Table of contents

Leuze electronic GmbH + Co. KG BPS 3007i 3

Table of contents

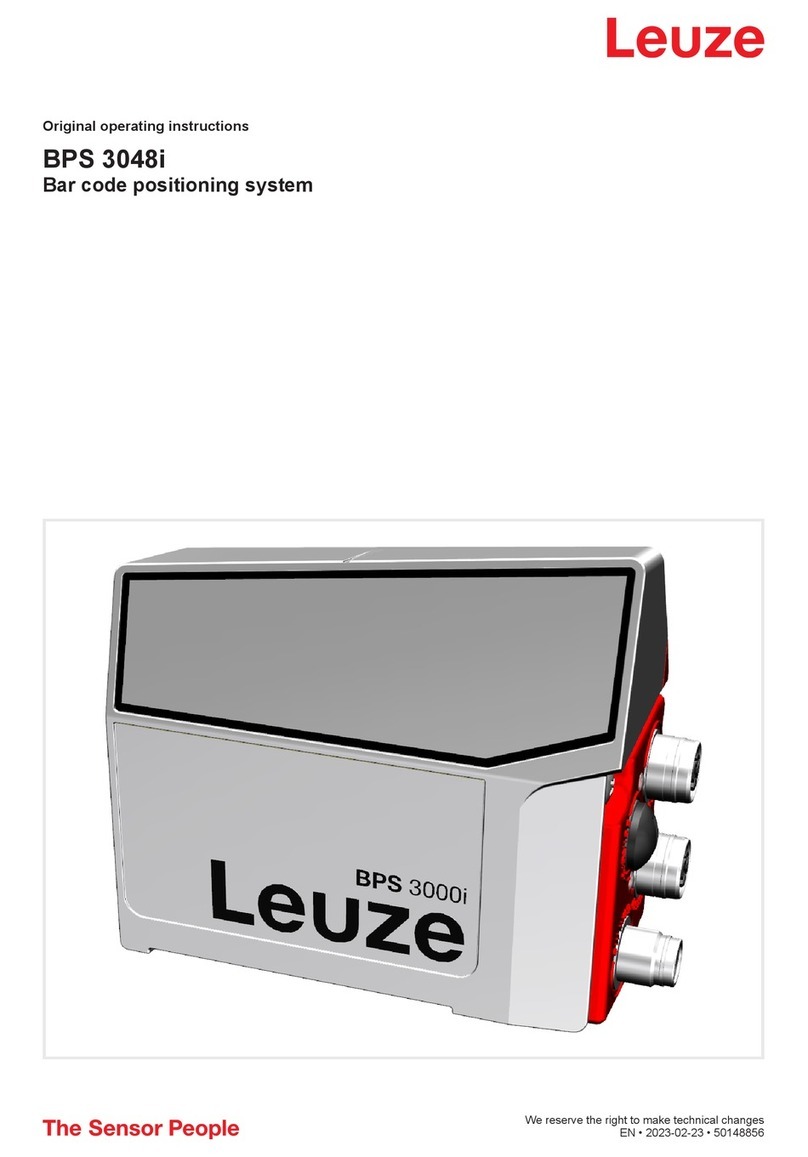

1 About this document ............................................................................................5

1.1 Used symbols and signal words .............................................................................................5

2 Safety .....................................................................................................................6

2.1 Intended use ...........................................................................................................................6

2.2 Foreseeable misuse................................................................................................................6

2.3 Competent persons.................................................................................................................7

2.4 Disclaimer ...............................................................................................................................7

2.5 Laser warning notices .............................................................................................................7

3 Device description ................................................................................................8

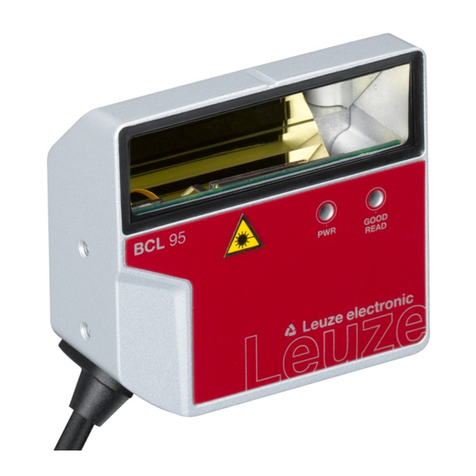

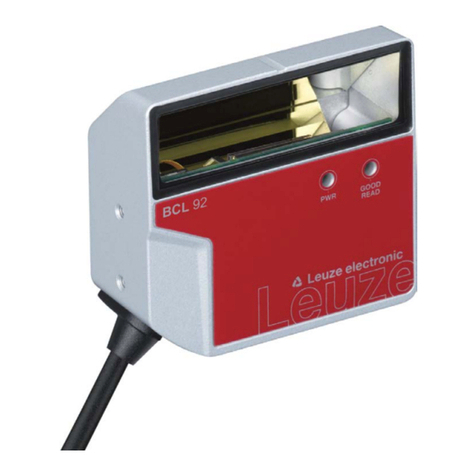

3.1 Device overview......................................................................................................................8

3.1.1 General information.............................................................................................................8

3.1.2 Performance characteristics................................................................................................8

3.1.3 Accessories .........................................................................................................................9

3.2 Connection technology ...........................................................................................................9

3.2.1 MS3007 connection hood with M12 connectors.................................................................9

3.2.2 MK3007 connection hood with spring-cage terminals........................................................9

3.3 Display elements...................................................................................................................11

3.4 Bar code tape........................................................................................................................12

3.4.1 General information...........................................................................................................12

3.4.2 Twin tapes .........................................................................................................................13

4 Applications ........................................................................................................14

4.1 High-bay storage device .......................................................................................................15

4.2 Electrical monorail system ....................................................................................................16

4.3 Gantry cranes .......................................................................................................................17

5 Mounting..............................................................................................................18

5.1 Mounting barcode tape ........................................................................................................18

5.1.1 Installation and application remarks ..................................................................................18

5.1.2 Cutting barcode tapes ......................................................................................................19

5.1.3 Mounting the BCB .............................................................................................................20

5.2 Mounting the barcode positioning system............................................................................23

5.2.1 Mounting instructions.........................................................................................................24

5.2.2 Orientation of the BPS to the bar code tape......................................................................24

5.2.3 Mounting with the BTU 0300M-W mounting device ..........................................................25

5.2.4 Mounting with the BT300W mounting bracket.................................................................26

5.2.5 Mounting with M4 fastening screws...................................................................................26

6 Electrical connection..........................................................................................27

6.1 MS3007 connection hood with connectors ..........................................................................27

6.2 MK3007 connection hood with spring-cage terminals .........................................................28

6.3 Pin assignment .....................................................................................................................29

6.3.1 PWR/SWIN/OUT (Power and switching input/output)....................................................29

6.3.2 SSI (HOST/BUSIN) ........................................................................................................30

6.4 Cable lengths and shielding..................................................................................................31

7 Starting up the device – Basic configuration...................................................32

7.1 Configuring the SSI interface ................................................................................................32

7.1.1 Principal functionality of the SSI interface .........................................................................32

7.2 Configuration via the switches of the connection hood.........................................................33