01284 757500

01284 703534

sales@sealey.co.uk

www.sealey.co.uk

Web

email

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.

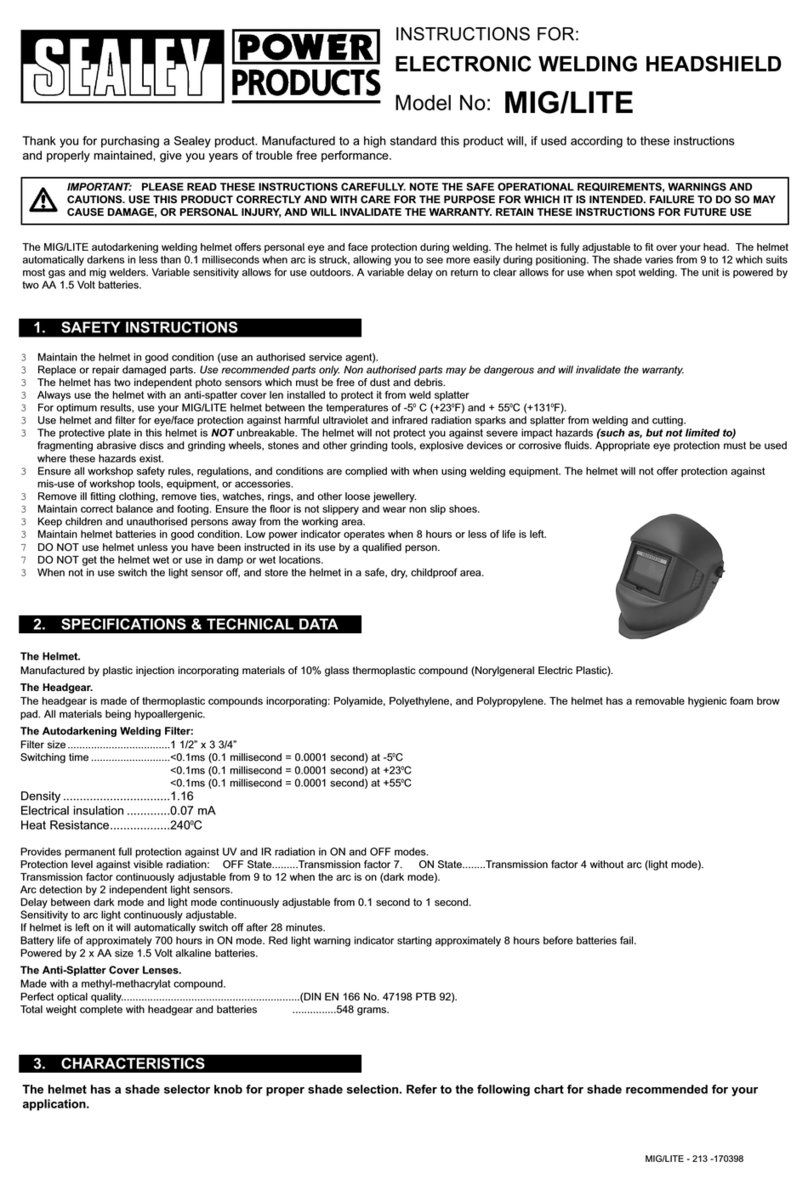

7.1 CUTTING CAPACITIES

Mild Nozzle Operating Pressure (bar - lbf/in²) Gas Consumption (ltr/m - ft³/h)

Steel Size Oxygen Acetylene O2- Cutting O2- Heating Acetylene

6mm / 1/4” 1/32” 1.4 - 20 0.30 - 4 14.15 - 30 8.5 - 18 8.0 - 17

13mm / 1/2” 3/64” 2.1 - 30 0.35 - 5 30.70 - 65 10.4 - 22 9.4 - 20

25mm / 1” 1/16” 2.8 - 40 0.40 - 6 67.50 - 143 13.2 - 28 11.8 - 25

50mm / 2” 1/16” 3.1 - 45 0.40 - 6 78.30 - 166 13.2 - 28 11.8 - 25

75mm / 3” 1/16” 3.5 - 50 0.40 - 6 88.70 - 188 13.2 - 28 11.8 - 25

7.2 WELDING CAPACITIES

Mild Nozzle Operating Pressure (bar - lbf/in²) Gas Consumption (ltr/m - ft³/h)

Steel Size Oxygen Acetylene O2- Welding O2- Heating Acetylene

1.2mm / 18SWG LW02 0.14 - 2 0.14 - 2 11.8 - 25 4.2 - 9 3.8 - 8

2.6mm / 12SWG LW05 0.28 - 4 0.21 - 3 23.5 - 50 4.2 - 9 3.8 - 8

4mm / 8SWG LW10 0.35 - 5 0.28 - 4 56.6 - 120 4.2 - 9 3.8 - 8

7. TECHNICAL INFORMATION

6. MAINTENANCE

6.1 Annual maintenance should be carried out by a person who has sufficient practical experience of oxyacetylene gas equipment and a

detailed theoretical knowledge of the functioning of the equipment, the properties of gases used and potential defects and hazards

which may occur and their importance to the integrity and safety of the equipment.

6.2 Regulator elastomers and seals will wear and deteriorate in service and will also deteriorate out of service. Regulators stored for 1

year or over without use should receive inspection as per the annual maintenance schedule.

EQUIPMENT MAINTENANCE

Each time equipment is used Annual Replacement/ Replacement/

(By the operator) Refurbishment Refurbisment

Intervals Guideline

REGULATORS Visual examination to determine Functional tests to ensure 5 years or manufactuers Replace with a new,

and their suitability for service (e.g. correct correct operation recommendations. repaired, or service

integral protective gas, pressure rating, damage, NOTE: If regulators are exchange unit.

devices. condition of threads and sealing repaired or refurbished

surfaces, oil or grease this shall be done in

contamination. accordance with the

BCGA Code of practice

Leak test all joints at working CP17 by a reputable

pressure. repairer.

FLASHBACK Visual examination to determine Check unit for flow restriction. 5 years or manufacturers Replace with a new,

ARRESTORS suitability for service (e.g. gas, Reverse flow to ensure recommendations. repaired, or service

and their integral pressure rating, damage, correct operation of non-return exchange unit.

cut off valves condition of threads and sealing valves and pressure sensitive

surfaces, oil or grease cut off valves where fitted. If

contamination. of the pressure sensitive type

check shut off in the tripped

Leak test all joints at working condition in the direction of

pressure. flow.

HOSE Visual safety check to determine Reverse hose to ensure the Determined by local Replace as required.

ASSEMBLIES suitabilty for service (e.g gas, correct operation of non-return operating conditions.

(including non- pressure rating, damage), valve where fitted. Bend hose

return valves ) condition of cover (e.g. kinking in a tight radius to ensure

and twisting ), threads and reinforcement is not visible.

sealing surfaces. Check

anti-whip restraints where fitted.

Leak test all joints at working

pressure.

BLOWPIPES Visual examination of the nozzle Test valve functions. Blank Determined by local Replace with a new,

and inlet seatings for damage. exits and leak test for internal operating conditions. repaired, or service

Leak test all joints at working malfunctions. exchange unit.

pressure.

©Jack Sealey Limited Original Language Version SGA1.V3 Issue: 1 - 27/09/13

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk, IP32 7AR

Environmental Protection.

Recycle unwanted materials instead of disposing of

them as waste. All tools, accessories and packaging

should be sorted, taken to a recycle centre and

disposed of in a manner which is compatible with the

environment.

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to www.sealey.co.uk

or phone 01284 757500.