SATO RWG500 User manual

2

Introduction

Table of Contents

Thank you for your purchase of the SATO Rewinder RWG500.

This manual helps first time users understand the basics of the

RWG500 in a short period of time.

To get the most out of the functions of the RWG500, make sure

to read this manual carefully.

Safety Precautions ·······················3

Main Body and Accessories ··················6

Parts Identification ·······················7

Joint plate setting ························ 9

First Roller Height Setting ··················14

Connection to Printer ····················15

Label Setting

Rewinding Direction ····················18

Rewinding Shaft

Direct Rewinding ····················20

3-Inch Paper-core Rewinding ·············21

Basic Usage of the Rewinder ··············· ·23

6-Inch Expansion Option ··················25

Basic Specifications ·····················28

Quick Guide

Rewinder for SATO Barcode Printer

RWG500

http://www.satoworldwide.com

Thank you for your purchase of the SATO

Rewinder RWG500.

Make sure to read this operation manual and

keep it in a handy place.

DCS & Labeling Worldwide

Marking and Symbols

Symbol example

Safety Precautions

!

!

!

Warning

Caution

In this section, safety precautions about rewinder operation are

explained to ensure proper care and usage.

Make sure to read these carefully before using your rewinder.

The following symbols or markings are used in this quick guide and on

the rewinder so that you can properly use the rewinder, and to prevent

any damage to property, harm or injury to yourself and others.

Make sure to read their explanations carefully to familiarize yourself

with their meanings.

This symbol indicates information that, if

ignored or applied incorrectly, creates the

danger of death or serious personal injury.

This symbol indicates information that, if ignored

or applied incorrectly, creates the possibility of

personal injury or property damage.

The triangle ( ) indicates something you should take

absolute care when doing. The cautions are indicated

concretely within the symbol. The symbol on the left indicates

caution with electric shock.

A diagonal line within a circle ( ) indicates something you

should not do. The symbol on the left indicates you should not

try to take the unit apart.

A black circle ( ) indicates something you need to do. The

symbol on the left indicates you should unplug the unit from

the wall outlet.

34

Warning

Liquids

Foreign Matter

Dropping and Damage

Abnormal Conditions

Do not place on an unstable place

Do not place the rewinder on an unstable place such as an

unsteady table, an inclined place or a place with vibration. The

rewinder may drop or topple over and cause injuries.

Do not place any containers with water or chemicals, such as

flower vases or cups, as well as small metallic objects near

the rewinder. Continued use creates the danger of fire or

electrical shock.

Do not drop or insert metallic or flammable objects into the

openings on the rewinder. Continued use creates the danger

of fire or electrical shock.

Do not use if the product has been dropped or damaged.

Continued use creates the danger of fire and electrical shock.

Do not use the rewinder if it is emitting smoke or strange odors.

Continued use creates the danger of fire and electrical shock.

* If any of these should fall into the rewinder, immediately turn

off the power and contact your nearest dealer or service

center.

* Should the rewinder ever fall or otherwise become

damaged, immediately turn off the power and contact your

nearest dealer or service center. Continued use creates the

danger of fire or electrical shock.

* Immediately turn off the power and contact your nearest

dealer or service center for repairs. Do not try to service the

rewinder by yourself.

* If any of these should fall into the rewinder, immediately turn

off the power and contact your nearest dealer or service center.

!

5

Warning

!

Disassembly

Never try to take the unit apart or modify it in any way. Doing

so creates the danger of fire or electrical shock. Contact your

nearest dealer or service center for repairs.

Location

Do not locate the rewinder in areas subjected to high humidity

or dew. Doing so creates the danger of electrical shock.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference in a residential installation.

This equipment generates use and can radiate radio frequency energy

and, if not installed and used in accordance with instructions, may cause

harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of

the following measures:

- Reorient or re locate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

* If dew forms inside the rewinder, immediately turn off the

power and do not use it until it has dried up.

FCC Notice

Caution

!

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY SAME TYPE AND RATING OF FUSE.

LOCATION : F1 , F2 RATING : 125V 3.5A

6

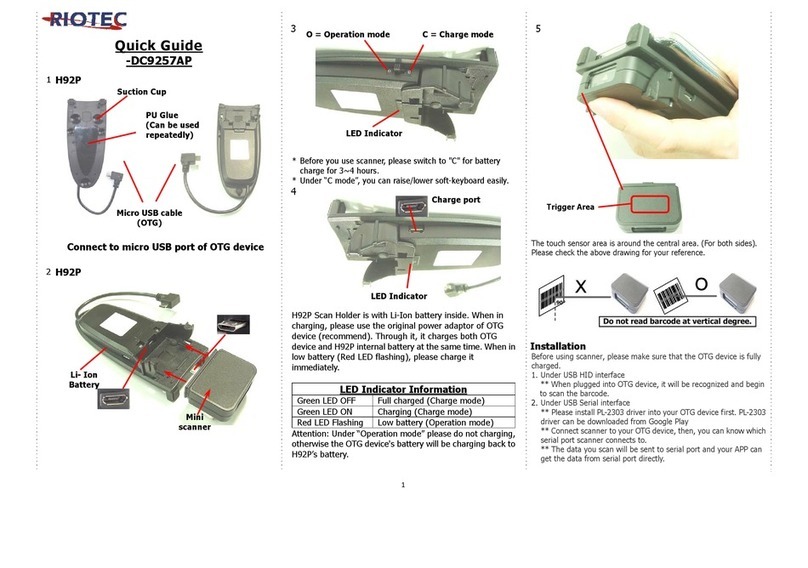

Main Body and Accessories

12

36

7

4

5RWG500 main body

Joint plate

EXT cable

Clip

3-inch core (2 pieces)

Label guide

Quick Guide (this booklet)

1

2

3

4

5

6

7

7

Status LED

First roller

Tension arm

Second roller

Control Panel

Rewinding START/STOP switch

CW : Clockwise winding

(Face in)

Indication LED

CCW : Counterclockwise

winding (Face out)

Indication LED

Parts Identification

8

Side Panel

Power switch

Earth terminal

Connector for printer connection

Connector for

AC adaptor connection

Rewinding direction

selector switch

9

1

2

Joint plate setting

Set the joint plate according to the printer model to be connected.

Loosen the screws

(2 places) of the joint

plate.

Phillips screwdriver

is necessary.

M4 Screw

For the setting for

each model, refer to

the subsequent pages

of this guide.

Slightly lift up the

plate indicated with

oblique lines, then set

it by sliding it left and

right or up and down.

10

G

T4XXe

M-84Pro

SR4XX

M-48Pro

Printer model name

Check the printer model

displayed.

Slide the plate so that the screws and

bosses are in the position indicated

below, then tighten the screws.

Screw

Boss Boss

GT4xxe

M-84Pro

Rear

Front

11

M-5900RVe

MT4xxe

Printer model

M-5900RVe

Check the printer model

displayed.

Slide the plate so that the screws and

bosses are in the position indicated

below, then tighten the screws.

Screw

Boss

Boss

Rear

Front

12

CL4xxe

MR4xxe

Check the printer model

displayed.

Slide the plate so that the screws and

bosses are in the position indicated

below, then tighten the screws.

Screw

Boss

Boss

Rear

Front

Printer model

CL4xxe

CL6xxe

MR6xxe

Check the printer model

displayed.

Slide the plate so that the screws and

bosses are in the position indicated

below, then tighten the screws.

Screw Screw

Boss Boss

Rear

Front

Printer model

CL6xxe

13 14

Check which of the following categories the printer to be

used belongs to.

Remove the screws (1 screw each for right and left) that

lock the first roller.

Phillips screwdriver is necessary.

Slide the first roller upwards or downwards.

Tighten the removed screws (1 screw each for right and left).

First Roller Height Setting

According to the printer to be connected, adjust the first roller

height to either upper or lower position.

1

2

3

Locking screw

on the upper side Locking screw

on the lower side

Roller position : Upper side Roller position : Lower side

Printer name First roller position Screw position

GT4xxe ······· Lower side Lower side

CL6xxe

·······

Lower side Lower side

Others

·

·····

·

·Upper side Upper side

15

Connection to Printer

1

2

Place the feet of the

rewinder (2 places) into

the positioning holes on

the joint plate.

Insert the FG terminal

into the earth terminal

on the side panel, and

then fix it.

Insert and attach the FG

terminal between the

screw and crow washer

and the rewinder .

Phillips screwdriver

is necessary.

16

3

4

Connect the EXT cable to the EXT

terminal of the printer.

For the position of the EXT

terminal, refer to the operating

manual of the printer

Place the feet of the

printer (2 places) into the

positioning holes on the

joint plate.

Example where the printer

used is CL400e.

17

!

5

Insert the EXT cable to

the connector for printer

connection on RWG 500.

Connection is completed.

When connecting, the power of both the printer and the

rewinder must be turned OFF.

Make sure that the printer and the rewinder is set correctly

with the joint plate. If they are not set correctly, Rewinding

error may occur.

CAUTION

18

Label Setting

This rewinder can perform 4 types of label rewinding methods by

combining rewinding shaft types and winding directions.

Printed label surface comes

outside when rewinding.

Printed label surface comes

inside when rewinding. Backing

sheet can be seen on outside.

There are 2 types of label winding direction, namely face out

rewinding and face in rewinding. For the above 2 types, the setting

direction against the rewinding shaft are different.

Rewinding Direction

Setting Direction

Face out Rewinding (CCW)

label route

Face in Rewinding (CW)

label route

Select the rewinding method according to the environment where

this rewinder is used, then set the paper.

Rewinding direction : Face in / Face out

Rewinding shaft : Direct Rewinding /

3-inch paper-core Rewinding

19

!

CAUTION

Switching of Rewinding Direction

The Status LED on the control panel blinks in green (idling state).

The power of the rewinder is turned OFF.

Switching of the Rewinding direction may be performed only in

either of the following states:

Switch the Rewinding direction with the Rewinding direction

selector switch on the side panel.

Face in Rewinding is set as the factory setting.

Side panel

(CW side)

(CCW side)

LED of CW lights up.

LED of CCW lights up.

Face in Rewinding

Face out Rewinding

Control panel

display

20

Set the label as inside or

outside Rewinding. Insert

the provided clip onto the

guide of the rewinding

shaft to fix the label.

Push the clip in until it

touches the end of the

guide.

Insert the label guide.

Label setting is completed.

Rewinding Shaft

Direct Rewinding

1

2

21

1

2

3-Inch Paper-core Rewinding

Attach the provided 3-inch core adaptor to the rewinding shaft.

At this time, align the locking screws to the guides (narrow-

width guide and deep-groove guide) of the rewinding shaft.

Left

Screw holes

Right

Adjust the core position

according to the label width,

and then lock it by tightening

the screws.

Number of cores to be used

should be determined

referring to the following

standard.

Phillips screwdriver is

necessary.

Teeth

(for fixing the paper tube)

Adjust the core teeth direction

so that it will be the same as

the Rewinding direction.

Face in Rewinding : Left direction

Face out

Rewinding : Right direction

Label width of below 65mm : 1 piece

Label width of 65mm : 2 pieces

Guide

(narrow-width guide,

deep-groove guide)

and above

22

3

4

Insert the paper tube, then fix

the label with an adhesive

tape, etc.

Lastly, insert the label guide.

Label setting is completed.

!

CAUTION

The Status LED on the control panel blinks in green (idling state).

The power of the rewinder is turned OFF.

Label setting may be performed only in either of the following states:

23

1

1

.

After the label has been set, rewinding of the label can be performed.

The followings are the rewinding procedures.

Turn on

the power switch on the side of the rewinder.

After for a while, the status LED on the control panel will start

blinking in green. At this time, the rewinder is in idling

status.

Press down and hold the START/STOP switch on the

control panel. The rewinding shaft starts rotating, and the

tension arm rises and then stops automatically. When the

LED is lit in green continuously, which shows the rewinder

is now in rewinding operation, release the switch.

Turn on the power of the rewinder.

Take up the slack in the label.

2

If the switch is released before the slack is taken up, the

rewinder stops automatically and the status LED continues

blinking in green (I.e., idling status). In this status, the

rewinder will not perform label rewinding operation.

Make sure to press down and hold the switch until the LED is

lit in green continuously.

Basic Usage of the Rewinder

24

5

5

After removing the label on the printer side, then remove

the label rewound with this rewinder.

The rewound label can be removed easily because the

tension arm has been down.

Remove the rewound label.

When the rewinding is completed, press the START/STOP

switch on the control panel.

The tension arm comes down and stops automatically.

The status LED blinks in green and the rewinder returns

to the idling status.

Operate the printer and start issuing the label.

Slack in the label and issuing speed are detected automatically

before performing rewinding.

Start automatic rewinding.

When the rewinding is completed.

3

4

25

6-Inch Expansion Option

Contents of the Optional Kit

To rewind the label with the width of more than 131mm, the expansion

optional kit is required.

Second roller joint

Second roller shaft guide

Core joint

Core shaft guide

1

2

3

4

12

34

26

How to Install

Install the optional kit correctly following the procedures shown below.

Remove the cap of the second

roller.

Reattach the cap.

A coin or a flat head screwdriver

is necessary.

1

Insert the 1second roller

joint and 2second roller shaft

guide and then tighten 2

counterclockwise.

2

1

1

2

3

27

4

4

5

6

3

4

Insert the 3core joint and 4

core shaft guide and then tighten

4counterclockwise.

Remove the cap of the rewinding

shaft.

A coin or a flat head screwdriver is

necessary.

Reattach the cap.

Installation of the optional kit is

completed.

28

Rewinding

method

Paper width

Paper type

Winding

direction

Rewinding

speed

Rewinding

monitoring

Power

supply

External

diameter

Width (W) 280mm

Depth (D) 320mm

Height (H) 230mm

Width: 25-131mm (standard)

Width: 25-180mm (when the optional kit is installed)

Label thickness: 0.08 - 0.26mm

Please use the genuine label for Sato printers.

Linerless label is not applicable for this rewinder.

ø40mm direct Rewinding, 3-inch paper-core

Rewinding

Slack in the paper, presence of paper and rewinding

speed are detected with the tension arm.

Automatic speed setting (MAX: 381mm / sec)

Face in / Face out (CW/CCW)

Selectable with the switch on the side panel.

Factory setting : Face in (CW)

Rewinding direction must be the same as the

winding direction of the label set on the printer.

7.5kg

Standard : Power is supplied from the SATO

printer main body with the

exclusive cable (EXT cable).

Option : AC adaptor exclusively for SATO

equipment.

DC25V

Weight

Basic Specifications

– MEMO – – MEMO –

–MEMO –

First edition 15.Oct.2004

DCS & Labeling Worldwide

Other manuals for RWG500

2

Table of contents

Other SATO Barcode Reader manuals

SATO

SATO MB400 User manual

SATO

SATO DR308e User manual

SATO

SATO M-8400RVe Series User manual

SATO

SATO CL4NX RIDF User manual

SATO

SATO CL4NX Plus User manual

SATO

SATO MB200 User manual

SATO

SATO PV4 User manual

SATO

SATO PV3 Assembly instructions

SATO

SATO GT400 series User manual

SATO

SATO WS408TT-STD User manual

SATO

SATO Argox AI-6800 User manual

SATO

SATO ARGOX AS-9400DC User manual

SATO

SATO CT4i Series User manual

SATO

SATO Argox OS-2130D User manual

SATO

SATO PV3 User manual

SATO

SATO CL4e Series User manual

SATO

SATO MB 200i User manual

SATO

SATO Argox AR-3100 User manual

SATO

SATO CG412DT User manual

SATO

SATO Argox AR-3201 User manual