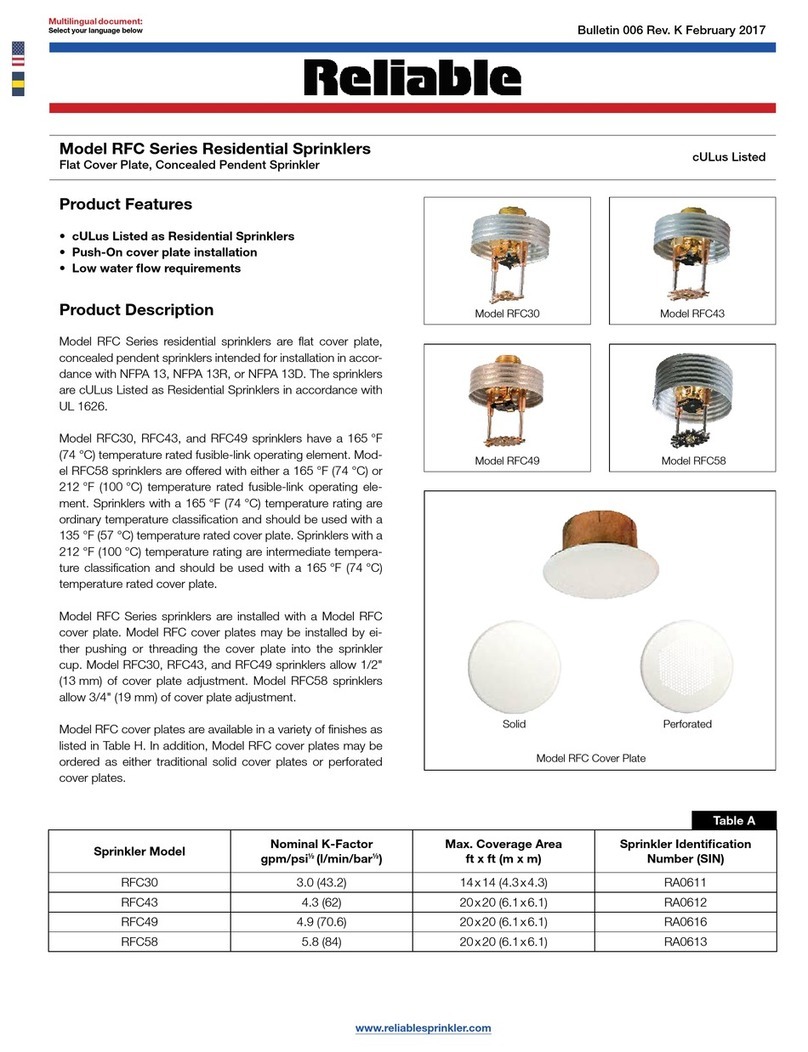

Reliable RFC Series Manual

Popular Irrigation System manuals by other brands

Hunter

Hunter Institutional Series instructions

Cellfast

Cellfast 52-305 user manual

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL A instruction manual

Oral Care Technologies

Oral Care Technologies Hydro Floss Instructions for use

Tyco Fire Product

Tyco Fire Product Gem F892 instruction manual

Toro

Toro 730 Series Installation and service instructions

Eden

Eden 97063-EDAMZ quick start guide

Tyco

Tyco TY-L Series quick start guide

Tyco Fire Product

Tyco Fire Product CENTRAL ELO-231 instruction manual

Johnson Controls

Johnson Controls tyco ESFR-17 manual

Victaulic

Victaulic VicFlex I-VICFLEX.AQC-U installation instructions