Chapter 1Technical Information

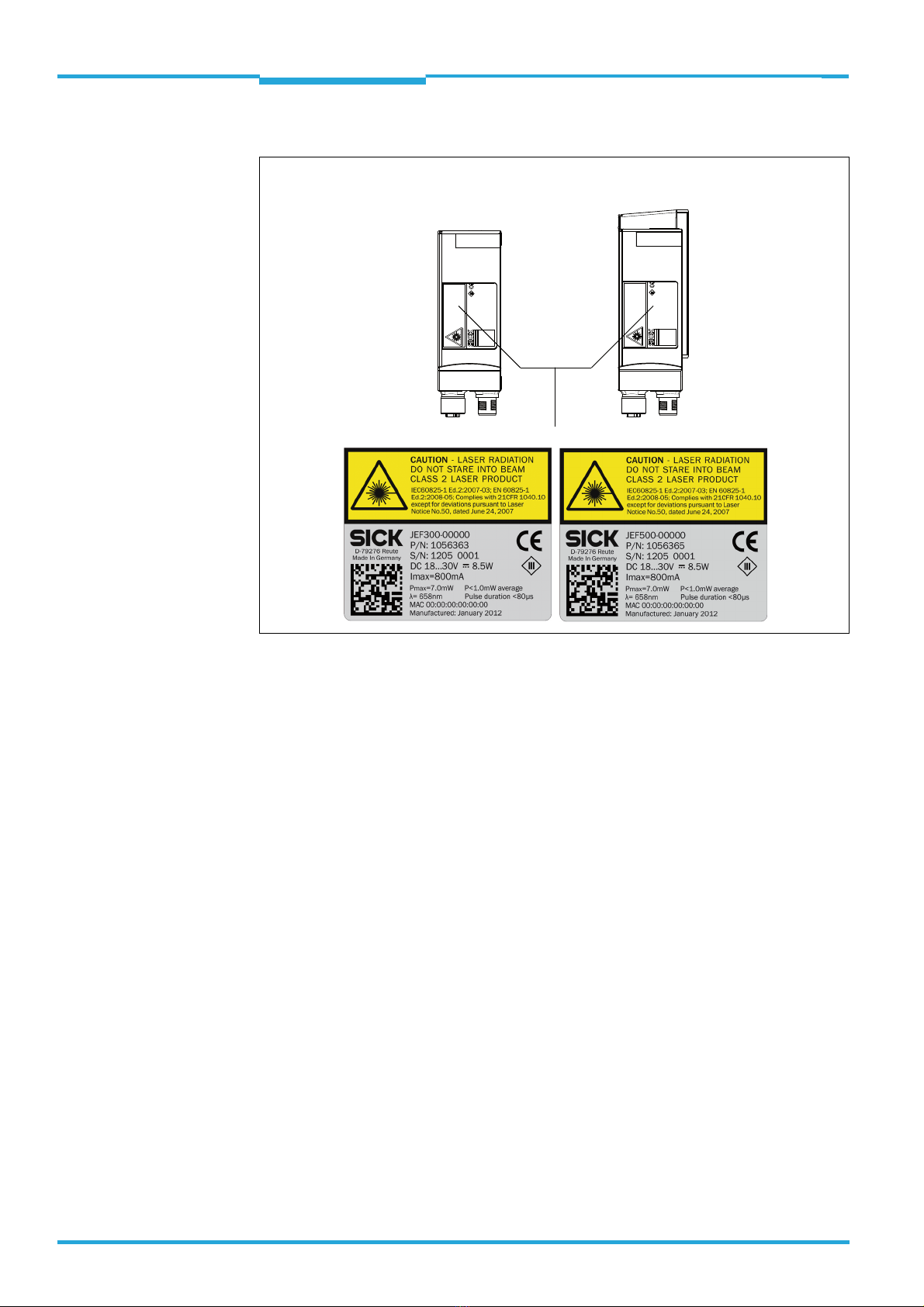

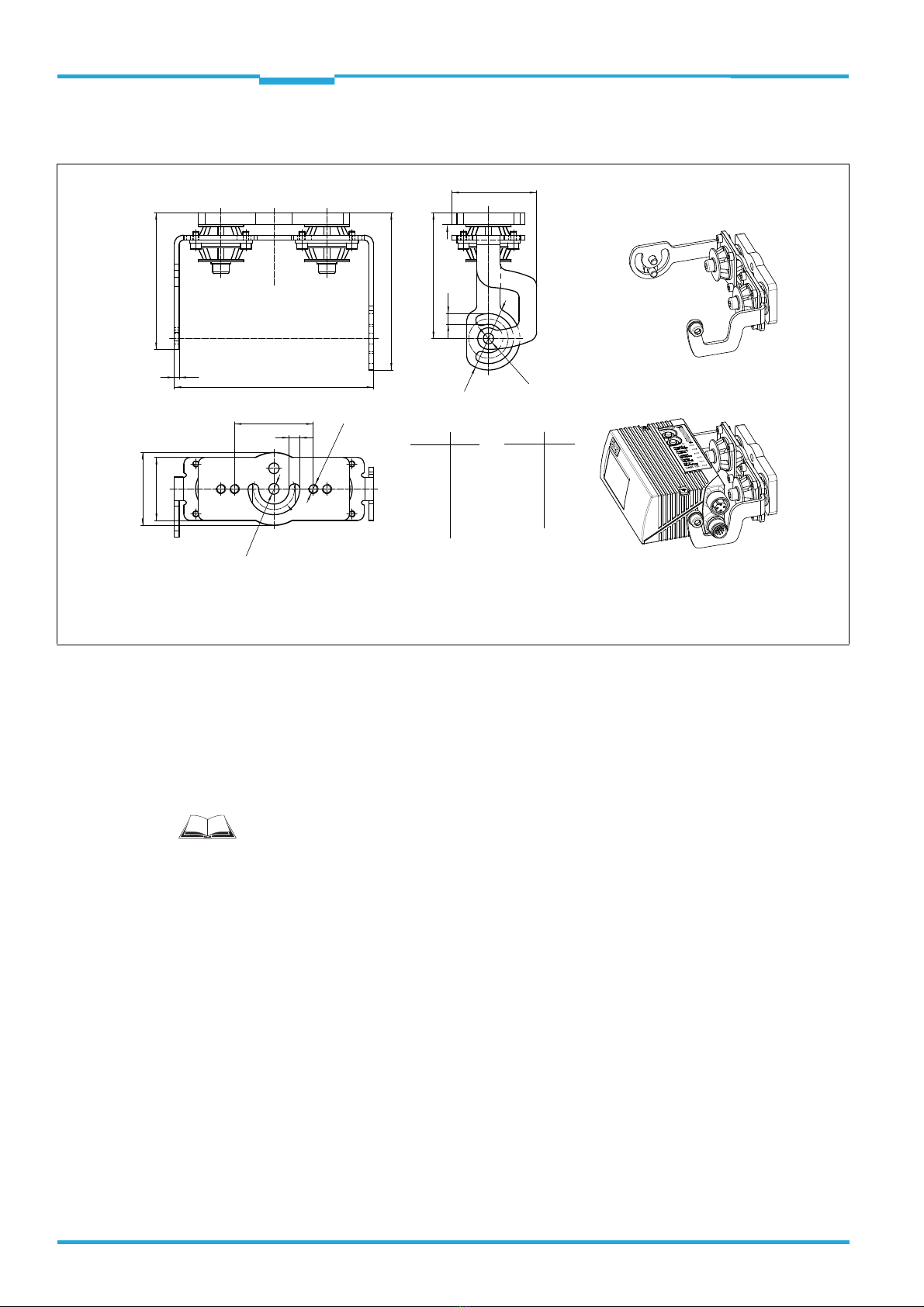

JEF300/500 laser measurement sensors

4©SICK AG · Germany · All rights reserved · Subject to change without notice 8014672/0000/2012-05-08

About this document

This symbol refers to supplementary technical documentation.

1.2 Safety information

Read the notes on mounting and electrical installation prior to carrying out the work.

Read additionally the operating instructions of the JEF300 respectively JEF500 to fa-

miliarize yourself with the device and its functions.

The JEF300/500 corresponds to laser class 2. For more on this, see Section “Laser

warning“, Page 5.

The JEF300/500 is an active sensor. It does not require any illumination for the objects,

any reflectors or position markers.

The JEF300/500 can only safely detect parts of objects, e.g. edges, surrounds or pro-

truding parts, when the area visible for the JEF300/500 is at least three times the an-

gular resolution resulting from the distance to the zero point. If the area is smaller,

distance measurements outside the tolerance of the JEF300/500 may be produced.

Function of the JEF300:

The JEF300 works as a triggered detection sensor in the Level Control application (e.g.

check for complete presence or absence of objects in a matrix). The detection process

can be started and ended via max. two physical switching inputs among other things.

The JEF300 outputs the results after the detection process is complete switching via

max. two physical switching outputs. The results are displayed based on selectable el-

ements from the matrix (matrix complete, row, column or element)

The additional use of a CDB620 connection module with the optional CMC600 param-

eter memory module provides software-controlled expansion by 2 additional switching

inputs and outputs. They are not suitable for time critical applications such as connect-

ing an incremental encoder.

After completing the detection process, the JEF300 also outputs the results as data via

the requesting data interface. After switching on the JEF300, the data is subscribed to

once by command. The results include element-related height values and the status of

the switching threshold evaluation via all rows, columns and elements of the entire ma-

trix.

Function of the JEF500:

As a triggered measurement sensor, the JEF500 outputs the measured values (scan

angle-related radial distance, remission, etc.) via the requesting data interface. After

switching on the JEF500, the data is subscribed to once by command. The data is only

output in realtime via a port of the Ethernet interface.

Only use the device under permitted ambient conditions (e.g. designated region, tem-

perature, ground potential). Where necessary, official and statutory regulations govern-

ing the operation must be complied with.

Opening the screws of the JEF300/500 housing will invalidate any warranty claims

against SICK AG.

Repair work on the JEF300/500 may only be performed by qualified and authorized

service personnel from SICK AG.

The JEF300/500 laser measurement sensors are not devices for protecting persons

as defined by current machine safety standards.