ABOUT THIS DOCUMENT 1

8024534 / 16UW / 2020-02-26 Operating Instructions | InspectorP Rack Fine Positioning 3

Subject to change without notice

Contents

1About this document ............................................................................ 5

1.1 About these operating instructions..............................................................5

1.2 Explanation of symbols ................................................................................. 5

1.3 Further information .......................................................................................6

2Safety information ................................................................................ 7

2.1 Intended use .................................................................................................7

2.2 Improper use ................................................................................................. 7

2.3 Internet protocol (IP) technology ..................................................................7

2.4 Limitation of liability ...................................................................................... 8

2.5 Modifications and conversions .................................................................... 8

2.6 Requirements for skilled persons and operating personnel ......................8

2.7 Operational safety and specific hazards...................................................... 9

3Product description .............................................................................10

3.1 Scope of delivery .........................................................................................10

3.2 Function and use ........................................................................................10

3.3 Principle of operation..................................................................................11

3.4 Single deep applications.............................................................................12

3.5 Single and double deep applications.........................................................12

3.6 Positioning mark .........................................................................................12

4Installation............................................................................................14

4.1 Software installation ...................................................................................14

4.1.1 SICK AppManager............................................................................14

4.1.2 SOPASair (web server) .....................................................................15

4.1.3 Saving parameter set ......................................................................15

4.1.4 Installing firmware updates.............................................................16

4.2 Mounting......................................................................................................16

4.2.1 Mounting requirements ...................................................................16

4.2.2 Mounting procedure ........................................................................19

4.2.3 Mounting device...............................................................................19

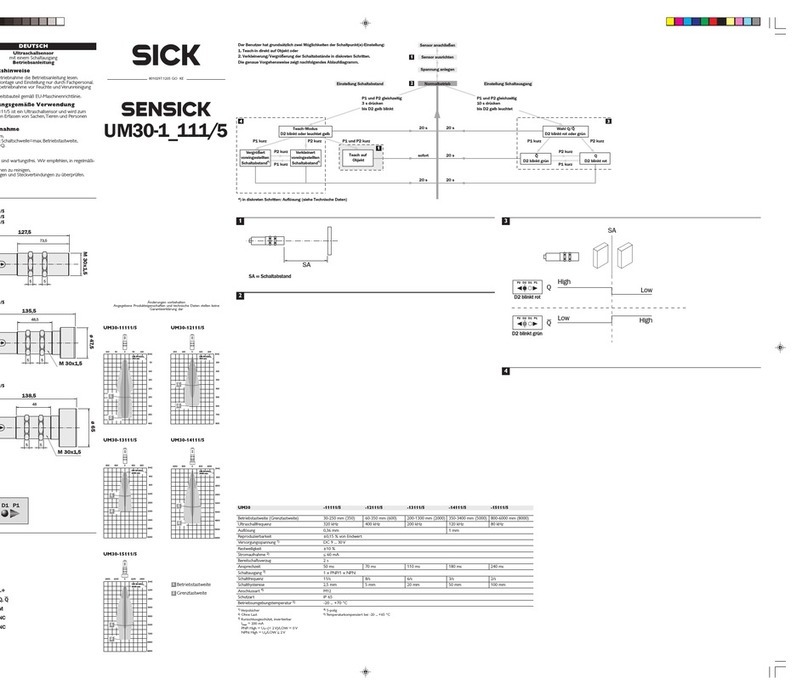

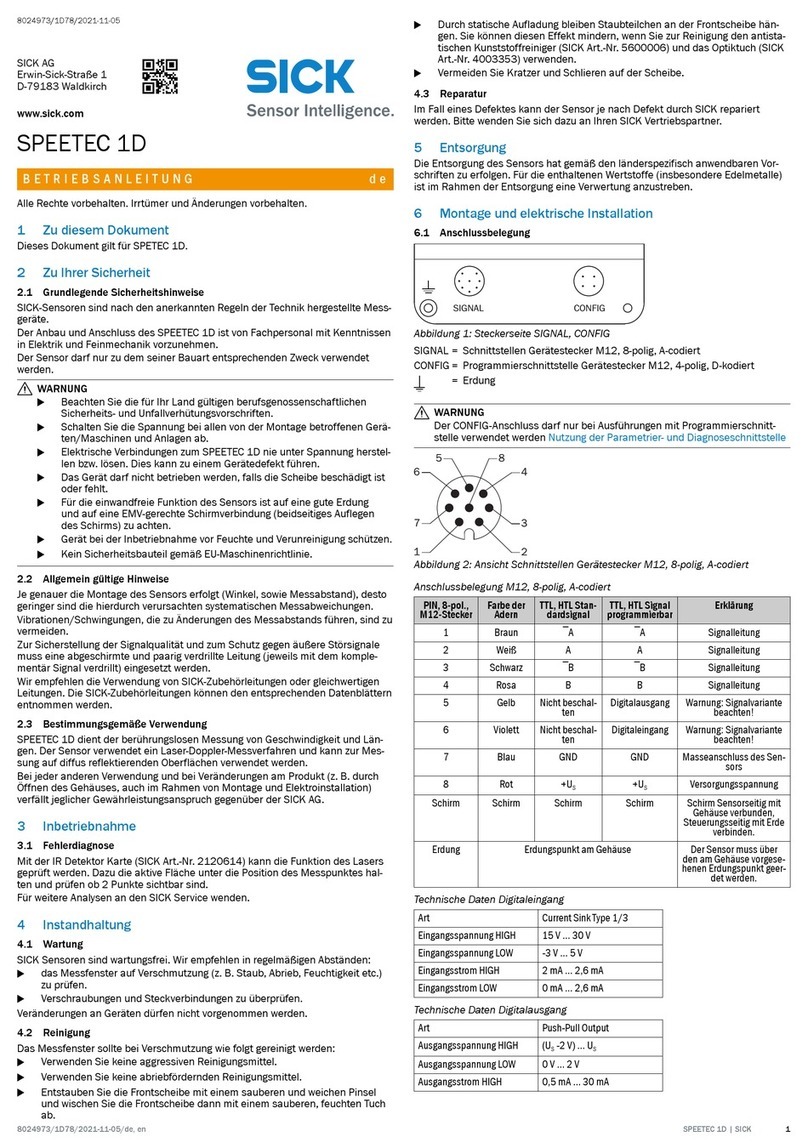

4.3 Electrical installation...................................................................................20

4.3.1 Notes on electrical installation .......................................................20

4.3.2 Interfaces .........................................................................................20

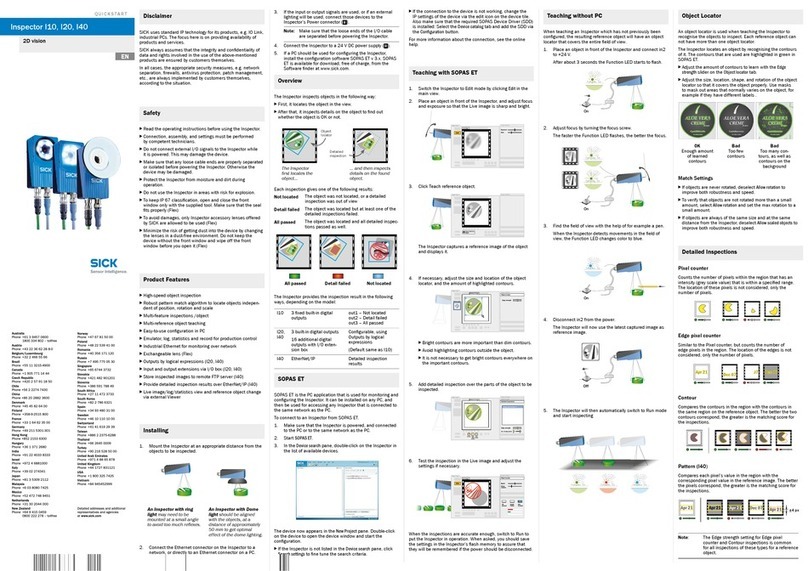

5Commissioning and operation ..........................................................21

5.1 Establishing a connection: Ethernet ..........................................................21

5.2 Establishing a connection: PROFINET........................................................21

5.3 Parameterizing device with SOPASair........................................................22

5.3.1 SOPASair user interface ..................................................................22

5.3.2 Setting up user interface .................................................................22

5.3.3 Fine adjustment of the device.........................................................23