SEA LYRA Instruction manual

LYRA, JACK 400/800/1200

Italiano

English

Français

Español

www.seateam.com

SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

67411740

Operatore oleodinamico interrato

Underground hydraulic operator

Opérateur hydraulique enterré

Actuador oleodinámico enterrado

REV 01 - 03/2015

JACK JACK

CASSA PORTANTE

CARRYING BOX

LYRA

LYRA

JACK 400 (with and without slowdown)

JACK 800 (with and without slowdown)

JACK 1200 (with and without slowdown)

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Note: The frequency of use is valid only for the first hour at 20°C

room Temperature.

123

4

5

Fig. 1

6

7

8

9

10

11

CARRYING BOX

Fig. 2

REV 01 - 03/201567411740

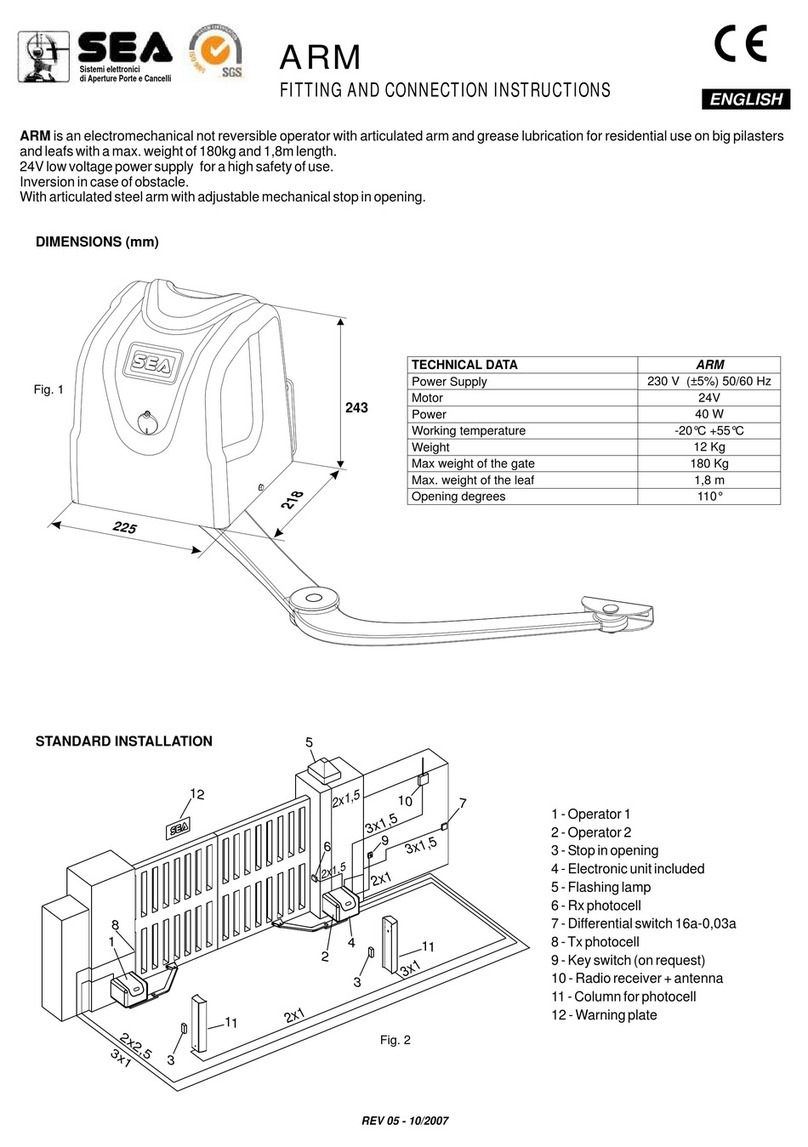

ENGLISH

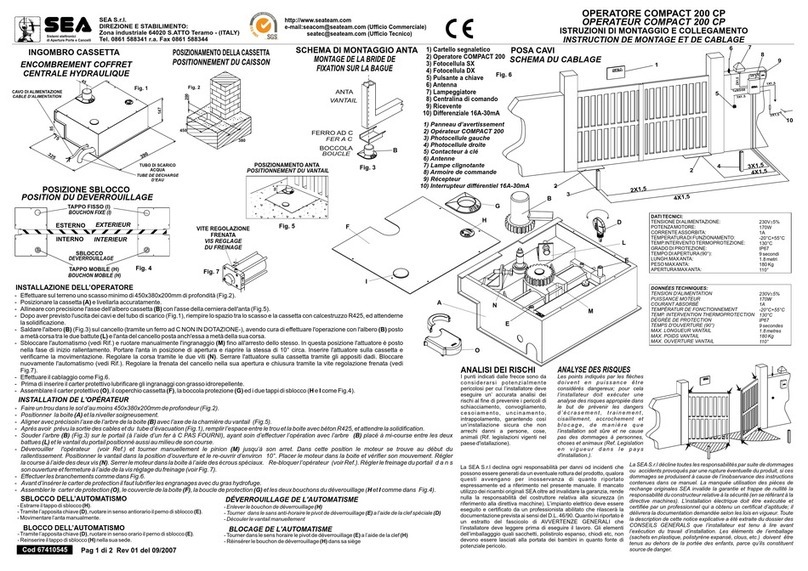

FITTING AND CONNECTION INSTRUCTIONS

MAIN PARTS NOMENCLATURE

GRAPHIC FOR THE USE OF

JACK 400 - 800 - 1200 OPERATORS

13

1Jack

2 Broached bush

3Box lid

4Box

5Foundation base

6Braking screw

(where provided)

7Exit hole for electric cables

8Water draining hole

adjusting

9 Air bleed screw

10

11

12 Hydraulic unit box

13 Oil charge cap

14

15 Hydraulic plug

16 Release screw

17 By pass valves

Greaser

Crank

Oil level cap

NON-CARRYING BOX

LYRA HYDRAULIC UNIT

The LYRA JACK consists of a hydraulic pump and a hydraulic

jack. The jack is placed inside a non carrying or carrying box

(inox only for carrying box).

The pump unit casing, which is used as an oil tank, contains the

electric motor, fluid pump, distributor and hydraulic oil. It is also

provided with an adjustable slowing-down device in the two

stop phases of the leaf (versions with slow-down only).

The wheeling unit is composed by a double piston connected to

a rack which engages with the pinion of the leaf dragging shaft.

Gates up to 2 meters long can be securely locked using the

operators internal hydraulic locking system, thus ensuring

perfect keeping in closing and in opening. For gate in excess of

stated value: A hydraulic non locking operator should be used in

conjunction with a separate electrical locking device to ensure

keeping in closing.

On the operators with hydraulic slow down it is present

only during the last 15° of rotation. The system comes with a

release which allows the manual opening of the leaves in case of

power failure.

Jack 400 Jack 800Lyra

12

13

14

15

15

16 17

Fig. 3

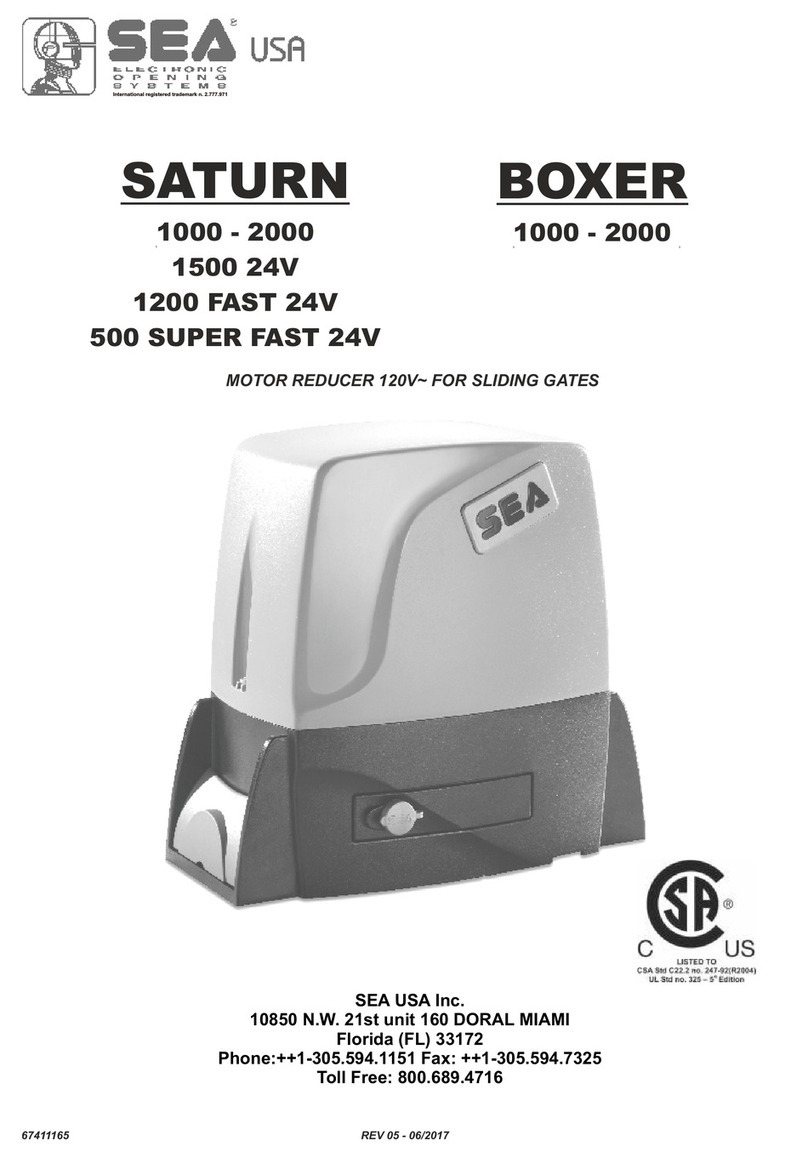

230 Vac 50/60 Hz

220W

1400 rpm

45

-20°C +55°C

130°

56 da N

12,5 µF

8 Kg

IP67

800 kg400 kg-

100° - 140° - 180°

-

Jack 1200

310W

60

1200 kg

100°

10 µF

75 da N

150°

Max. leaf length 5 m4 m

Pump capacity

Hydro slowdown

1,5 L

Angular speed 8,2° / s7° / s

0,5 L

SI 15° AP/CH (If present )

JACK 1200 JACK 1200

JACK 800 JACK 800

JACK 400

JACK 400

4 meters

800 kg

400 kg

5 meters

1200 kg

TECHNICAL DATA

Power supply

Motor Power

Motor rotation speed

Cycles hour

(with a 20°C temp.)

Operating temperature

Thermal protection intervention

Max torque

Starting capacitor

Weight

Protection class

Maximum weight of the gate

Jack rotation angle

Max leaf weight

Max leaf width

Underground hydraulic operators

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 8

60

0

300

160

Dimensions (mm)

401

210

121

Dimensions (mm)

Fig. 6

0

400- 44

121

202

152

400 mm ®100° - 140°

440 mm ®180°

Dimensions (mm)

Fig. 4

Fig. 5

188

320

14 0

68

55 Dimensions (mm)

Fig. 7

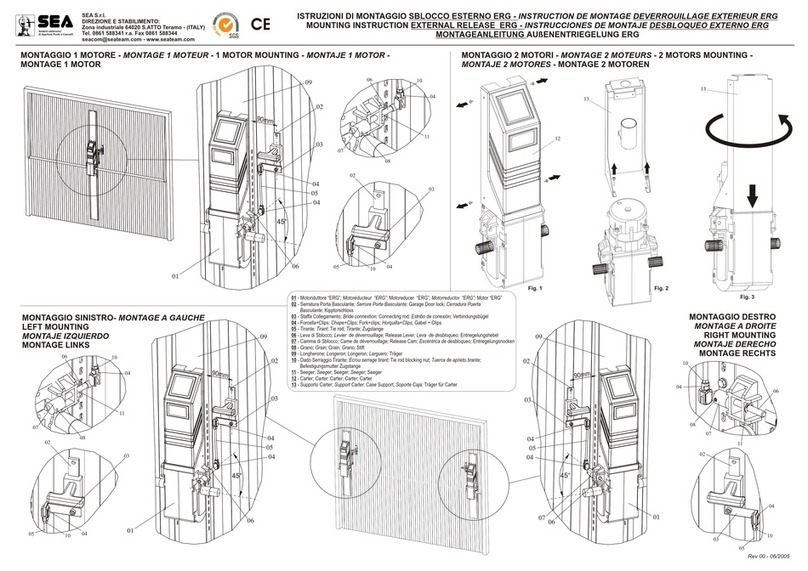

1. GATE ARRANGEMENT

You must do some checks on the gate to see if fitting a LYRA,

JACK system is possible:

A. (Make sure that) the fixed and moving parts of the gate are

strong and non-deformable;

B. the weight of each gate leaf must not exceed 400 kg (Jack

400), 800 kg (Jack 800), 1200 kg (Jack 1200) see the graphic

(A);

C. the hinges and general structure must be in good condition

and the gate must move smoothly throughout its travel;

D. the upper hinge alone is sufficient to install the unit; those

which are unnecessary can be eliminated (the lower and that in

the middle if exists);

E. as the limit switches are not provided within the actuator, it is

necessary to install mechanical limit switches stops to be fixed to

the ground in closing and in opening (Fig. 7).

ENGLISH

Weight kg

Leaf length M

GRAPHIC (A)

Limit switch stop

in opening

Limit switch stop

in closing

CARRYING BOX

14 67411740

NON-CARRYING BOX

LYRA HYDRAULIC UNIT

2. NON-CARRYING BOX INSTALLATION

2.1. The excavation which contains the non-carrying box must

have the approximate dimensions mentioned in Fig. 8. For a

correct placing, it is obligatory to closely follow the quote of 55

mm which corresponds to the minimum distance of the rotation

axis from the pillar.

REV 01 - 03/2015

800

700

600

500

400

300

200

100

00 2 2,5 3 4 5 6 7 8

JACK 400

JACK 800

1200

1100

1000

900

AK 0

0JC 1

2

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 10

Fig. 11

Fig. 14

Fig. 12

Fig. 13

Fig. 9

=

=

ENGLISH

Flexible pipe

for water

draining

15

67411740

2.2. Inside the excavated pit you have to plan:

- rain water drainage;

- a water waste pipe in flexible plastic of about 40 mm of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 9). It must be brought to the drain of the

sewer line;

- a sheath for the passage of the hydraulic tubes of about 32

mm of diameter which must be brought to the proximity of the

hydraulic unit box (Fig. 9).

2.3. Before concreting the box, use a level to make it perfectly

horizontal to the ground (Fig. 10) and perpendicular to the axis of

the gate (Fig. 11).

Hydraulic tubes

sheath

Hydraulic unit

Pivot

Bush

U-shaped bar

Leaf

4. MOUNTING OF THE LEAF ON NON-

CARRYING BOX

4.1. Insert the broached bush on the shaft of the jack.

Turn the shaft of the jack toward closing until it stops.

WARNING: For operators with brake make sure that the jack

has reached the stop and not the beginning of the

slowdown.

4.2. Go back about 5° and weld the bush to the U-shaped bar

(not supplied) and to the leaf of the gate (Fig. 14).

3. INSTALLATION OF THE OPERATOR

INSIDE THE NON-CARRYING BOX

3.1. Place the jack inside the foundation box (Fig.12)

positioning the axis of the output shaft aligned with the axis of

the hinge of the gate and weld the four angular ends to fix the

same (Fig. 13).

REV 01 - 03/2015

Fig. 15

55 mm min.

Fig. 16

Fig. 17

Fig. 18

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

40

20

Fig. 19

Fig. 20

Fig. 21

ENGLISH

16 67411740

4.3. Be careful not to place the leaf outside the axis (Fig. 16

and 17) and make sure that the shaft corresponds to the

rotation axis of the jack.

5. HYDRAULIC UNIT BOX WALL

INSTALLATION (Fig.19)

5.1. Connect the hydraulic tubes with the hydraulic unit and the

jack (Fig.21, Fig.22, Fig.23).

After having installed the box, the gate and the operator, try to

slowly move the gate by hand to make sure that there are no

irregular frictions and that the movement is uniform for the whole

range.

Notice: To do this last operation, release the operator as

described in the related paragraph.

Hydraulic

tubes

inlet

Cable

inlet

REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

8. BRAKING REGULATION (where present)

8.1. It is possible to regulate the leaf slowdown in opening and in

closing, through the braking adjusting screw (Fig. 26).

8.2.To regulate slowdown operate as follow:

- Loosen the blocking screw of braking regulation;

- Act on the adjusting screw clockwise to have a higher braking

and a speed decrease;

- Act on the adjusting screw anti-clockwise to have a lower

braking and a speed increase;

-After the regulation fix the blocking screw of braking regulation.

On the operators with hydraulic slow down it is prensent

only during the last 15° of rotation.

Fig. 26

+

-

+

-

Fig. 23

Fig. 22

Fig. 24

-+

By-Pass Valves

Fig. 25

ENGLISH

+-

Grey

n

e

t

m

t

s

i

u

n

j

d

o

a

p

e

e

n

c

r

i

n

o

g

F

+-

Yellow

e

t

n

m

t

s

i

u

n

j

d

c

a

l

o

e

s

c

r

i

n

o

g

F

Braking regulation screw

Opening/closing

Blocking screw for

braking regulation

17

67411740

Copper

tube

Flexible

tube

6. BLEED CAP REPLACEMENT (Fig.24)

Remove the red cap and replace it with the supplied black one

after startup.

7. FORCE ADJUSTMENT

If necessary the thrust force of the leaf can be adjusted by the

two adjusting screws (grey and yellow) placed on the front lower

place of the hydraulic pump unit (Fig. 25).

*The operator is adjusted at 15 Kg force ex works so to

guarantee the anti-crush safety.

We recommend to adjust it only in case of necessity.

Red cap

9. BLEEDING OPERATION

During the connection phase between hydraulic unit and jack, air

will inevitably enter into the system and cause an irregular

operation of the operator. The irregular operation shows by an

abnormal movement of the leaf and excessive noise during

operation. To solve this problem it is necessary to proceed as

follows:

REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Air bleed screw

Fig. 27

CLOSING

OPENING EXT

INT

A A

B B

Fig. 28

Fig. 29

600

450

215

Dimensions (mm)

10. CARRYING BOX INSTALLATION

10.1. The hole which contains the carrying box must have the

approximate dimensions mentioned in Fig. 29.

For a correct placing, it is obbligatory to follow closely the quote

of 55 mm which corresponds to the minimum distance of the

rotation axis from the pillar.

Fig. 31

10.3. Before concreting the carrying box, use a level to make it

perfectly horizontal to the ground (Fig. 31) and perpendicular to

the axis of the gate (Fig. 32).

The axis of the upper hinge of the gate must correspond exactly

to the axis of the carrying box shaft.

Fig. 30

ENGLISH

18 67411740

a) command opening of the gate;

b) during opening of the gate, loosen the air bleed screw related

to opening (Fig.28-rif.A);

c) release any air from the hydraulic circuit until non-emulsified

oil appears;

d) tighten the air bleed screw before the operator completes the

opening cycle;

e) command closing of the gate;

f) during closing of the gate, loosen the air bleed screw related to

closing (Fig.28-rif.B);

g) release any air from the hydraulic circuit until non-emulsified

oil appears;

h) tighten the air bleed screw before the operator completes the

closing cycle.

It is recommended to repeat this operation on both air bleed

screws at intervals of 2/3 opening and closing cycles.

i) Replace the oil from the oil filler cap. Any top-ups should be

performed only with oil SEA0x29 (supplied).

10.2. Inside the excavated pit you have to plan:

- rain water drainage;

- a water waste pipe in flexible plastic of about 40 mm of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 30). It must be brought to the drain of the

sewer line;

- a sheath of about 32 mm diameters for the passage of

hydraulic tubes must be brought to the proximity of the

hydraulic unit box (Fig. 30).

Hydraulic

unit

Hydraulic tubes

sheath

Flexible pipe

for water

draining

REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 34

Fig. 33

Fig. 37

55 mm min.

Fig. 36

11. LEAF ASSEMBLING ON CARRYING BOX

Before installing the gate make sure that the concrete has

hardened into the foundation hole.

11.1. Position the leaf of the gate on the leaf device making

reference to the rotation axe of the leaf hinge (Fig. 34);

11.2. Weld with care the leaf device to the leaf of the gate

realizing a tract fixation of ca. 3-4 cm along the surface of the

contact, avoiding the welding next to the threaded holes,

Fig. 32

10.4. Introduce the buckle of creeping in the box and fix it with

the special screws (Fig. 33).

10.5. Insert the units as in Fig. 33.

N.B.: During the insertion of the units lubricate

them with the supplied grease.

furthermore it is necessary to respect the perpendicularity to the

axe of rotation (Fig. 35)

Fig. 35

11.3. Be careful not to place the leaf outside the axis (Fig. 16

and 17), but make sure the shaft corresponds to the hinge

rotation axis remembering that the minimum distance from the

pillar is 55 mm (Fig. 37).

ENGLISH

Leaf device

Leaf rotation axe

Leaf

Crank shaft Crank

19

67411740 REV 01 - 03/2015

RELEASE PLUS

13.2. Grease the hinge (A) and mount the release system under

the leaf device using the 5 furnished screws (Fig. 42).

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 38

Fig. 40

2

Fig. 39

Fig. 41

A

12. IINSTALLATION OF THE OPERATOR IN

THE CARRYING BOX

12.1. Insert manually the operator into the carrying box (Fig. 38)

also insert the splined shaft of the operator into the splined bush

of the box and fix the operator with the special screws as in

Fig.40.

N.B.: It is advisable to weld the crank with the crank shaft after

having also installed the Jack, to use the whole available run and

the point of beginning of the desired slowdown (version with

hydraulic slowdown).

Before welding, make sure that one of the level of the crank shaft

corresponds with a side of the crank (see fig.39 and 40) to

guarantee the maximum angle with the mechanical stops Kit.

N.B.: If the Jack is not installed immediately but in a second time,

it is recommended to weld the crank shaft and the crank during

the installation of the Jack.

Carry out the electrical connections to the control unit as

described in the instructions supplied with SEA control unit.

Fig. 42

A

Fig. 43

1

ENGLISH

Release

Release Plus

14. ADJUSTABLE MECHANICAL STOPS

20 67411740

12.1. Connect the hydraulic tubes with the hydraulic unit and the

jack (Fig.21, Fig.22, Fig.23).

After the installation of the above mentioned carrying box, of the

gate and the operator, try to move the gate slowly by hand

verifying that there are no irregular frictions and that the

movement is uniform for the whole range.

Notice: To do this last operation, release the operator as

described in the related paragraph.

13. RELEASE MOUNTING

For the Jack are foreseen two types of release:

RELEASE (with personalised key) and RELEASE PLUS

(with DIN key).

RELEASE

13.1. Grease the hinge (A) and mount the release system

under the leaf device using the 4 furnished screws (Fig. 41)

REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 45

Fig. 44

Fig. 47

0

-15°

105°

Fig. 48 Fig. 48

Fig. 46

When putting in function the installation it is peremptory to

lubricate the box as in Fig. 50 until the grease comes out.

se grease typeDIN 51502 KP 2 N-20 - K 2 K-20).(U

Fig. 50

Fig. 51

2,

X15

2X1,5

G

1XR58

1

23

4

2

5

6

789

10

11

X4 1 , 5

1,5

X1

2X5

1,

3X1,5

X315 ,

,5

4X1

,X 153

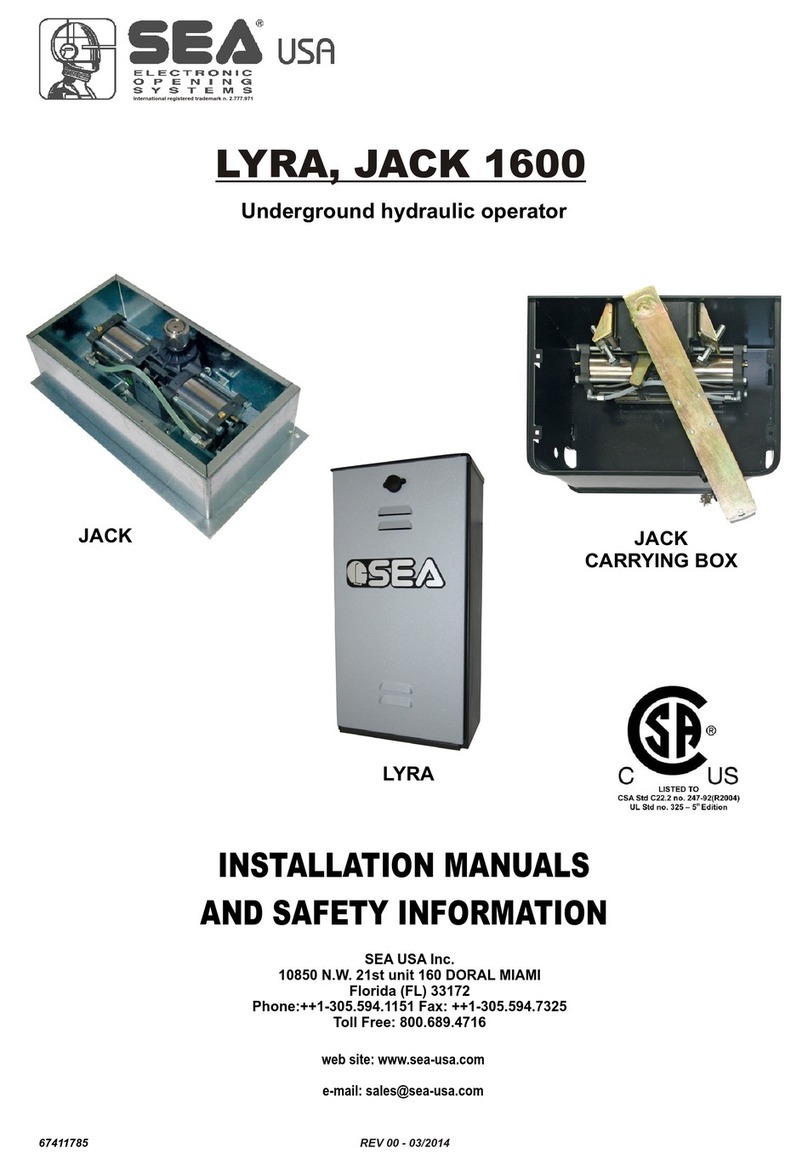

15. CABLE LAYOUT (Fig. 51)

16. RISK EXAMINATION

The points pointed by arrows in Fig. 52 are potentially

dangerous. The installer must take a thorough risk examination

to prevent crushing, conveying, cutting, grappling, trapping so

as to guarantee a safe installation for people, things and animals

(Re. Laws in force in the country where installation has been

made).

ENGLISH

Max. Angle with mechanical stops kit

RIGHT

LEFT Outside

Inside

Outside

Inside

1) Warning notice

2) Jack 400/800/1200

3) Left photocell

4) Right photocell

8) Electronic control unit

9) Receiver

10) 16A-30mA differential switch

11) Electric lock (SB version only)

5) Key switch

6) Antenna

7) Flashing warning lamp

21

67411740 REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Fig. 52

SEA can not be deemed responsible for any damage or

accident caused by product breaking, being damages or

accidents due to a failure to comply with the instructions herein.

Read the general instructions attentively.

SAFETY GATE

For a correct and safe installation it is strongly recommended to

install a Safety Gate, which allows the fulfilment of the force

diagram included in the norm EN 12453 and consequently the

test and start of the whole installation.

Fig. 53

ENGLISH

17. PERIODICAL MAINTENANCE

Check the oil level

(Trasparent cap n.14 in Fig. 3) Annual

Change the oil

Verify the functionality of the by-pass valves

(check the force in opening and closing)

Check the release function

Verify the slowdown regulation (where present)

Check the correct drain of the rainwater

Check the integrity of the connection cables

Grease all the moving parts

Grease the rotation axis of the box as in Fig.50

4 years

Annual

Annual

Annual

Annual

Annual

Annual

Annual

SAFETY GATE

SAFETY PRECAUTIONS:

All electrical work should conform to current regulations. A 16 A

0,030 A differential switch must be incorporated into the source

of the operators main electrical supply and the entire system

properly earth bonded. Always run mains carrying cables in

separate ducts to low voltage control cables to prevent mains

interference.

SPARE PARTS:

To obtain spare parts contact:

SEA S.p.A. - Zona Ind.le, 64020 S. ATTO Teramo Italia

SEA reserves the right to do changes or variations that may be

necessary to its products with no obligation to notice.

18. ACCESSORIES FOR JACK

CARRYING BOX INOX

RELEASE

RELEASE PLUS

KIT MECHANICAL STOP

22 67411740 REV 01 - 03/2015

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

20. RELEASE SYSTEM OF THE LEAVES

RELEASE

20.1. To release act as follows:

-Insert the enclosed key into the keyhole (S) and turn the handle

about 180° against the centre of the gate (Fig. 55) .

-Keep the key locked and move the leaf, now turn back the key to

the normal position and extract it.

20.2. To stop again act as follows:

-Move the leaf until the lock has coupled again.

S

Fig. 55

180°

RELEASE PLUS

20.3. To release act as follows:

-Insert the enclosed key into the keyhole and turn it about 90° in

clockwise direction (Fig. 56).

- Pull the key against the external of the release making come

out the handle of the lock until it reaches the stop (Fig.57).

- Move the leaf and make return the handle of the release in its

original position and extract the key.

21.4. To stop again act as follows:

-Move the leaf until the lock has coupled again.

Fig. 56

90°

Stop

Release handle

Fig. 57

Hydraulic pump

manual release

Fig. 54

ENGLISH

To the attention of users and technicians

Release Lock

23

67411740

19. HYDRAULIC UNIT RELEASE SYSTEM

19.1. To release do as follows:

- Open the door with the delivered special key.

- Turn the release srew, placed on the hydraulic unit.about 90°

into anti-clockwise direction.

- Move the beam with the hand.

19.2. To re-lock do as follows:

- Turn the release screw, placed on the hydraulic unit.about 90°

into clockwise direction

- Close the door.

½ turn

REV 01 - 03/2015

CONDIZIONI DI VENDITA

EFFICACIA DELLE PRESENTI CONDIZIONI GENERALI DI VENDITA: Le presenti condizioni generali di vendita si applicano a tutti gli ordini

indirizzati a SEA S.p.A. Tutte le vendite fatte da SEA ai clienti sono regolate secondo le presenti condizioni di vendita che costituiscono parte

integrante del contratto di vendita ed annullano ogni clausola contraria o pattuizioni particolari presenti nell’ ordine o in altro documento

proveniente dall’acquirente (cliente)

AVVERTENZE GENERALI Gli impianti di automazioni porte e cancelli vanno realizzati esclusivamente con componenti SEA, salvo accordi

specifici. L’inosservanza delle norme di sicurezza vigenti (Norm. EUROPEE EN 12453 - EN 12445 e altro) e di buona tecnica esclude la SEA da

ogni responsabilità. La SEAnon risponde del mancato rispetto della corretta e sicura installazione secondo le norme.

1) PROPOSTA D’ORDINE La proposta d’ordine si intenderà accettata solo dopo la sua approvazione da parte della SEA. Conseguenza della sua

sottoscrizione, l’acquirente sarà vincolato alla stipula di un contratto d’acquisto, secondo quanto contenuto nella stessa proposta d’ordine e nelle

presenti condizioni di vendita. Viceversa, la mancata comunicazione all’acquirente dell’aprovazione della proposta d’ordine, non comporta la sua

automatica accettazione da parte della SEA

2) VALIDITÀ OFFERTA Le offerte proposte dalla SEA o dalla sua struttura commerciale periferica, avranno una validità di 30 giorni solari, salvo

diversa comunicazione in merito.

3) PREZZI I prezzi della proposta d’ordine sono quelli del listino in vigore alla data della redazione della stessa. Gli sconti applicati dalla struttura

commerciale periferica della SEA si intenderanno validi solo dopo la loro accettazione da parte della SEA. I prezzi si intendono per merce resa

franco ns. stabilimento in Teramo, esclusi IVA ed imballaggi speciali. La SEA si riserva il diritto di modificare in qualsiasi momento il listino, dando

opportuno preavviso alla rete di vendita. Le condizioni speciali riservate agli acquisti con formula agevolata Qx, Qx1, Qx2, Qx3 sono riservate ai

distributori ufficiali dietro accettazione scritta da parte della direzione SEA.

4) PAGAMENTI Le forme di pagamento ammesse sono quelle comunicate o accettate di volta in volta dalla SEA. Il tasso di interesse sul ritardo da

pagamento è del 1,5% mensile e comunque non oltre il tasso massimo legalmente consentito.

5) CONSEGNA La consegna avverrà indicativamente ma non tassativamente entro 30 giorni lavorativi dalla data di ricezione dell’ordine, salvo

diverse comunicazioni in merito. Il trasporto degli articoli venduti sarà effettuato a spese ed a rischio dell’acquirente. La SEA si libera dall’obbligo

della consegna rimettendo la merce al vettore, sia esso scelto dalla SEA oppure dall’acquirente. Eventuali smarrimenti e/o danneggiamenti della

merce dovuti al trasporto, sono a carico dell’acquirente.

6) RECLAMI Eventuali reclami e/o contestazioni dovranno pervenire alla SEAentro 8 giorni solari dalla ricezione della merce, supportati da idonei

documenti provanti la loro veridicità.

7) FORNITURA L’ordine in oggetto viene assunto da SEA senza alcun impegno e subordinatamente alle possibilità di approvvigionamento delle

materie prime occorrenti alla produzione; eventuali mancate esecuzioni totali o parziali non possono dar luogo a reclami e riserve per danni. La

fornitura SEAè strettamente limitata alla sola merce di sua produzione, esclusi il montaggio, l’installazione ed il collaudo. La SEAdeclina pertanto

ogni responsabilità per danni che dovessero derivare, anche a terzi, dall’inosservanza delle norme di sicurezza e della buona regola d’arte nelle

fasi dell’installazione e dell’impiego dei prodotti venduti.

8) GARANZIALa garanzia minima è di 12 mesi e può essere estesa, come di seguito, in caso di riconsegna del certificato di garanzia.

SILVER: Le parti meccaniche degli operatori rientranti in tale categoria sono garantite per 24 mesi dalla data di fabbricazione riportata

sull’operatore.

GOLD: Le parti meccaniche degli operatori rientranti in tale categoria sono garantite per 36 mesi dalla data di fabbricazione riportata

sull’operatore.

PLATINUM: Le parti meccaniche degli operatori rientranti in tale categoria sono garantite per 36 mesi dalla data di fabbricazione riportata

sull’operatore. La garanzia di base (36 mesi) sarà estesa per ulteriori 24 mesi (fino ad un totale di 60 mesi) qualora venga acquistato il certificato di

garanzie che dovrà essere compilato e rispedito alla SEA S.p.A. entro 60 giorni dall’acquisto. L’elettronica e le centrali di comando sono garantite

per 24 mesi dalla data di fabbricazione. Nell’eventualità di difettosità del prodotto, la SEAsi impegna alla sua sostituzione gratuita oppure alla sua

riparazione, previa restituzione al proprio centro di riparazione. La definizione di stato di garanzia è ad insindacabile giudizio della SEA. I pezzi

sostitutivi restano di proprietà della SEA. In modo vincolante, il materiale dell’acquirente ritenuto in garanzia deve essere spedito al centro di

riparazione della SEA in porto franco e sarà rispedito dalla SEA in porto assegnato. La garanzia non si estende alla manodopera eventualmente

accorsa. I difetti riconosciuti non produrranno alcuna responsabilità e/o richiesta di danni, di qualsiasi natura essi siano, da parte dell’acquirente

nei riguardi della SEA. La garanzia non è in ogni caso riconosciuta qualora sia stata apportata alla merce qualsivoglia modifica, oppure vi sia stato

un uso improprio, oppure si sia in presenza di una qualsivoglia sua manomissione o di un montaggio non corretto, oppure se sia stata rimossa

l’etichetta apposta dal produttore comprensiva del marchio SEA registrato n° 804888. La garanzia non è inoltre valida nel caso la merce SEA sia

stata in parte o in toto accoppiata a componenti meccanici e/o elettronici non originali, ed in particolare in assenza di una specifica autorizzazione

in merito, ed inoltre nel caso in cui l’acquirente non sia in regola con i pagamenti. La garanzia non comprende danni derivati dal trasporto,

materiale di consumo, avarie dovute al mancato rispetto delle specifiche prestazionali dei prodotti indicate nel listino. Non è riconosciuto alcun

indennizzo durante il tempo di riparazione e/o sostituzione della merce in garanzia. La SEAdeclina ogni responsabilità per danni a cose o persone

derivanti dall’inosservanza delle norme di sicurezza e della non conforme installazione o dall’impiego errato dei prodotti venduti. La riparazione

dei prodotti in garanzia e fuori garanzia è subordinata al rispetto delle procedure comunicate da SEA.

9) RISERVATO DOMINIO Sulla merce venduta è valida la clausola del riservato dominio, della quale la SEA deciderà autonomamente se

avvalersi o meno, in virtù della quale l’acquirente acquisisce la proprietà della merce, solo dopo che il suo pagamento sia stato completamente

effettuato.

10) FORO COMPETENTE Per qualsiasi controversia avente per oggetto l’applicazione di questo contratto, viene eletto competente il Foro di

Teramo. La lingua valida nell’interpretazione di cataloghi, manuali di installazione, condizioni di vendita o altro è quella italiana. La SEAsi riserva la

facoltà di apportare modifiche tecniche atte a migliorare i propri prodotti, presenti o meno in questo Listino, in qualsiasi momento senza preavviso.

La SEAdeclina ogni responsabilità derivante da possibili inesattezze contenute nel presente listino, derivanti da errori di stampa e/o trascrizione. Il

presente Listino annulla e sostituisce quelli precedenti. L’acquirente ai sensi della legge 196/2003 (codice privacy) acconsente all’inserimento dei

propri dati personali derivanti dal presente contratto negli archivi informatici e cartacei della SEA S.p.A. al loro trattamento per motivi commerciali

ed amministrativi.

Diritti di proprietà industriale: il cliente, con l’acquisto, accetta le presenti condizioni di vendita e riconosce in capo a SEA la titolarità esclusiva

del marchio internazionale SEA registrato n. 804888 apposto sulle etichette dei prodotti e/o sui manuali e/o su ogni altra documentazione, e si

impegna ad utilizzare il medesimo nella propria attività di rivendita e/o installazione secondo modalità che non ne riducano in alcun modo i diritti, a

non rimuovere, sostituire o alterare marchi o altri segni distintivi di qualsiasi genere apposti ai prodotti.

E’ vietata ogni forma di riproduzione o utilizzo del marchio SEA e di ogni altro segno distintivo presente sui prodotti, salvo autorizzazione scritta di

SEAS.p.A..

Agli effetti dell’articolo 1341 del C.C. si approvano specificatamente per iscritto le clausole di cui ai numeri:

4) PAGAMENTI - 8) GARANZIA- 10) FORO COMPETENTE

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ITALIANO

6741174046 REV 01 - 03/2015

TERMS OF SALES

EFFICACY OF THE FOLLOWING TERMS OF SALE: the following general terms of sale shall be applied to all orders sent to SEAS.p.A.

All sales made by SEA to all costumers are made under the prescription of this terms of sales which are integral part of sale contract and

cancel and substitute all apposed clauses or specific negotiations present in order document received from the buyer.

GENERAL NOTICE The systems must be assembled exclusively with SEA components, unless specific agreements apply. Non-

compliance with the applicable safety standards (European Standards EM12453 – EM 12445) and with good installation practice

releases SEA from any responsibilities. SEA shall not be held responsible for any failure to execute a correct and safe installation under

the above mentioned standards.

1) PROPOSED ORDER The proposed order shall be accepted only prior SEA approval of it. By signing the proposed order, the Buyer

shall be bound to enter a purchase agreement, according to the specifications stated in the proposed order.

On the other hand, failure to notify the Buyer of said approval must not be construed as automatic acceptance on the part of SEA.

2) PERIOD OF THE OFFER The offer proposed by SEA or by its branch sales department shall be valid for 30 solar days, unless

otherwise notified.

3) PRICING The prices in the proposed order are quoted from the Price List which is valid on the date the order was issued. The discounts

granted by the branch sales department of SEA shall apply only prior to acceptance on the part of SEA. The prices are for merchandise

delivered ex-works from the SEAestablishment in Teramo, not including VAT and special packaging. SEAreserves the right to change at

any time this price list, providing timely notice to the sales network. The special sales conditions with extra discount on quantity basis (Qx,

Qx1, Qx2, Qx3 formula) is reserved to official distributors under SEAmanagement written agreement.

4) PAYMENTS The accepted forms of payment are each time notified or approved by SEA. The interest rate on delay in payment shall be

1.5% every month but anyway shall not be higher than the max. interest rate legally permitted.

5) DELIVERY Delivery shall take place, approximately and not peremptorily, within 30 working days from the date of receipt of the order,

unless otherwise notified. Transport of the goods sold shall be at Buyer’s cost and risk. SEA shall not bear the costs of delivery giving the

goods to the carrier, as chosen either by SEAor by the Buyer.Any loss and/or damage of the goods during transport, are at Buyer’s cost.

6) COMPLAINTS Any complaints and/or claims shall be sent to SEA within 8 solar days from receipt of the goods, proved by adequate

supporting documents as to their truthfulness.

7) SUPPLY The concerning order will be accepted by SEAwithout any engagement and subordinately to the possibility to get it’s supplies

of raw material which is necessary for the production; Eventual completely or partially unsuccessful executions cannot be reason for

complains or reservations for damage. SEAsupply is strictly limited to the goods of its manufacturing, not including assembly, installation

and testing. SEA, therefore, disclaims any responsibility for damage deriving, also to third parties, from non-compliance of safety

standards and good practice during installation and use of the purchased products.

8) WARRANTY The standard warranty period is 12 months. This warranty time can be extended by means of expedition of the warranty

coupon as follows:

SILVER: The mechanical components of the operators belonging to this line are guaranteed for 24 months from the date of

manufacturing written on the operator.

GOLD: The mechanical components of the operators belonging to this line are guaranteed for 36 months from the date of manufacturing

written on the operator.

PLATINUM: The mechanical components of the operators belonging to this line are guaranteed for 36 months from the date of

manufacturing written on the operator. The base warranty (36 months) will be extended for further 24 months (up to a total of 60 months)

when it is acquired the certificate of warranty which will be filled in and sent to SEA S.p.A. The electronic devices and the systems of

command are guaranteed for 24 months from the date of manufacturing. In case of defective product, SEA undertakes to replace free of

charge or to repair the goods provided that they are returned to SEA repair centre. The definition of warranty status is by unquestionable

assessment of SEA. The replaced parts shall remain propriety of SEA. Binding upon the parties, the material held in warranty by the

Buyer, must be sent back to SEA repair centre with fees prepaid, and shall be dispatched by SEA with carriage forward. The warranty

shall not cover any required labour activities.

The recognized defects, whatever their nature, shall not produce any responsibility and/or damage claim on the part of the Buyer against

SEA. The guarantee is in no case recognized if changes are made to the goods, or in the case of improper use, or in the case of tampering

or improper assembly, or if the label affixed by the manufacturer has been removed including the SEAregistered trademark No. 804888.

Furthermore, the warranty shall not apply if SEAproducts are partly or completely coupled with non-original mechanical and/or electronic

components, and in particular, without a specific relevant authorization, and if the Buyer is not making regular payments. The warranty

shall not cover damage caused by transport, expendable material, faults due to non-conformity with performance specifications of the

products shown in the price list. No indemnification is granted during repairing and/or replacing of the goods in warranty. SEA disclaims

any responsibility for damage to objects and persons deriving from non-compliance with safety standards, installation instructions or use

of sold goods. The repair of products under warranty and out of warranty is subject to compliance with the procedures notified by SEA.

9) RESERVED DOMAIN Aclause of reserved domain applies to the sold goods; SEAshall decide autonomously whether to make use of

it or not, whereby the Buyer purchases propriety of the goods only after full payment of the latter.

10) COMPETENT COURT OF LAW In case of disputes arising from the application of the agreement, the competent court of law is the

tribunal of Teramo. SEA reserves the faculty to make technical changes to improve its own products, which are not in this price list at any

moment and without notice. SEA declines any responsibility due to possible mistakes contained inside the present price list caused by

printing and/or copying. The present price list cancels and substitutes the previous ones. The Buyer, according to the law No. 196/2003

(privacy code) consents to put his personal data, deriving from the present contract, in SEA archives and electronic files, and he also

gives his consent to their treatment for commercial and administrative purposes.

Industrial ownership rights: once the Buyer has recognized that SEA has the exclusive legal ownership of the registered SEA brand

num.804888 affixed on product labels and / or on manuals and / or on any other documentation, he will commit himself to use it in a way

which does not reduce the value of these rights, he won’t also remove, replace or modify brands or any other particularity from the

products. Any kind of replication or use of SEA brand is forbidden as well as of any particularity on the products, unless preventive and

expressed authorization by SEA.

In accomplishment with art. 1341 of the Italian Civil Law it will be approved expressively clauses under numbers:

4) PAYMENTS - 8) GUARANTEE - 10) COMPETENT COURT OF LOW

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

ENGLISH

67411740 47

REV 01 - 03/2015

Italiano

English

Français

AVVERTENZE GENERALI PER INSTALLATORE E UTENTE

1. Leggere attentamente le Istruzioni di Montaggio e le Avvertenze Generali prima di iniziare l’installazione del prodotto. Conservare la documentazione per

consultazioni future

2. Non disperdere nell’ambiente i materiali di imballaggio del prodotto e/o circuiti

3. Questo prodotto è stato progettato e costruito esclusivamente per l’utilizzo indicato in questa documentazione. Qualsiasi altro utilizzo non espressamente indicato

potrebbe pregiudicare l’integrità del prodotto e/o rappresentare fonte di pericolo. L’uso improprio è anche causa di cessazione della garanzia. La SEA S.p.A. declina

qualsiasi responsabilità derivata dall’uso improprio o diverso da quello per cui l’automatismo è destinato.

4. I prodotti SEA sono conformi alle Direttive: Macchine (2006/42/CE e successive modifiche), Bassa Tensione (2006/95/CE e successive modifiche), Compatibilità

Elettromagnetica (2004/108/CE e successive modifiche). L’installazione deve essere effettuata nell’osservanza delle norme EN 12453 e EN 12445.

5. Non installare l’apparecchio in atmosfera esplosiva.

6. SEAS.p.A. non è responsabile dell’inosservanza della Buona Tecnica nella costruzione delle chiusure da motorizzare, nonché delle deformazioni che dovessero

verificarsi durante l’uso.

7. Prima di effettuare qualsiasi intervento sull’impianto, togliere l’alimentazione elettrica e scollegare le batterie. Verificare che l’impianto di terra sia realizzato a

regola d’arte e collegarvi le parti metalliche della chiusura.

8. Per ogni impianto SEAS.p.A. consiglia l’utilizzo di almeno una segnalazione luminosa nonché di un cartello di segnalazione fissato adeguatamente sulla struttura

dell’infisso.

9. SEAS.p.A. declina ogni responsabilità ai fini della sicurezza e del buon funzionamento della automazione, in caso vengano utilizzati componenti di altri produttori.

10. Per la manutenzione utilizzare esclusivamente parti originali SEA.

11. Non eseguire alcuna modifica sui componenti dell’automazione.

12. L’installatore deve fornire tutte le informazioni relative al funzionamento manuale del sistema in caso di emergenza e consegnare all’Utente utilizzatore

dell’impianto il libretto d’avvertenze allegato al prodotto.

13. Non permettere ai bambini o persone di sostare nelle vicinanze del prodotto durante il funzionamento. L’applicazione non può essere utilizzata da bambini, da

persone con ridotte capacità fisiche, mentali, sensoriali o da persone prive di esperienza o del necessario addestramento. Tenere inoltre fuori dalla portata dei

bambini radiocomandi o qualsiasi altro datore di impulso, per evitare che l’automazione possa essere azionata involontariamente.

14. Il transito tra le ante deve avvenire solo a cancello completamente aperto.

15. Tutti gli interventi di manutenzione, riparazione o verifiche periodiche devono essere eseguiti da personale professionalmente qualificato. L’utente deve

astenersi da qualsiasi tentativo di riparazione o d’intervento e deve rivolgersi esclusivamente a personale qualificato SEA. L’utente può eseguire solo la manovra

manuale.

2

16. La lunghezza massima dei cavi di alimentazione fra centrale e motori non deve essere superiore a 10 m. Utilizzare cavi con sezione 2.5 mm . Utilizzare cablaggi

con cavi in doppio isolamento (cavi con guaina) nelle immediate vicinanze dei morsetti specie per il cavo di alimentazione (230V). Inoltre è necessario mantenere

adeguatamente lontani (almeno 2.5 mm in aria) i conduttori in bassa tensione (230V) dai conduttori in bassissima tensione di sicurezza (SELV) oppure utilizzare

un’adeguata guaina che fornisca un isolamento supplementare avente uno spessore di almeno 1 mm.

GENERAL NOTICE FOR THE INSTALLERAND THE USER

1. Read carefully these Instructions before beginning to install the product. Store these instructions for future reference

2. Don’t waste product packaging materials and /or circuits.

3. This product was designed and built strictly for the use indicated in this documentation. Any other use, not expressly indicated here, could compromise the good

condition/operation of the product and/or be a source of danger. SEA S.p.A. declines all liability caused by improper use or different use in respect to the intended

one.

4. The mechanical parts must be comply with Directives: Machine Regulation 2006/42/CE and following adjustments), Low Tension (2006/95/CE), electromgnetic

Consistency (2004/108/CE) Installation must be done respecting Directives: EN12453 and En12445.

5. Do not install the equipment in an explosive atmosphere.

6. SEAS.p.A. is not responsible for failure to observe Good Techniques in the construction of the locking elements to motorize, or for any deformation that may occur

during use.

7. Before attempting any job on the system, cut out electrical power and disconnect the batteries. Be sure that the earthing system is perfectly constructed, and

connect it metal parts of the lock.

8. Use of the indicator-light is recommended for every system, as well as a warning sign well-fixed to the frame structure.

9. SEAS.p.A. declines all liability as concerns the automated system’s security and efficiency, if components used, are not produced by SEAS.p.A..

10. For maintenance, strictly use original parts by SEA.

11. Do not modify in any way the components of the automated system.

12. The installer shall supply all information concerning system’s manual functioning in case of emergency, and shall hand over to the user the warnings handbook

supplied with the product.

13. Do not allow children or adults to stay near the product while it is operating. The application cannot be used by children, by people with reduced physical, mental

or sensorial capacity, or by people without experience or necessary training. Keep remote controls or other pulse generators away from children, to prevent

involuntary activation of the system.

14. Transit through the leaves is allowed only when the gate is fully open.

15. The User must not attempt to repair or to take direct action on the system and must solely contact qualified SEApersonnel or SEA service centers. User can apply

only the manual function of emergency.

2

16. The power cables maximum length between the central engine and motors should not be greater than 10 m. Use cables with 2,5 mm section. Use double

insulation cable (cable sheath) to the immediate vicinity of the terminals, in particular for the 230V cable. Keep an adequate distance (at least 2.5 mm in air), between

the conductors in low voltage (230V) and the conductors in low voltage safety (SELV) or use an appropriate sheath that provides extra insulation having a thickness

of 1 mm.

CONSIGNES POUR L’INSTALLATEUR ET L’UTILISATEUR

1. Lire attentivement les instructions avant d’installer le produit.Conserver les instructions en cas de besoin.

2. Ne pas dispenser dans l’environnement le materiel d’ emballage du produit et/ou des circuits

4. Ce produit a été conçu et construit exclusivement pour l’usage indiqué dans cette fiche. Toute autre utilisation non expressément indiquée pourraient

compromettre l’intégrité du produit et/ou représenter une source de danger. SEAS.p.A. décline toute responsabilités qui dériverait d’usage impropre ou différent de

celui auquel l’automatisme est destiné.Une mauvaise utilisation cause la cessation de la garantie.

5. Les composants doivent répondre aux prescriptions des Normes: Machines (2006/42/CE et successifs changements); Basse Tension (2006/95/CE et successifs

changements); EMC (2004/108/CE et successifs changements). L’installation doit être effectuée conformément aux Normes EN 12453 et EN 12445.

6. Ne pas installer l’appareil dans une atmosphère explosive.

7. SEAS.p.A. n’est pas responsable du non-respect de la Bonne Technique de construction des fermetures à motoriser, ni des déformations qui pourraient intervenir

lors de l’utilisation.

8. Couper l’alimentation électrique et déconnecter la batterie avant toute intervention sur l’installation.Vérifier que la mise à terre est réalisée selon les règles de l’art

et y connecter les pièces métalliques de la fermeture.

9. On recommande que toute installation soit doté au moins d’une signalisation lumineuse, d’un panneau de signalisation fixé, de manière appropriée, sur la

structure de la fermeture.

10. SEA S.p.A. décline toute responsabilité quant à la sécurité et au bon fonctionnement de l’automatisme si les composants utilisés dans l’installation

n’appartiennent pas à la production SEA.

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

6741174048 REV 01 - 03/2015

11. Utiliser exclusivement, pour l’entretien, des pièces SEAoriginales.

12. Ne jamais modifier les composants d’automatisme.

13. L’installateur doit fournir toutes les informations relatives au fonctionnement manuel du système en cas d’urgence et remettre à l’Usager qui utilise l’installation

les “Instructions pour l’Usager” fournies avec le produit.

14. Interdire aux enfants ou aux tiers de stationner près du produit durant le fonctionnement. Ne pas permettre aux enfants, aux personnes ayant des capacités

physiques, mentales et sensorielles limitées ou dépourvues de l’expérience ou de la formation nécessaires d’utiliser l’application en question. Eloigner de la portée

des enfants les radiocommandes ou tout autre générateur d’impulsions, pour éviter tout actionnement involontaire de l’automatisme.

15. Le transit entre les vantaux ne doit avoir lieu que lorsque le portail est complètement ouvert.

16. L’utilisateur doit s’abstenir de toute tentative de réparation ou d’intervention et doigt s’adresser uniquement et exclusivement au personnel qualifié SEA ou aux

centres d’assistance SEA. L’utilisateur doigt garder la documentation de la réparation. L’utilisateur peut exécuter seulement la manoeuvre manuel.

17. La longueur maximum des câbles d’alimentation entre la carte et les moteurs ne devrait pas être supérieure à 10 m. Utilisez des câbles avec une section de 2,5

2

mm . Utilisez des câblage avec cable à double isolation (avec gaine) jusqu’à proximité immédiate des terminaux, en particulier pour le câble d’alimentation (230V). Il

est également nécessaire de maintenir une distance suffisante (au moins 2,5 mm dans l’air), entre les conducteurs en basse tension (230V) et les conducteurs de

très basse tension de sécurité (SELV) ou utiliser une gaine ayant une épaisseur d’au moin 1 mm, qui fournisse une isolation supplémentaire.

ADVERTENCIAS GENERALES PARA INSTALADORES Y USUARIOS

1 Leer las instrucciones de instalación antes de comenzar la instalación. Mantenga las instrucciones para consultas futura

2. No disperdiciar en el ambiente los materiales de embalaje del producto o del circuito

3. Este producto fue diseñado y construido exclusivamente para el uso especificado en esta documentación. Cualquier otro uso no expresamente indicado puede

afectar la integridad del producto y ser una fuente de peligro. El uso inadecuado es también causa de anulación de la garantía. SEA S.p.A. se exime de toda

responsabilidad causadas por uso inapropiado o diferente de aquel para el que el sistema automatizado fue producido.

4. Los productos cumplen con la Directiva: Maquinas (2006/42/CE y siguientes modificaciones), Baja Tension (2006/95/CE, y siguientes modificaciones),

Compatibilidad Electromagnética (2004/108/CE modificada). La instalación debe ser llevada a cabo de conformidad a las normas EN 12453 y EN 12445.

5. No instalar el dispositivo en una atmósfera explosiva.

6. SEA S.p.A. no es responsable del incumplimiento de la mano de obra en la construcción de la cacela a automatizar y tampoco de las deformaciones que puedan

producirse durante el uso.

7. Antes de realizar cualquier operación apagar la fuente de alimentación y desconectar las baterías. Comprobar que el sistema de puesta a tierra sea diseñado de

una manera profesional y conectar las partes metálicas del cierre.

8. Para cada instalación se recomienda utilizar como mínimo una luz parpadeante y una señal de alarma conectada a la estructura del marco.

9. SEA S.p.A. no acepta responsabilidad por la seguridad y el buen funcionamiento de la automatización en caso de utilización de componentes no producidos por

SEA.

10. Para el mantenimiento utilizar únicamente piezas originales SEAS.p.A..

11. No modificar los componentes del sistema automatizado.

12. El instalador debe proporcionar toda la información relativa al funcionamiento manual del sistema en caso de emergencia y darle al usuario el folleto de adjunto

al producto.

13. No permita que niños o adultos permanecen cerca del producto durante la la operación. La aplicación no puede ser utilizada por niños, personas con movilidad

reducida de tipo fìsico, mental, sensorial o igual por personas sin experiencia o formación necesaria. Tener los radiomandos fuera del alcance de niños asì como

cualquier otro generador de impulsos radio para evitar que el automación pueda ser accionada accidentalmente.

14. El tránsito a través de las hojas sólo se permite cuando la puerta está completamente abierta.

15. Todo el mantenimiento, reparación o controles deberán ser realizados por personal cualificado. Evitar cualquier intente a reparar o ajustar. En caso de necesitad

comunicarse con un personal SEAcalificado. Sólo se puede realizar la operación manual.

2

16. La longitud máxima de los cables de alimentación entre motor y central no debe ser superior a 10 metros. Utilizar cables con 2,5 mm . Utilizar cables con doble

aislamiento (cables con váina) hasta muy cerca de los bornes, especialmente por el cable de alimentación (230V).Además es necesario mantener adecuadamente

distanciados (por lo menos 2,5 mm en aire) los conductores de baja tensión (230V) y los conductores de baja tensión de seguridad (SELV) o utilizar una váina

adecuada que proporcione aislamiento adicional con un espesor mínimo de 1 mm.

ALLGEMEINE HINWEISE FUER DEN INSTALLATEUR UND DEN NUTZER

1.Lesen Sie die Installierungsanweisungen sorgfältig durch bevor Sie mit der Installierung beginnen.Diese Anweisungen an einem leicht zugänglichen Ort

aufbewahren.

2.Verpackungsmaterial des Produkts und/oder der Schaltkreise umweltgerecht entsorgen.

3. Dieses Produkt wurde speziell und ausschließlich für den, in den Unterlagen beschriebenen Zweck, geplant und hergestellt. Jede andere Verwendung, die nicht

ausdrücklich angegeben wurde kann die Integrität des Produkts schädigen und/oder eine Gefahrenquelle darstellen. Die nicht fachgerechte Nutzung des Produkts

bewirkt die Erlöschung der Garantie. SEAS.p.A. lehnt jegliche Haftung, für unsachgemäße oder andere Nutzung, als die wofür das Produkt bestimmt ist, ab.

4. SEA Produkte entsprechen den folgenden Richtlinien: Maschinenrichtlinie (2006/42/EG und nachträglich geänderten Fassungen), Niederspannungs-Richtlinie

(2006/95/EG und nachträglich geänderten Fassungen), EMV (2004/108/EG und nachträglich geänderten Fassungen). Installation gemäß Standard EN12453 und

EN12445 durchführen.

5. Installieren Sie das Gerät nicht in explosionsgefährdeten Umgebungen, das Vorhandensein von brennbaren Gasen oder Dämpfen stellt ein ernstes

Sicherheitsrisiko dar.

6. SEA S.p.A. ist nicht für die Nichtbeachtung der Guten Technik bei der Herstellung von zu motorisierenden Toren und für deren eventuellen Verformungen, die

während des Gebrauchs auftreten könnten, haftbar.

7. Vor allen Eingriffen, das Gerät ausschalten und die Batterien trennen. Sicherstellen, dass die Erdung fachgerecht hergestellt wurde und die Metallteile des Tores

daran anschließen.

8. Für jedeAnlage wird empfohlen, mindestens ein Blinklicht zu montieren und ein Warnschild auf derTorstruktur anzubringen.

9. SEAS.p.A. übernimmt keine Haftung für Sicherheit und reibungslosen Betrieb desAntriebs, bei Verwendung von Komponenten, die nicht von der SEA Produktion

stammen.

10. Für die Wartung nur SEAOriginalteile verwenden.

11. Keinerlei Änderungen auf Komponenten derAutomation vornehmen.

12. Der Installateur muss den Nutzer des Antriebs über den manuellen Betrieb des Systems im Notfall unterrichten und ihm, das, dem Produkt beiliegende,

Handbuch übergeben.

13. Der Aufenthalt von Kindern oder Erwachsenen in der Nähe des Tores während seines Betriebes ist nicht gestattet. Die Anlage darf nicht von Kindern,

Personen mit eingeschränkten körperlichen, geistigen oder sensorischen Fähigkeiten oder von Menschen ohne notewendige Erfahrung oderAnweisungen benutzt

werden. Fernbedienungen oder andere Impulsgeber außerhalb der Reichweite von Kindern halten, um die versehentlicheAktivierung derAnlage zu verhindern.

14. Die Durchfahrt zwischen den Flügeln ist nur bei vollständig geöffnetem Tor zulässig.

15. Sämtliche Wartungs-und Reparaturarbeiten oder periodische Kontrollen, müssen von qualifiziertem Fachpersonal durchgeführt werden. Der Endverbraucher

muss davon absehen eigenständig Reparaturen oder Eingriffe jeder Art an der Anlage durzuführen und muss sich aussschliesslich an qualifiziertes SEA

Fachersonal wenden. Der Endverbraucher darf nur die manuelle Notfunktion durchführen.

2

16. Die maximale Länge der Stromkabel zwischen Steuerung und Motoren ist 10 Meter. Verwenden Sie Kabel mit 2,5 mm Querschnitt und Doppelisolierung

(Kabelmantel) in der unmittelbaren Nähe von Klemmen, insbesondere für das Speisungskabel (230V). Die Speisungskabel (230V) und die Sicherheits-

Niederspannugnskabel (SELV) müssen in einem Abstand von mindestens 2,5 mm gehalten werden, oder eine geeignete Hülse von 1mm Dicke , für eine

zusätzliche Isolierung verwenden..

Español

Deutsch

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

67411740 49

REV 01 - 03/2015

Questo articolo è stato prodotto seguendo rigide procedure

di lavorazione ed è stato testato singolarmente al fine di

garantire i più alti livelli qualitativi e la vostra soddisfazione.

Vi ringraziamo per aver scelto SEA.

This item has been produced following strict production

procedures and has been singularly tested for the highest

quality levels and for your complete satisfaction.

Thanks for choosing SEA.

Este articulo ha sido producido siguiendo rigidos

procedimientos de elaboracion y ha sido probando

singolarmente a fin de garantizar los mas altos inveles de

calidad y vuestra satisfaccion.

Le agradecemos por haber escogito SEA.

Cet article a été produit suivant des procédures d'usinage

strictes et il a singulièrement été testé afin de garantir

les plus hauts niveaux de qualité pour votre satisfaction.

Nous vous remercions d'avoir choisi SEA.

CERTIFICATO DI ESTENSIONE GARANZIA

CERTIFICATE OF WARRANTY EXTENTION

PRODOTTO/ PRODUCT

- Modello/Model____________________________________________________

- Matricola n. /Serial Number_________________________________________

- Data di acquisto/Date of order________________________________________

- Data di installazione/Date of installation_______________________________

Centrale/Control unit

Fotocellule/Photocells

RX - TX

Altri accessori /Other accessories

SEA

SEA

SEA

SEA

Altri/Others

Altri/Others

Altri/Others

Altri/Others

UTENTE/Customer

Nome e Cognome_____________________________________________________

First Name and Family Name _________________________________________

Indirizzo/Address_____________________________________________________

___________________________________________________________________

INSTALLATORE/Installer

Ragione sociale/Company Name ________________________________________

Nome e Cognome/First and Family Name_________________________________

Indirizzo/Address ____________________________________________________

INSTALLATORE/INSTALLER

Firma per il trattamento dei dati personali 196/2003

Agreement of law No. 196/2003 (Privacy Code)

Firma e Timbro

Sign and Stamp ___________________________

Copia da restituire

Copy to be returned

N.B: L’estensione della garanzia legale di 12 mesi a 24 mesi e 36 mesi è va-

lida solo se il presente modulo viene rispedito per posta o fax a SEA

S.p.A. entro 15gg dalla data di acquisto. Allegare relativa fattura d’acquisto.

- - - - - - - - - - -

S.p.A

Note: The extension of the legal standard warranty of 12 months to 24 months

and to 36 months, is valid only if the present form is returned by mail or fax to

SEA within 15days from the date of purchase. Attach customer invoice.

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

SEA S.p.A. - Zona Industriale San Atto- 64020 Teramo (Italy)

Phone +39 0861 588341- Fax +39 0861588344

n.

C

C

SEA S.p.A.

Zona industriale 64020 S.ATTO Teramo - (ITALY)

Tel. 0861 588341 r.a. Fax 0861 588344

www.seateam.com

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Other manuals for LYRA

1

This manual suits for next models

3

Table of contents

Other SEA Gate Opener manuals

SEA

SEA Cougar 270 User manual

SEA

SEA FIELD Series User manual

SEA

SEA LEPUS Series User manual

SEA

SEA ALPHA 200 PLUS User manual

SEA

SEA 1110 User manual

SEA

SEA SATURN User manual

SEA

SEA GATE 2 DG INVERTER User manual

SEA

SEA SURF 350 Reversible User manual

SEA

SEA Libra Mini Tank User manual

SEA

SEA FLIPPER User manual

Popular Gate Opener manuals by other brands

Amazing Gates

Amazing Gates AG900HD installation manual

Nice

Nice ROX Series Instructions and warnings for installation and use

BFT

BFT SP4000 Installation and user manual

Beninca

Beninca BILL 50M manual

Platinum Access Systems

Platinum Access Systems BLSW1016-B Installation instructions & owner's manual

quiko

quiko NEO Series user manual