8

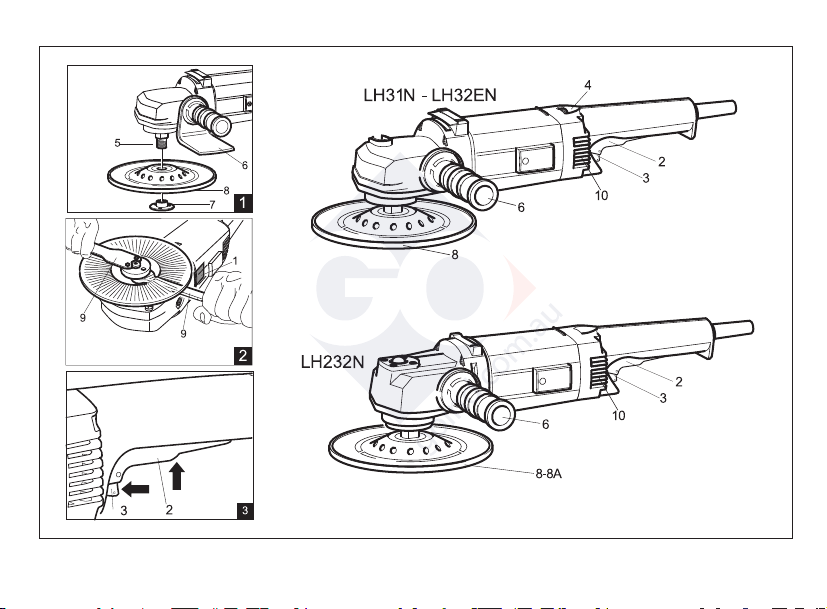

TYPE LH232N LH31N LH32EN

INSULATION CLASS II II II

ABSORBED POWER 1200 W 1200 W 1200 W

ELECTRONIC OVERLOAD PROTECTION NO NO YES

ELECTRONIC SPEED CONTROL NO NO YES

ROTATION RPM 1600÷3400 3400 1400÷3400

MECHANICAL SPEED CONTROL YES* NO NO

ABRASIVE DISC DIAMETER mm 178 178 178

BUFFER DIAMETER MAX mm 200 — —

SPINDLE THREAD M14 M14 M14

WEIGHT Kg 3,7 3,3 3,3

TECHNICAL DATA ENGLISH

GENERAL WARNINGS

The safety and accident prevention instructions are reported in

the “SAFETY INSTRUCTION” booklet which forms an integral part

of these documents. This OPERATING INSTRUCTIONS MANUAL

indicates the additional information required specifically for use

of the tool.

CORRECT USAGE

This tool is designed to be used as a polisher. Read all the

warnings, instructions, indications provided on drawings and

specifications supplied with this tool. Failure to comply with all the

instructions provided below may cause electrical shocks, fires and/or

serious injuries.

This tool is not intended to be used for smoothing, metal

brushing and cutting operations. The use of this tool for unintended

applications may cause hazards and injuries to people.

The tool must be used with accessories that have been

specifically designed or recommended by the manufacturer. The

fixing of the accessory to the tool does not guarantee a safe

operation.

The rated speed of the accessories must be at least equivalent to

the maximum speed specified on the tool. Using the accessories

at speeds above the rated one, may cause them to break or be

projected into the air.

The external diameter and thickness of the accessories must

match the specifications of the tool. Accessories with incorrect

dimensions cannot be adequately protected or controlled.

The configuration of accessories must match the tool. The use of

accessories that cannot be perfectly fitted on the tool may result in

imbalance, excessive vibrations and in the impossibility of controlling

the tool.

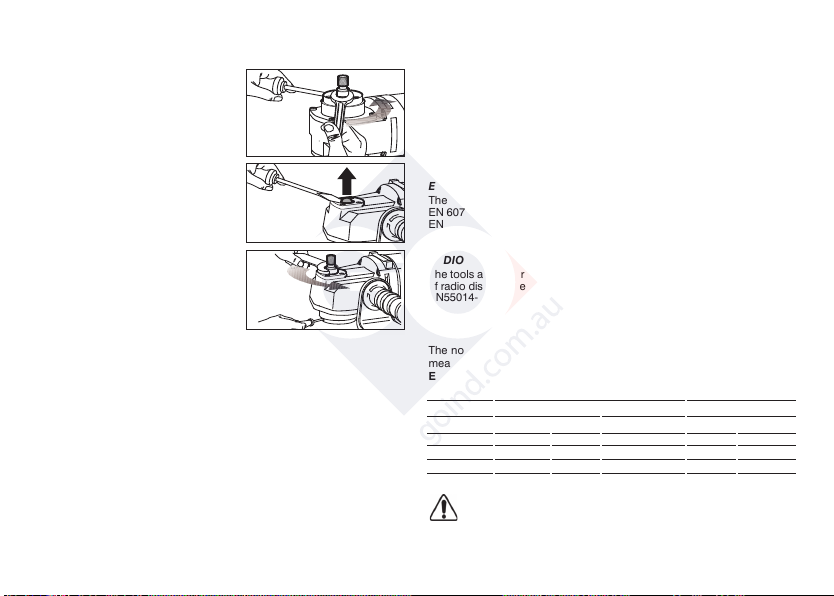

Do not use damaged accessories. Before use, inspect all the

accessories. Inspect the supporting pads and verify there are no

cracks, tears or excessive wear. If the tool or accessory has

fallen, verify that it is not damaged or install a new accessory.

After inspecting or installing an accessory, test the operation of

the tool at maximum speed and without load for one minute,

keeping at a safety distance. If the accessories are damaged, they

will break during this test.

8

The values shown are based on a nominal voltage of 230V/50Hz. In the case of voltages and frequencies of different power values may

vary. Refer to the label technical specifications to the nominal values of the tool.

(*) The tool must be connected to a suitable dust extraction system (not supplied).

according to EPTA-Procedure 01/2003