Test input

Test input: the WT34-B / -V sensors feature a test input (“TI” or “Test” on the connec‐

tion diagram [see "WT34-Bxxx, WT34-Vxxx", page 7 and see table 7]), which can be

used to switch the sender off and, therefore, check that the sensor is functioning cor‐

rectly: if female cable connectors with LED indicators are used, you have to ensure that

the TI is assigned accordingly.

If an object is detected, activate the test input (see the connection diagram [see

"WT34-Bxxx, WT34-Vxxx", page 7 and see table 7], PNP: TE → M). The send LED is shut

down or no object being detected is simulated. Use the following table to check the

function. If the switching output fails to behave in accordance with the following table,

check the application conditions. See section Fault diagnosis.

Table 7: Test

Test

8 Commissioning

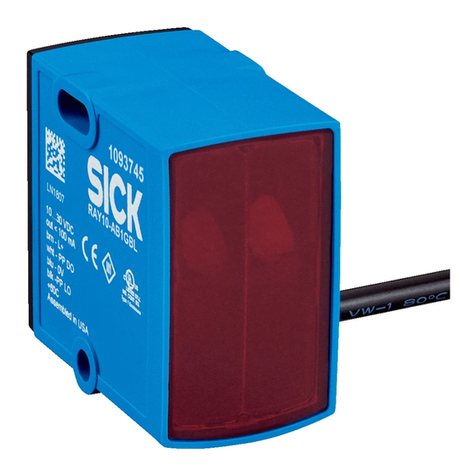

1Alignment

WT34-Xx4x, -Xx5x: align sensor on object. Select the position so that the red emitted light

beam hits the center of the object. You must ensure that the optical opening (front screen)

of the sensor is completely clear [see figure 3 and figure 4].

WT34-Xx1x, -Xx2x: align sensor on object. Select the position so that the infrared light (not

visible) hits the center of the object. The correct alignment can only be detected via the

LED indicators. See figure 3 and figure 4. You must ensure that the optical opening (front

screen) of the sensor is completely clear.

Figure 3: Alignment Figure 4: Alignment 2

2Sensing range

7 ADDITIONAL FUNCTIONS

10 8009202.11O1 | SICK

Subject to change without notice