Note: Maintenance and repair must only be carried out by qualified person. Contact your Sealey dealer for details.

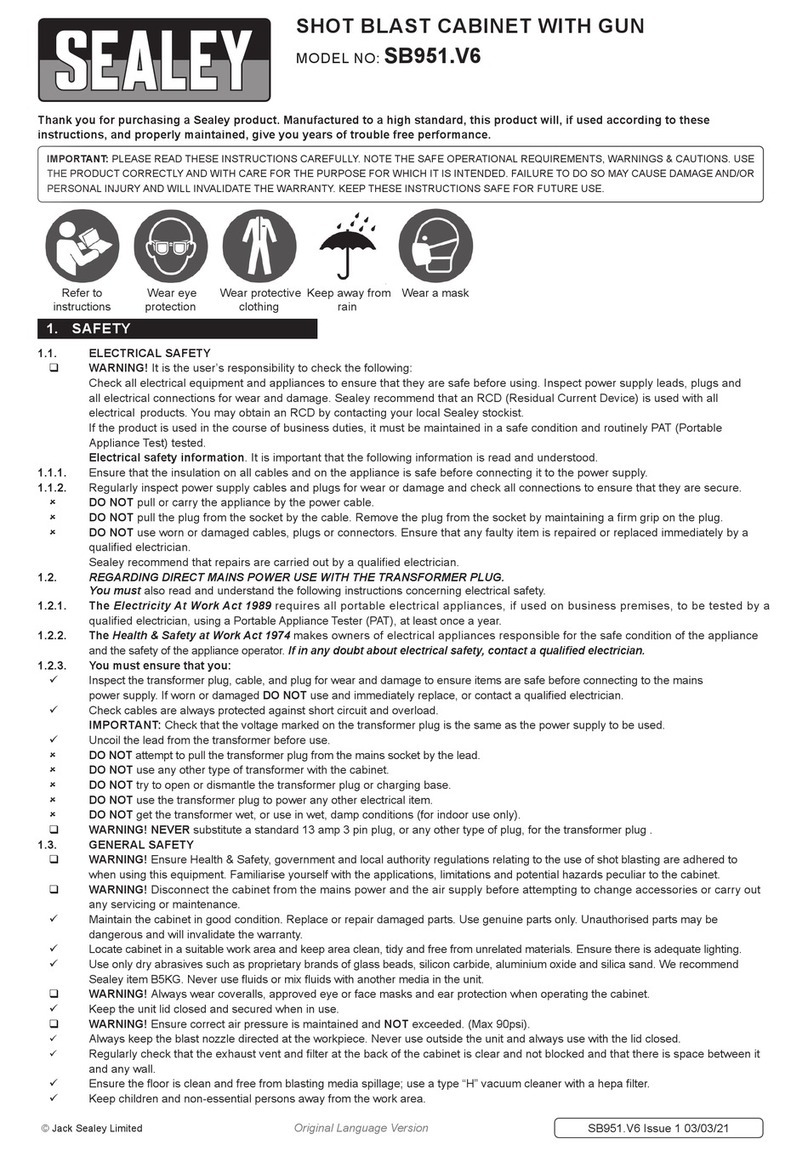

5.1. Periodically lubricate all joints and moving parts.

5.2. Always keep the press clean, dry, and protected from harsh conditions.

5.3. To check hydraulic oil level remove the oil filler nut (34) from the pump. If it needs filling, use only Sealey hydraulic jack oil.

(DO NOT use brake fluid. Contact your local Sealey dealer for details). Replace oil filler nut and purge system of air (see 4.1.2.).

5.4. When replacing the hydraulic oil, ensure the piston is fully retracted.

5.5. If press efficiency begins to drop, purge the system to eliminate any air from the hydraulic system (see 4.1.2.).

5.6. When not in use, store the press in a dry, childproof location with the ram and piston fully retracted.

5. MAINTENANCE

Declaration of Conformity We, the sole importer into the UK, declare that the product listed below is in conformity with the following

standards and directives.

20 Ton Hydraulic Floor Press

Model: YK20F

98/37/EC Machinery Directive

93/68/EEC CE Marking Directive

4. INSTALLATION & OPERATING

4.1. INSTALLATION.

4.1.1. Securely attach the press to a flat, firm, level surface taking into account clearance for workpieces.

4.1.2. Before operating the press, purge the hydraulic system in order to eliminate any air that may have built up during transit. Open the

release valve by turning it anti-clockwise and pump the handle several times to eliminate any air in the system, then close release

valve. Note: Should the system malfunction at any time, repeating this process may resolve the problem.

!

! DANGER! Models are purpose designed to withstand greater loads than the hydraulic units can develop. For safety reasons, always

ensure the workpiece and press tools are secured on the table and will not flex or suddenly “give way” causing danger to operator or the

component. Also ensure you have read and understood Section 1 safety instructions.

4.2. OPERATING INSTRUCTIONS.

4.2.1. Position the working table at the required operating height by inserting the support pins into the appropriate holes in the main frame.

4.2.2. Place the arbor plate (17) on press bed frame (18), then place workpiece onto the arbor plate and align beneath the ram as required.

Note: care must be taken to ensure an arbor does not fall from the press work table. If necessary hold the configuration in position with

clamps.

4.2.3. Close the release valve by turning it clockwise until it is firmly closed.

4.2.4. Pump the handle slowly until the ram is close to, or just touching, the workpiece. Before applying any pressure to the workpiece, recheck

the alignment with the ram and ensure that the workpiece and press tools are supported in such a way that they cannot flex.

4.2.5. Pump the handle to apply load onto workpiece.

4.2.6. When work is done, stop pumping the handle. Slowly and carefully free load from workpiece by turning the release valve

anti-clockwise in small increments.

Note: Always keep the piston retracted after use to avoid ram corrosion.

4.2.7. Once ram has fully retracted, remove workpiece from bed frame.

YK20F.- 1 - 060706

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE OF THE MACHINE.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

DO NOT RETURN PRODUCT TO US. Please telephone us on 01284 757500 to obtain the address and phone number of your local agent.

If product is under guarantee please contact your dealer.

De-commissioning Product

Should the product become completely unserviceable and require disposal, draw off the hydraulic oil into an approved container and dispose

of the product and the hydraulic oil according to local regulations.

The construction file for this product is held by the Manufacturer and may be

inspected, by a national authority upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Quality Machinery

6th July 2006

Signed by Mark Sweetman.

3.6. Join the two press bed frames (18) together by inserting the four bolts (27) through the bushings (28) and the holes in the bed

frames, then secure the four bolts with the washers (14), lock washers (15) and nuts (16).

3.7. Insert bed frame pins (19) into the holes in the posts, then insert the joined press bed frames (18) into press frame and lower onto

bed frame pins (19).

3.8. Attach the setting plate (31) to the right post, using bolts (25), washers (22), lock washers (23) and nuts (24), then secure the

pump assemblies using the screws (29) and washers (30), insert the handle in the handle bracket.

3.9. Connect the hydraulic hose fitting (36) to the connection nut (37) and fit the pressure gauge (1) to the pressure gauge connection nut

(38) which is on the top of ram (3).

3.10. Tighten all nuts, bolts and screws.

01284 757500

01284 703534 sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

www.sealey.co.uk

Web

email

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.