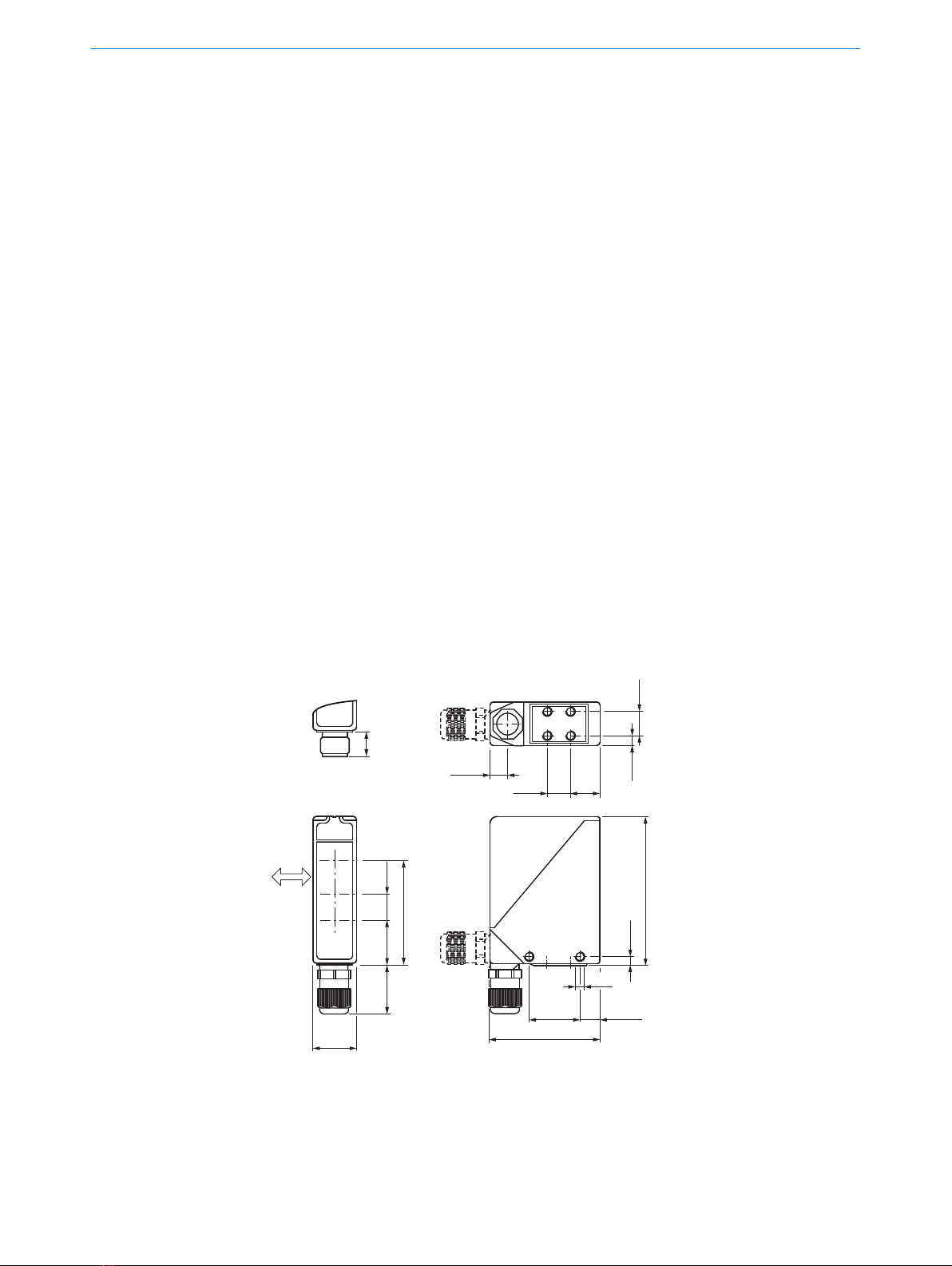

6Center of optical axis, receiver (far range)

7M5 threaded mounting hole, 6 mm deep

8M5 threaded mounting hole, through-hole

9M16 screw fixing and plug rotatable by 90°

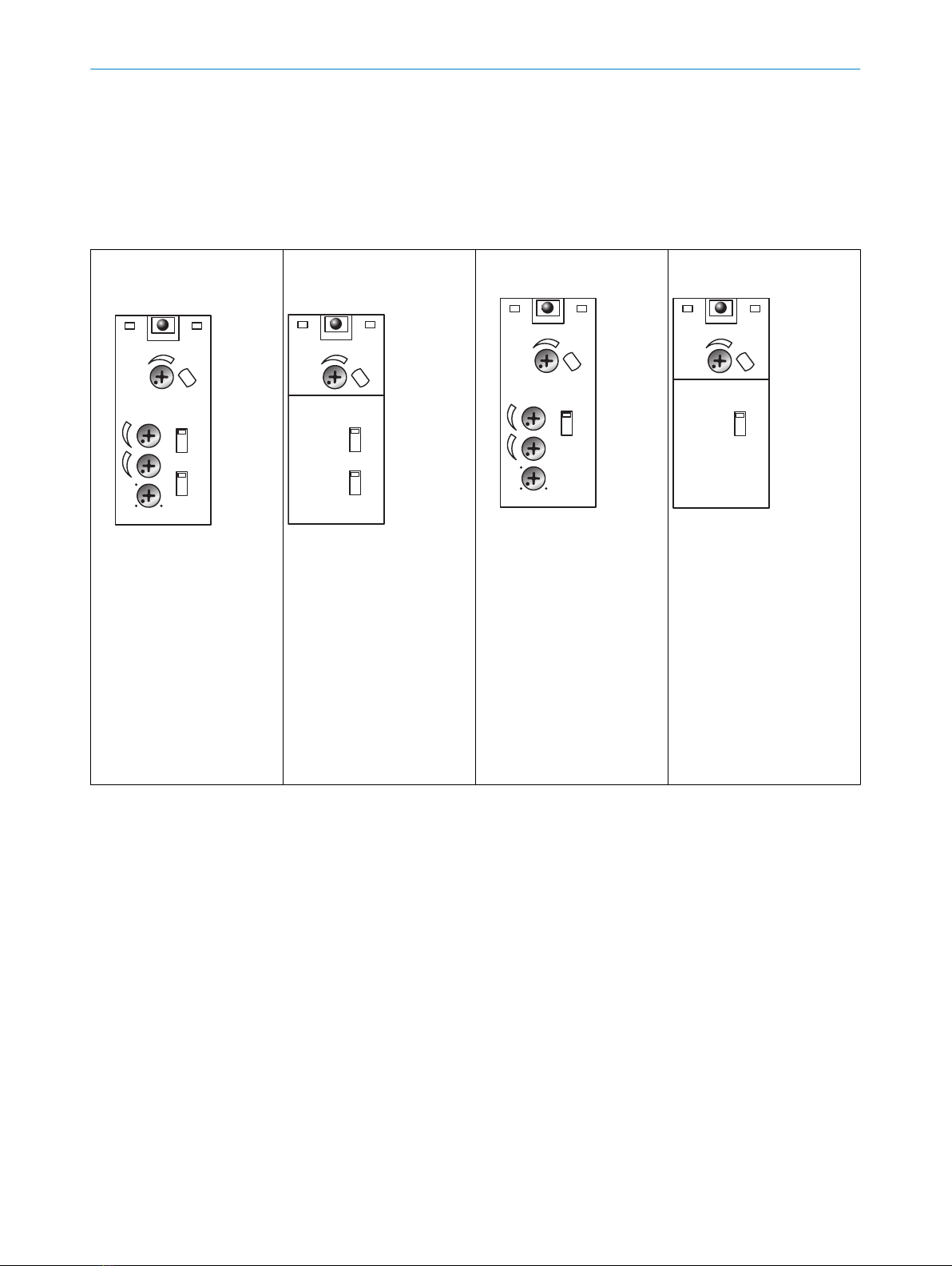

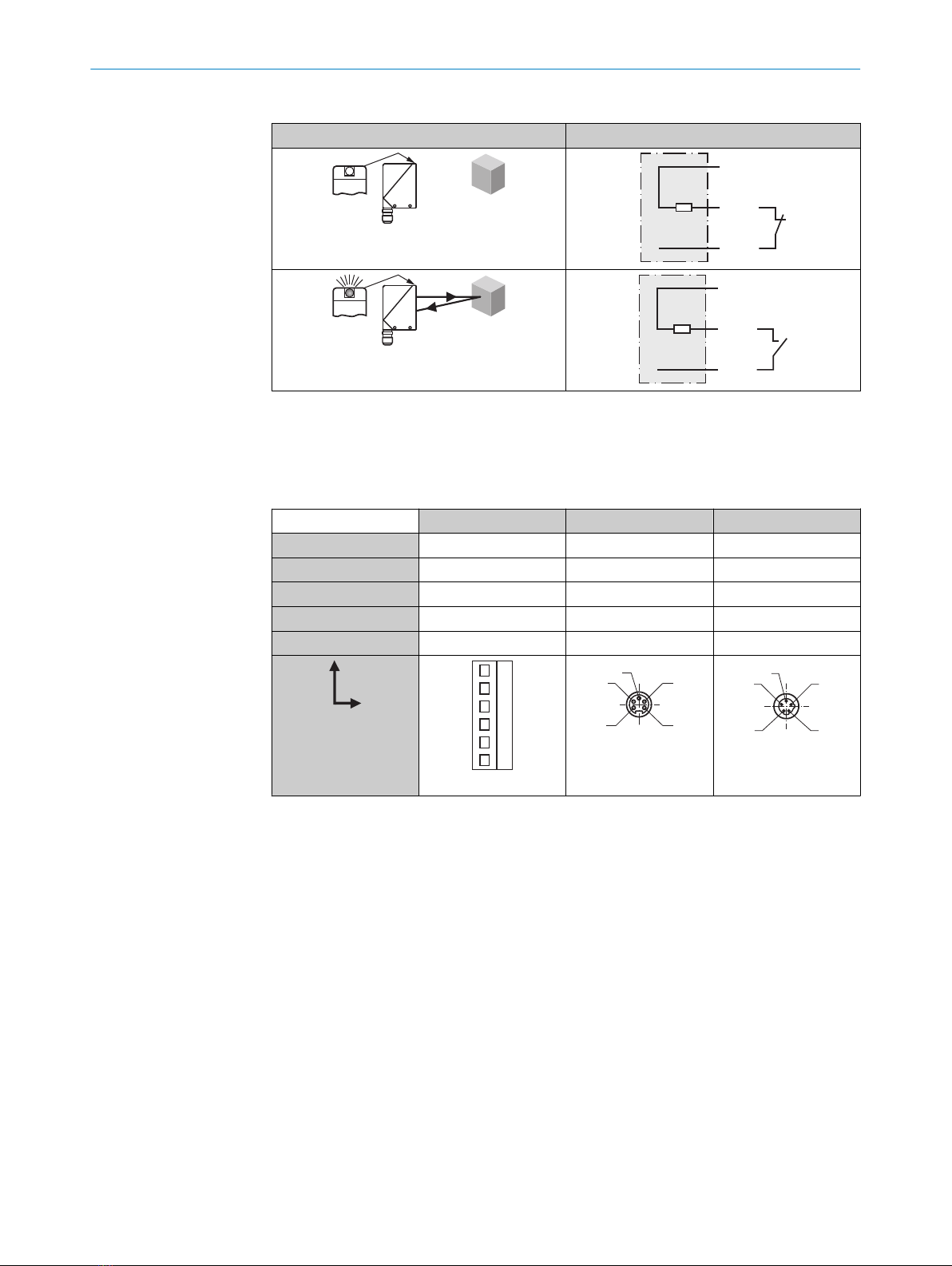

Table 1: Display and operating elements

WT24-2Bx2x, -2Vx2x, -2Bx5x,

-2Vx5x

t2

t2

t1

t1

t1+ t2

t0

PNP

NPN

D

H

1

2

3

6

4

5

7

1.0

1Yellow LED indicator

2Potentiometer: adjust‐

ing the sensing range

3Switch: light (L) / dark

(D)

4Switch: NPN / PNP

5Potentiometer: adjust‐

ment of time delay t2

6Potentiometer: adjust‐

ment of time delay t1

7Potentiometer: adjust‐

ment of time stage

WT24-2Bx1x, -2Vx1x, -2Bx4x,

-2Vx4x

1Yellow LED indicator

2Potentiometer: adjust‐

ing the sensing range

3Switch: light (L) / dark

(D)

4Switch: NPN / PNP

WT24-2Rx2x, -2Rx5x

t2

t2

t1

t1

t1+ t2

t0

D

H

1.0

1

2

3

5

4

6

1Yellow LED indicator

2Potentiometer: adjust‐

ing the sensing range

3Switch: light (L) / dark

(D)

4Potentiometer: adjust‐

ment of time delay t2

5Potentiometer: adjust‐

ment of time delay t1

6Potentiometer: adjust‐

ment of time stage

WT24-2Rx1x, -2Rx4x

1Yellow LED indicator

2Potentiometer: adjust‐

ing the sensing range

3Switch: light (L) / dark

(D)

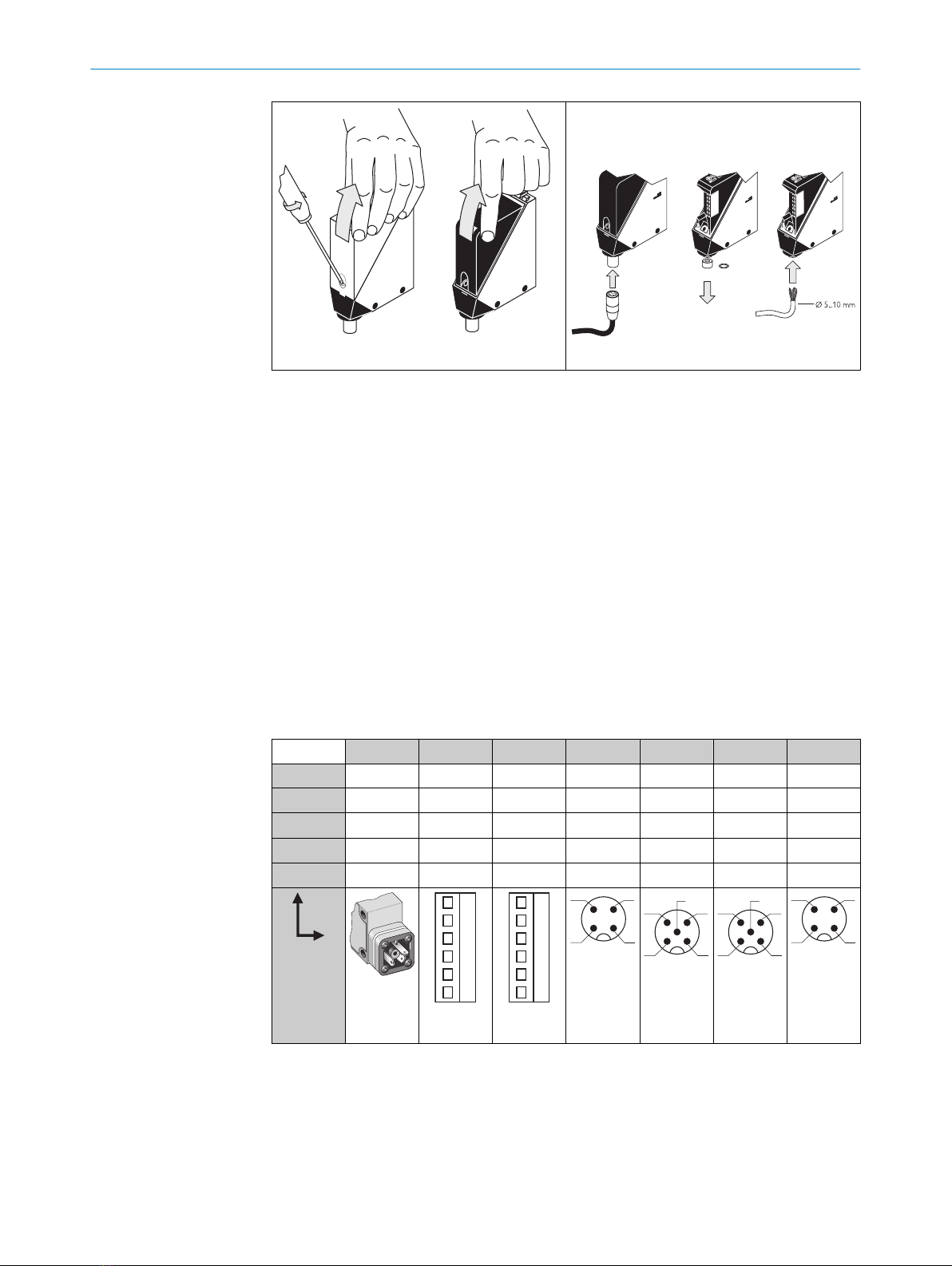

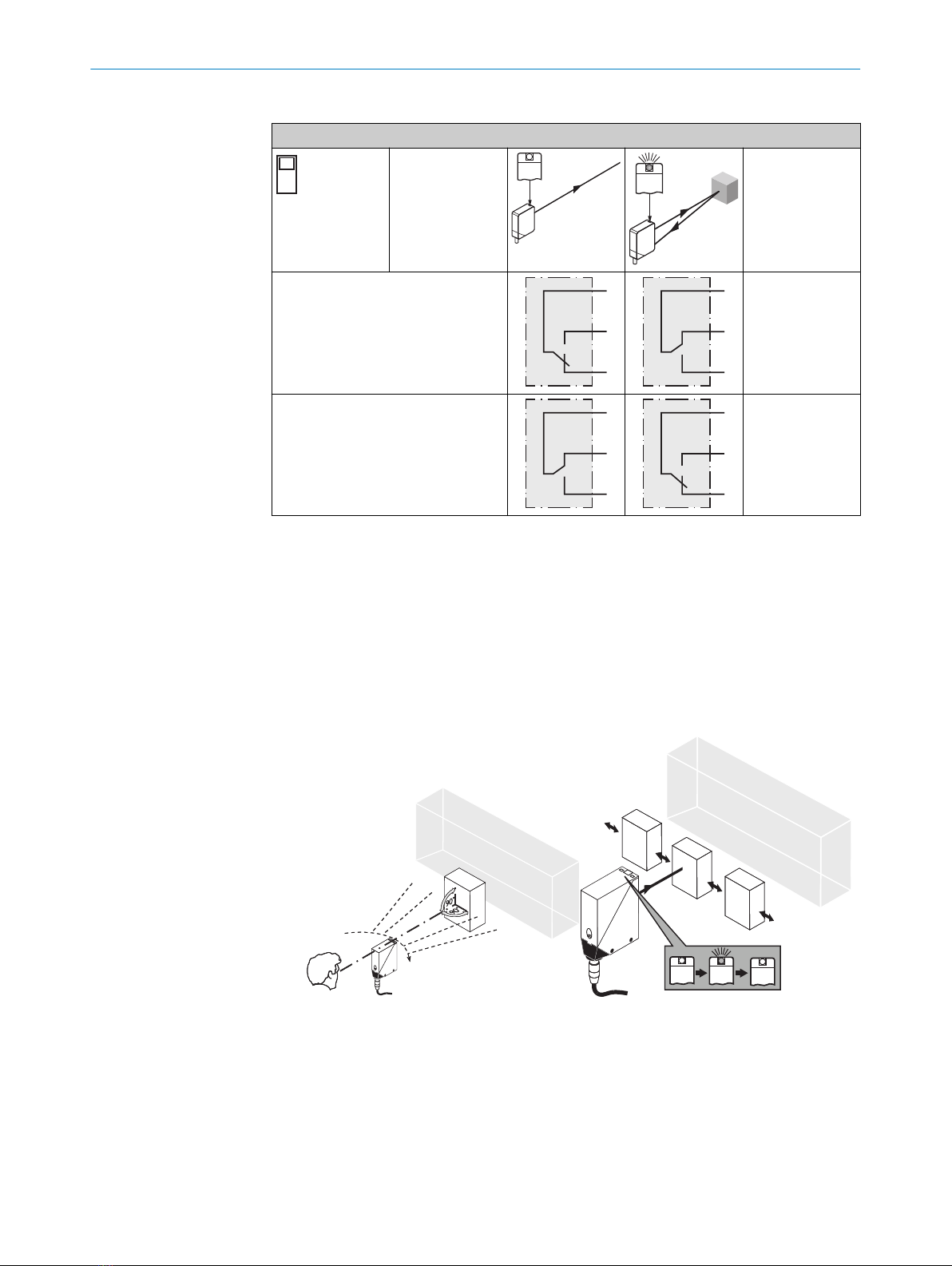

4 Mounting

Mount the sensor using a suitable mounting bracket (see the SICK range of accesso‐

ries).

Note the sensor's maximum permissible tightening torque of 2 Nm.

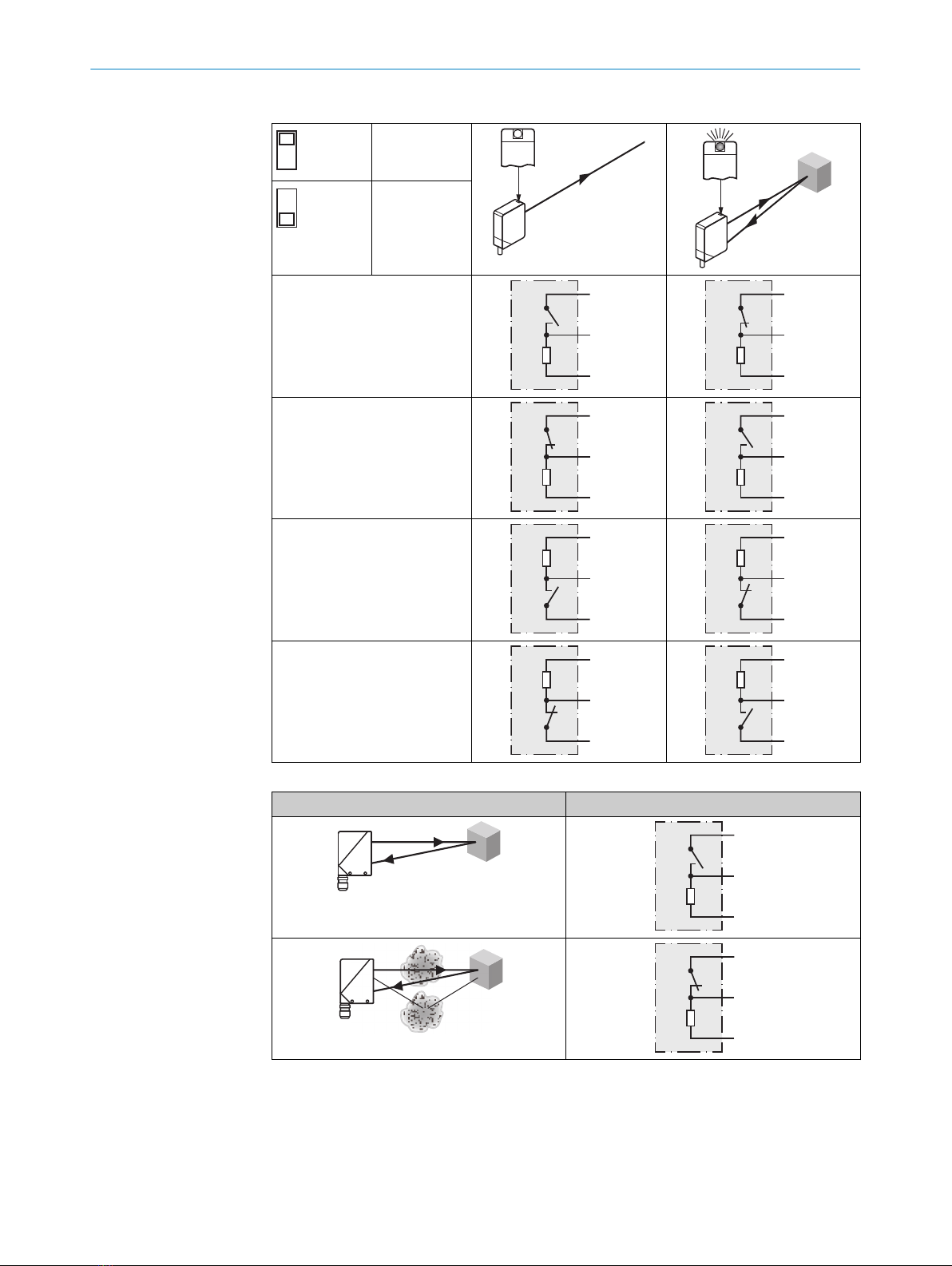

Note the preferred direction of the object relative to the sensor, cf. figure 1.

5 Electrical installation

The sensors must be connected in a voltage-free state (UV = 0 V). The following informa‐

tion must be observed, depending on the connection type:

– Plug connection: note pin assignment: when the lid is open, the male connector

can be swiveled horizontally and vertically.

– Terminal connection: Note the permissible cable diameter of 5 to 10 mm. When

the lid is open, the M16 connector can be swiveled horizontally and vertically.

Unscrew the M16 connector and remove sealing plug. Lead voltage-free supply

cable through and connect sensor in accordance with table 2 table 6. Retighten

M16 connector with seal so that the IP enclosure rating of the device is ensured.

3 OPERATING AND STATUS INDICATORS

68008784.Z474 | SICK

Subject to change without notice