Original Language Version

© Jack Sealey Limited PWH616 Issue 1 04/12/20

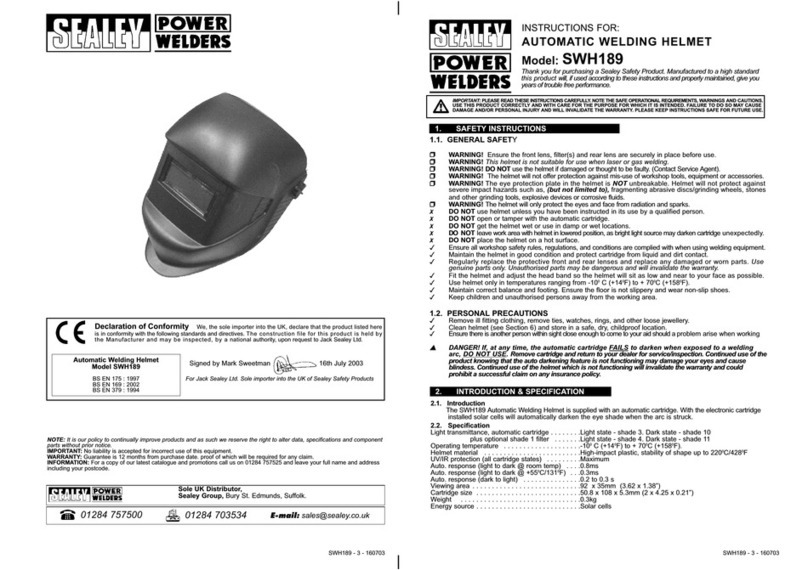

8DO NOT place the helmet on a hot surface.

8DO NOT use helmet without front cover window tted. To do so will invalidate your warranty.

9 Clean helmet (see section 5.5) and store the helmet in a safe, dry, childproof location.

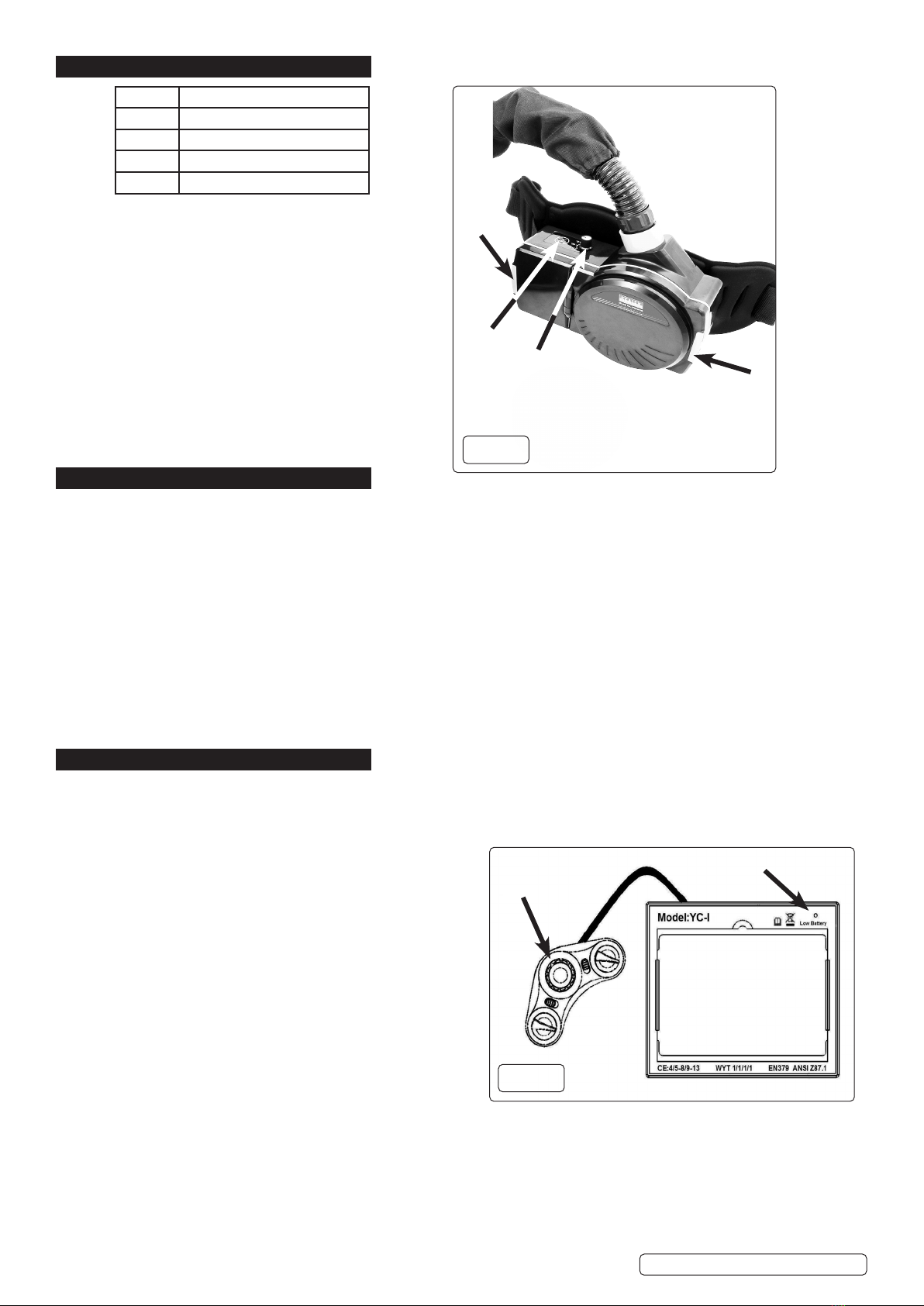

WARNING! Before welding always inspect the cartridge lter to ensure that it is not damaged. To test the lter prior to welding, direct

the front of the cartridge lter to a bright light source which will cause the lens to darken. Then using your hand rapidly cover and

uncover the sensor. The lter should lighten momentarily then return to a dark state.

WARNING! DO NOT use the helmet if damaged or you suspect it may be faulty. (Contact Sealey Stockist).

▲DANGER! DO NOT use if, at any time, the face plate in the cartridge FAILS to darken when exposed to a welding spark. Remove

cartridge and return to your Sealey stockist for checking.

9 Continued use of the product knowing that the auto darkening feature is NOT FUNCTIONING may DAMAGE YOUR EYES and

CAUSE BLINDNESS.

▲DANGER! DO NOT wear this respirator system to enter areas where:

1. Atmospheres are oxygen decient.

2. Contaminant concentrations are unknown.

3. Contaminant concentrations are Immediately Dangerous to Life or Health.

4. Contaminant concentrations exceed the maximum use concentration determined using the assigned Protection Factor for the

specic respirator system.

WARNING! The Particle lter cannot be cleaned. DO NOT attempt to remove contamination using for example compressed air as

this will destroy the lters, the equipment will not give the expected protection and the warranty will be invalidated.

9If ventilation is poor, wear an approved air-supplied respirator.

9Read and understand the Material Safety Data Sheets and the manufacturer’s instructions for metals, consumables, coatings,

cleaners, and degreasers.

9 Work in conned space only if it is well ventilated, or while wearing an air-supplied respirator. Always have a trained watch-

person nearby. Welding fumes and gases can displace air and lower the oxygen level causing injury or death. Be sure the breathing

air is safe.

8DO NOT weld in locations near degreasing, cleaning, or spraying operations. The heat and rays of the arc can react with vapours to

form highly toxic and irritating gases.

8DO NOT weld on coated metals, such as galvanized, lead, or cadmium plated steel, unless the coating is removed from the weld

area, the area is well ventilated, and while wearing an air-supplied respirator. The coatings and any metals containing these

elements can give o toxic fumes if welded. RESPIRATOR (PAPR) MISUSE can be hazardous. Welding produces fumes and gases.

Breathing these fumes and gases can be hazardous to your health.

9Read and follow these instructions and the safety labels carefully. The powered air purifying respirator (PAPR) helps protect the

user from specic airborne contaminants but must be used correctly to be fully eective. Have an industrial hygienist test the air

in your facility to ensure the PAPR provides adequate protection from contaminants in your environment. If you have questions

about the respirator, see equipment warning label and consult your Safety Director and a certied Industrial Hygienist.

9 Follow all applicable EN/ANSI/CSA/AS&NZS, and other regulatory guidelines pertaining to the use of respirators.

8DO NOT use the powered air purifying respirator where there is danger of re or explosion.

8DO NOT use the powered air purifying respirator in windy conditions or negative pressure inside the hood may draw in

contaminants from the outside air.

8DO NOT use the powered air purifying respirator without a properly installed spark guard cover. Without the spark guard cover,

welding sparks may ignite the lter, or damage the lter and allow unltered air into the helmet.

9 The powered air purifying respirator does not supply oxygen. Use the respirator only in atmospheres for which it is EN/ANSI/CSA/

AS&NZS approved. DO NOT use the respirator where oxygen levels are 19.5% or lower, where contaminant levels are unknown or

are immediately dangerous to life or health, or where the contaminant levels exceed the respirator specications.

8DO NOT enter a hazardous area until you are sure the respirator equipment is correctly assembled, working properly, and properly

worn.

9 Before each use, inspect the respirator equipment for damage and verify it operates properly, Before using the respirator, test air

ow to verify it is providing an adequate volume of air.

8DO NOT use the powered air purifying respirator without all lter components or with the blower turned o, as hazardous levels of

oxygen and carbon dioxide may accumulate in helmet.

9Always wear the powered air purifying respirator when entering a contaminated area. DO NOT remove the respirator until outside

the contaminated area.

9Dangerous contaminants may not smell or be visible. Leave the area immediately if you notice the following:

- Breathing becomes dicult.

- You experience dizziness, impaired vision, or eye, nose, or mouth irritation.

- The powered air purifying respirator alarm sounds.

- The equipment is damaged.

- Air ow decreases or stops.

- If you think the equipment is not supplying adequate protection.

8DO NOT remove the equipment until you are in a safe area.

8DO NOT repair, modify, or disassemble the powered air purifying respirator or use with parts or accessories not supplied by the

manufacturer. Use only those components that are part of the approved assembly.

9 Replace damaged or clogged lters. DO NOT wash or reuse lters. DO NOT clean lters by tapping or with compressed air or lter

elements may be damaged. Dispose of used lter elements according to local, state, and federal requirements.

9 The powered air purifying respirator must be used with the helmet, hood, and lters recommended by the manufacturer to provide a

respirator system. See the label on the blower for information on the required equipment.

8DO NOT use the powered air purifying respirator belt or shoulder straps(if equipped) as a safety harness.

2. INTRODUCTION

PAPR (Powered Air Purifying Respirator) system with auto darkening welding helmet. Lithium battery powered respirator unit provides the user

a constant ltered stream of air to their head and face for up to approx. 8 hours. The lter is designed to reduce or remove dust and particles but

not vapours and gases. The kit meets performance class TH1 according to EN 12941:1998/A2:2008. Adjustable airow settings of 150/180/210L/