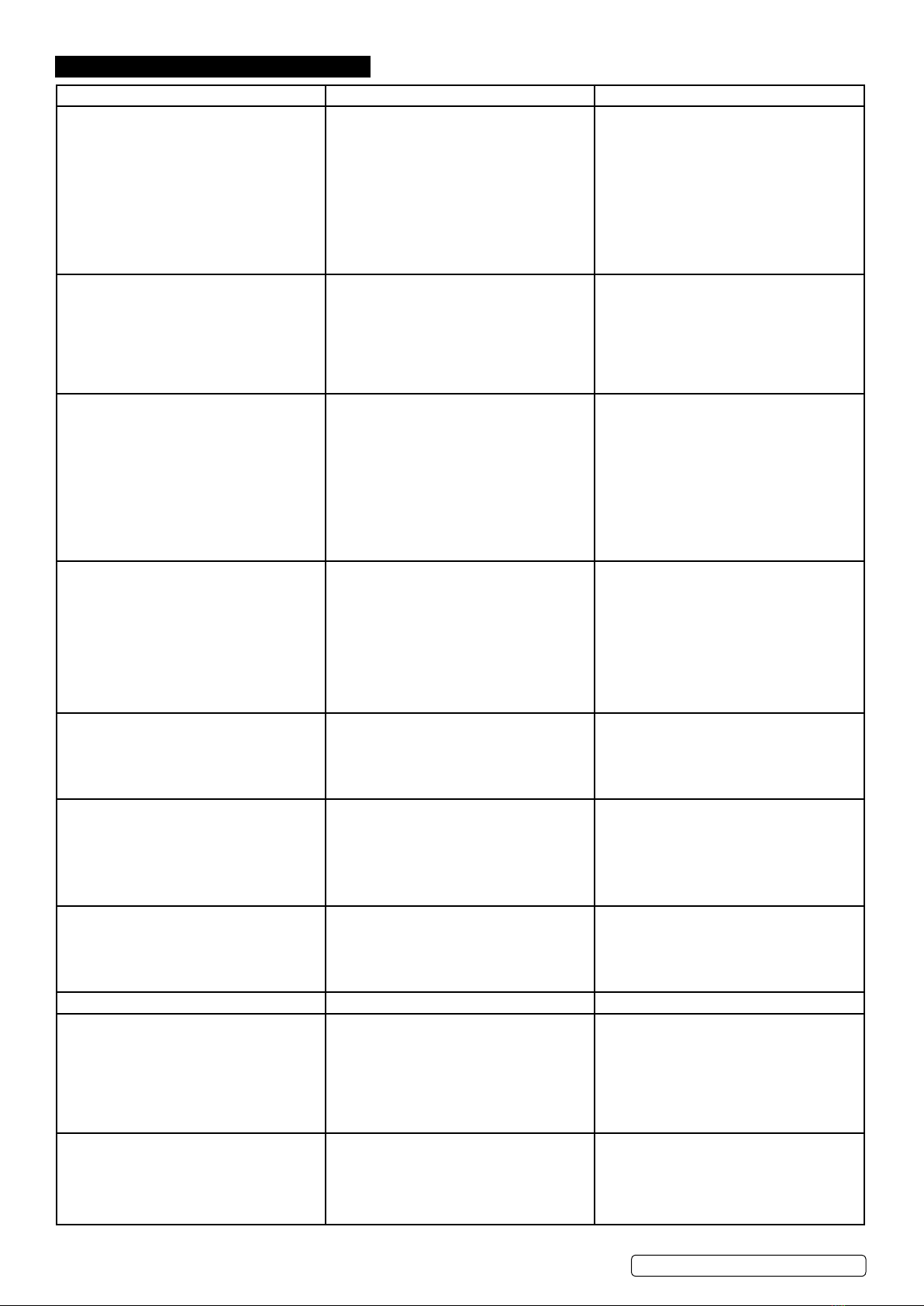

10. TROUBLESHOOTING

PW2000HW | Issue:1 25/07/18

Original Language Version

© Jack Sealey Limited

Fault Probable cause Solution

The pump does not start when the switch is

pressed.

The plug is not properly connected to the

socket.

The electrical socket is not working.

The mains voltage is insufcient.

The gauge of the electrical power lead is too

small.

The pump has cut out.

Connect the plug to the power socket

correctly.

Have the electrical socket checked.

Check that the system is suitable.

Refer to the section detailing the electrical

connection.

Turn the switch to ON while keeping the gun

lever pressed;

If the problem persists contact an authorised

service centre.

The machine starts but no water comes out. Pump, hoses or accessories frozen.

No water supply.

Water lter fouled.

Nozzle fouled.

Allow the pump and hoses to thaw.

Connect the machine to the water supply

system and turn on the tap.

Remove and clean the lter (see

“MAINTENANCE” section).

Remove the lance from the gun and clean the

nozzle with the pin provided.

The pump runs but pressurisation does not

take place.

Insufcient water.

Suction lter fouled.

Pressure regulator valve (if tted) on

minimum pressure setting.

Lance nozzle worn.

Suction or delivery valves fouled or worn.

Nozzle jet blocked, causing too high

pressure, pump cuts out.

Check that the delivery rate is at least

12 l/min.

Remove and clean the lter (see

“MAINTENANCE” section).

Increase the pressure by turning the

handgrip.

Replace the lance.

Contact an authorised service centre.

Clean jet in nozzle with nozzle cleaning pin

provided.

Uneven working pressure. Lance nozzle fouled or dirty.

Air in intake water.

Suction lter fouled.

Suction or delivery valves fouled or worn.

Gaskets worn.

Pressure regulator valve gaskets worn.

Remove the lance from the gun and clean the

nozzle with the pin provided.

Supply the machine with water correctly, refer

to section 6.

Remove and clean the lter (see

“MAINTENANCE” section).

Contact an authorised service centre.

Contact an authorised service centre.

Contact an authorised service centre.

The motor stops suddenly. Machine’s safety overload cutout has been

tripped.

The gauge of the electrical power lead is too

small.

Allow the motor to cool for a few minutes. If

the problem persists contact an authorised

service centre.

Refer to the section detailing the electrical

connection.

Water leaks from the machine. Leaks from hose reel (if used).

Leaks from intake coupling.

Leaks from pump.

Tighten the couplings; if the problem persists

contact an authorised service centre.

Make sure that the coupling has been

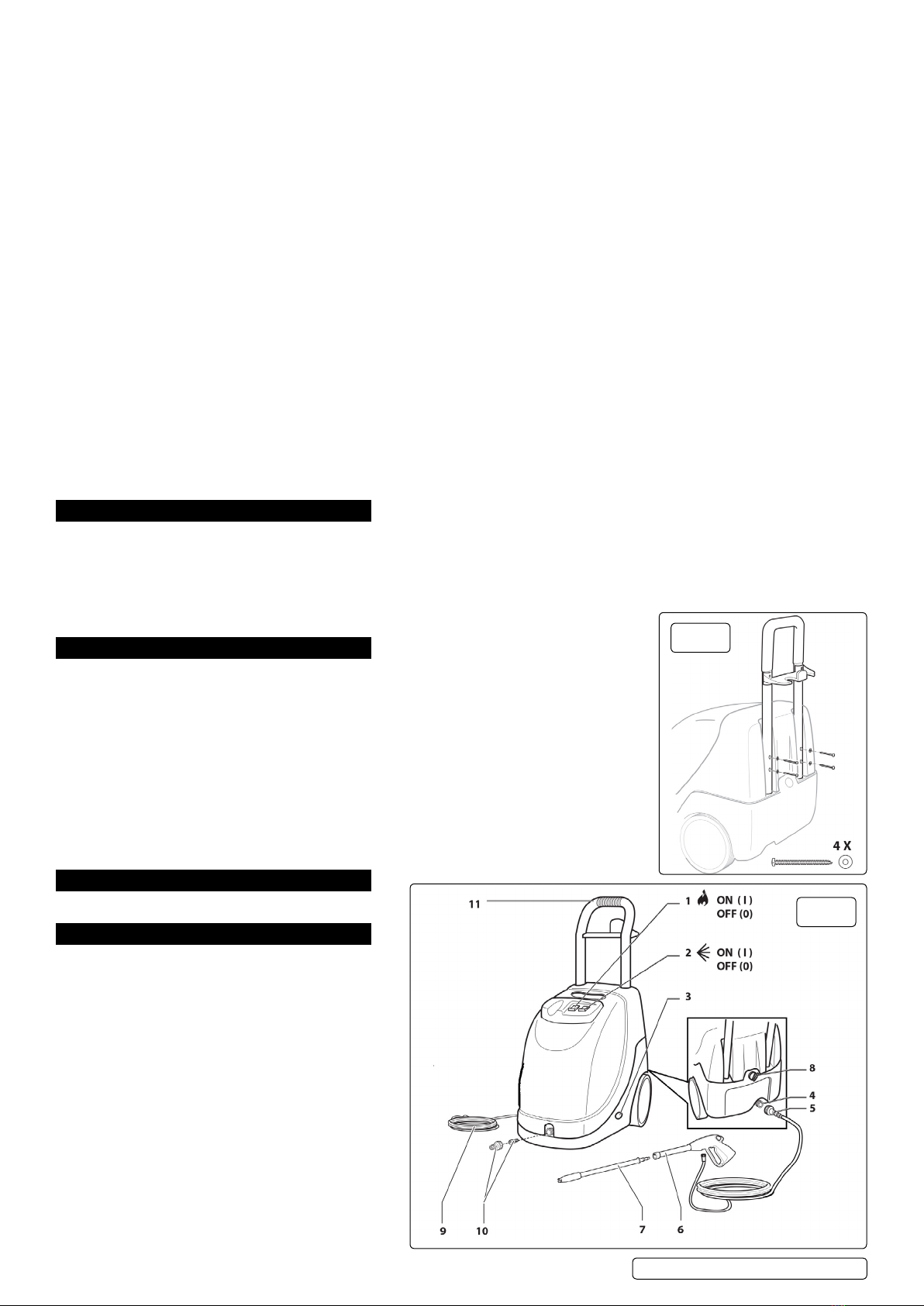

tted correctly (See illustrations in the

“INSTALLATION” section).

Contact an authorised service centre.

Abnormal noise. Suction lter fouled.

Intake water temperature too high.

Suction or delivery valves fouled or worn.

Bearings worn.

Remove and clean the lter (see

“MAINTENANCE” section).

Reduce the temperature below 40°C.

Contact an authorised service centre.

Contact an authorised service centre.

Water in the oil. O-ring seals worn. Contact an authorised service centre.

The machine restarts with the gun released. Water leak from hose - gun connection

(except models with hose and gun supplied

ready connected).

Air in intake water.

Water leak from the gun.

Water leak from the pump.

Tighten the connection with 2 spanners.

Supply the machine with water correctly, refer

to section 6.

Contact an authorised service centre.

Contact an authorised service centre.

The machine does not suck in the detergent. Tank empty.

Lance handgrip is on high pressure setting (if

present).

Transparent suction pipe damaged or

disconnected.

Fill the tank.

Move it to the low pressure setting by pulling

the lever towards the nozzle.

Reconnect the pipe. If the problem persists

contact an authorised service centre.