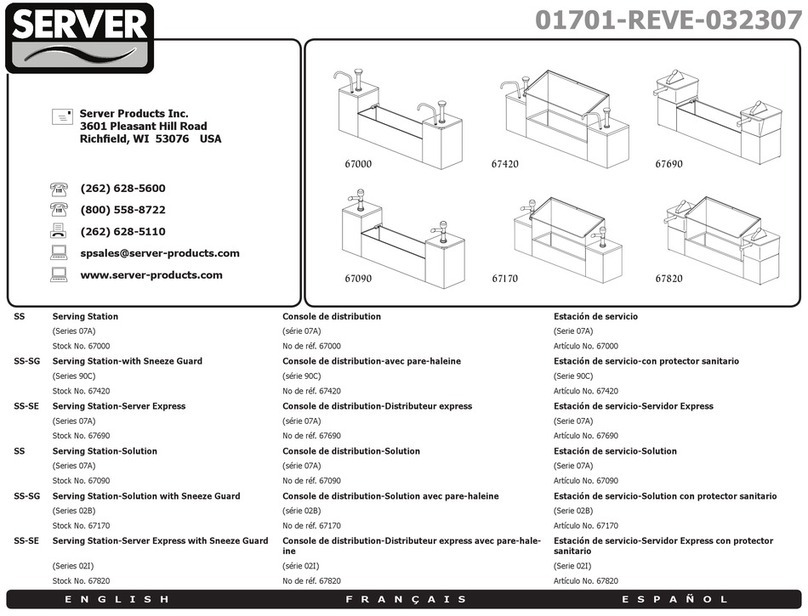

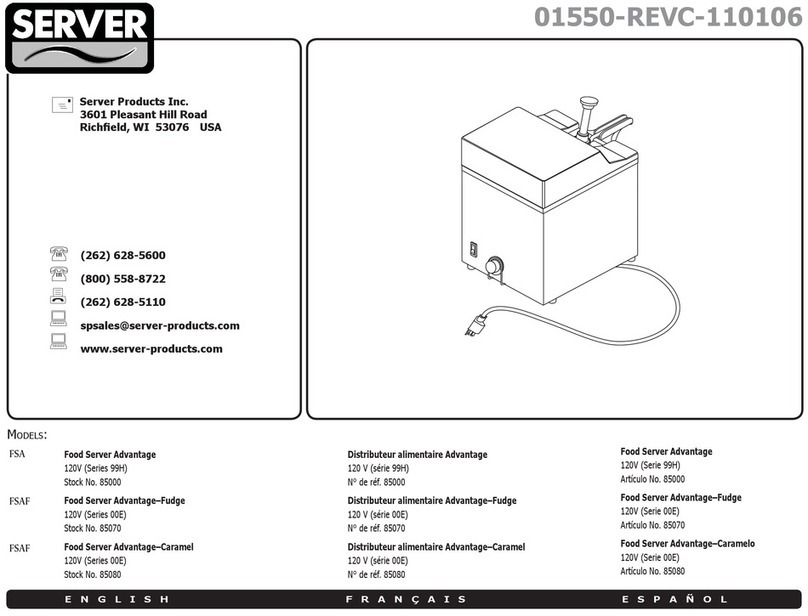

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

www.server-products.com

GENERAL SERVICE, REPAIR, OR

RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer

service to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number.

Merchandise being returned for credit must be in new

and unused condition and not more than 90 days old and

will be subject to a 20% (percent) restocking charge.

Electrical parts (thermostats, heating elements etc.) are

not returnable.

Server Products maintains a fully staffed service

department with highly skilled factory trained personnel.

Service is extremely prompt. Under normal circumstances,

a repaired unit is shipped out the day after it is received.

Labor charges are reasonable.

SERVICE

Contact your dealer or Server Products Inc.

customer service department for the following:

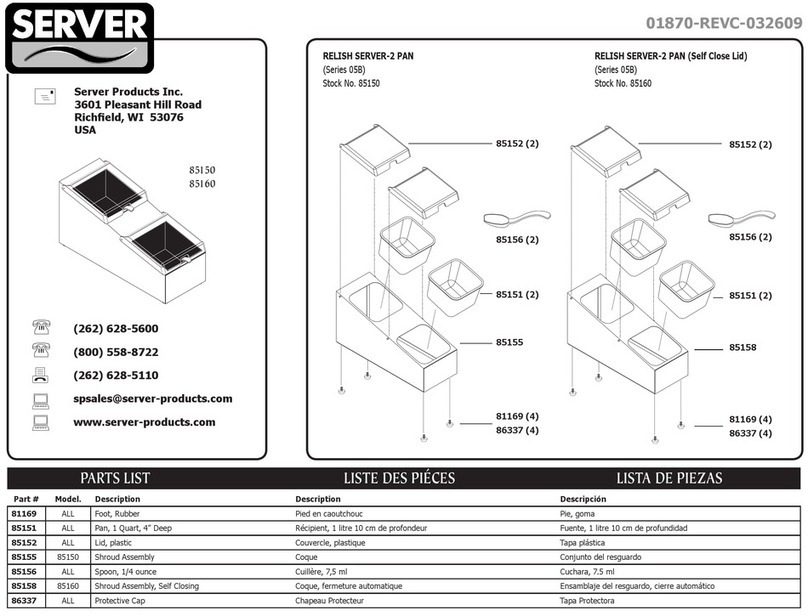

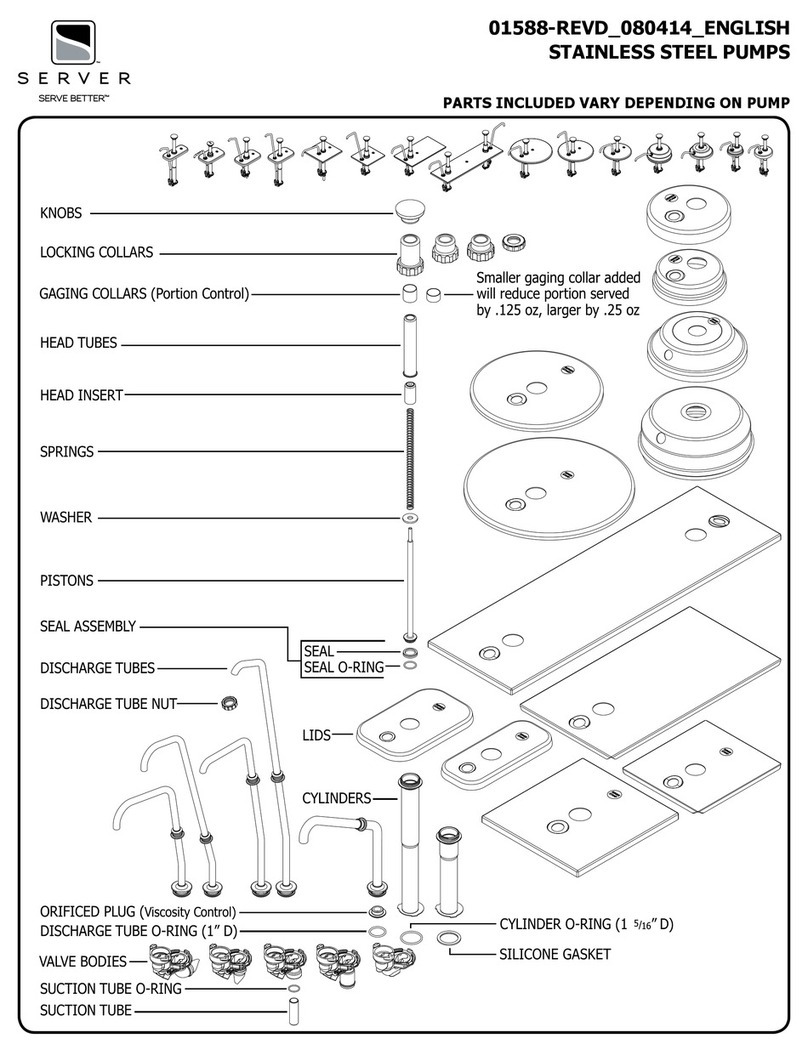

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

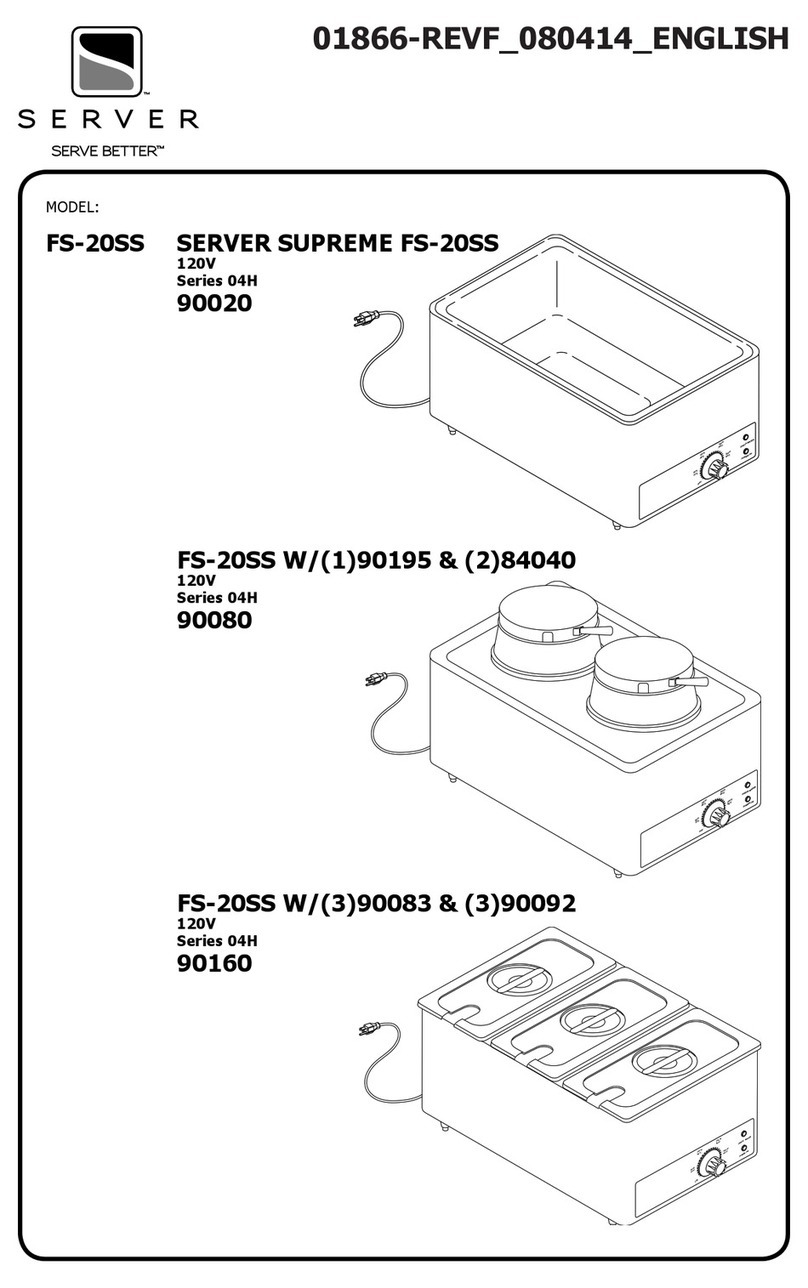

• Model Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

This information and other important data is stamped on

the lid or cylinder of pumps or on the bottom or back side

of every unit.

TROUBLESHOOTING

PROBLEMS WITH PUMP OPERATION AND/OR FLOW:

• Clean pump.

PUMP DISPENSES LITTLE OR NO PRODUCT.

• Product may be too stiff or contain a solid

that will not pass through pump.

PORTION CONTROL IS NOT CONSISTENT.

• Inspect gaging collar for any damage and/or

proper installation.

PUMP PLUNGER DOES NOT RETURN TO TOP OF STROKE

AFTER DISPENSING PRODUCT.

• Inspect spring for any damage; bent or

broken. Replace spring if necessary.

PUMP DRIPS.

• Clean discharge tube with supplied cleaning

brushes.

• Ensure product is not being heated by any

external source(s) causing product to expand

and drip from pump.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a

two-year limited warranty against defects in materials and

workmanship. For complete warranty information go to:

www.server-products.com

SCOPE OF WARRANTY:

Server Products Inc. (“Server Products”) warrants that,

for a period of two (2) years from the date of purchase

(the “Warranty Period”), the equipment manufactured by

it will be free from defects in workmanship and materials

provided the equipment is used in the manner and in the

environment for which they were manufactured.

DISCLAIMERS AND LIMITATIONS:

Other than as set forth above, Server Products specically

disclaims all express and implied warranties, including but

not limited to, warranties of merchantability and/or tness

for a particular purpose or use.

This warranty does not extend to repairs or alterations

undertaken without the prior written consent of Server

Products or for goods that are misused, abused or

neglected or if the goods are not properly stored,

maintained, installed or operated.

Server Products shall not be liable for incidental, special,

indirect, exemplary, punitive or consequential damages

resulting from the use of the good or arising out of any

breach of this warranty; including but not limited to

damage to property or loss of prots or revenue.

CLAIMS ADMINISTRATION:

All warranty claims must be made by calling our customer

service department for a return authorization during the

Warranty Period and any alleged defective unit must be

returned to Server Products factory, freight prepaid.

Upon receipt of any defective unit, Server Products, at its

option, may either: (i) replace any equipment proved to be

defective, (ii) remedy or repair such defect or (iii) refund

the purchase price of the defective equipment in the form

of a credit applicable to future purchases. Server Products

obligation and Buyer’s sole remedy will be limited to these

options. In the case of units or parts purchased by Server

Products from a third-party supplier: Server Products’

obligation and Buyer’s sole remedy against Server Products

or Server Products’s suppliers shall not exceed the

settlement which Server Products is able to obtain from its

supplier.

SAFETY GUIDELINES WHEN

USING THIS PUMP:

According to food and safety regulations, most foods must

be stored and/or served at certain temperatures or they

could become hazardous. Check with your local food and

safety regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for the

serving of potentially hazardous product.

NSF International lists this pump as:

“Not acceptable for dispensing potentially

hazardous foods.”

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless

steel. Server Products, Inc. regrets that we can not

honor warranty claims on stainless steel parts that

have been affected by sauerkraut

or Aus Jus.

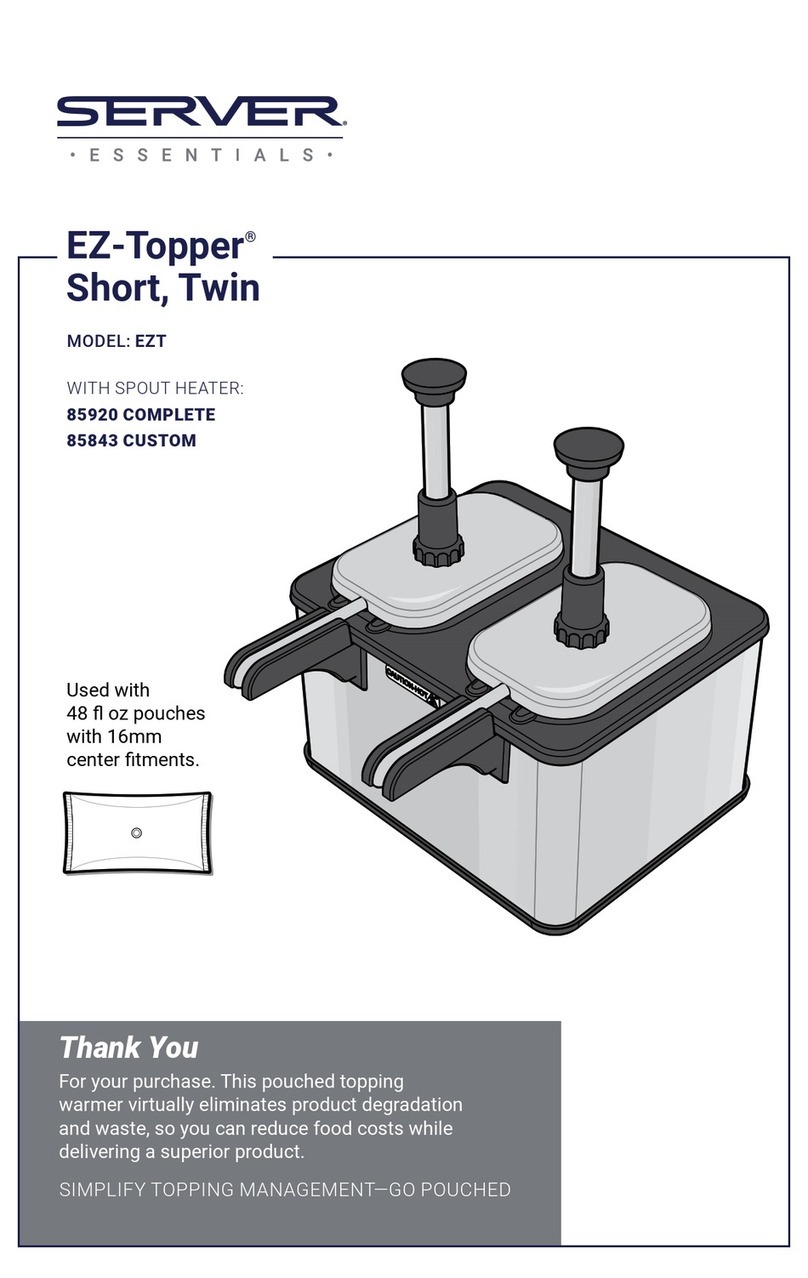

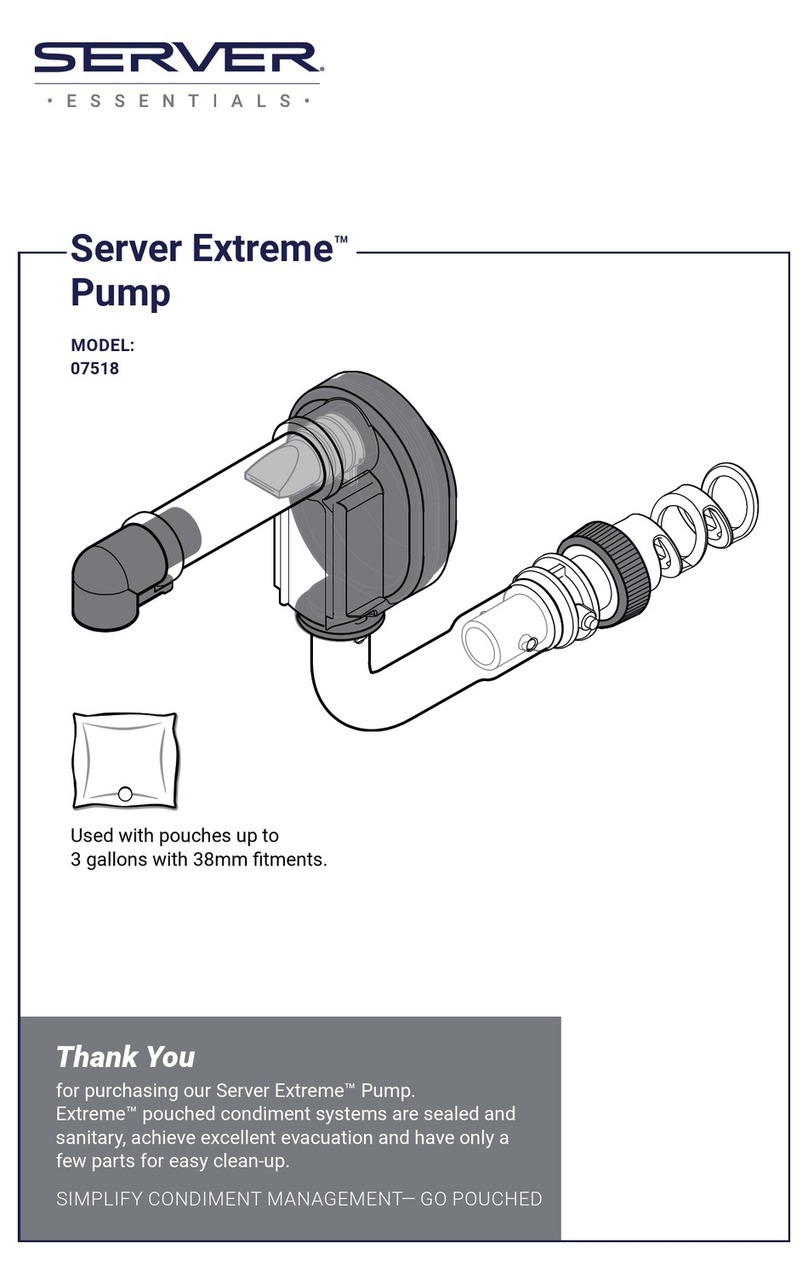

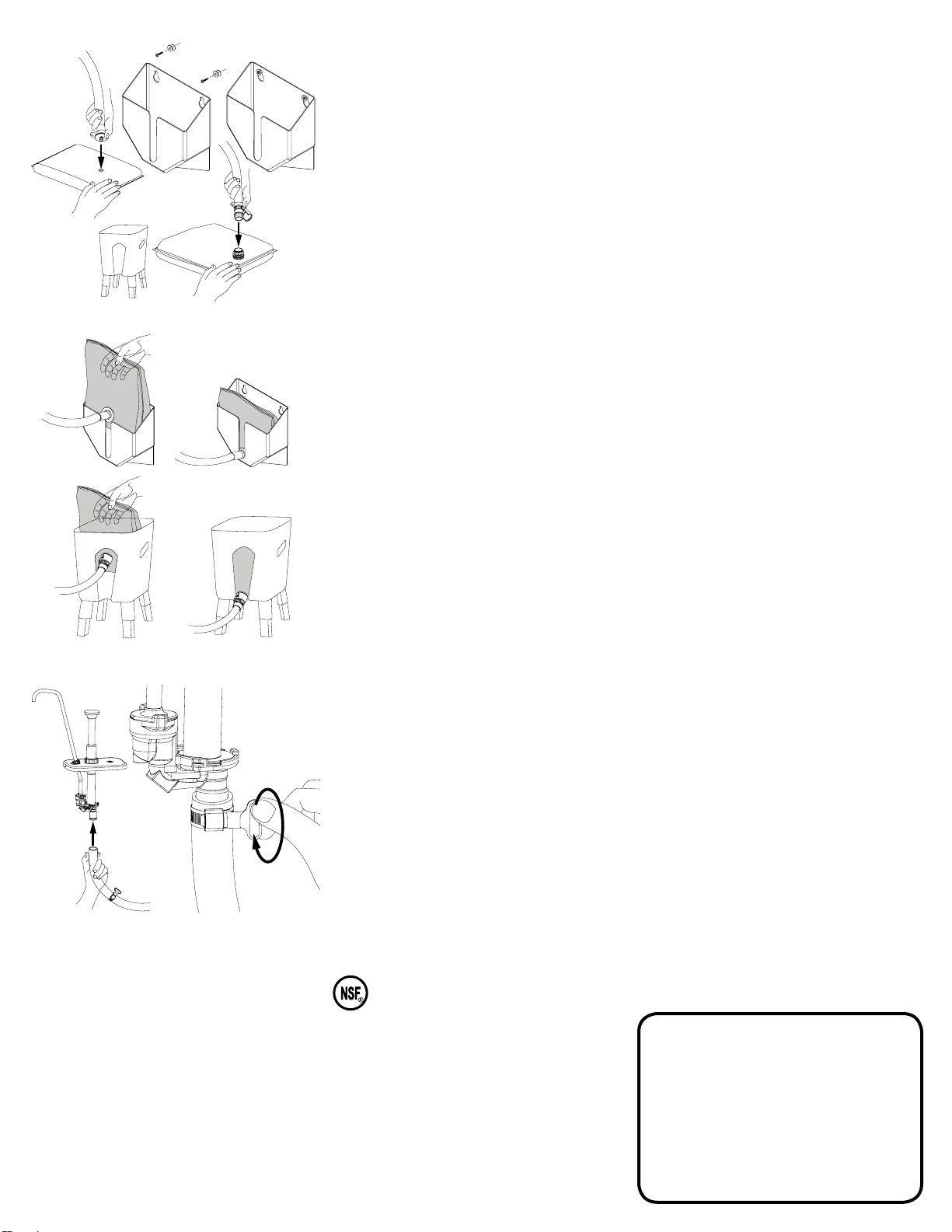

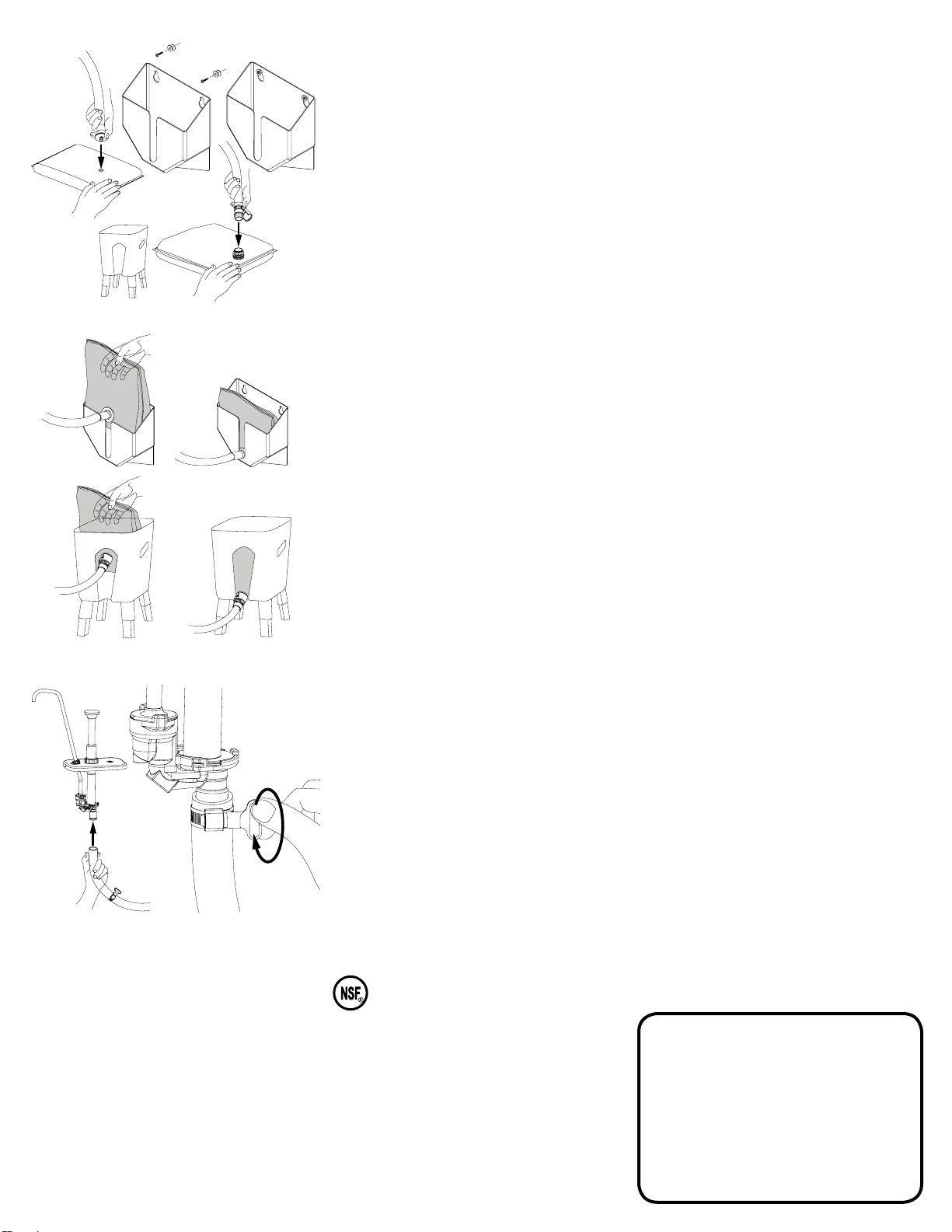

1ATTACH HOSE TO PRODUCT POUCH

2INSTALL PRODUCT POUCH INTO HOLDER

3ATTACH HOSE TO PUMP: SECURE BY ROTATING

TURN KEY CLAMP ON HOSE CLOCKWISE TO TIGHTEN

CLAMP AROUND HOSE AND VALVE BODY.