For Jack Sealey Ltd. Sole UK importer of Sealey Power Welders.

Declaration of Conformity We, the sole UK importer, declare that the product listed below is in

conformity with the following standards and directives.

The construction file for this product is held by the Manufacturer and may be inspected, by a national

authority, upon request to Jack Sealey Ltd.

OXYGEN REGULATOR

Model: SGA3

BS EN 2503,1998 Gas Welding

Equipment

Signed by Mark

Sweetman 19th October 2005

6. DECLARATION OF CONFORMITY

5. MAINTENANCE

5.1 Each time the equipment is used.

5.1.1 The regulator should be visually examined to determine its suitability for service. If any of

the following conditions apply the regulator should be withdrawn from service:

5.1.2 There should be no contamination with oil or grease or solvents.

5.1.3 The inlet and outlet connections should be free from grit and other particles.

5.1.4 There should be no damage to threads, sealing surfaces, or seals.

5.1.5 There should be no visible damage to the pressure gauges or dials and indicators under the

pressure gauge windows.

5.2 When assembled to an oxygen cylinder with flashback arrestor and hose attached all joints

shall be leak tested.

5.3 Annually.

5.3.1 The gauge should be tested under known conditions to determine that it is still working properly.

5.4 Replacement/refurbishment intervals.

5.4.1 Subject to conditions of use the regulator should be replaced with a new, repaired, or service

exchange unit every 5 years or in accordance with the manufacturers recommendations. If

regulators are repaired or refurbished this should be done in accordance with the BCGA

(British Compressed Gas Association) Code of practice CP7.

4. OPERATION

4.1 Ensure that the regulator is closed by turning the adjusting knob anti-clockwise to relieve

the pressure on the diaphragm before opening the cylinder valve. If this is not done,

pressure from the cylinder can damage the diaphragm and render the regulator inoperative.

4.2 Slowly open the oxygen cylinder valve. As you do so the high pressure gauge (left hand) will

register the cylinder pressure.

4.3 Slowly open the regulator by turning the adjusting knob clockwise. As you do so the outlet

pressure gauge (right hand) will register the outlet pressure of gas being fed to the torch.

Adjust the pressure according to the size of nozzle in use and the thickness of the material

to be cut or welded. The manufacturer of the torch will normally supply a data chart to refer to.

4.4 Shutting down process. On completion close the cylinder valve.

4.5 Drain gas from the regulator and hose by opening the appropriate oxygen control valve on

the torch for a few seconds.

Ensure adequate ventilation when doing this.

3.10. Close the regulator by turning the adjusting knob anti-clockwise.

01284 757500

01284 703534

E-mail:

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

Web address: www.sealey.co.uk

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and

component parts without prior notice. IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim. INFORMATION: For a copy of

our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.

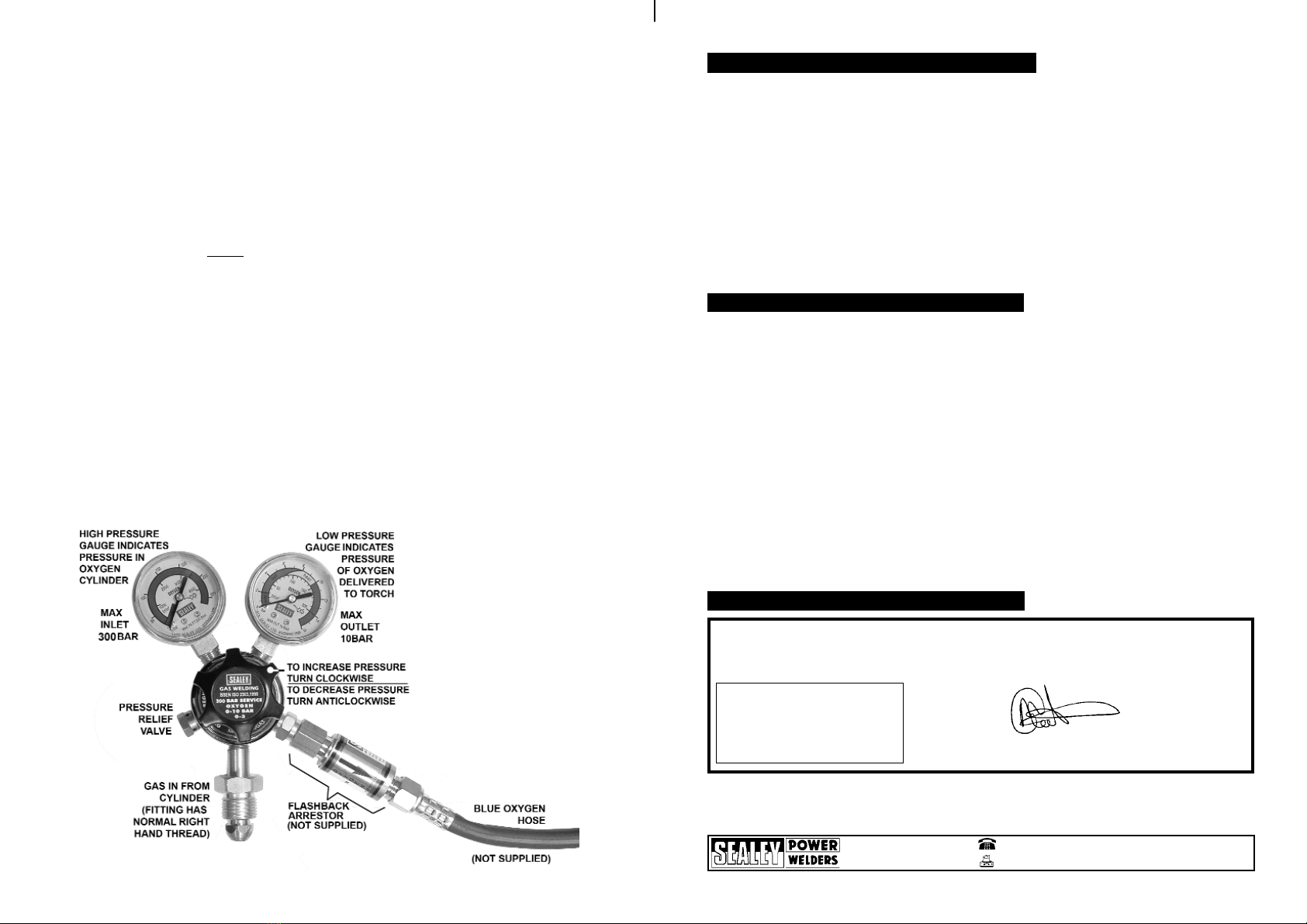

3.3. Attaching the regulator. Ensure the inlet filter is in place and is not blocked or

contaminated. If an '0' ring is fitted to the inlet, check for damage and replace if necessary

with an '0' ring recommended by the regulator manufacturer. Do not use any form of

jointing paste or tape between regulator and cylinder valve. Before attaching the

regulator wipe the fitting with a clean dry cloth. Screw the union at the base of the regulator

to the cylinder by hand. Ensure that the guages are correctly orientated so as to be seen

properly by the operator. The regulator to cylinder fitting has a normal right handed

thread.To tighten turn clockwise. Awrench should be used to ensure tight connections.

3.3.1 Close the regulator by turning the adjusting screw anti-clockwise to relieve the pressure on

the diaphragm before opening the cylinder valve. If this is not done, pressure from the

cylinder can damage the diaphragm and render the regulator inoperative.

3.3.2 The cylinder valve-to-regulator connection should be checked for leaks using an approved

leak detection spray or water and soap solution. Stand so that the cylinder valve is between

you and the regulator.Slowly open the cylinder valve.

3.4 Connecting a flashback arrestor.According to safety regulations, when regulators are

used with oxygen (which promotes combustion), it is compulsory to use a flashback arrestor.

This should be connected directly to the gas outlet on the regulator as shown below and the

gas hose should then be fitted to the flashback arrestor. The flash back arrestor should be

colour coded BLUE for OXYGEN and has to be fitted the right way round. It will have the

direction of flow marked on it. Follow the instructions provided with the arrestor.

3.5. Connecting a hose.

3.5.1 NOTE: New hoses contain a preservative talc which must be blown out with

compressed air before use.

3.5.2 Connect a hose coded BLUE for OXYGEN to the flashback arrestor as shown below.

Tighten nut securely with wrench. If any sign of oil or grease is found, discontinue use

immediately.

3.5.3 Prior to attaching the torch, blow out the hose to eliminate any particles or debris. Do

this in a well ventilated area, otherwise you may create conditions for fire or explosion.

a. Turn the regulator adjusting knob slowly clockwise until the outlet gauge registers 5psi

and oxygen begins to pass through hose.

b. Allow the oxygen to flow approximately 10 seconds to purge the hose.

SGA3 - 4 - 22/11/05