2

Contents

1. Outline of the Product..................................................................................................................................... 3

Preface............................................................................................................................................................ 3

Purpose of use................................................................................................................................................ 3

Definition of DANGER, WARNING, CAUTION and NOTE ............................................................................ 4

Method of confirmation for CE marking type .................................................................................................. 4

2. Important Notices on Safety........................................................................................................................... 5

2-1. Danger cases........................................................................................................................................... 5

2-2. Warning cases ......................................................................................................................................... 6

2-3. Precautions.............................................................................................................................................. 6

3. Product Components...................................................................................................................................... 7

3-1. Main unit and standard accessories........................................................................................................ 7

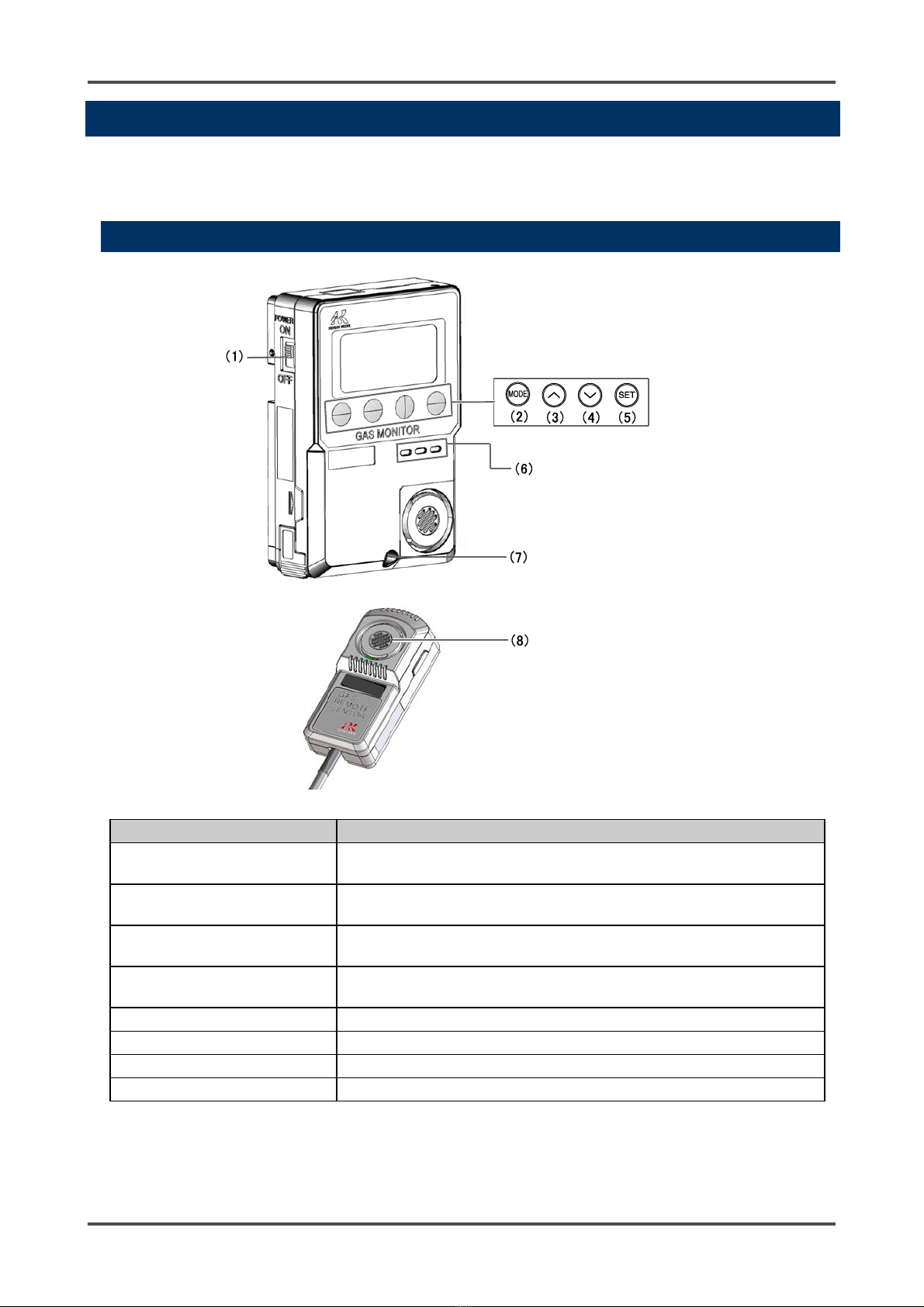

3-2. Names and functions for each part ......................................................................................................... 9

4. How to Install Gas Monitor ........................................................................................................................... 11

4-1. Precautions for installation points ......................................................................................................... 11

4-2. Precautions for system designing .........................................................................................................12

4-3. Installation of monitor ............................................................................................................................14

4-4. Precautions for wiring ............................................................................................................................17

5. How to Use ...................................................................................................................................................20

5-1. Before using the monitor .......................................................................................................................20

5-2. Preparation for start-up ......................................................................................................................... 20

5-3. Basic operating procedures................................................................................................................... 21

5-4. Power-on ...............................................................................................................................................22

5-5. Modes ....................................................................................................................................................23

5-6. User mode .............................................................................................................................................24

5-7. Power-off ...............................................................................................................................................26

6. Alarm Activation and Functions ....................................................................................................................27

6-1. Gas alarm activation.............................................................................................................................. 27

6-2. Fault alarm activation ............................................................................................................................29

7. Maintenance .................................................................................................................................................30

7-1. Maintenance intervals and items...........................................................................................................30

7-2. Maintenance (regular maintenance) mode ........................................................................................... 32

8. Storage and Disposal ...................................................................................................................................45

8-1. Procedures to store the monitor or leave it for a long time...................................................................45

8-2. Procedures to relocate the monitor or use it again ...............................................................................45

8-3. Disposal of products ..............................................................................................................................45

9. Troubleshooting ............................................................................................................................................46

10. Product Specifications................................................................................................................................48

10-1. List of specifications ............................................................................................................................48

10-2. List of accessories ...............................................................................................................................48

10-3. Optional accessories ...........................................................................................................................49

11. Appendix .....................................................................................................................................................50

11-1. Detection principle of semiconductor type ..........................................................................................50

11-2. Definition of terms................................................................................................................................ 51