6. MAINTENANCE (WASHER)

5. OPERATION

WARNING! RISK OF FLUID INJECTION. This washer

operates at fluid pressures and velocities high enough to

penetrate human and animal flesh. If there is an

occurrence of fluid injection seek medical help

immediately.

WARNING! Ensure you read, understand and apply

Section 1 safety instructions.

WARNING! Dry running can seriously damage the unit.

WARNING! DO NOT leave motor running for more than

2 minutes without operating the trigger, as temperature/

pressure increase may damage sealing system.

WARNING! If the engine switch is left switched to the ’ON’

position when not in use, a drain on the battery will

occur over long periods of time. To prevent this the switch

must be switched to ‘OFF’ when the unit is not in use.

5.1. MANUAL STARTING PROCEDURE.

5.1.1. Check engine oil level before each use.

5.1.2. Check that the mains water feed hose is laid straight, and

then fully open the water tap. Check to ensure there are no

leaks from hoses or connections.

5.1.3. Release gun trigger safety catch and depress trigger to allow

any air left in the system to escape, hold for 10 seconds and

release.

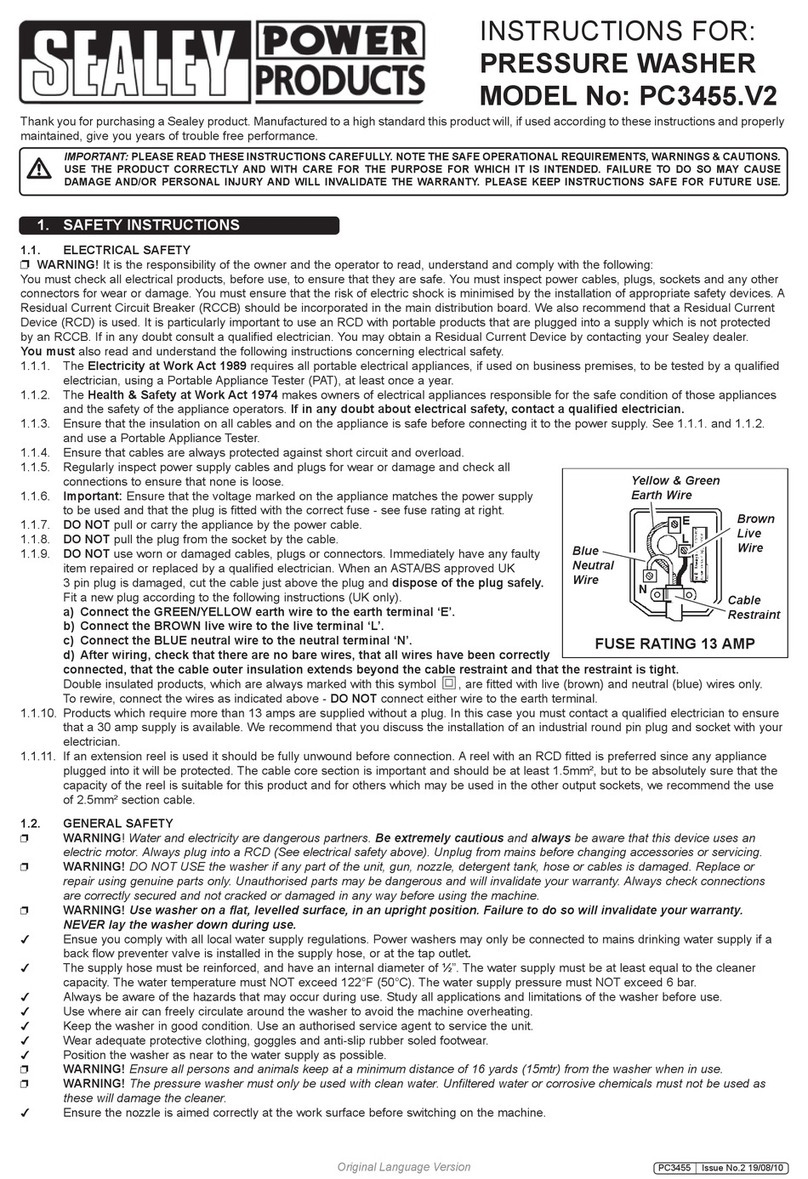

5.1.4. Rotate the engine switch clockwise to the ON position. See fig.6.

5.1.5. Fig.6 shows the fuel tap in the OFF position. Push the

fuel tap up to the left to the open position.

5.1.6. Move the fuel control lever to the ‘RUN’ position where it will

latch.

5.1.7. Take hold of the recoil starter handle (see fig.1) and pull it

slowly until you feel resistance, then let it return slowly.

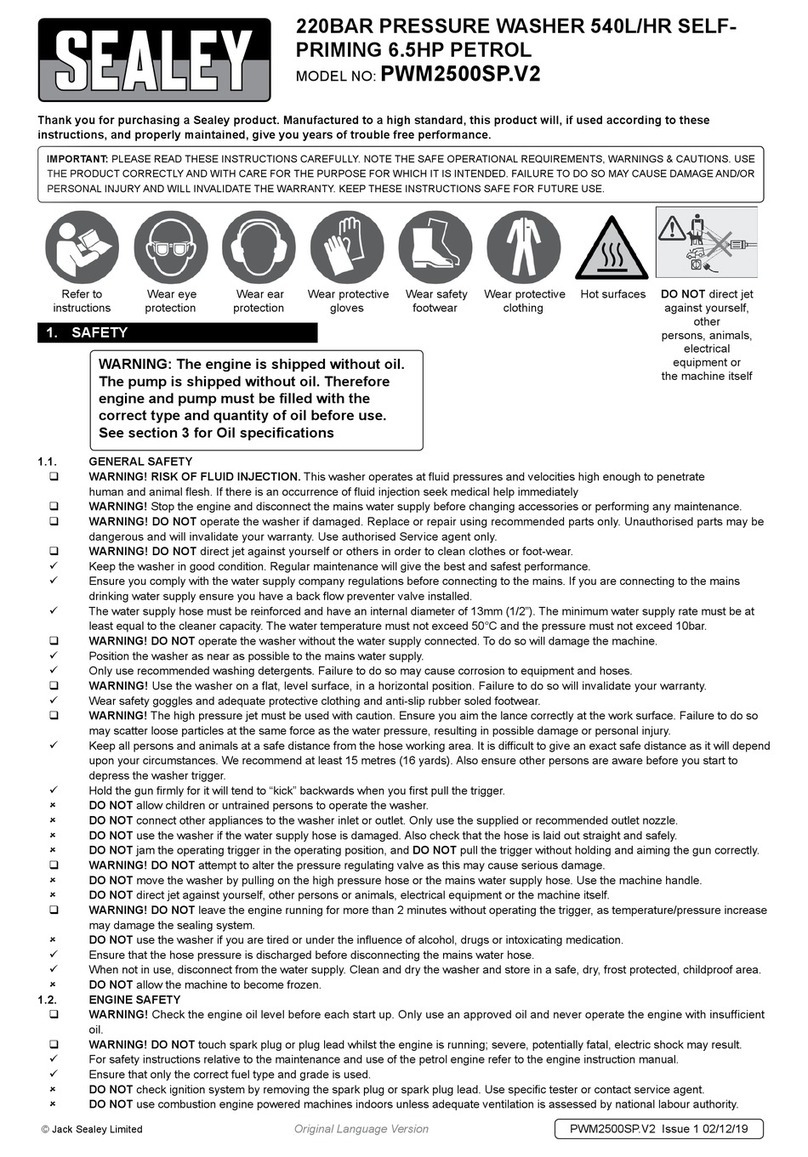

5.1.8. Push the decompression lever down and release it. (see fig.7).

5.1.9. Now pull the starting handle hard and fast all the way out. Use

two hands if necessary.

5.1.10. If the engine doesn’t start repeat the process from 5.1.8.

5.1.11. NOTE: The engine is fitted with a cold start device. When

starting in low temperature conditions, press the heater

switch and hold for 20 to 30 seconds. Release the button

and perform sections 5.1.4. to 5.1.9. inc.

fig.6

fig.7

5.2. ELECTRIC STARTING PROCEDURE.

5.2.1 Check engine oil level before each use.

5.2.2 Check that the mains water feed hose is laid straight, and

then fully open the water tap. Check to ensure there are no

leaks from hoses or connections.

5.2.3 Release gun trigger safety catch and depress trigger to allow

any air left in the system to escape, hold for 10 seconds and

release.

5.2.4 Fig.6 shows the fuel tap in the OFF position. Push the fuel tap

up to the left to the open position.

5.2.5 Move the fuel control lever to the ‘RUN’ position where it will

latch.

5.2.6 Rotate the engine switch clockwise to the ON position. See fig.6.

5.2.7 When you are ready, turn the key to the ‘START’ position and

hold it there until the engine starts. Release the key as soon

as the engine starts. If the engine does not start within ten

seconds release the key. Wait 15 seconds before attempting a

restart.

5.2.8 Once the engine is running the speed is automatically

adjusted according to the amount of load placed on it. The

speed setting is factory set. If a running speed problem arises

the unit should be returned to your Sealey dealer for

adjustment by a qualified service engineer.

5.3. CLEANING.

5.3.1. Only apply detergent using the black low pressure nozzle.

5.3.2. Depress the trigger to apply the detergent to the dry surface

which is to be cleaned.

Vertical surfaces must be cleaned from the bottom upwards.

5.3.3 When detergent application is complete remove the syphon

tube from the detergent container and place it in a container

of clean water. Run the washer at low pressure to purge the

gun of detergent.

5.3.4. Leave the detergent to act for 1-2 minutes, but DO NOT allow

the surface to dry.

5.3.5. The detergent should be rinsed off using either the YELLOW,

WHITE or GREEN high pressure nozzles depending on the

spray angle required. DO NOT use the RED nozzle as the

aggressive spray action may erode the surface being

cleaned. Always lock the gun trigger before changing nozzles.

5.3.6. Hold the gun firmly and position the nozzle at least 30cm

(12”) from the surface and commence washing with high

pressure clean water. Work from the bottom upwards, and

avoid the water running onto unwashed surfaces.

5.4. SHUT DOWN PROCEDURE.

5.4.1. When cleaning has finished and the unit is no longer

required allow the engine to run unloaded for 3 minutes

before shutting down.

5.4.2. Stop the engine by pushing the red stop lever downwards.

(See fig.6)

5.4.3. Turn the engine switch to the OFF position and remove the

key. (See fig.6)

WARNING! If the engine switch is left switched to the

’ON’ position when not in use, a drain on the battery will

occur over long periods of time. To prevent this the

switch must be switched to ‘OFF’ when the unit is not in

use.

5.4.4. Turn off the fuel tap. (See fig.6)

5.4.5. Turn off the mains water supply.

5.4.6. Discharge residual pressure from the washer by pressing the

trigger until no more water comes out of the nozzle.

5.4.7. Engage the gun trigger safety catch.

CAUTIONS!

a) Avoid sudden bursts of water as this will cause the

water pressure to drop and put extreme pressure on the

hoses and connections.

b) If another person is using water from the same supply as

the washer, the water pressure will drop and the washer will

not operate correctly. Switch the engine off immediately

and wait until the pressure is restored.

Maintenance should only be performed with the engine turned

off and the unit disconnected from the mains water supply.

6.1. CLEANING THE NOZZLES. Pull back the brass sleeve on

the end of the lance and pull out the nozzle. Clean the nozzle

with wire provided (fig 8). If this does not improve the flow

from the nozzle it should be replaced.

Original Language Version

© Jack Sealey Limited PWDM3600 Issue: 1 - 08/05/13