Server 07A Series User manual

Other Server Commercial Food Equipment manuals

Server

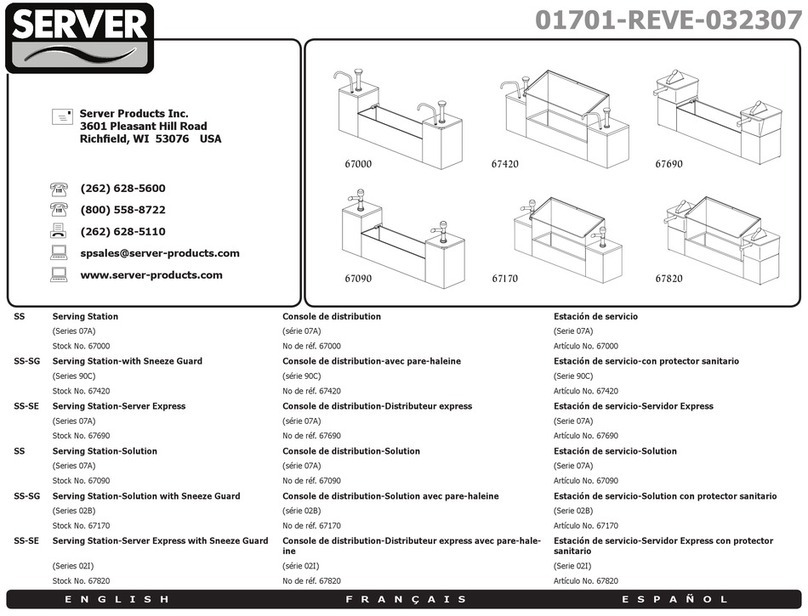

Server 07A Series User manual

Server

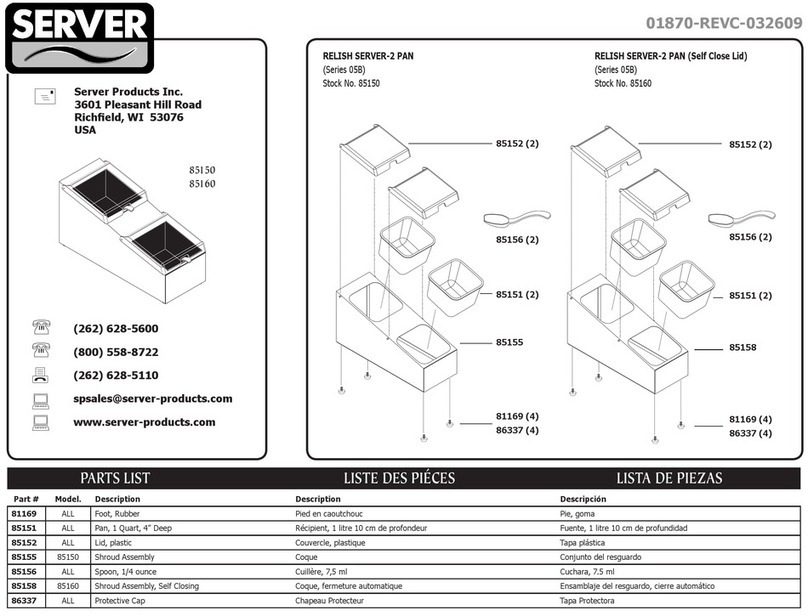

Server 85150 User manual

Server

Server 07A Series User manual

Server

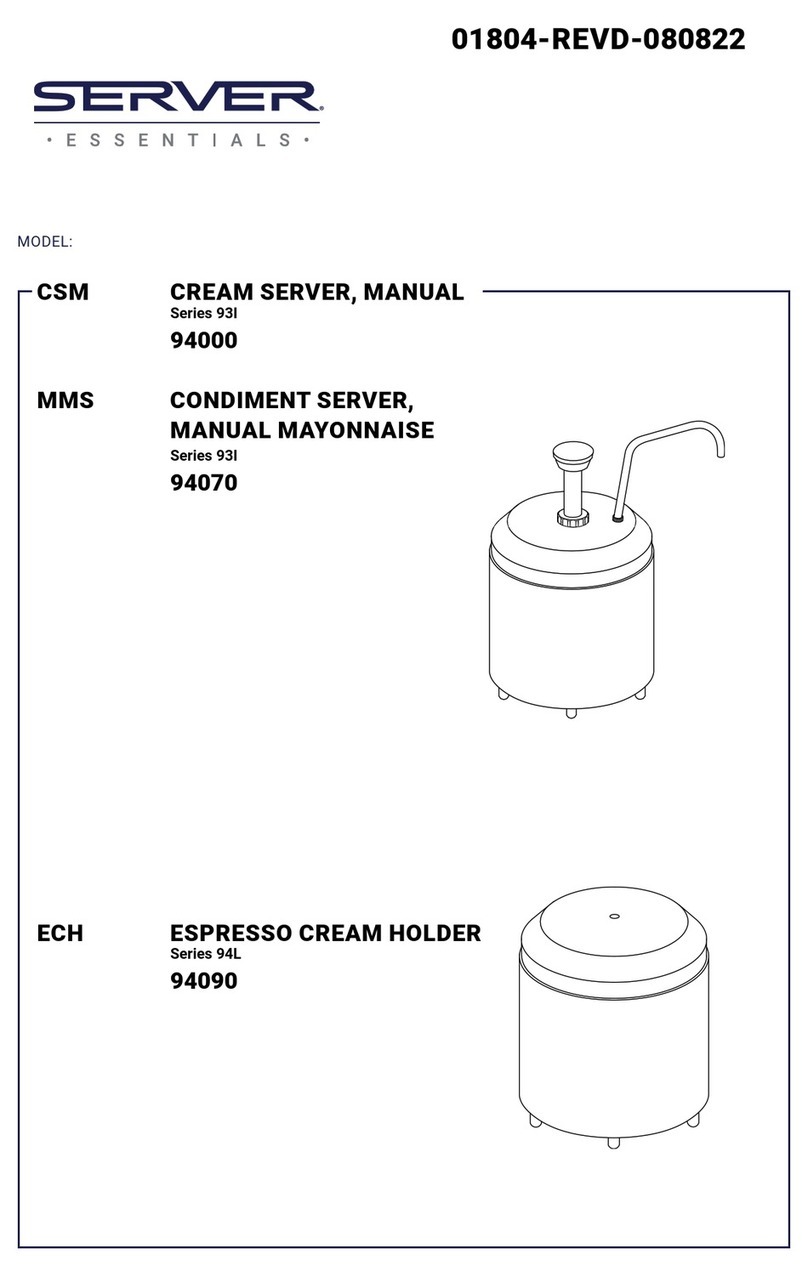

Server 93I Series User manual

Server

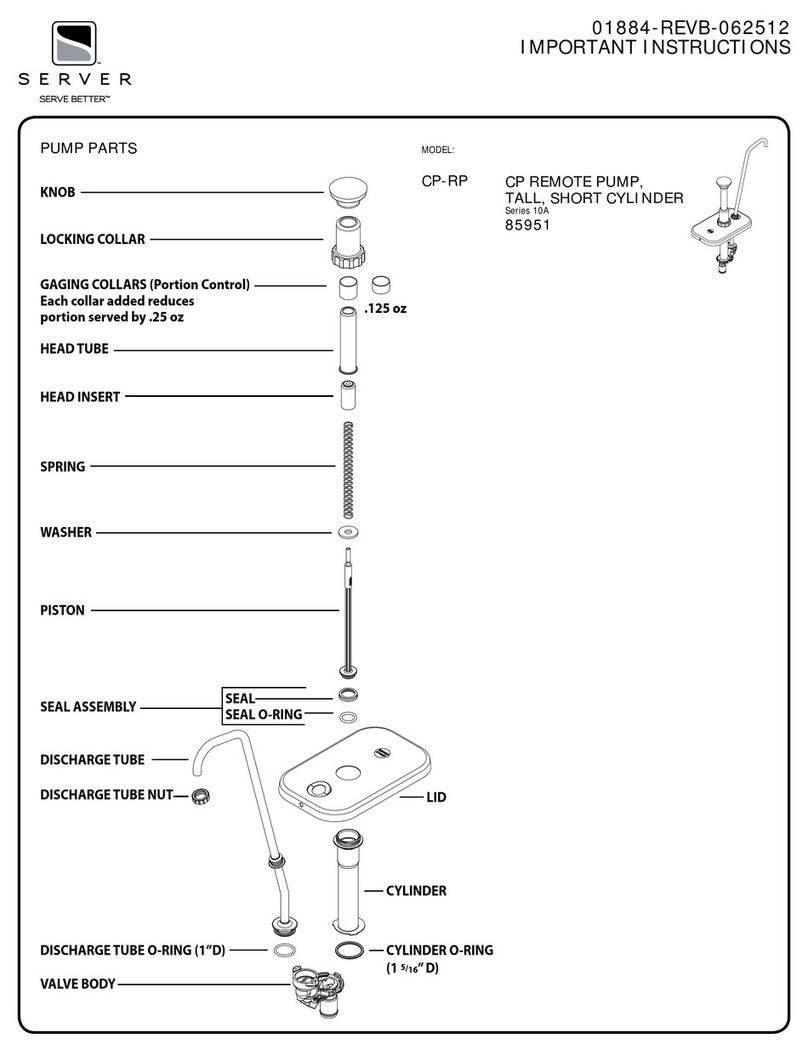

Server CP-RP User manual

Server

Server CONSERVEWELL 13E Series User manual

Server

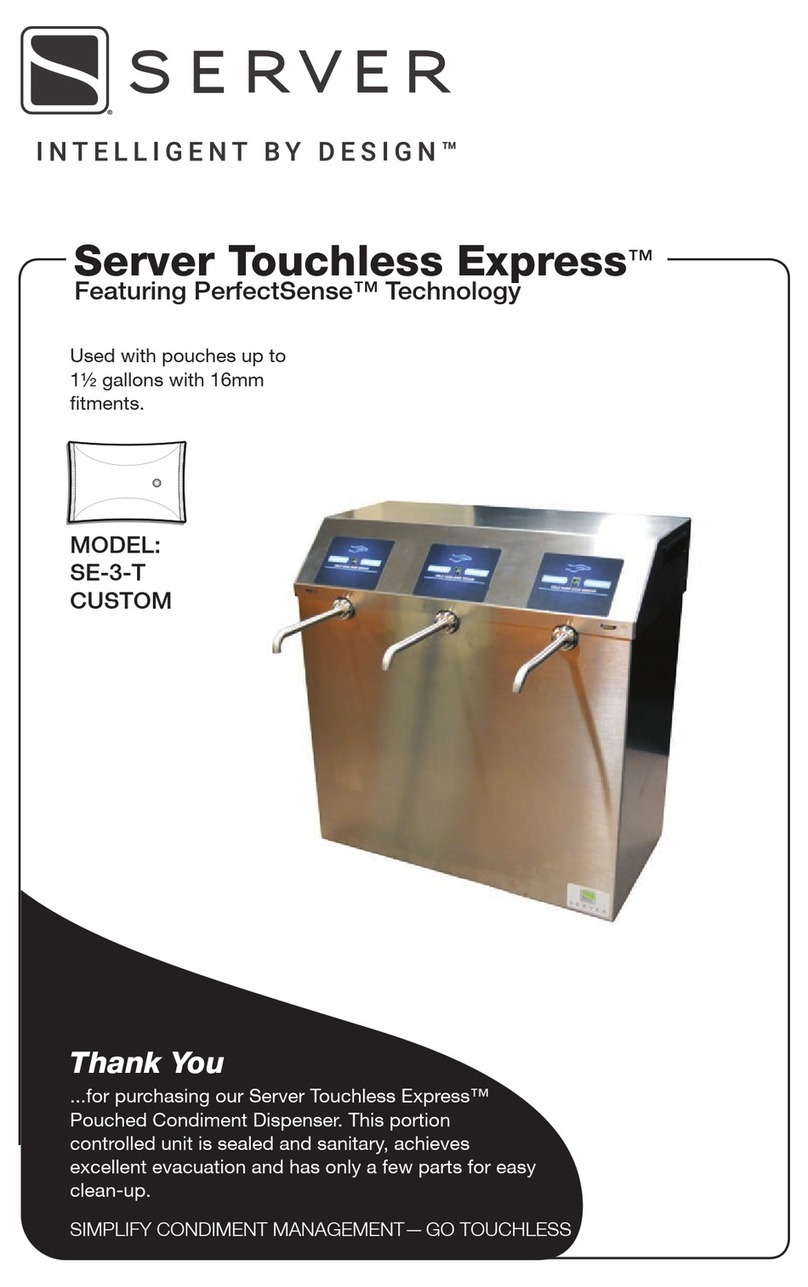

Server Touchless Express SE-3-T User manual

Server

Server PPO-3 User manual

Server

Server PPO-5 User manual

Server

Server CSM 94000 User manual

Server

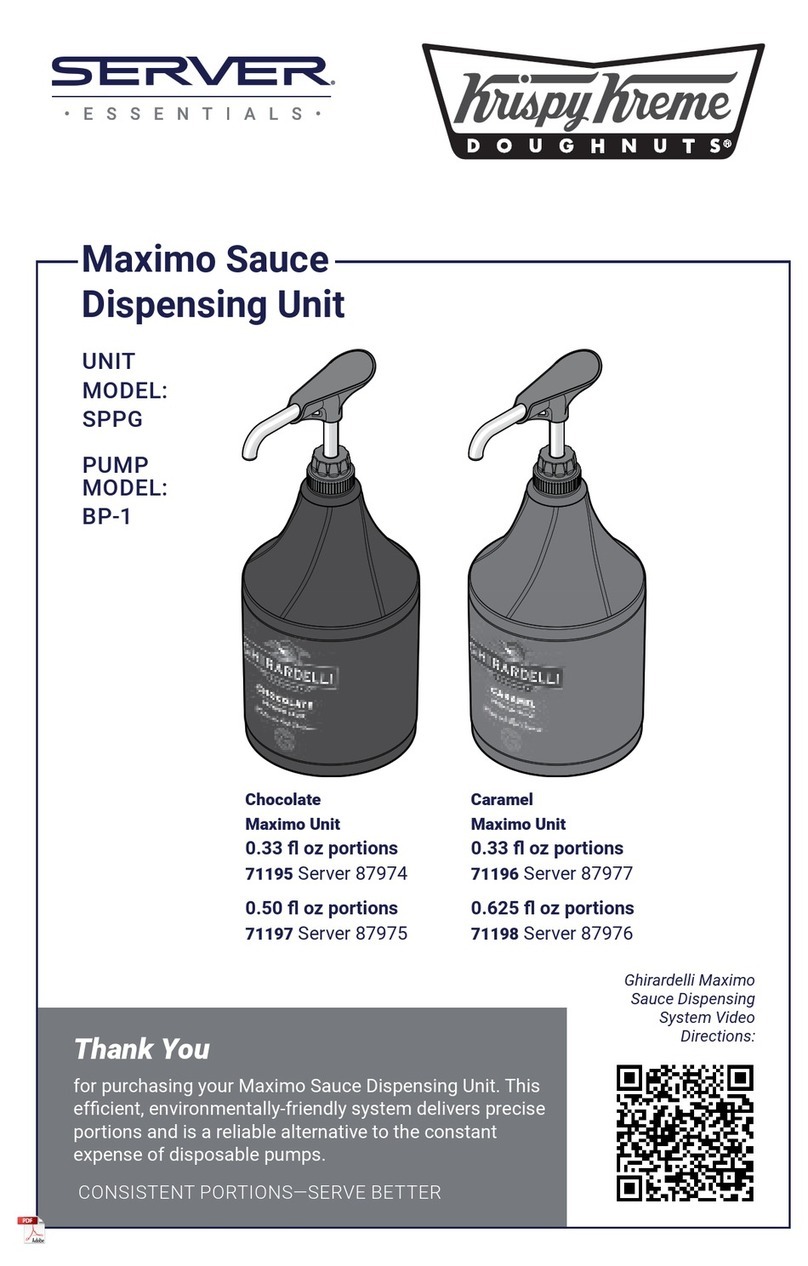

Server Krispy Kreme SPPG User manual

Server

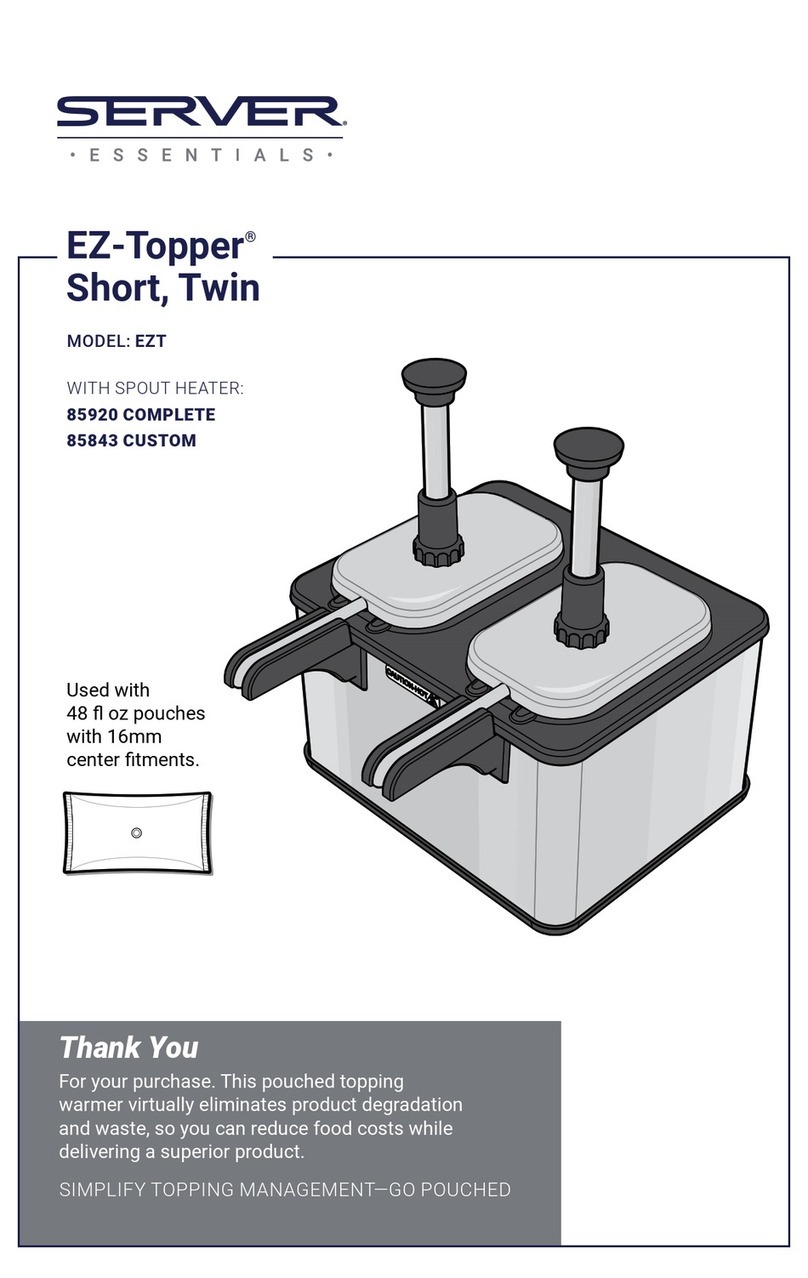

Server EZ-Topper Short EZT User manual

Server

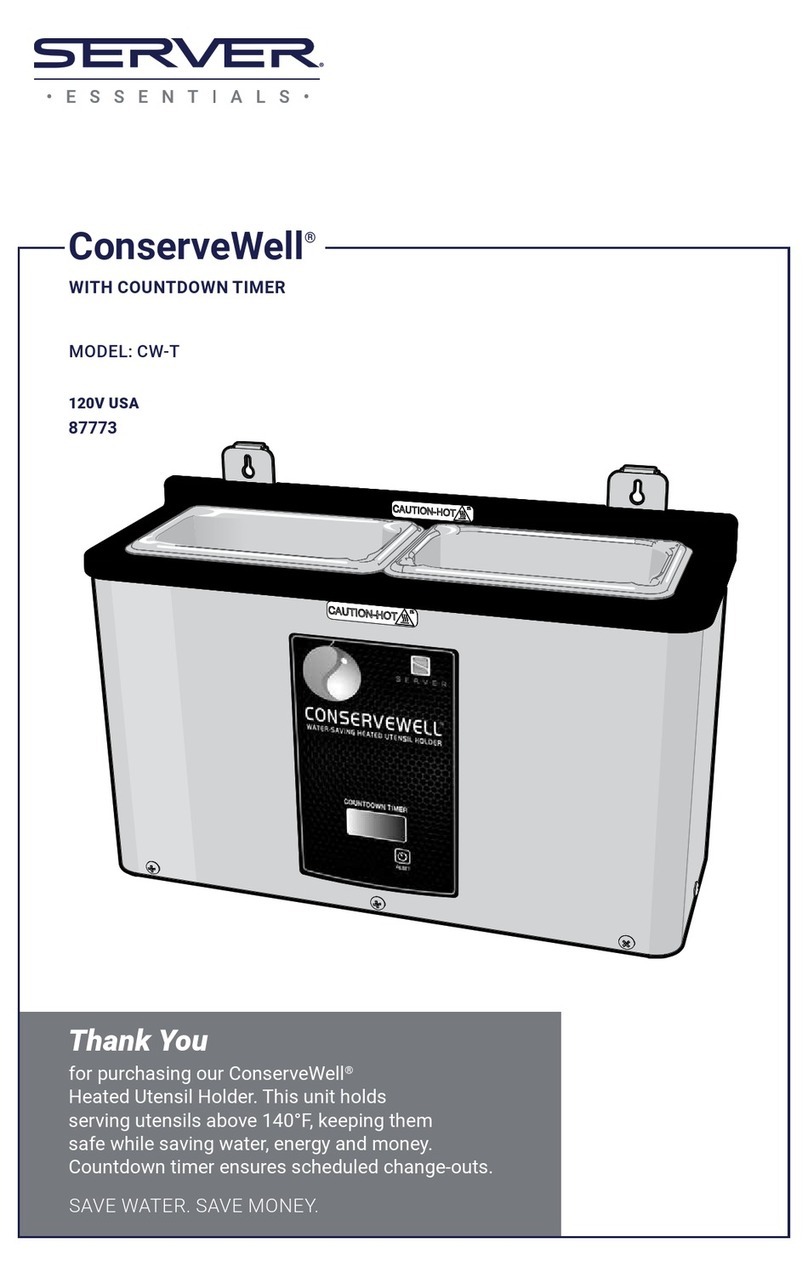

Server ConserveWell CW-T User manual

Server

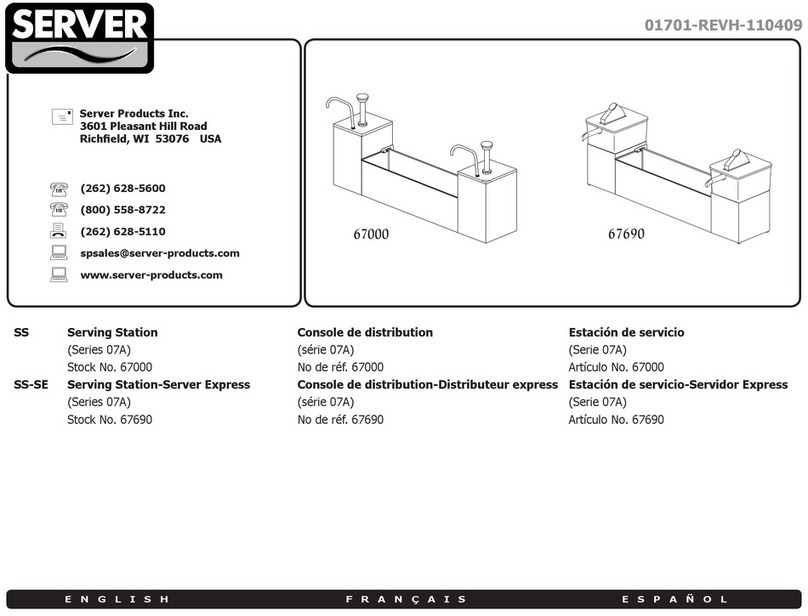

Server 67000 User manual

Server

Server TWIN FS User manual

Server

Server TWIN FS 81220 Installation instructions manual

Server

Server SBH-1 User manual

Server

Server FS-2 User manual

Server

Server 82093 User manual

Server

Server 67770 IRS-2 User manual

Popular Commercial Food Equipment manuals by other brands

Felix Storch

Felix Storch SUMMIT RFBW61G instruction manual

Lotus

Lotus LIBR.ISTR.FT110G Installation and operating instructions

Star

Star RTW14M Installation and operation instructions

Electrolux Professional

Electrolux Professional IC43316 installation manual

JUKA

JUKA VDL 108 instruction manual

Diamond

Diamond SA/61G Instructions for use and installation

Maxima

Maxima Soup Kettle 10L user manual

Lotus

Lotus PC-74GA Installation and operating instructions

Woodson

Woodson W.HFH23 Specification, installation and operation manual

Hatco

Hatco GLO-RAY GRS Series Installation & operating manual

Grainfather

Grainfather Conical Fermenter instructions

Mono

Mono OMEGA TOUCH 450 Operating and maintenance manual

CombiSteel

CombiSteel 7178.0905 Instruction & maintenance manual

Cossiga

Cossiga LS Series user guide

Bartscher

Bartscher W3B-1 Original instruction manual

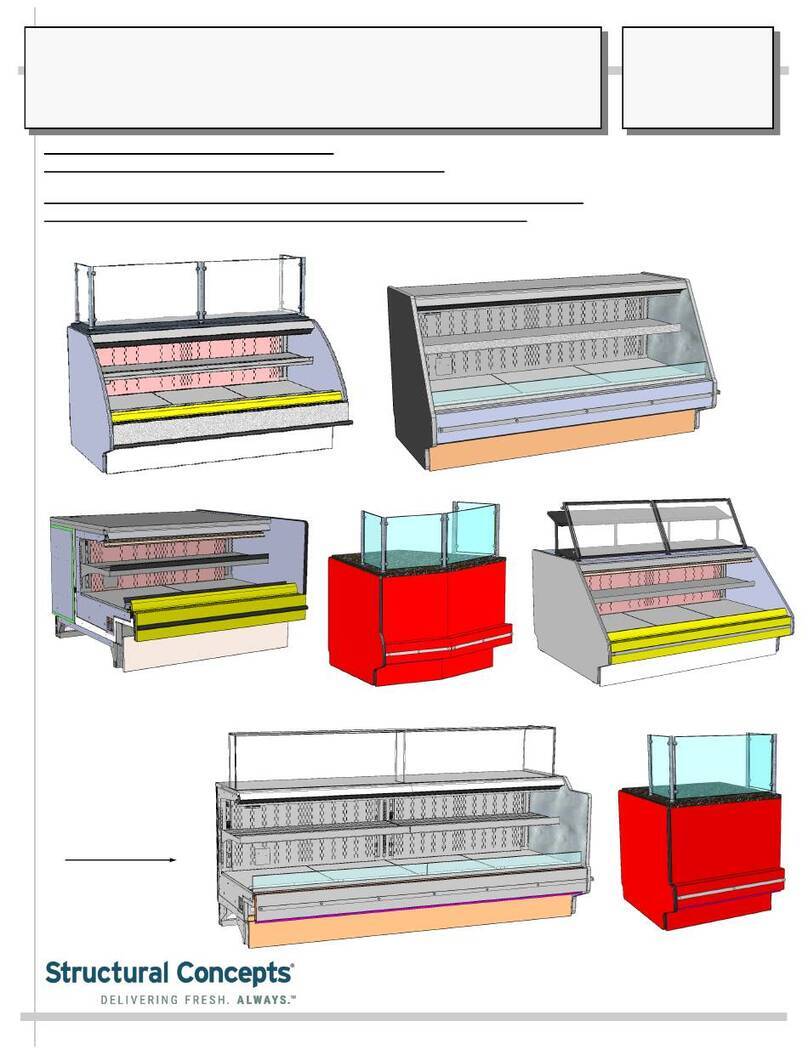

Structural Concepts

Structural Concepts FUSION user manual

Angelo Po

Angelo Po 1G0GRG Use and installation manual

Convotherm

Convotherm OEB Series Service handbook