Inspection/Maintenance

Inspect the Punch Head before each use for issues that could affect safe

use.

1. With the battery removed from the tool, depress the QCS sleeve

and remove the head.

2. Clean the head and remove all dirt, oil, grease, and debris to aid in

inspection and improve control. Pay close attention to the QCS cou-

pling to ensure there is no debris to damage the coupling. Ensure

that the threaded hole is free of debris.

3. Inspect the head for:

• Proper assembly and completeness.

• Wear, corrosion or other damage. Dim-

ples in the grooves of the QCS coupling

are normal with use and are not consid-

ered damage.

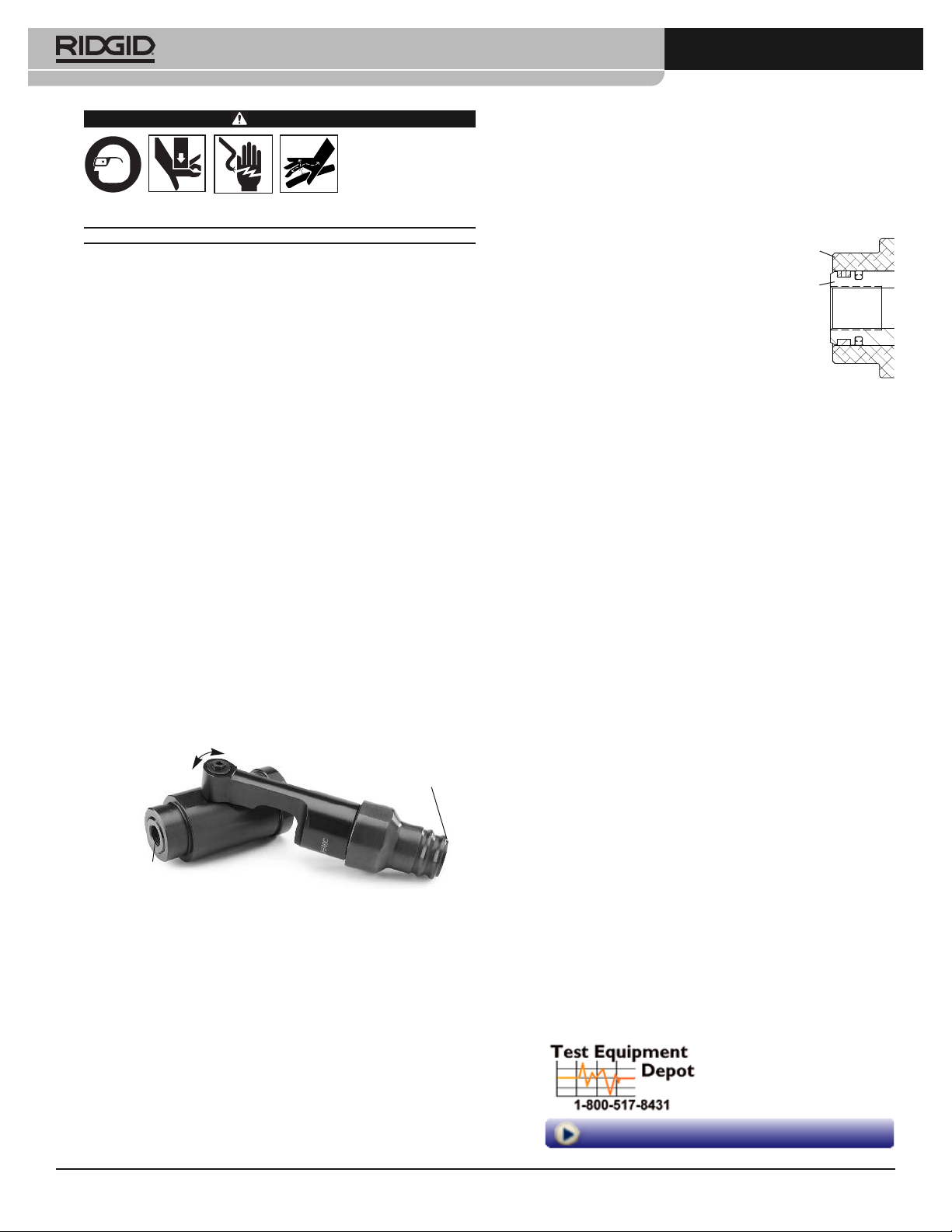

•Oil Leaks. If the draw stud piston ex-

tends past the tool face (Figure 2), the

oil is low. Have the punch head serviced

– do not attempt to add oil.

• Presence and readability of head mark-

ings.

If any issues are found, do not use head until corrected.

4. Inspect the electrical tool and any other equipment being used as

directed in their instructions. Make sure other knockout components

are in good working condition.

5. The QCS coupling is lubricated for life at the factory and does not

require any further lubrication. Do not disassemble the Punch Head.

Unit contains compressed spring.

WARNING

Read and understand

these instructions, the

electrical tool instruc-

tions, and the warn-

ings and instruc tions

for all equipment and material being used before operating this tool

to reduce the ris of serious personal injury.

SAVE THESE INSTRUCTIONS!

•Keep your fingers and hands away from the punch head during

the punch cycle. Your fingers or hands can be crushed, fractured or

amputated if they are caught between the punch dies or the compo-

nents and any other object.

•This head is not insulated for use on or near energized conduc-

tors. Use of this head on or near energized conductors may lead to

electrical shock, causing severe injury or death.

•Large forces are generated during product use that can break or

throw parts and cause injury. Stand clear during use and wear ap-

propriate protective equipment, including eye protection.

•Do not handle punch head while punching. The punch head con-

tains high pressure oil during punching. High pressure oil escaping

from punch head can penetrate the skin and cause serious injury. If oil

is injected under the skin, seek immediate medical attention.

•Never repair a damaged head. A head that has been welded,

ground, drilled or modified in any manner can break during use. Only

replace components as indicated in these instructions. Discard dam-

aged heads to reduce the risk of injury.

•Only use a PH-60C Swiv-L-Punch™ Head with a RIDGID®RE 6 or

RE 60 Electrical Tool. Use of other tools with this head may damage

the head, tool, draw stud, punch dies, or result in serious injury.

If you have any questions concerning this RIDGID®product:

• Contact your local RIDGID distributor.

• Visit www.RIDGID.com to find your local RIDGID contact point.

• Contact Ridge Tool Technical Service Department at rtctechservic -

es@emerson.com, or in the U.S. and Canada call (800) 519-3456.

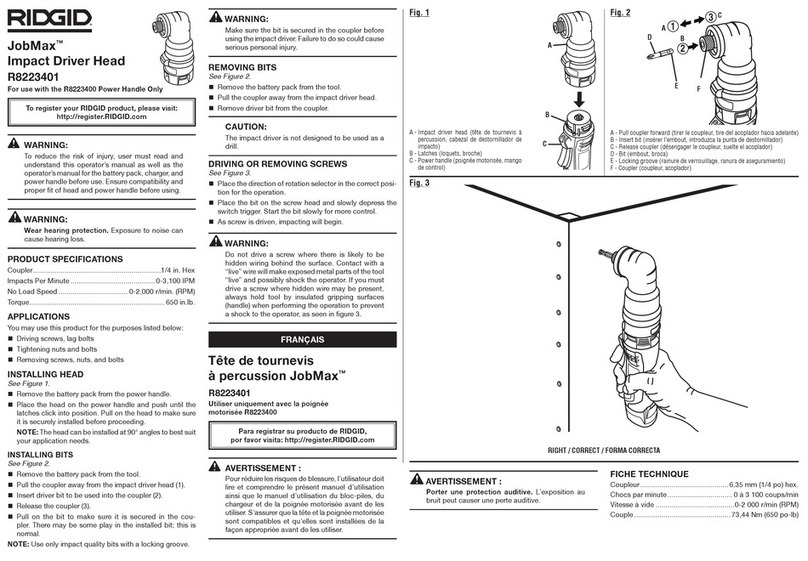

Description

The RIDGID®Swiv-L-Punch™ Head is designed for use with punches

and dies (such as knockout punches) to punch holes through sheet ma-

terials such as mild or stainless steel.

The Punch Head attaches to the RIDGID RE 6 or RE 60 Electrical Tool

equipped with the RIDGID QuickChange System™ Coupling (QCS™)

and includes 360 degrees of articulation. Combined, these allow for bet-

ter access in tight areas.

Figure 1 – PH-60C Swiv-L-Punch Head

Specification

Material Thickness .............Mild Steel – Up to 10 gauge

(0.134", 3.4 mm)

Stainless Steel – Up to 12 gauge

(0.109", 2.8 mm)

Max. Punch Diameter...........Up to 5" (120 mm) in 12 gauge mild steel

and 14 gauge stainless steel

Up to 2" (50,8 mm) in 10 gauge mild steel

and 14 gauge stainless steel

Draw Stud Thread ................3/4" – 16 U F

Compatible QCS Types......6T QCS

60k QCS

Maximum Output Force......14,600 lbf (64 k )

Weight.................................4.4 lb (2.0 kg)

Punching capacity depends on a variety of factors including punch

size/configuration, material thickness, type, and hardness. Holes may not

be able to be completed in all cases based on these and other variables.

PH-60C Swiv-L-Punch™ Head Instructions

QCS Coupling

¾" – 16 NF Thread For

Draw Stud

Printed 11/15

999-999-526.10

EC41390 REV. A

360° Articulation

Tool Face

Draw Stud

Piston

Figure 2 – Punch Head

Oil Low

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com