Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Internet protocol (IP) technology.............................................................. 7

2.4 Limitation of liability................................................................................. 7

2.5 Modifications and conversions................................................................ 8

2.6 Requirements for skilled persons and operating personnel.................. 8

2.7 Operational safety and particular hazards.............................................. 9

3 Product description........................................................................... 10

3.1 Scope of delivery....................................................................................... 10

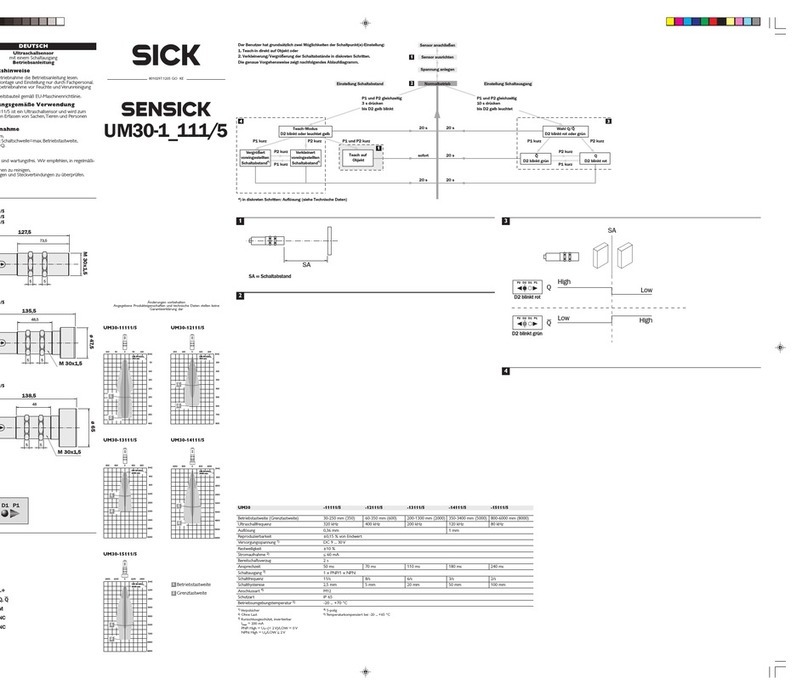

3.2 Setup and dimensions............................................................................. 10

3.3 Display and operating elements.............................................................. 11

3.4 Type code.................................................................................................. 11

3.5 Product identification............................................................................... 12

3.6 Principle of operation............................................................................... 12

3.6.1 Measurement principle........................................................... 12

3.6.2 Range finding........................................................................... 13

3.6.3 Direction measurement.......................................................... 13

3.6.4 Object sizes.............................................................................. 14

3.6.5 Impact of object surfaces on the measurement................... 15

3.6.6 Scanning range........................................................................ 17

3.6.7 Filter.......................................................................................... 17

4 Transport and storage....................................................................... 20

4.1 Transport................................................................................................... 20

4.2 Unpacking.................................................................................................. 20

4.3 Transport inspection................................................................................. 20

4.4 Storage...................................................................................................... 20

5 Mounting............................................................................................. 21

5.1 Mounting instructions............................................................................... 21

5.2 Mounting device....................................................................................... 21

5.3 Mutual interference.................................................................................. 22

6 Electrical installation........................................................................ 23

6.1 Prerequisites for safe operation of the device........................................ 23

6.2 Electrical block diagram for commissioning........................................... 26

6.3 Wiring instructions.................................................................................... 26

6.4 Connection diagram................................................................................. 26

CONTENTS

8026151//2020-11-15 | SICK O P E R A T I N G I N S T R U C T I O N S | TiM4xx 3

Subject to change without notice