Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

INSTRUCTIONS FOR:

PETROL PRESSURE WASHER

MODEL No:PCM2500SP.V2

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

GENERAL SAFETY

WARNING! RISK OF FLUID INJECTION. This washer operates at fluid pressures and velocities high enough to penetrate human

and animal flesh. If there is an occurrence of fluid injection seek medical help immediately.

WARNING! Stop the engine and disconnect the mains water supply before changing accessories or performing any maintenance.

WARNING! DO NOT operate the washer if damaged. Replace or repair using recommended parts only. Unauthorised parts may

be dangerous and will invalidate your warranty. Use authorised Service agent only.

Keep the washer in good condition. Regular maintenance will give the best and safest performance.

Ensure you comply with the water supply company regulations before connecting to the mains. If you are connecting to the mains drinking

water supply ensure you have a back flow preventer valve installed.

The water supply hose must be reinforced and have an internal diameter of 13mm (1/2”). The minimum water supply rate must be at least

equal to the cleaner capacity. The water temperers must not exceed 60oC, and the pressure must not exceed 10bar.

WARNING! DO NOT operate the washer without the water supply connected. To do so will damage the machine.

Position the washer as near as possible to the water supply.

Only use recommended washing detergents. Failure to do so may cause corrosion to equipment and hoses.

WARNING! Use the washer on a flat, level surface, in a horizontal position. Failure to do so will invalidate your warranty.

Wear safety goggles and adequate protective clothing, and anti-slip rubber soled footwear.

WARNING! The high pressure jet must be used with caution. Ensure you aim the lance correctly at the work surface. Failure to do so may

scatter loose particles at the same force as the water pressure, resulting in possible damage or personal injury.

Keep all persons and animals at a safe distance from the hose working area. It is difficult to give an exact safe distance as it will depend upon your

circumstances. We recommend at least 15 metres. Also ensure other persons are aware before you start to depress the washer trigger.

Hold the gun firmly with both hands as it will tend to “kick” backwards when you first pull the trigger.

DO NOT allow children or untrained persons to operate the washer.

DO NOT connect other appliances to the washer inlet or outlet. Only use the supplied or recommended outlet nozzle.

DO NOT use the washer if the water supply hose is damaged. Also check that the hose is laid out straight and safely.

DO NOT jam the operating trigger in the operating position and DO NOT pull the trigger without holding and aiming the gun correctly.

WARNING! DO NOT attempt to alter the pressure regulating valve as this may cause serious damage.

DO NOT move the washer by pulling on the high pressure hose or the mains water supply hose. Use the machine handle.

DO NOT direct jet against yourself, other persons or animals, electrical equipment or the machine itself.

WARNING! DO NOT leave the engine running for more than 2 minutes without operating the trigger, as temperature/pressure increase

may damage the sealing system.

DO NOT use the washer if you are tired or under the influence of alcohol, drugs or intoxicating medication.

Ensure that the hose pressure is discharged before disconnecting the mains water hose.

When not in use, disconnect from the water supply. Clean and dry the washer and store in a safe, dry, childproof area.

DO NOT allow the machine to become frozen.

ENGINE SAFETY

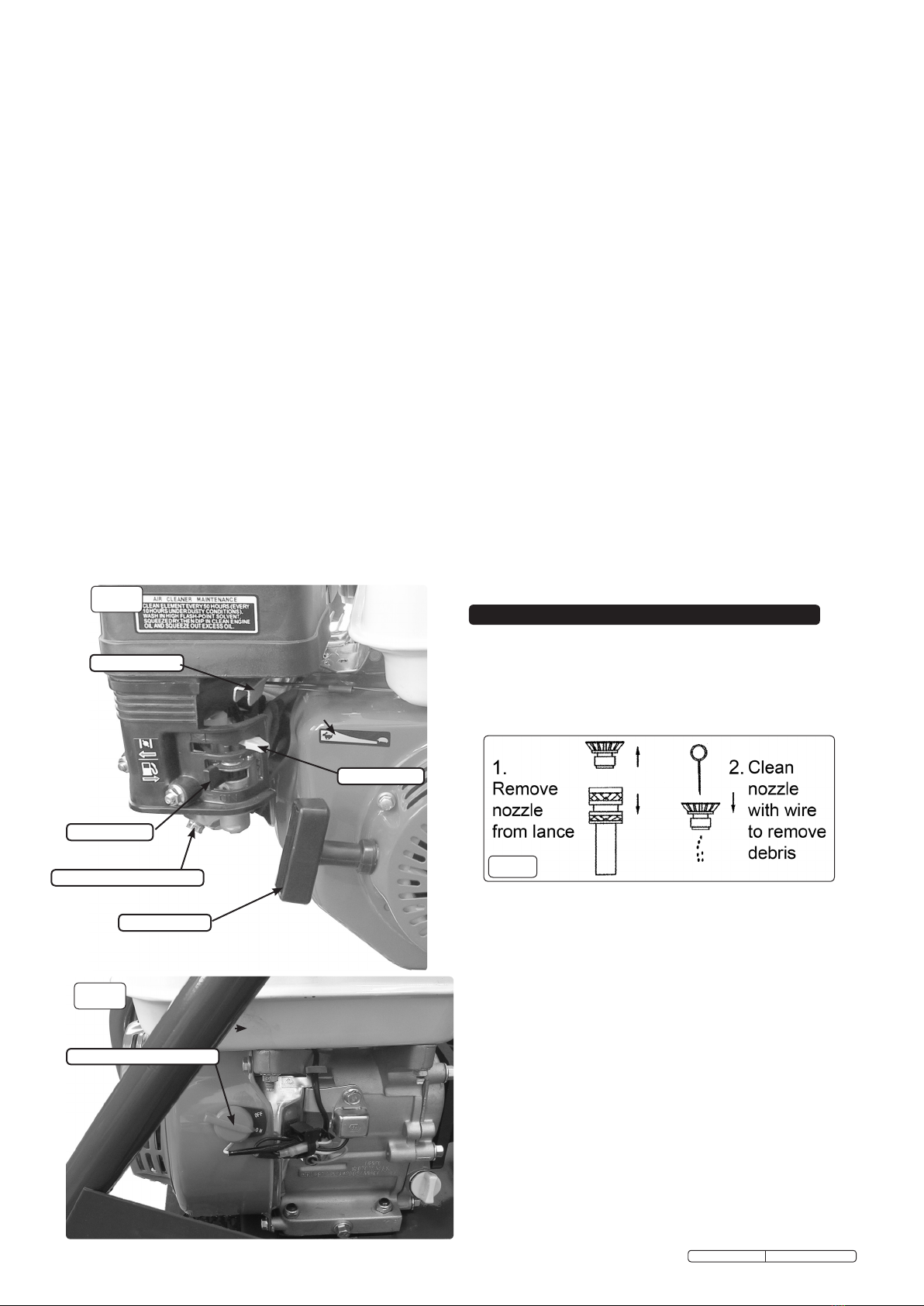

WARNING! Check the engine oil level before each startup. Only use a specified oil and never operate the engine with insufficient oil.

DO NOT operate the washer in an enclosed area as the motor exhaust fumes are a health hazard.

DO NOT use the washer with flammable, toxic or corrosive liquids.

DO NOT leave the washer unattended whilst operating and DO NOT remove the fuel cap whilst the engine is running.

DO NOT refuel the engine whilst it is running. Stop the engine and allow it to cool for two minutes before attempting to refuel.

DO NOT refuel in a closed or poorly ventilated environment as there is a danger of explosion or fire. Refuel out doors.

DO NOT smoke or place the washer near any naked flames whilst re-fuelling.

DO NOT operate washer if there is a fuel leak. Move the unit and avoid any combustion until the leak has been fixed and the machine is dry.

DO NOT start the engine if there are any flammable materials near the exhaust system or in the path of the exhaust gases.

DO NOT block the engine ventilation grilles.

Ensure engine fuel is stored in an approved container.

For long term storage ensure the fuel is drained and that the washer is adequately protected against frost.

DO NOT operate the engine with either the silencer or air filter removed.

DO NOT touch the engine during or after use. To avoid burns allow it to cool before handling.

WARNING: The warnings, cautions and instructions discussed in this manual cannot cover all possible conditions and situations that may

occur. It must be understood that common sense and caution are factors which cannot be built into this product, but must be applied by

the operator

2. SPECIFICATION & INTRODUCTION

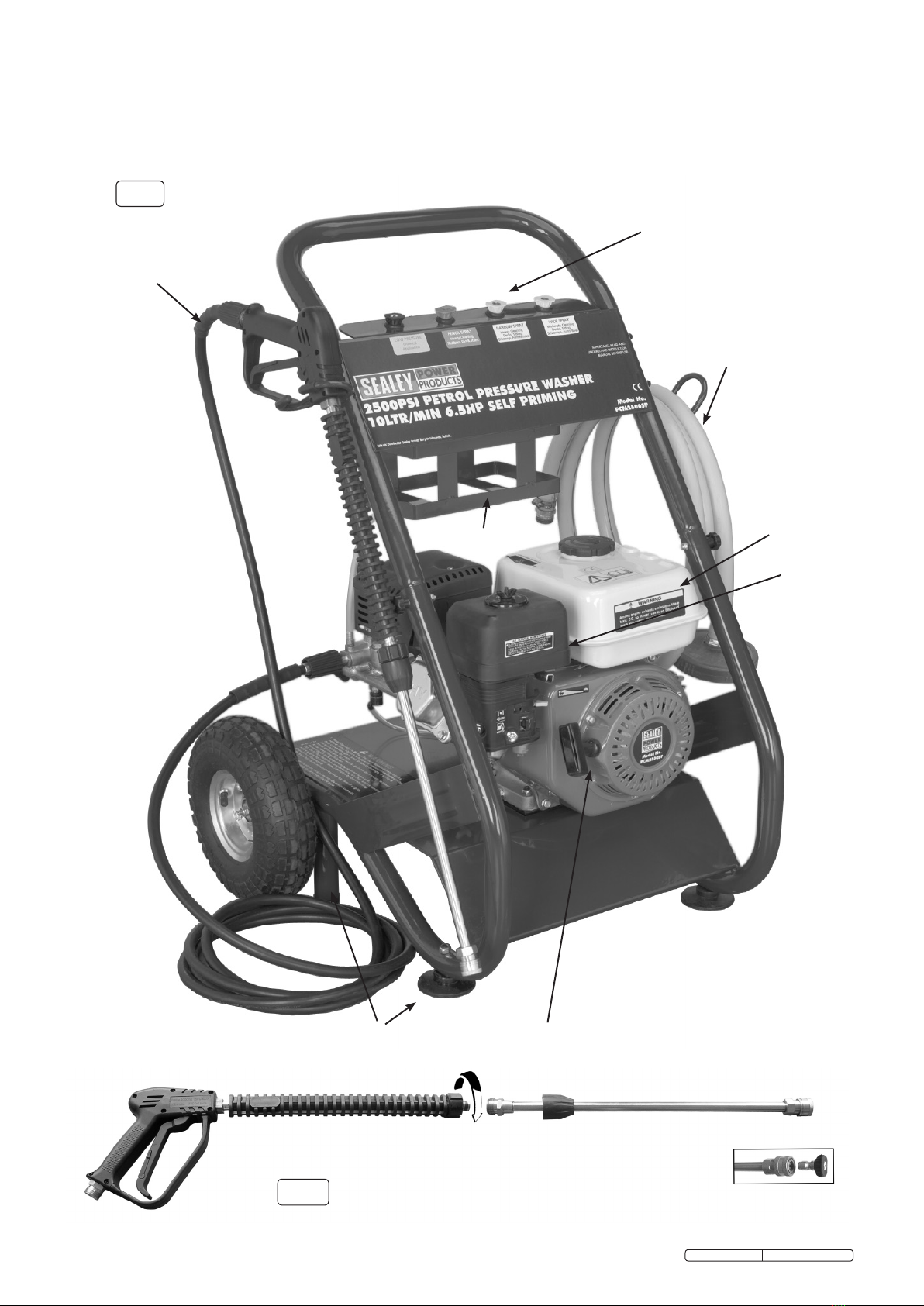

Output Pressure/Flow:....................... 2500psi/600ltr/hr

Hose Length: .......................................5.0mtr

Nozzles:....Low Pressure, Wide Angle, High Pressure, 0°, 15°, 40°

Maximum Inlet Temperature:............................60°C

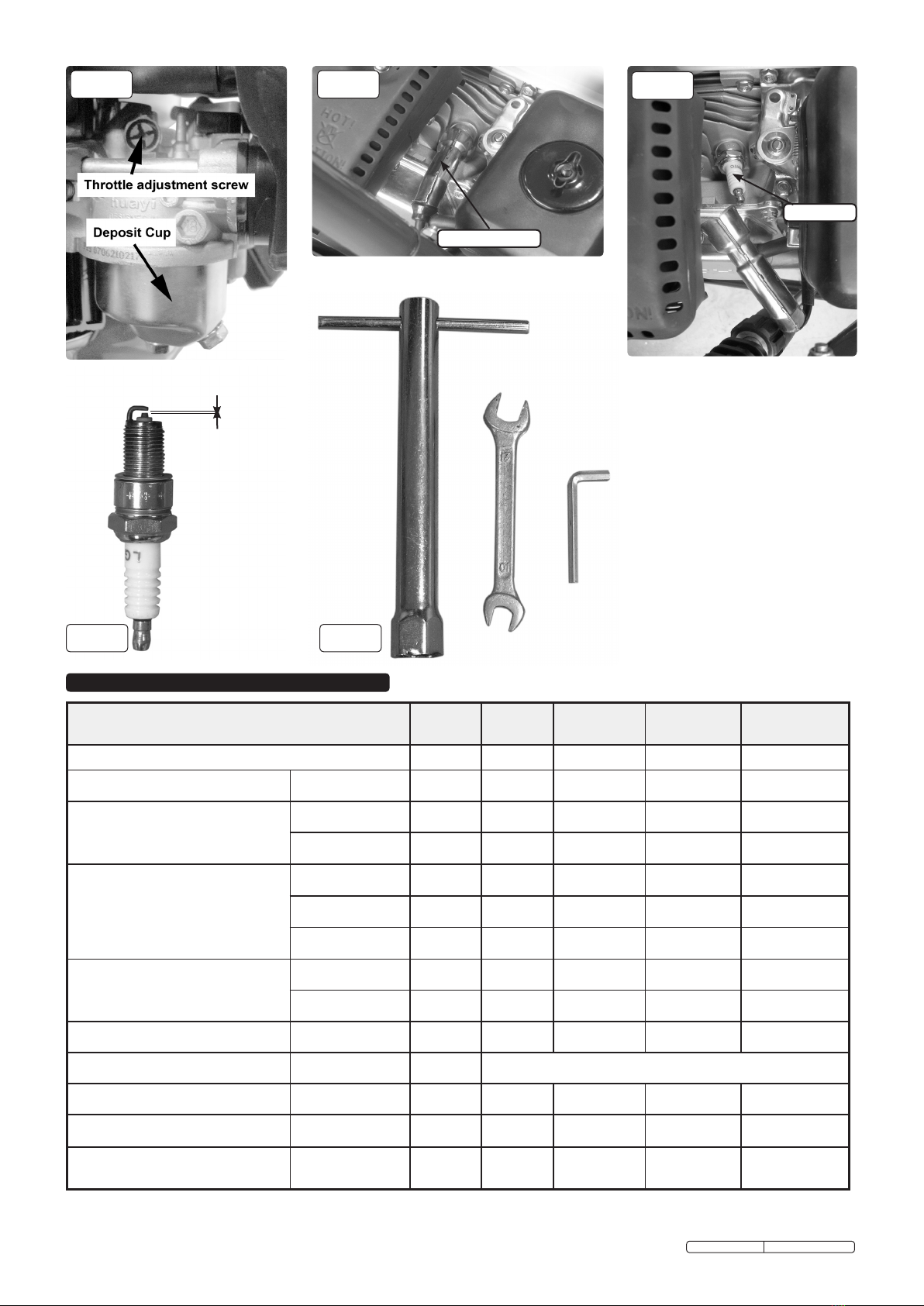

Engine Type: ...................4 Stroke, single cylinder, Petrol

Engine Capacity: ....................................196cc

Engine Power ......................4.8kW(6.5hp) @ 3600rpm

Starting: ...........................................Recoil

Weight: ............................................46kg

FuelTank:......................................... .3.6ltr

Fuel:. . . ....................Unleaded Petrol 85 RON minimum

Fuel Consumption: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.1 - 2.6ltr/hr

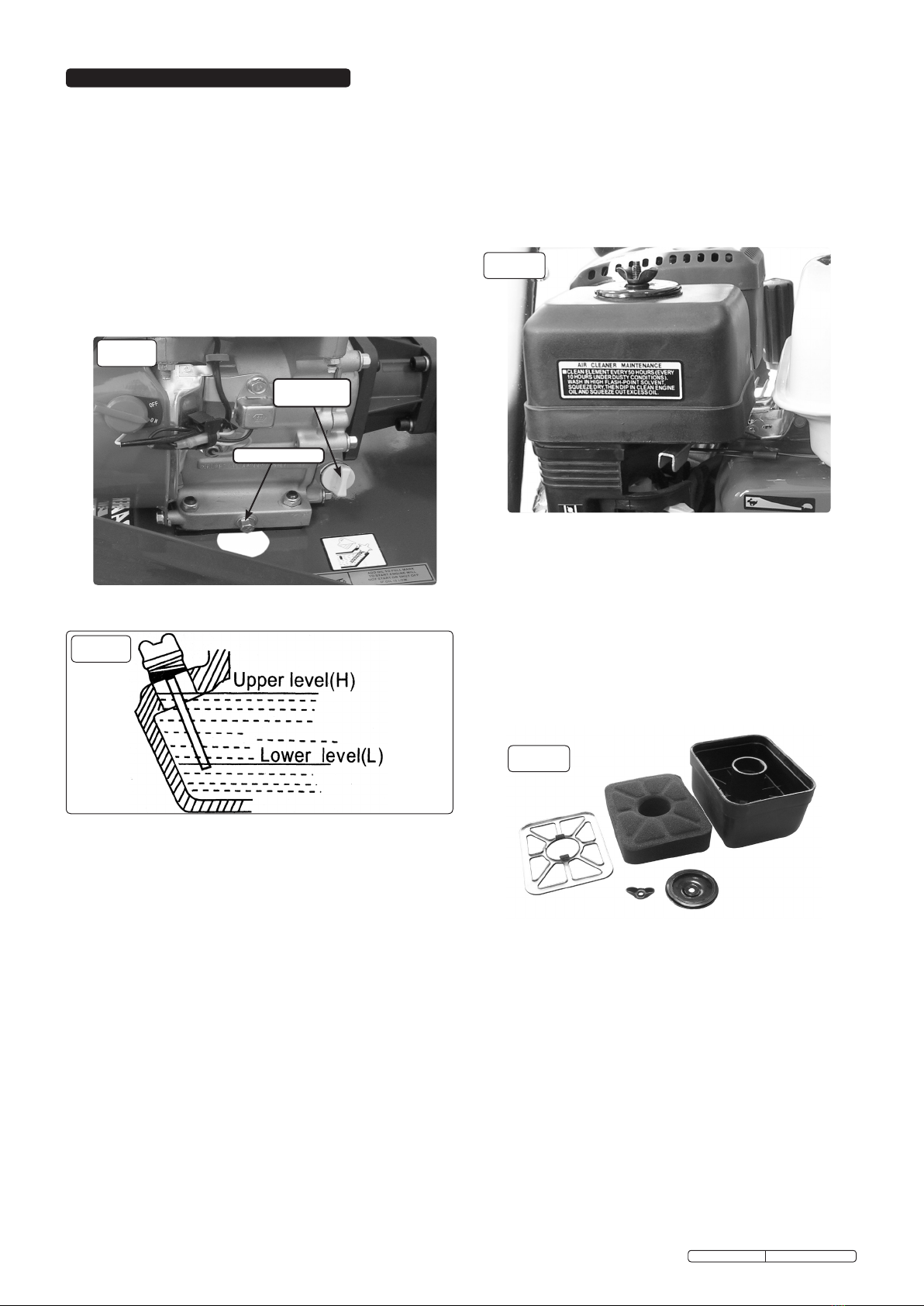

EngineOil: ...................................SAE10W-30

Spark Plug: .........................NGK BP6ES or BPR6ES

SparkPlugGap: ...............................0.7-0.8mm

Idle Speed:. .................................1700 +/- 15rpm

Valve Clearance (cold engine): Inlet .............0.15 +/- 0.02mm

................................................: Exhaust ..........0.20 +/- 0.02mm

Original Language Version PCM2500SP.V2 Issue: 1 - 27/01/12