WIRELESS GLASS

BREAK

DETECTOR

«STEKLO-3RK»

1 Introduction

1.1 The wireless glass break detector «Steklo-3RK» (hereinafter, the Detector)

is intended for detecting destruction of all known kinds of construction glass:

common, quenched, patterned, armored, multilayer and laminated with polymer

film, glass units, as well as hollow glass blocks installed in structural units

(openings) and/or interior elements of closed spaces.

1.2 The Detector transmits status messages via two-way communication in

the 433.05 to 434.79 MHz frequency range to the control panel (hereinafter, CP)

supporting the «Rielta-Contact-R» wireless communication protocol:

- «Norm» – under the absence of any impact on the protected glass,

- «Alarm» – in case of impact on the protected glass detection,

- «Tamper» - in course of case or wall tampering,

- «Main battery discharge» – if main power supply battery voltage drops lower

than 2,5-0,2 V,

- «Backup battery discharge» – if backup power supply battery voltage drops

lower than 2,5-0,2 V.

1.3 The Detector provides case and wall tamper protection.

1.4 The Detector may be installed on the wall, ceiling or on a pier between the

monitored glass and curtains.

1.5 The Detector ensures remote monitoring of controlled glazed structures

of any shape.

1.6 The Detector provides multilevel microprocessor signal processing and

functional self-test.

1.7 The Detector adjusts the sensitivity depending on the interference situation

at the monitored facility.

1.8 The Detector operates at one of 8 possible operating frequency numbers.

Each number contains two operating frequencies: the main and the reserve one.

1.9 The Detector automatically switches over backup frequency in case of

impairment of interference conditions at the main operating frequency.

1.10 The Detector is able to switch on and off an identification and status LED

indication by the CP relevant command.

1.11 The Detector the following rates of control radio exchange may be

assigned: 10 s,15 s, 30 s, 60 s ,300 s, or 600 s during binding procedure with

CP. Alarm messages are transmitted immediately.

1.12 The Detector is powered by two batteries, the main – CR123A and the

backup one – CR2450.

1.13 The Detector refers to single-zone (single-address) detector type.

2 Field of Application

The Detector can be applied in offices, shops, museums, exhibition halls,

banks, accommodation rooms, etc.

3 Specifications

Table 1

Parameter Value

Maximum detection range 6 m

Angle of coverage 120о

Installation height at least 2 m (see Figures 3 – 7)

Operating temperatures range

from minus 20 to +55

°С

Relative air humidity at 25 °С

up to 98 %

Broadcast period (programmed during the

CB binding) 10 sec to 10 min

Probability value of glass destruction at least 0.9

Warm-up time, not more than 30 s

Sensitivity value ( at a signal duration 20 ms

or more):

- on first operating frequency

- on second operating frequency

(80 ± 3) dB

(90 ± 3) dB

Weight (without power batteries) maximum 0.1 kg

Dimensions

maximum 105 x 50 x 40 mm

Battery life (under normal conditions, and messa-

ges transmitting period not less than 60 sec)

up to 5 years

IP rating IP30

Mean time-to-failure, not less than 60 000 h

Average service life, not less than 8 years

4 Scope of Delivery

Each Detector unit package contains the items listed in Table 2.

Table 2

Name Qty

Wireless glass break detector «Steklo-3RK»

Wall plug 5x25

Screw 3-3x30.016

CR123A lithium power-supply battery

CR2450 lithium power-supply battery

Wireless glass break detector «Steklo-3RK». Installation Guide

1 pc.

2 pcs.

2 pcs.

1 pc.*

1 pc.*

1 copy

* - Supplied optionally

Installation Guide

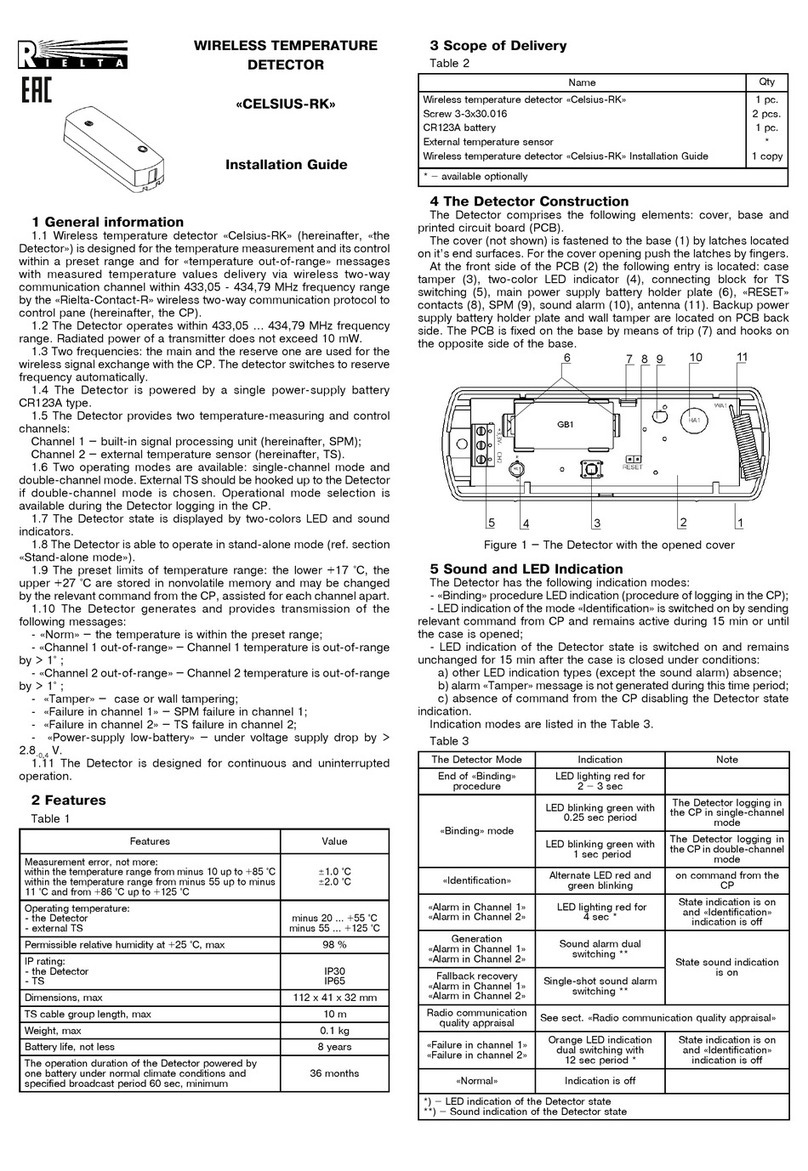

5 Binding with the CP

The binding procedure is intended for the logging of the Detector in the CP

and exchange of service information.

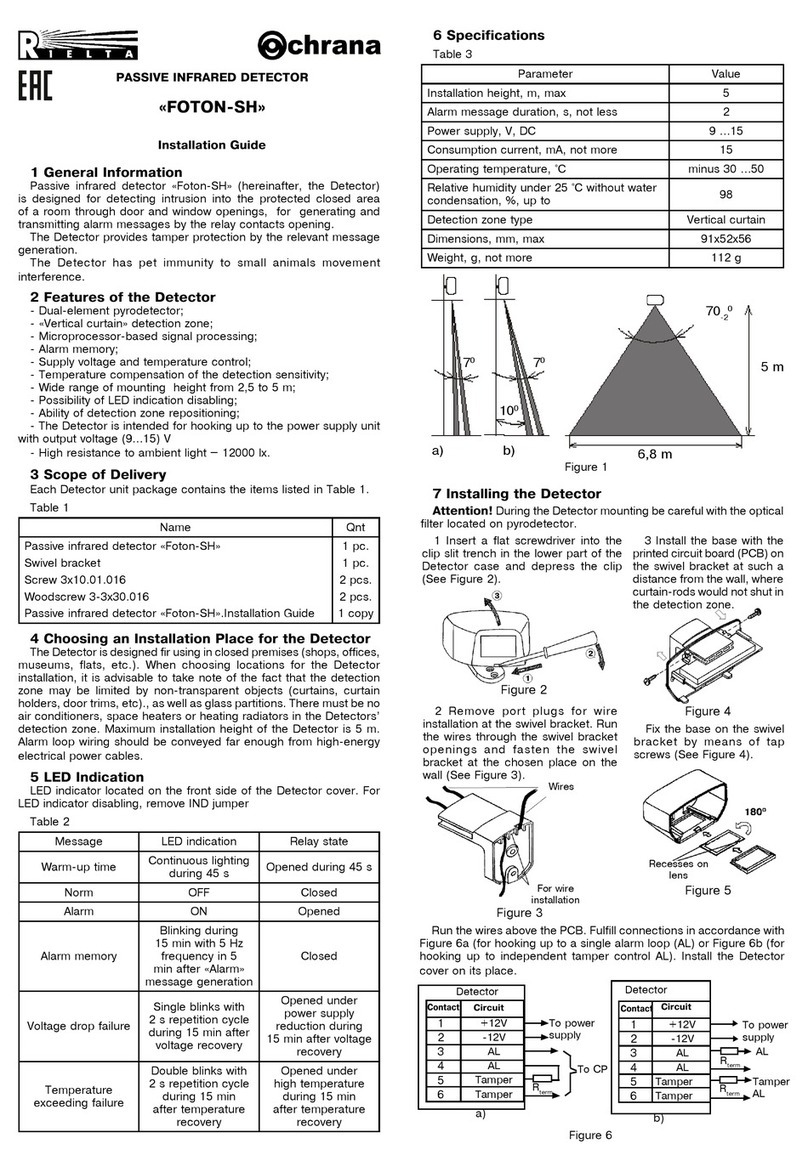

1. Observing the polarity install the СR2450 backup power supply battery into

the holder located on the reverse side of the Detector PCB, thereafter install

the СR123А main power supply battery. If batteries are already installed, then

remove the isolators.

2. LED indicator blinking green displays the Detector readiness to the binding

procedure. In case of the LED indication absence, the Detector should be trans-

ferred to the «Binding» mode by closing the «RESET» contacts until the green

LED indicator starts blinking.

3. In case of successful binding with the CP (repeater), the LED indicator

blinks red for 1 s.

Note – The zone number is determined in accordance to the CP user manual.

The binding procedure is limited up to 70 sec, whereupon the Detector transfers

to the sleep mode. To restart the «Binding» mode close «RESET» contacts for

a short time.

6 LED Indication

Table 3

Detector Status

Indication Note

«Norm» LED indication is OFF

«Binding» mode LED indicator blinking green peri-

odically

The Detector logging

in the CP

«Alarm»

LED indicator single time blinking red

«Tamper» see section «Communication Quality Appraising»

«Identification» LED indicators alternate blinking red

and green

Upon the relevant

command from the CP

«Adjustment»

LED indicator blinking green every 1 s

Upon the DIP-switch

3 is ON

«Interference» the LED indicator lights up green During the interference

time

Norm LED indication is OFF

Communication

quality see section «Communication Quality Appraising»

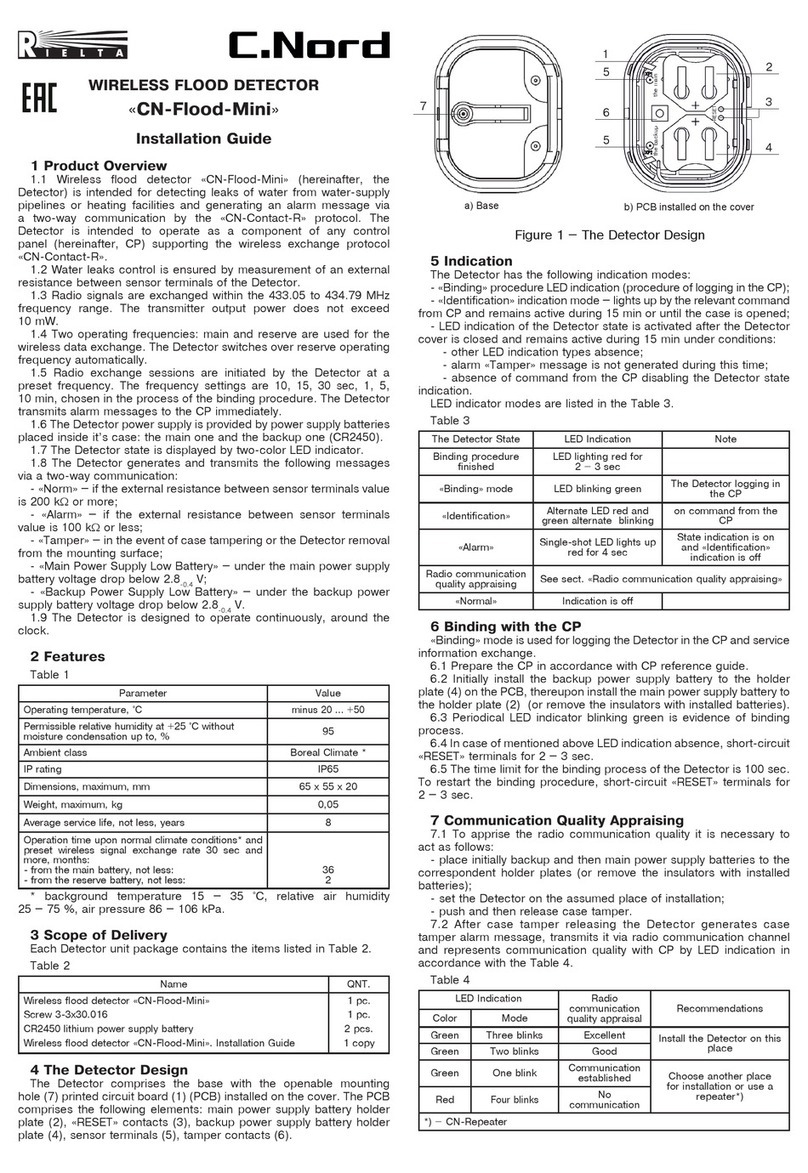

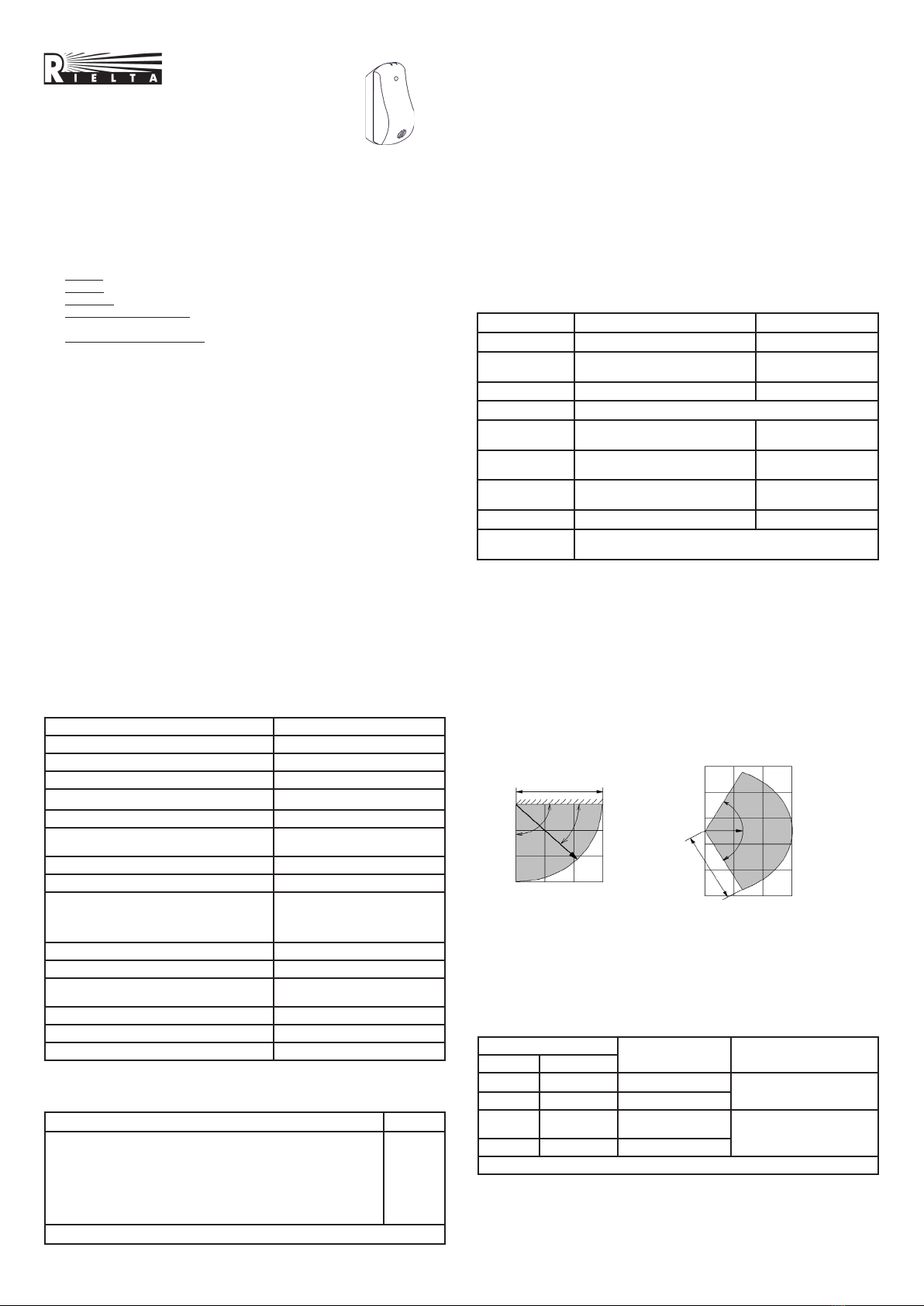

7 Choosing the Detector Location

Before installing the Detector, get acquainted with the following requirements:

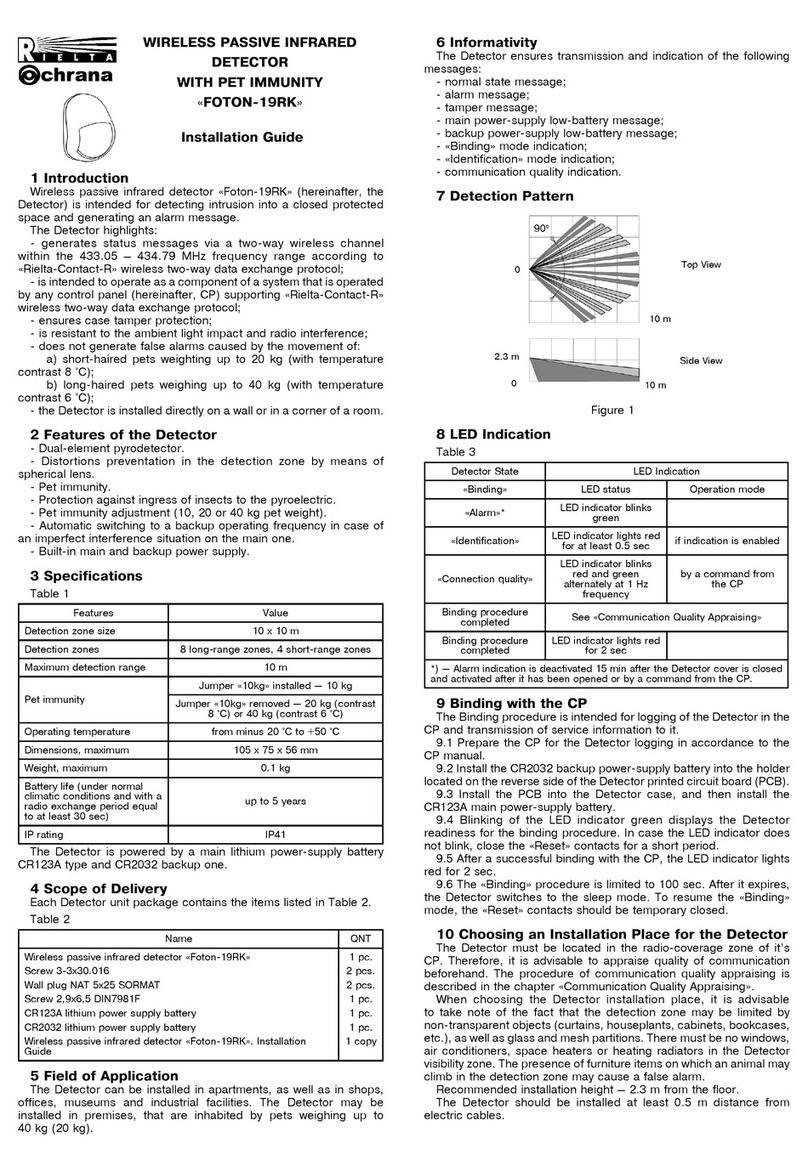

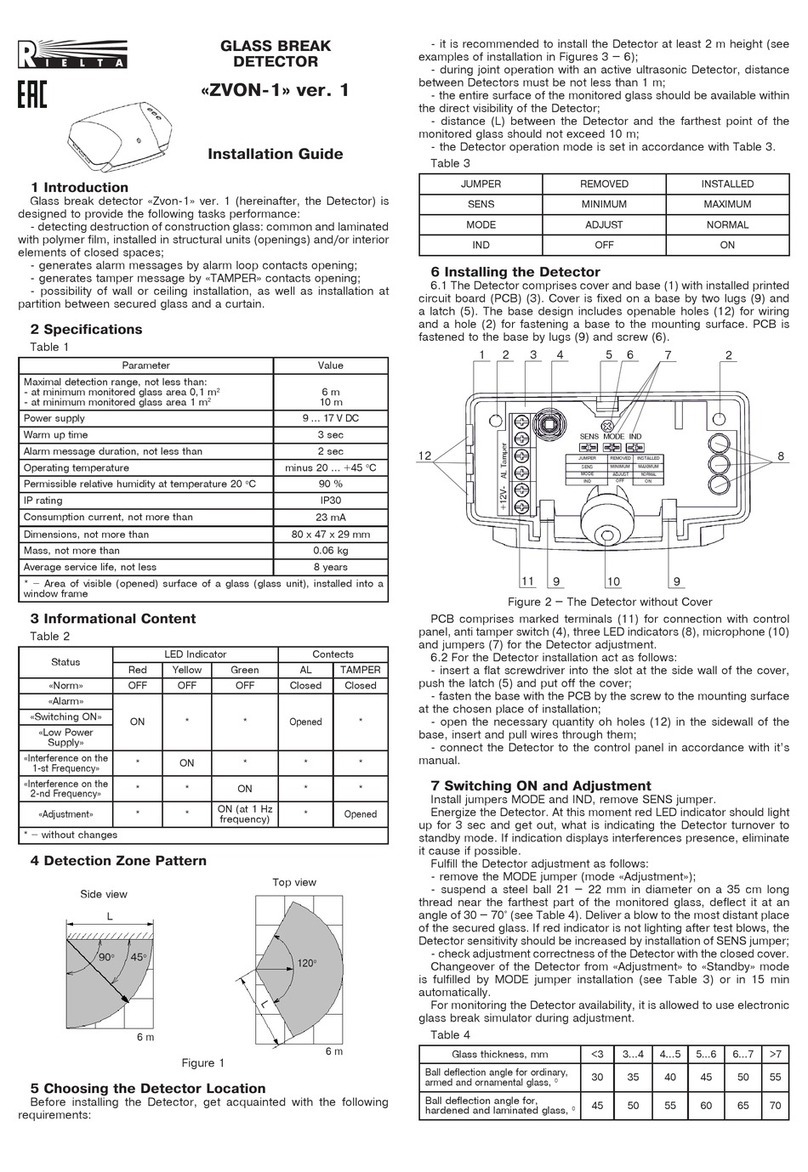

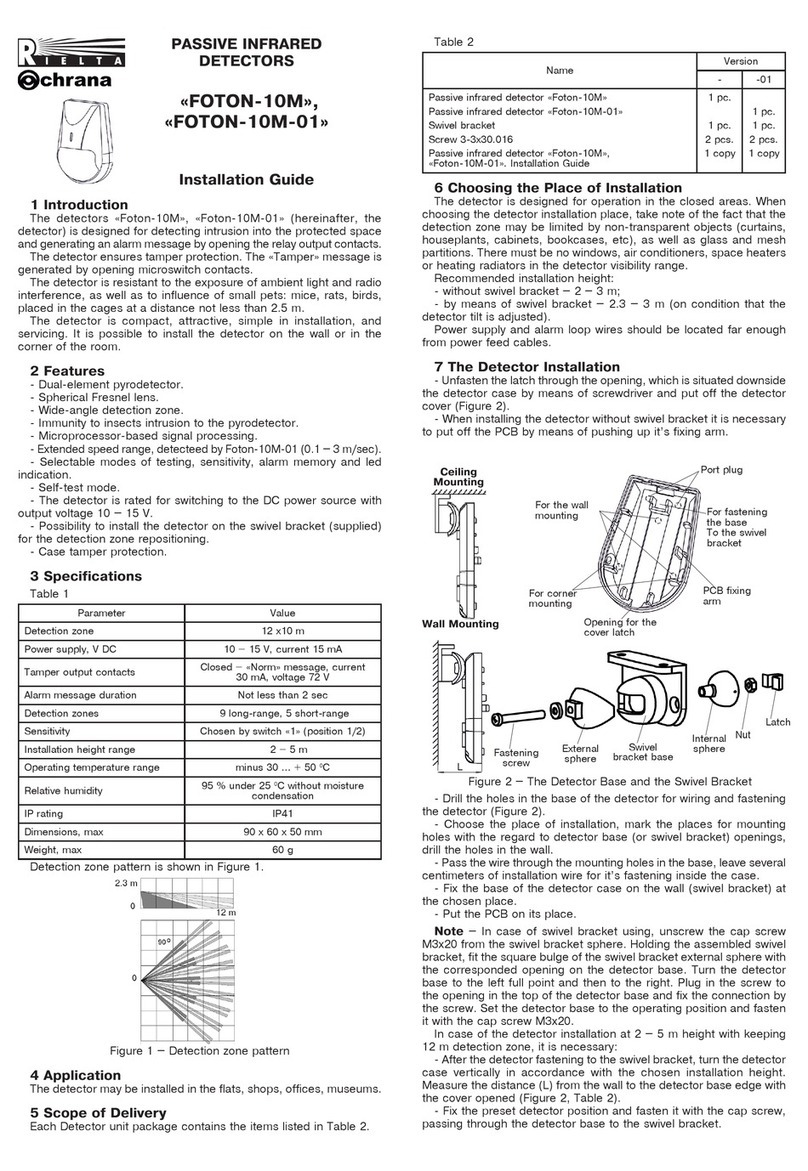

- it is recommended to install the Detector at least 2 m height (see examples

of installation in Figures 3 – 7);

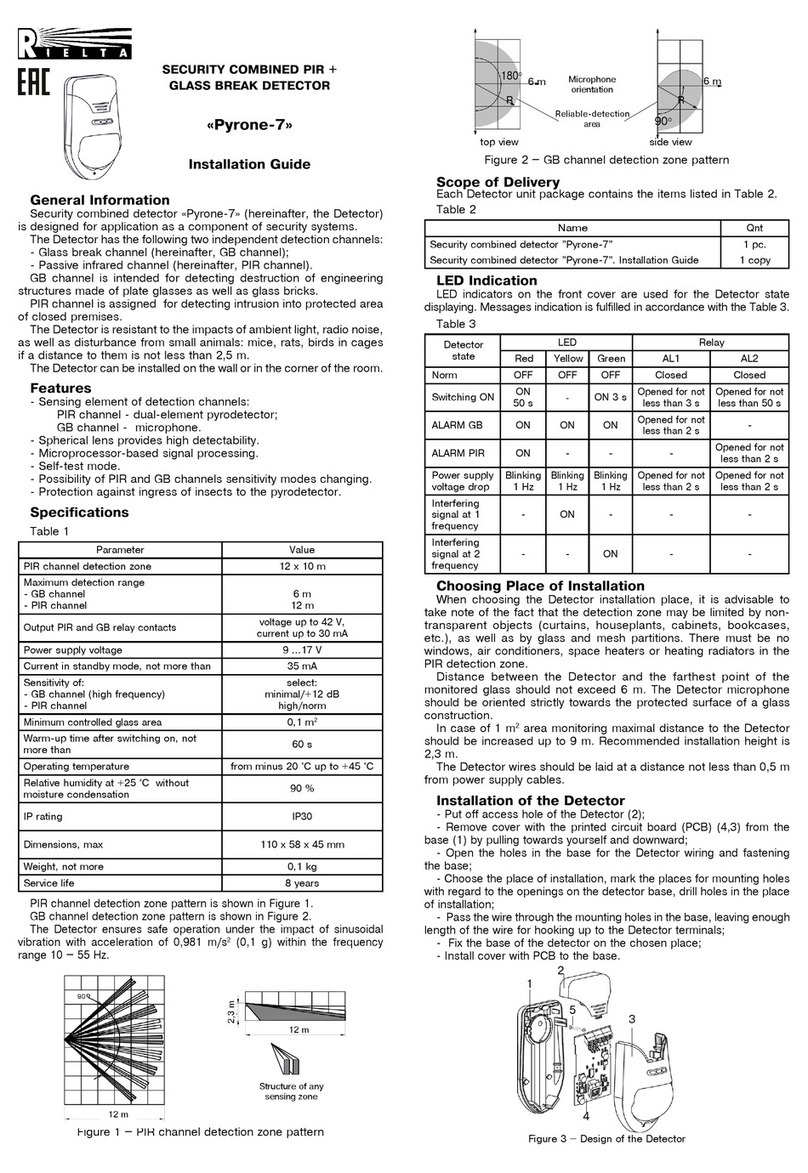

- when choosing the place of installation, the Detector detection zone location

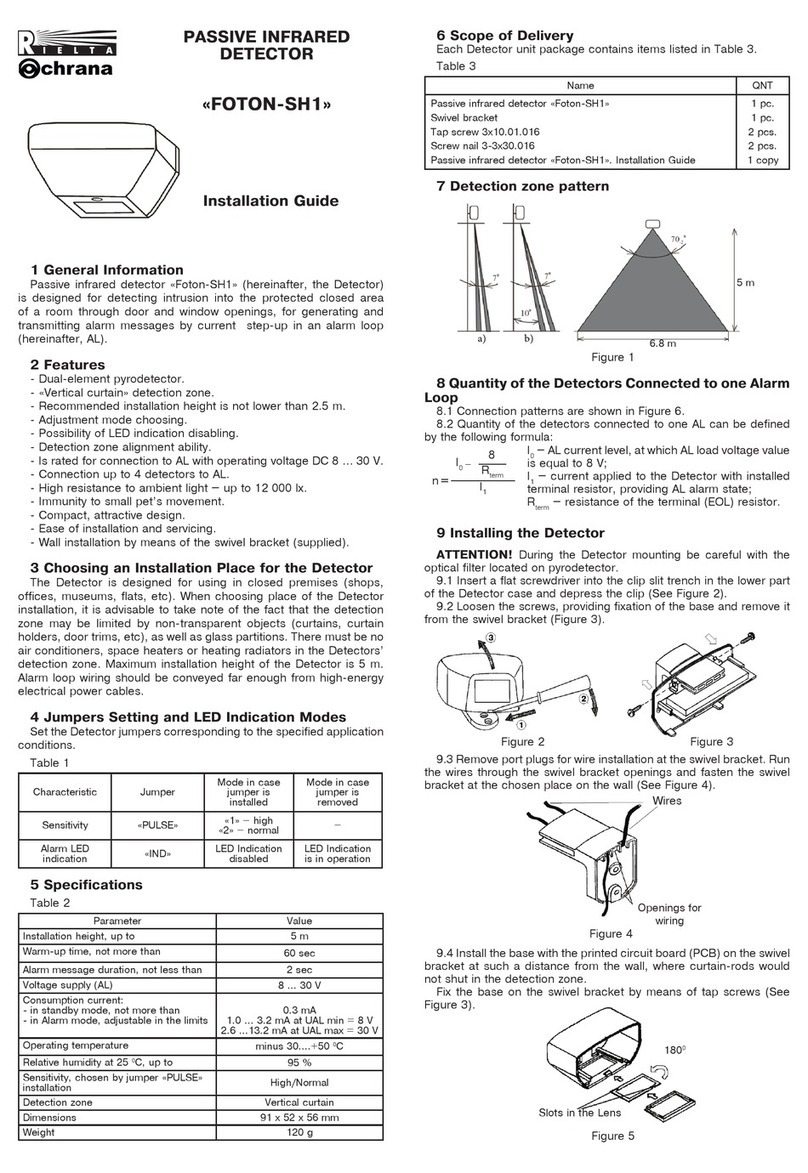

must be taken into account (Figure 1);

- distance (L) between the Detector and the farthest point of the monitored

glass should not exceed 6 m;

- during joint operation with an active ultrasonic Detector, distance between

Detectors must be not less than 1 m;

- the entire surface of the monitored glass should be available within the direct

visibility of the Detector.

The Detector must be located within the radio visibility zone of its repeater;

therefore, it is recommended to estimate the quality of communication with the

CP (repeater). Top View

Side View

L

45о

120

о

Figure 1 – Detection Pattern

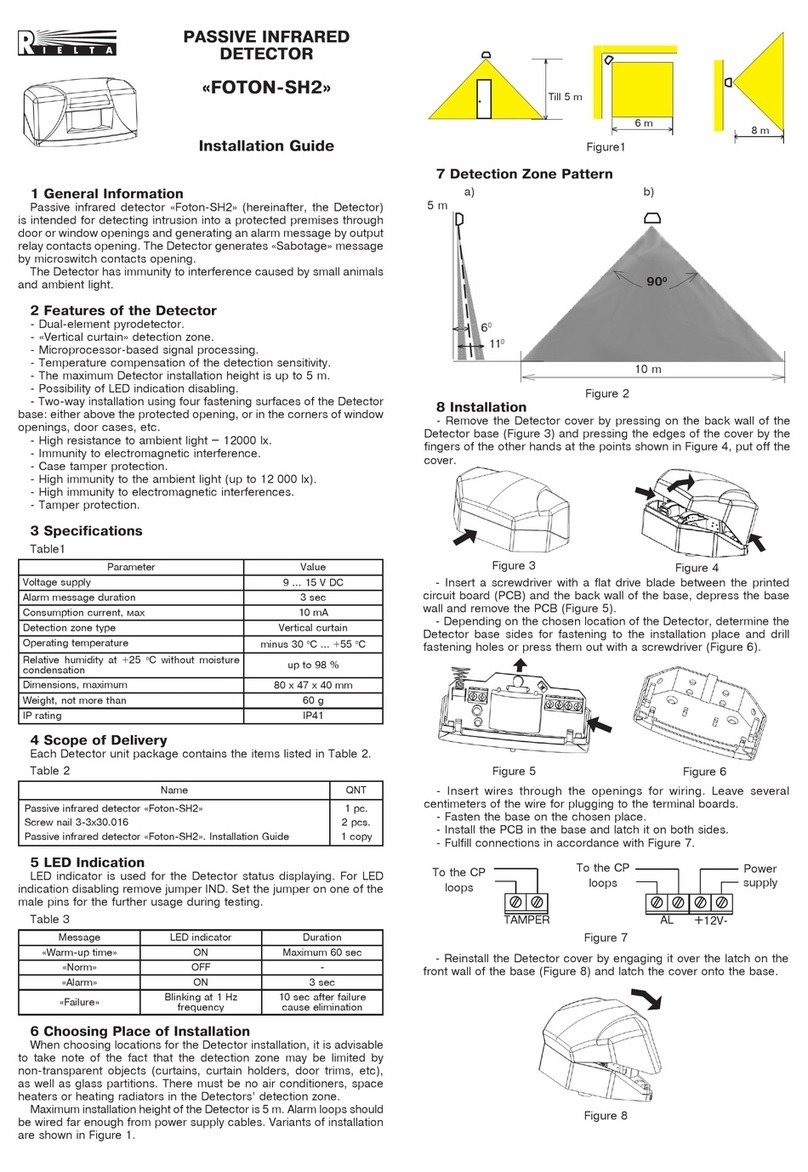

8 Communication Quality Appraising

To estimate the communication quality:

1 Place the Detector on its installation place;

2 Press the Detector tightly to a hard surface in order to close the tamper output;

3 Remove the Detector cover. Whereupon the Detector transmits a tamper

message (the LED indicator lights red) and then the LED indicator displays com-

munication quality with the CP by a three-grade scale (see Table 4).

Table 4

LED Indication Communication

Quality Appraisal Recommendations

Color Mode

Green Three blinks Excellent

Install the Detector at this

place

Green Two blinks Good

Green One blink Communication

established

Choose another place

for installation or use a

repeater*)

Red Four blinks No communication

*) – «Ladoga-RK» system repeater

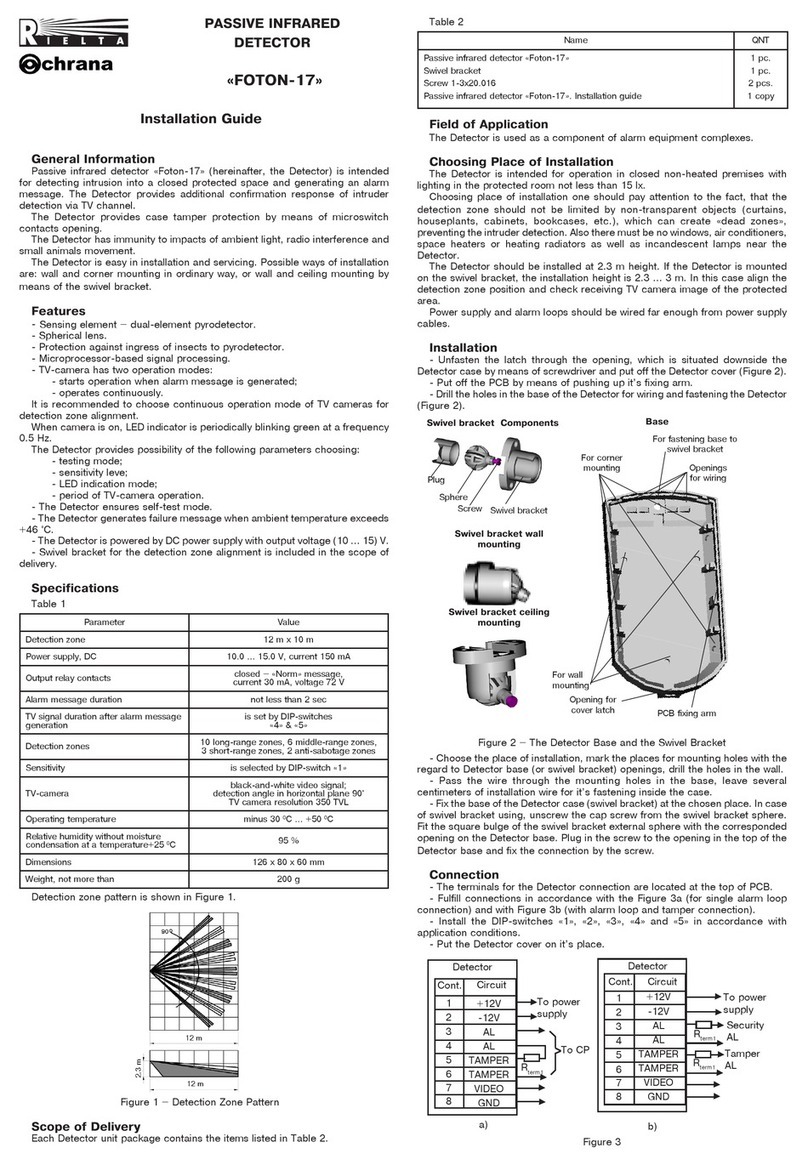

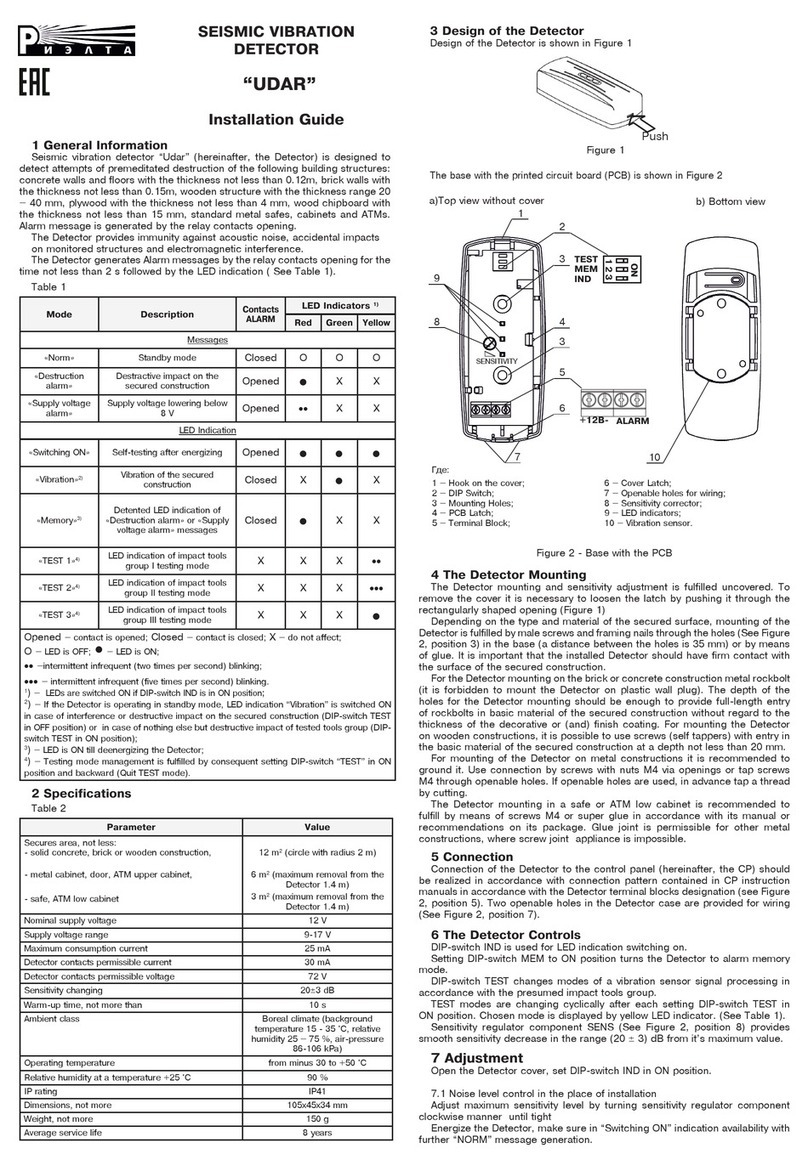

9 Installation of the Detector

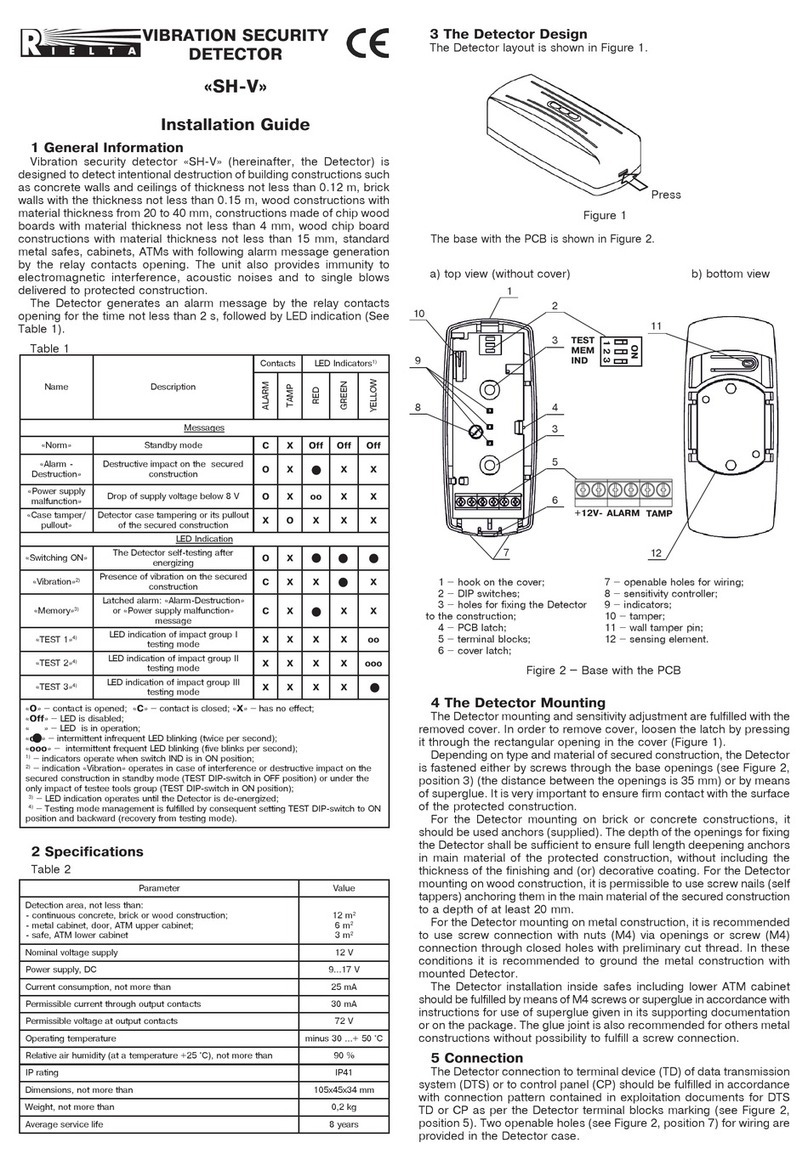

Remove the cover and PCB of the Detector and fasten the Detector with the

help of screws. Choose the place of the Detector installation and mark out its

fastenings using the Detector base (

Figure

2) for the purpose. Fix the base by the

screws (supplied).