PARTS FOR:

HVLP SPRAY GUN

Model: HVLP-79

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used

according to these instructions and properly maintained, give you years of trouble free performance.

INSTRUCTIONS FOR:

HVLP SPRAY GUN

Model: HVLP-79

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL

INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

3Familiarise yourself with the application, limitations and potential hazards peculiar to the spray gun.

pWARNING! Disconnect the spray gun from the air supply before changing accessories, servicing or

performing any maintenance.

3Maintain the spray gun in good condition (use an authorised service agent).

3Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous

and will invalidate the warranty.

3Keep the spray gun clean for best and safest performance.

3Ensure that the compressed air system can supply the spray gun air consumption (550l/min - 19.4cfm).

3Wear approved safety respiratory protection and safety eye goggles.

3If spraying isocyanate based finisher, wear approved respirator/clean air breathing apparatus and cover

exposed skin with latex gloves and an impervious hooded coverall.

3Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and tie back long hair.

3Locate the spray gun in a suitable work area. Keep area clean and tidy and free from unrelated materials

and ensure that there is adequate ventilation and lighting.

3Keep children and unauthorised persons away from the work area.

3When not in use, ensure that the air supply is turned off.

3Avoid unintentional operation of spray gun.

7DO NOT point spray gun at yourself, other persons or animals.

7DO NOT direct air from the air hose at yourself, other persons or animals.

7DO NOT carry the spray gun by the hose, or yank the hose from the air supply.

7DO NOT exceed the maximum air pressure of 75psi.

7DO NOT use the spray gun for any purpose other than that for which it is designed.

7DO NOT allow untrained persons to operate the spray gun.

7DO NOT get the spray gun wet or use in damp or wet locations or in areas where there is condensation.

7DO NOT operate the spray gun if any parts are missing or damaged as this may cause failure and/or

personal injury.

2. DESCRIPTION & SPECIFICATIONS

HVLP-79 - 1 - 200802

01284 757500

E-mail: sales@sealey.co.uk

Web: www.sealey.co.uk

01284 703534

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No responsibility is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your name and address, including postcode.

Item Part No. Description

1HVLP79.01 Retaining ring - available only

in Set 08, 10 or 14

2HVLP79.02 Air cap - available only in Set

08, 10 or 14

3HVLP79.03 Fluid nozzle and gasket

(includes item 4) - available

only in Set 08, 10 or 14

4HVLP79.04 Gasket - available only in Set

08, 10 or 14

5HVLP79.05 Lock screw

6HVLP79.06 Dowel pin

7HVLP79.07 Baffle

8HVLP79.08 Lock nut

9HVLP79.09 Fluid connector

10 HVLP79.10 Screw

11 HVLP79.11 Trigger

12 HVLP79.12 Stud

13 HVLP79.13 Gasket

14 HVLP79.14 Bushing

15 HVLP79.15 Fluid Needle (available only in

Set 08, 10 or 14)

16 HVLP79.16 Spring

17 HVLP79.17 Adjusting screw

18 HVLP79.18 Side port control assembly -

contains items 19, 20, 21 & 22

19 HVLP79.19 Retaining ring

20 HVLP79.20 Bushing

21 HVLP79.21 O-Ring

22 HVLP79.22 Side port stem assembly

23 HVLP79.23 Air valve assembly - contains

items 24, 25, 26, 27, 28, 29 & 30

24 HVLP79.24 Snap ring

Item Part No. Description

25 HVLP79.25 Washer

26 HVLP79.26 "U" Cup seal

27 HVLP79.27 Air valve bushing

28 HVLP79.28 Air valve

29 HVLP79.29 Spring

30 HVLP79.30 Gasket

31 HVLP79.31 Air pressure elbow

32 HVLP79.32 Steel ball

33 HVLP79.33 Spring

34 HVLP79.34 O-Ring

35 HVLP79.35 Air pressure plug

36 HVLP79.36 Packing

37 HVLP79.37 Packing screw

38 HVLP79.38 Gun body

39 HVLP79.39 Nipple

40 HVLP79.40 Air supply tube (Available only with item 51)

41 HVLP79.41 Fluid tube (Available only with item 51)

42 HVLP79.42 Yoke (Available only with item 51)

43 HVLP79.43 Cam (Available only with item 51)

44 HVLP79.44 Lid (Available only with item 51)

45 HVLP79.45 No-drip elbow assembly (Available only with item 51)

46 HVLP79.46 No-drip tube

47 HVLP79.47 Gasket

48 HVLP79.48 Locking washer

49 HVLP79.49 Nut

50 HVLP79.50 Cup

51 HVLP79.51 Lid assembly, contains items 40, 41, 42, 43, 44, 45 &52

52 HVLP79.52 Adapter (Available only with item 51)

HVLP79.Set.08 Set up, 0.8mm, contains items 1, 2, 3 & 15

HVLP79.Set.10 Set up, 1.0mm, contains items 1, 2, 3 & 15

HVLP79.Set.14 Set up, 1.4mm, contains items 1, 2, 3 & 15

Issue No: 1

Date Issued: 200802

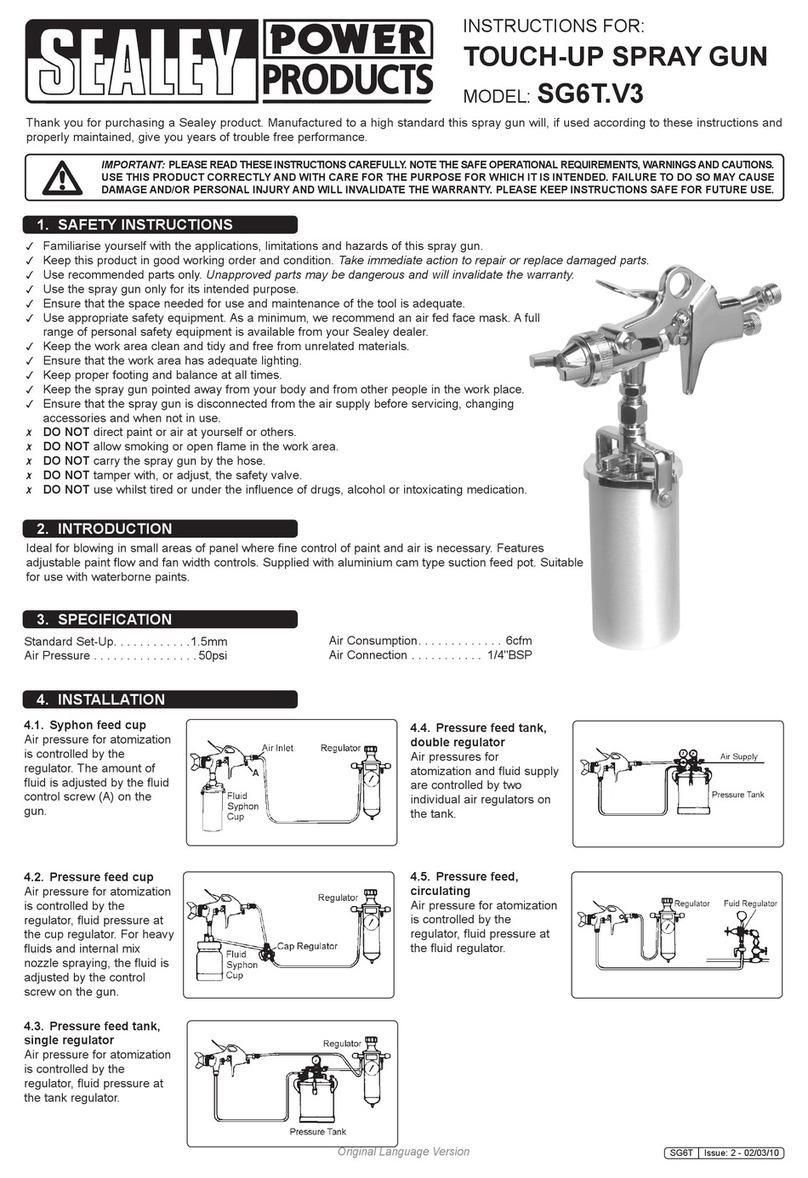

The HVLP spray gun has an anodised body which resists corrosion and has a low affinity for paint, making this

unit easy to clean. The gun also has adjustable paint and fan width controls. HVLP (High Volume, Low Pressure)

uses lower air pressure but at a far higher throughput. The result of this is that very much more of the paint stays

on the panel and less disappears into the atmosphere. Suitable for heavy commercial use and particularly suitable

for applying commercial vehicle primers. Well balanced gun with positive pressure suction pot for smooth material

flow. Supplied with 1.0mm set-up. 0.8 and 1.4 set-ups available separately.

SPECIFICATIONS

Standard set-up . . . . . . . . . . . . . . . . . . . . .1.0mm

Available set-ups . . . . . . . . . . . . . . . . .0.8, 1.4mm

Working pressure range .50 - 75psi (3.5 - 5.0 bar)

Max. safe pressure . . . . . . . . . . . . . .75psi (4 bar)

Air consumption . . . . . . . . . . . . . . . . . . . . .19cfm