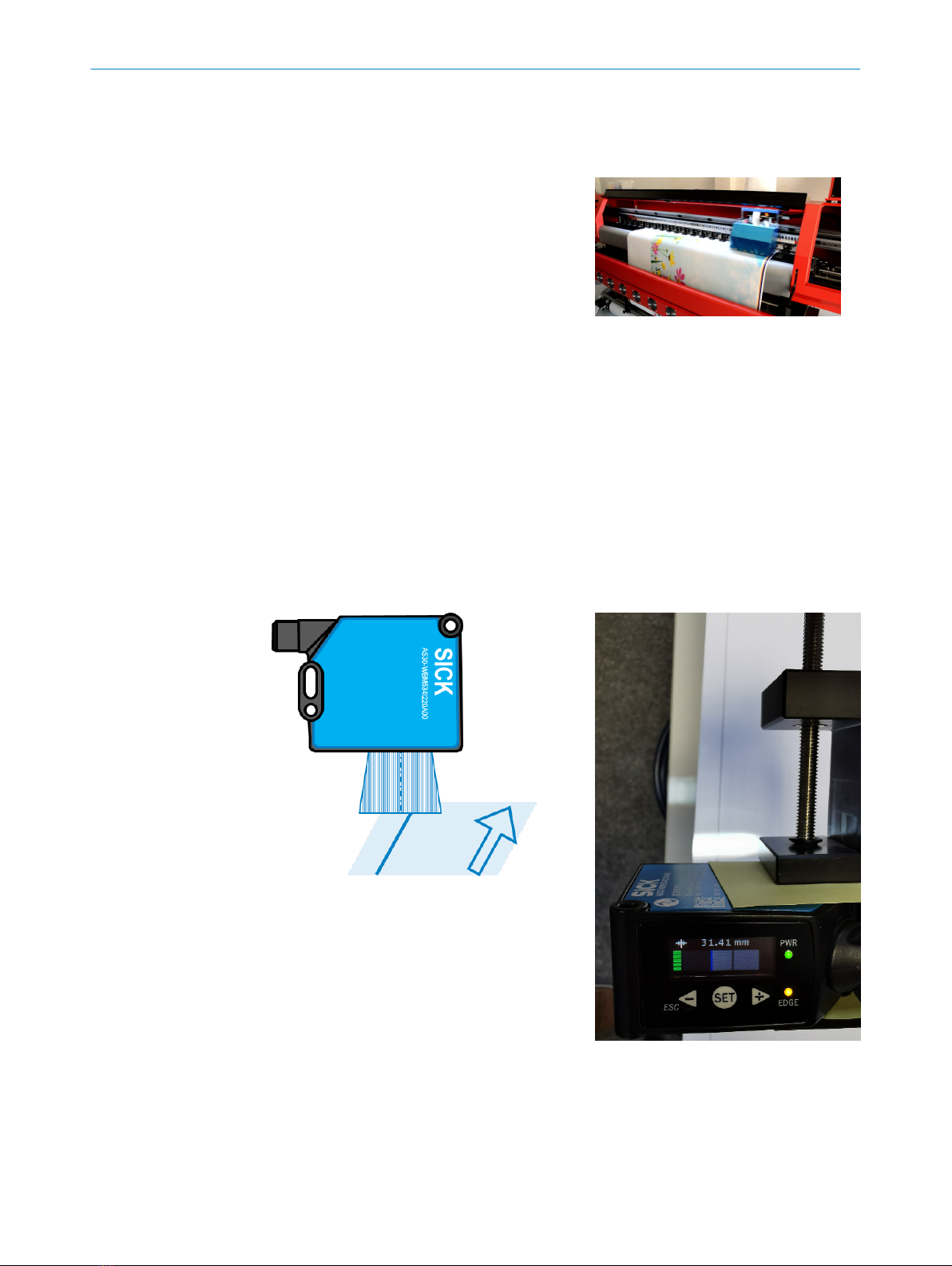

4 Guide line detection in print industry

Task:

In large printing houses, the alignment

of the paper is extremely important. On

many occasions, a printing alignment

line is also used. With this line, the

paper edge and the printing edge are

both measured to ensure alignment of

printer head and paper. Camera sys‐

tems have been used to manage this

task, but due to lighting and different

print line colors, repeated setup is

often needed. The customer requires

an accuracy of 0.1 mm with the dis‐

tance from Line to edge calibrated to

13 mm.

How to ... (Setup and configuration)

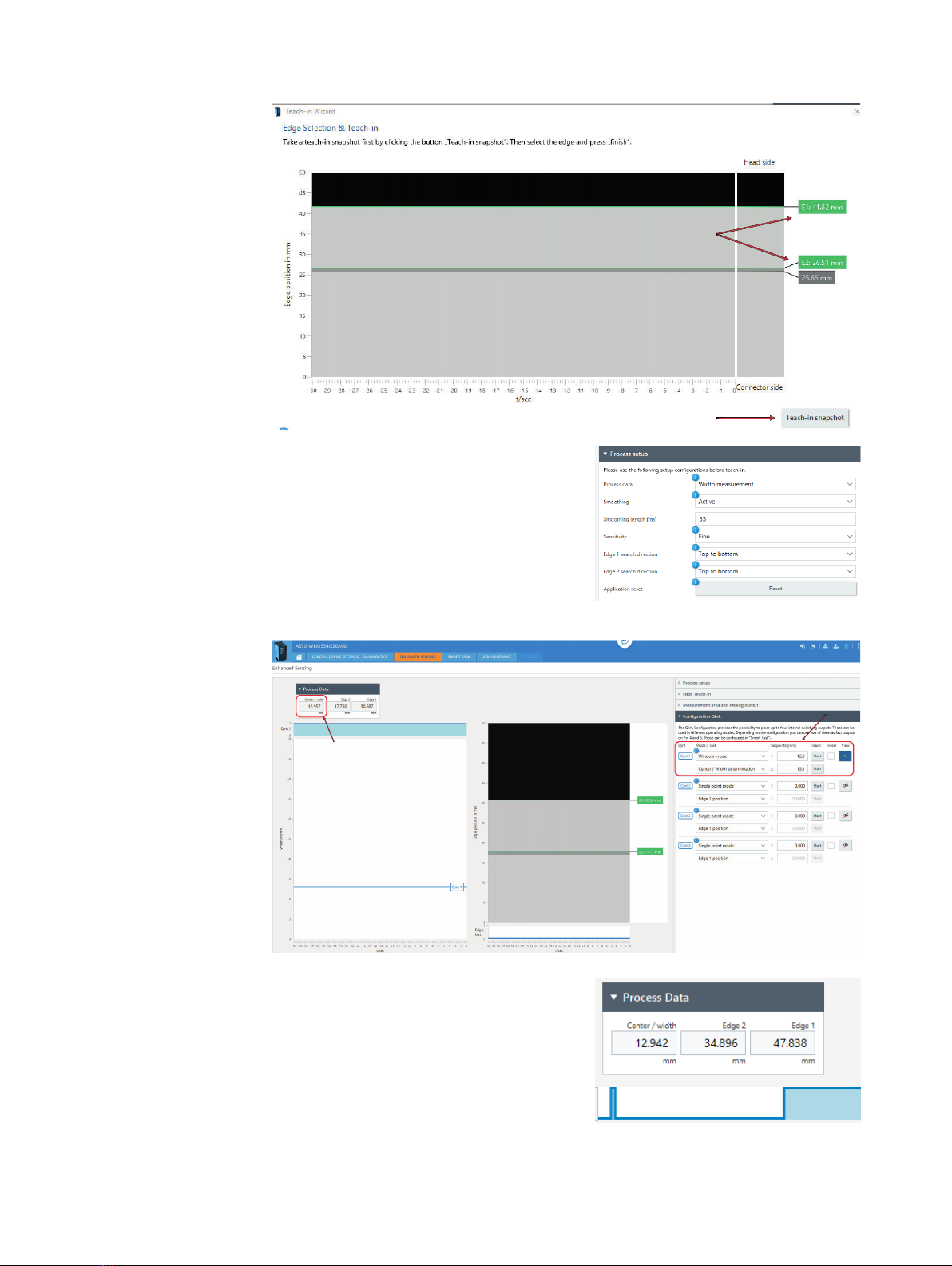

Using Sopas, the AS30 can be configured to width measurement. Also ensure that the

sensitivity is set to Fine.

On the target, select an Easy Teach-in to detect the first two edges in edge search direc‐

tion.

Select Advanced Teach-in to select the preferred edges.

Sopas

In the Teach-in Wizard, select the Teach-in snapshot and then select the preferred edge.

GUIDE LINE DETECTION IN PRINT INDUSTRY 4

8025153/2019-12-10 | SICK T E C H N I C A L I N F O R M A T I O N | AS30 9

Subject to change without notice