SEA SEAGEAR 1180MEC0 Original instructions

Table of contents

Other SEA Gate Opener manuals

SEA

SEA SURF 350 Reversible User manual

SEA

SEA LIBRA Series Original instructions

SEA

SEA 1110 User manual

SEA

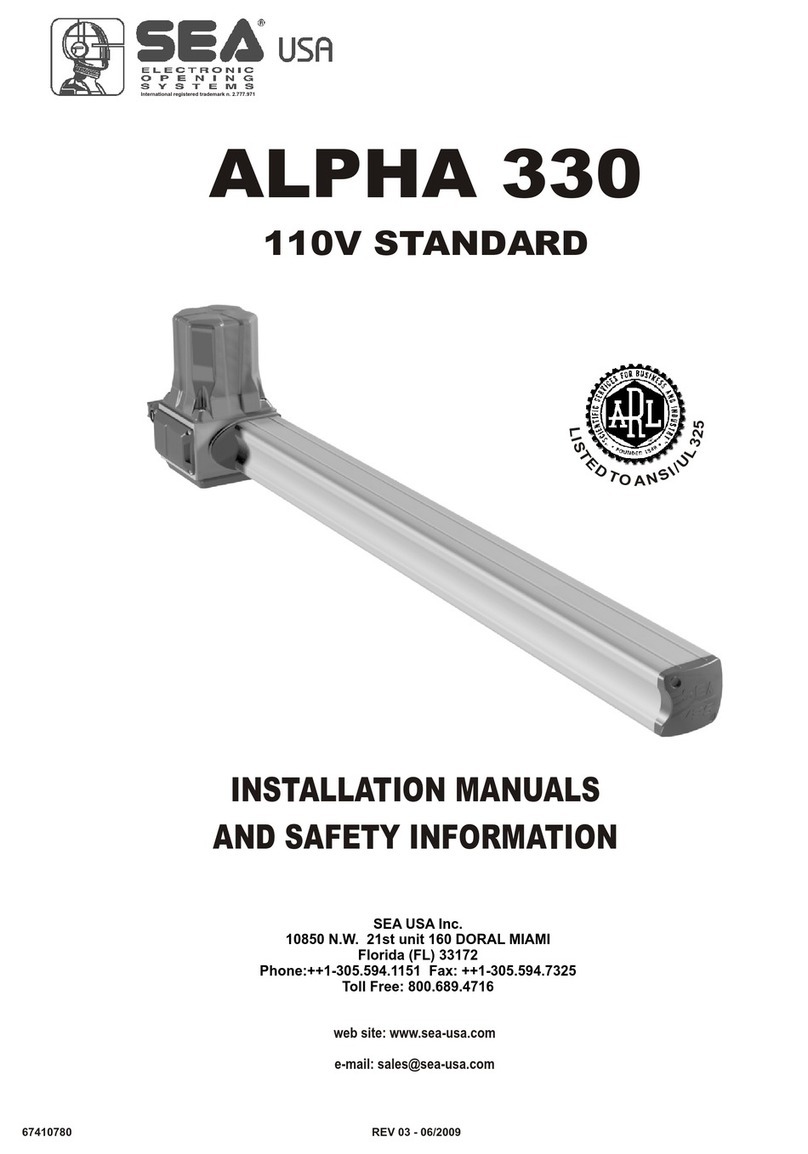

SEA ALPHA 330 STANDARD Original instructions

SEA

SEA full tank User manual

SEA

SEA KITE User manual

SEA

SEA SURF 350 Reversible User manual

SEA

SEA TAURUS BOX 1000 User manual

SEA

SEA SURF K 500 User manual

SEA

SEA SUPER FULL TANK Series Original instructions

SEA

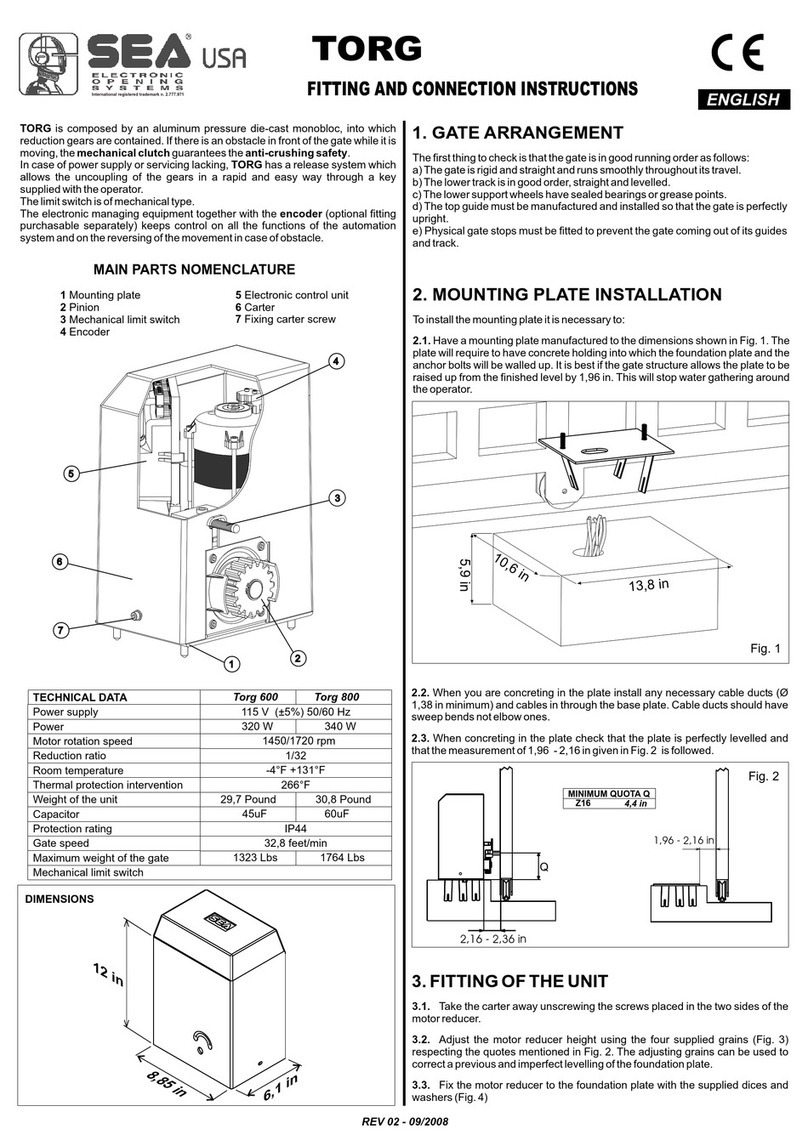

SEA TORG Series Instruction manual

SEA

SEA LEPUS BOX 120V/24V User manual

SEA

SEA SATURN User manual

SEA

SEA HALF TANK User manual

SEA

SEA SURF Series User manual

SEA

SEA LEPUS 800 Instruction manual

SEA

SEA saturn-boxer 2000 User manual

SEA

SEA Boxer 1000 User manual

SEA

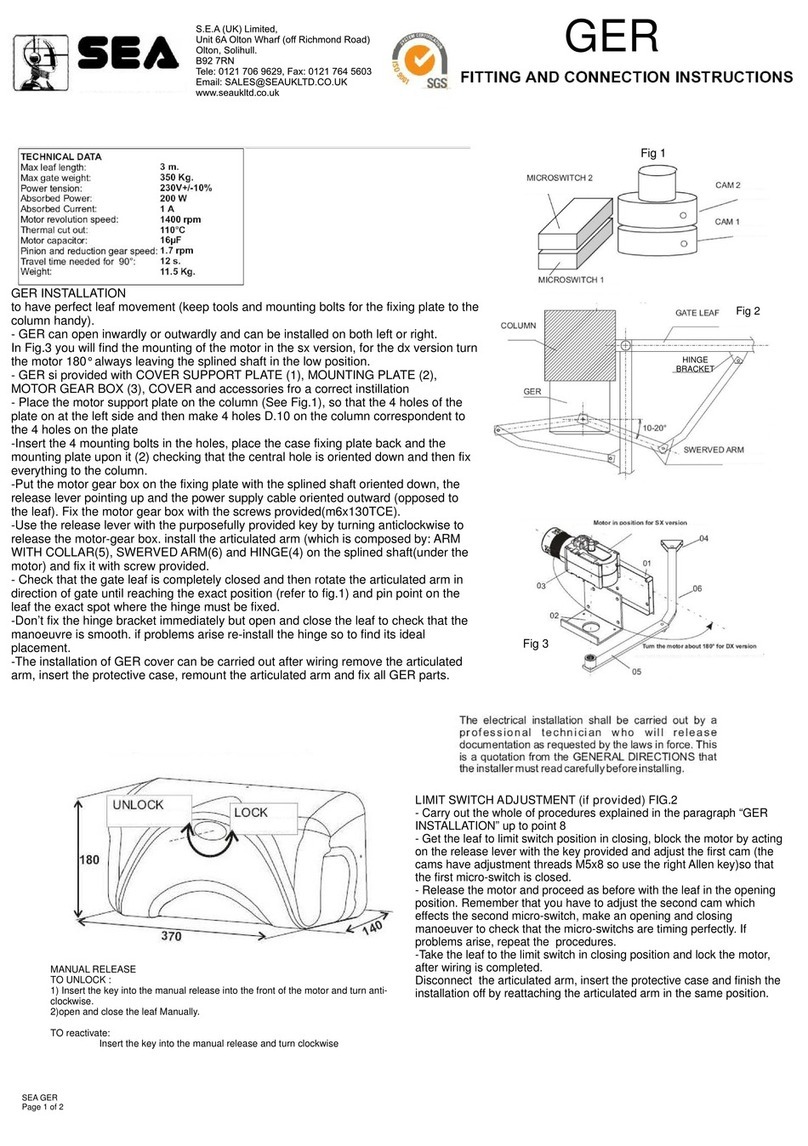

SEA GER Instruction manual

SEA

SEA SUPER FULL TANK 20 G6 380V User manual

Popular Gate Opener manuals by other brands

Riello Elettronica

Riello Elettronica CARDIN ACE FAST Instruction handbook

MFZ Ovitor

MFZ Ovitor E6L user manual

FAAC

FAAC 820 installation manual

Maximum Controls

Maximum Controls Max Megatron 1400 Installation and owner's manual

Schartec

Schartec P190 Control Box user manual

Nice

Nice ROBUS350 Instructions and warnings for the fitter

Telcoma

Telcoma ACE 300 Instruction handbook

PNI

PNI MAB300 user manual

Nice

Nice Wingo 5024 Kit Instructions and warnings for installation and use

McConnel

McConnel 3 Wheel Backing Gate Drive owner's manual

Chamberlain

Chamberlain CPS-OPEN4 quick start guide

Chamberlain

Chamberlain THE ROBO SLIDE instruction manual

Avidsen

Avidsen Styrka 310 manual

Dea

Dea Ghost 100 Series Operating instructions and warnings

Elvox

Elvox ES Series instruction manual

Maximum Controls

Maximum Controls MAX F18 Installation and owner's manual

Relcross Door Controls

Relcross Door Controls 9130 installation instructions

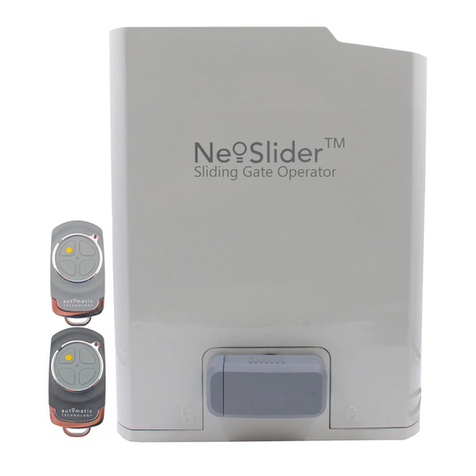

Automatic Technology

Automatic Technology NeoSlider NES-500 manual