3

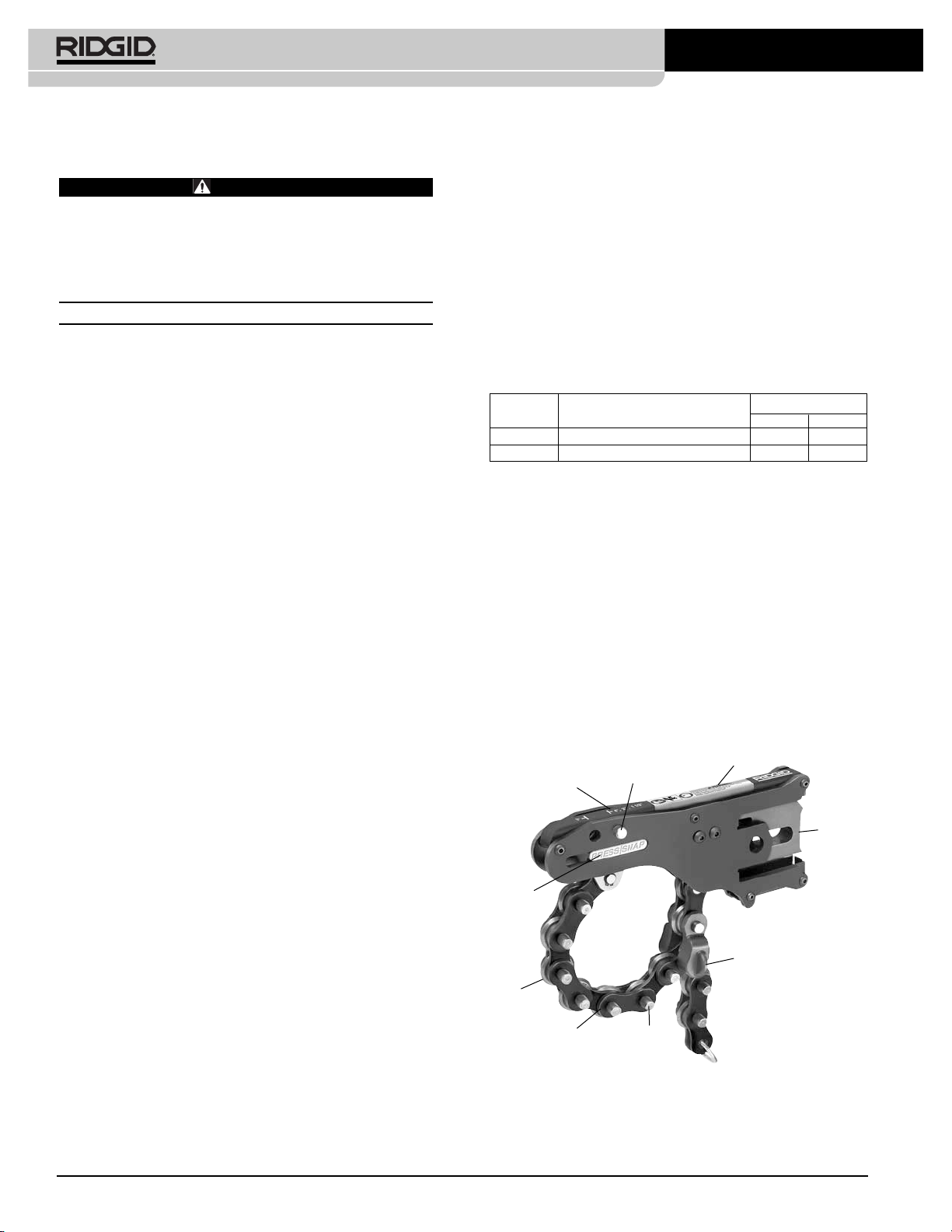

Press Snap™ Soil Pipe Cutter

Keep others out of work area while cutting. Stand

clear of the pipe. Cutting can cause pieces of pipe

to be thrown with considerable force. This can

cause striking injuries, eye injuries, or other serious

personal injury.

Always wear eye protection to protect your eyes

against dirt and other foreign objects.

Keep your fingers and hands away from the Press

Snap cutter during the cutting cycle. They can be

crushed, fractured or amputated if they become

caught between the pipe and cutter or other

objects.

1. Check work area for adequate lighting and a clear,

dry, level, stable place to work.

2. Inspect the pipe to be cut. Determine the size and

type of material. If cutting pipe that is already in ser-

vice, determine the pipe contents.

3. Determine the correct pipe cutter for the applica-

tion. The RIDGID Press Snap Soil Pipe Cutter is

designed to cut most 1.5" to 4" No-hub and service

weight cast iron soil pipe.

4. Make sure that the Press Snap cutter has been prop-

erly inspected.

5. Prepare the pipe to be cut.

• Take any appropriate steps required to drain the

pipe and/or deal with any potential spillage.

• Clean mud, corrosion or other coatings off of the

pipe at the point to be cut. Excessive corrosion, mud

or coatings can cause poor quality cuts and damage

cutter wheels.

• Make sure there is enough room to get the chain

around the pipe. Approximately 11/2" of space is

required around the pipe for the chain to fit. If cutting

loose pipe, to protect the cutter wheels from dam-

age against concrete or other hard surfaces, place

the pipe on short stands or wood blocks to get the

pipe off the floor or work on a softer surface like a

piece of plywood.

• When cutting short sections, restrain the pipe to pre-

vent it from being thrown when cut. This can be

done by placing a smaller piece of pipe or lumber

through the center of the pipe, or by other methods.

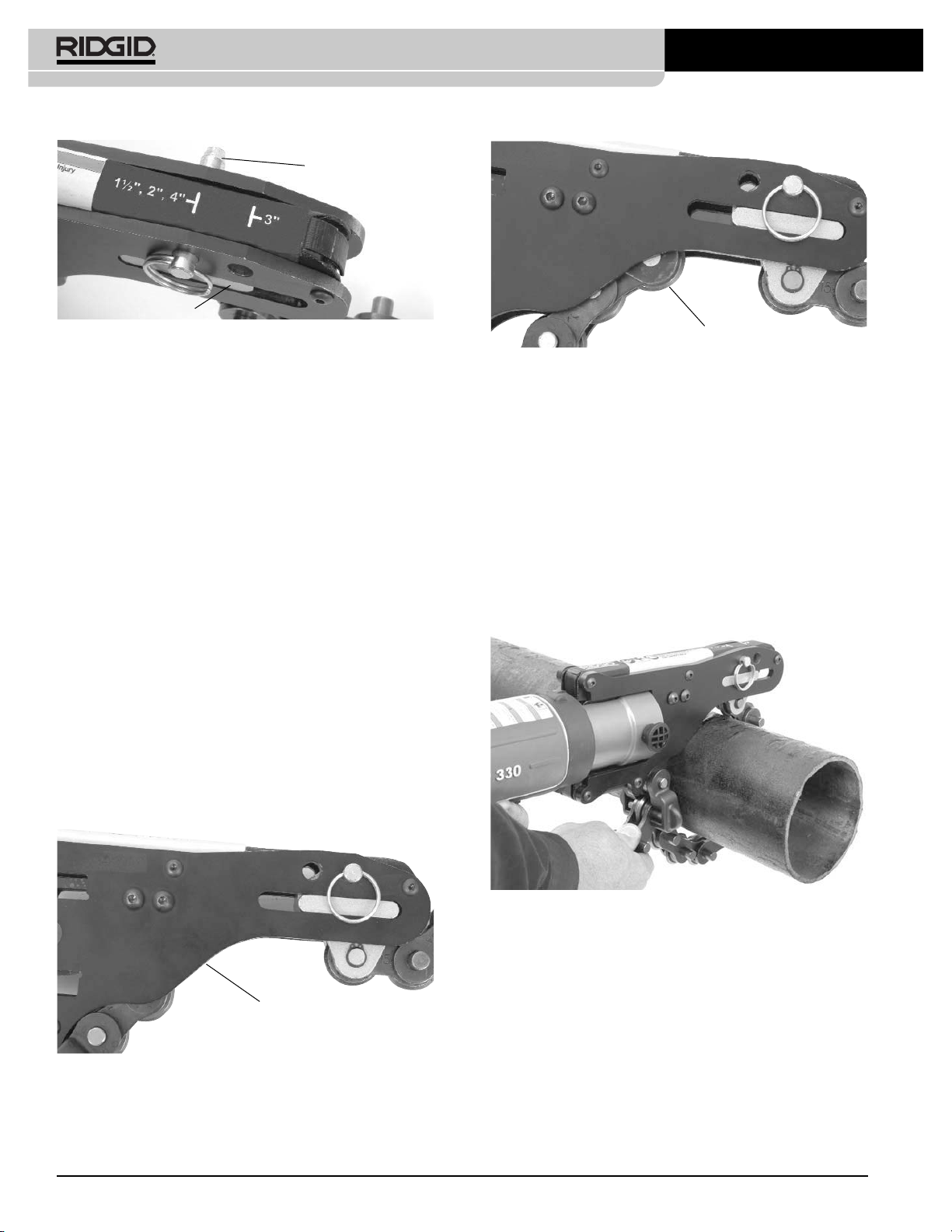

6. Adjust the Press Snap cutter for the size of soil pipe to

be cut. The size adjustment has two positions

.

The

position closest to the press tool is used for 1.5", 2"

and 4", while the position away from the press tool is

for 3". To adjust, pull the pin out and move the adjust-

ment block to the other position. Fully insert the pin.

(See Figure 2).

Pre-Operation

Inspection/Maintenance

WARNING

Before each use, inspect and maintain your Press

Snap Soil Pipe Cutter and correct any problems to

reduce the risk of serious injury from striking or

impact injuries and other causes and to prevent tool

damage.

1. Remove the Press Snap cutter from the press tool.

2. Clean the soil pipe cutter and remove all dirt, oil,

grease and debris. If needed, the chain can be

cleaned with a wire brush. This aids in inspection

and helps prevent the tool from slipping during use.

3. Inspect the soil pipe cutter for the following items:

• Proper assembly and completeness

• Broken, cracked, missing, bent or binding parts

• Excessive corrosion and wear

• Smooth, free movement of ram, chain, hooks and

linkages

• Presence and readability of warning labels

(See

Figure 1).

4. Inspect the chain for signs of overload or other dam-

age. There should be no significant gaps between

the plates of the chain. If there are large gaps between

the links of the chain or other damage, the chain

should be replaced. Check the cutter wheels for wear

and damage. Worn and damaged cutter wheels

increase cut force and can cause poor quality cuts.

5. Inspect the press tool and any other equipment being

used as directed in their instructions.

6. If any problems are found, do not use the soil pipe

cutter until corrected.

7. If needed, lubricate pivot points and the chain with a

light lubricating oil. Wipe any excess oil off.

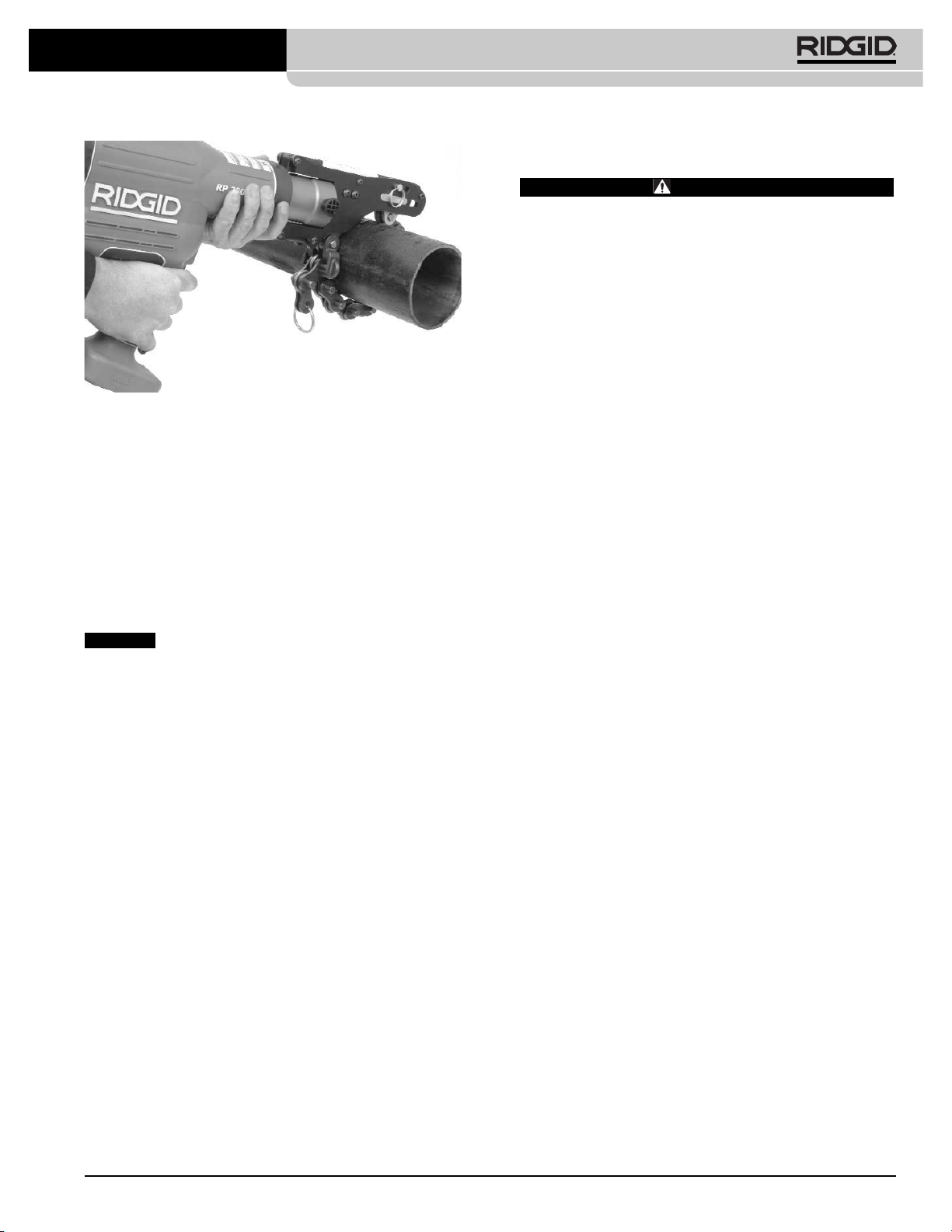

Tool Set Up and Operation

WARNING

Follow set up and operating instructions to reduce

the risk of serious injury from striking or impact

injuries and other causes and to prevent machine

damage.