Viewing area . . . . . . . .98 x 43mm (3.86 x 1.74).

Size of Cartridge . . . . .110x90x9mm (4.33x3.54x0.35)

Power supply . . . . . . . .Solar cells

Power On/Off. . . . . . . .Fully Automatic

UV/IR Protection . . . . .Up to shade Din.16 at all times

Adjustable shade . . . . .From 9 - 13

Clear state . . . . . . . . . .Shade DIN 3.

Response (light to dark) 1/20,000 sec

Response (dark to light) l Position slow = 0.6 - 0.8sec

. . . . . . . . . . . . . . . . . .lPosition fast = 0.25 - 0.35sec

Sensitivity . . . . . . . . . .Adjustable high/low

Helmet material . . . . . .Hi-impact Polyamide Nylon/Polyprop.

Total weight . . . . . . . . .435g

Operating temperature .-50C to 550C (230F to 1310F).

Storing temperature . . .-200C to 700C (-40F to 1580F).

PWH599 - 3 - 231003

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this equipment. WARRANTY: Guarantee is 12 months from purchase date. proof of which will be

required for any claim. INFORMATION: Call us for a copy of our latest catalogue on 01284 757525 and leave your full name and address including your

postcode.

Thank you for purchasing a Sealey Power Product. Manufactured to a high

standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR

WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE OR PERSONAL INJURY, AND WILL

INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

AUTOMATIC WELDING HELMET

INSTRUCTIONS FOR MODEL NO: PWH599

1. SAFETY INSTRUCTIONS

p

p

WARNING! THIS HELMET IS NOT SUITABLE FOR USE WITH LASER OR GAS-WELDING.

Ensure all workshop safety rules, regulations, and conditions are complied with when using welding equipment.

The helmet will not offer protection against mis-use of workshop tools, equipment, or accessories.

Maintain the helmet in good condition, and protect cartridge from liquid and dirt contact.

Regularly replace the protective lens and replace any damaged or worn parts. Use

genuine parts only. Non authorised parts may be dangerous and will invalidate the

warranty. NEVER open or tamper with the shade cartridge.

Select the shade level before use.

Ensure the front cover lens is securely in place before use.

Fit the helmet and adjust the head band so the helmet will sit as low and near to

your face as possible,

Use helmet only in temperatures ranging from -50C to 550C (230F to 1310F).

The eye protective plate in helmet is NOT unbreakable. Helmet will not protect

you against severe impact hazards (such as, but not limited to) fragmenting

abrasive discs/grinding wheels, stones and other grinding tools, explosive devices or

corrosive fluids. The helmet will only protect the eyes and face from radiation and sparks.

Remove ill fitting clothing, remove ties, watches, rings, and other loose jewellery. Maintain

correct balance and footing. Ensure the floor is not slippery and wear non slip shoes.

Keep children and unauthorised persons away from the working area.

p

p

WARNING! DO NOT use the helmet if damaged or you suspect it may be faulty. (Contact Service Agent).

DO NOT use helmet unless you have been instructed in its use by a qualified person.

DO NOT get the helmet wet or use in damp or wet locations.

DO NOT leave work place with helmet in lowered position, as bright light source may darken cartridge unexpectedly.

DO NOT place the helmet on a hot surface.

Clean helmet (see section 5.9) and store the helmet in a safe, dry, childproof location.

s

s

DANGER! If, at any time, the face plate in the cartridge FAILS to darken when exposed to a welding spark,

DO NOT USE. Remove cartridge and return to your dealer for checking. Continued use of the product

knowing that the auto darkening feature is NOT FUNCTIONING may DAMAGE YOUR EYES and CAUSE

BLINDNESS. Continued use of the helmet which is not functioning will invalidate the warranty and could

prohibit a successful claim on any insurance company.

3. SPECIFICATION

2. INTRODUCTION

High quality variable shade 9-13 lens manufactured and tested to BSEN379. Fully automatic, switches from light

to dark on striking arc. Fitted with solar power panel, no batteries required. Features sensitivity switch and delay

speed switch control for switching dark to light, preventing arc eye when welding at high power, whilst still providing

fast switching for tack welding. Deluxe contoured helmet design approved to BSEN175 gives full neck protection

and protects lens from scratching when helmet is laid down. Comfortable headband and non slip quick release

ratchet mechanism. Suitable for MIG and arc welding. (Not suitable for use with laser or gas-welding).

01284 757500

01284 703534

E-mail:

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

Web address: www.sealey.co.uk

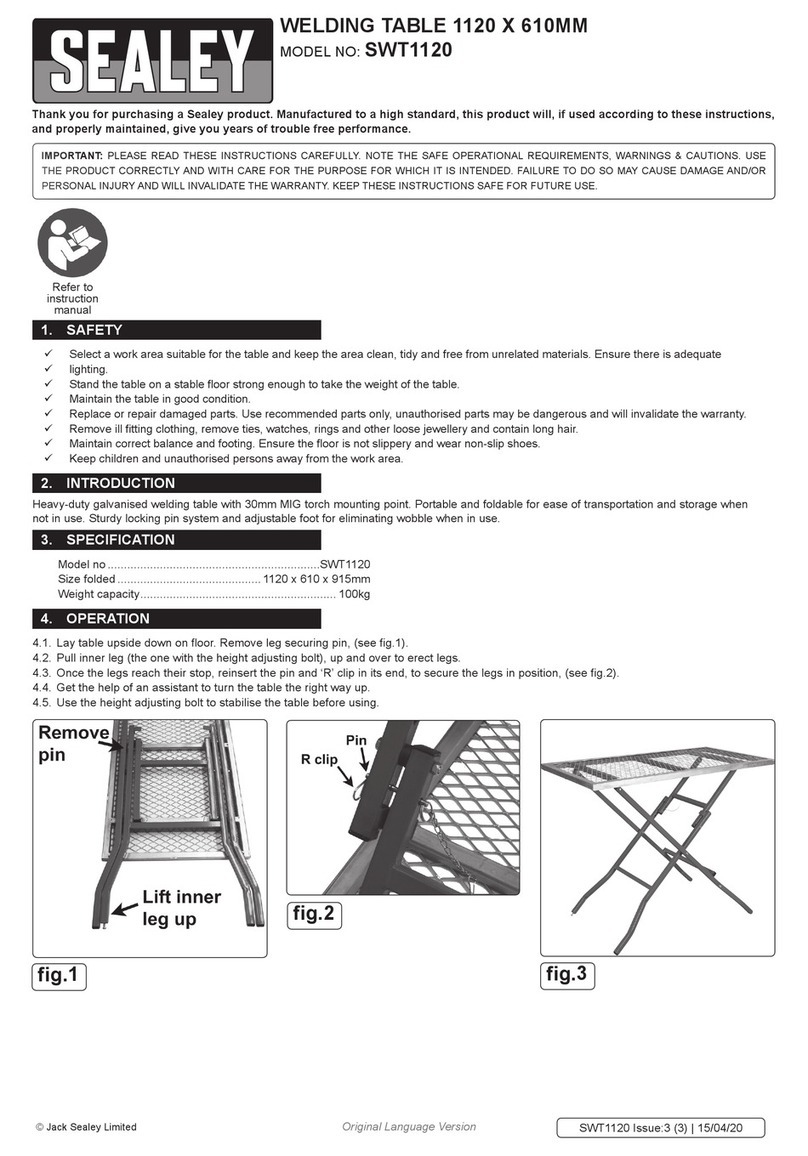

7. SPARE PARTS

REF. PART NO. DESCRIPTION

(fig.4) 168/445505 Front cover lens 112x93mm

(fig.5a) 168/445510 Shade cartridge

168/445525 Shade knob

168/445530 Inside cover lens

168/445535 Helmet shell

(fig.6-X) 168/445540 Sweat band

(fig.6) 168/445545 Adjustable Head band

(fig.6-6) 168/445550 Block nut

(fig.6-2) 168/445555 Washer x 4

(fig.6-4) 168/445560 Limitation washer (adjustable)

(fig.6-3) 168/445565 Limitation washer LEFT

(fig.2) 168/445570 Screw

(fig.6-3) 168/445575 Limitation washer RIGHT

IRREGULAR DARKENING The headband may have been unevenly set on the two Readjust the distance of the shade

OR DIMMING. sides of the helmet (unequal distances from the eyes cartridge.

to the shade cartridge).

SHADE CARTRIDGE DOES The sensors are soiled or obstructed. Clean

NOT DARKEN OR FLICKERS. Front cover lens oiled or damaged. Clean or replace

Welding current too low.Adjust weld amps

POOR VISION Operative lenses and/or shade cartridge soiled. Check, clean or replace

Insufficient ambient light. Adjust light

Shade level incorrectly set. Refer to Shade Guide for setting

SLOW RESPONSE Operating temperature too low Do not use at temperatures

below -50C (230F) .

WELDING HELMET SLIPS Headband adjustments incorrect. Refer to section 4.

6. PROBLEM SOLVING

s

s

DANGER! If, at any time, the face plate in the cartridge FAILS to darken when exposed to a welding spark, DO NOT USE.

Remove cartridge and return to your dealer for checking. Continued use of the product with auto darkening feature NOT

FUNCTIONING may DAMAGE YOUR EYES and CAUSE BLINDNESS. Use of malfunctioning product will invalidate the

warranty, and any right of claim on any insurance policy.

fig 6

Issue date 14/10/03

Issue No, 3