1 General safety notes

■Read these operating instructions before commissioning the device.

■

Connection, mounting and configuration of the device must only be carried

out by qualified personnel.

■

This device does not constitute a safety component as defined in the

Machinery Directive.

■

When commissioning the device, ensure adequate protection against mois‐

ture, contamination and UV radiation (sunlight).

■These operating instructions contain information required during the life cycle of

the photoelectric sensor.

2 Notes on UL approval

The device shall be supplied from an isolating transformer having a secondary overcur‐

rent protective device that complies with UL 248 to be installed in the field rated either:

a) max 5 amps for voltages 0 ~ 20 V (0 ~ 28.3 V peak), or

b) 100 / Vp for voltages of 20 ~ 30 V (28.3 ~ 42.4 V peak).

Alternatively, they can be supplied from a Class 2 power supply.

UL Environmental Rating: Enclosure type 1

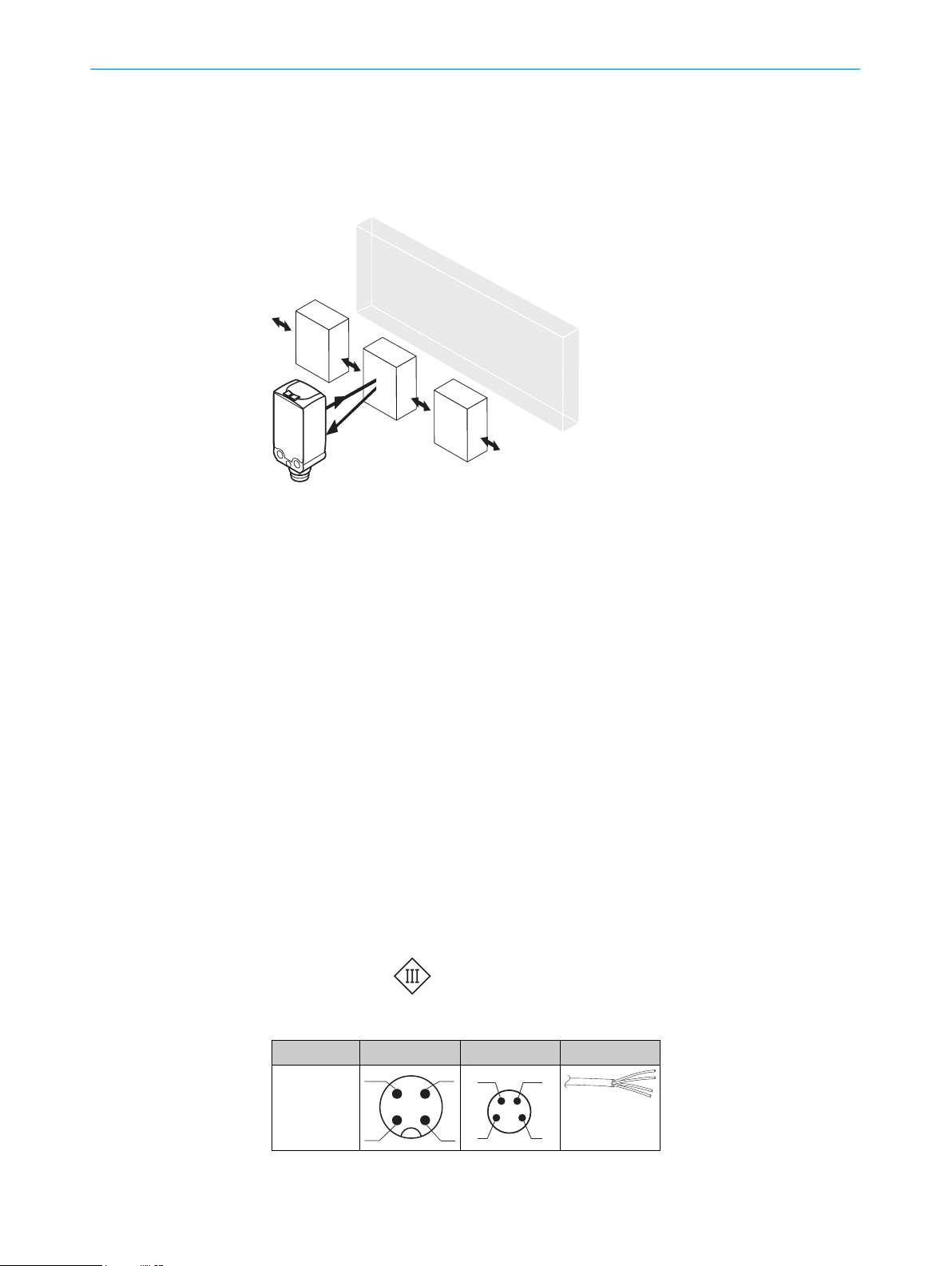

3 Intended use

The WTB4FP MultiSwitch is an opto-electronic photoelectric background suppression

proximity sensor (referred to as “sensor” in the following) for the optical, non-contact

detection of objects, animals, and persons. If the product is used for any other purpose

or modified in any way, any warranty claim against SICK AG shall become void.

4 Operating elements and status indicators

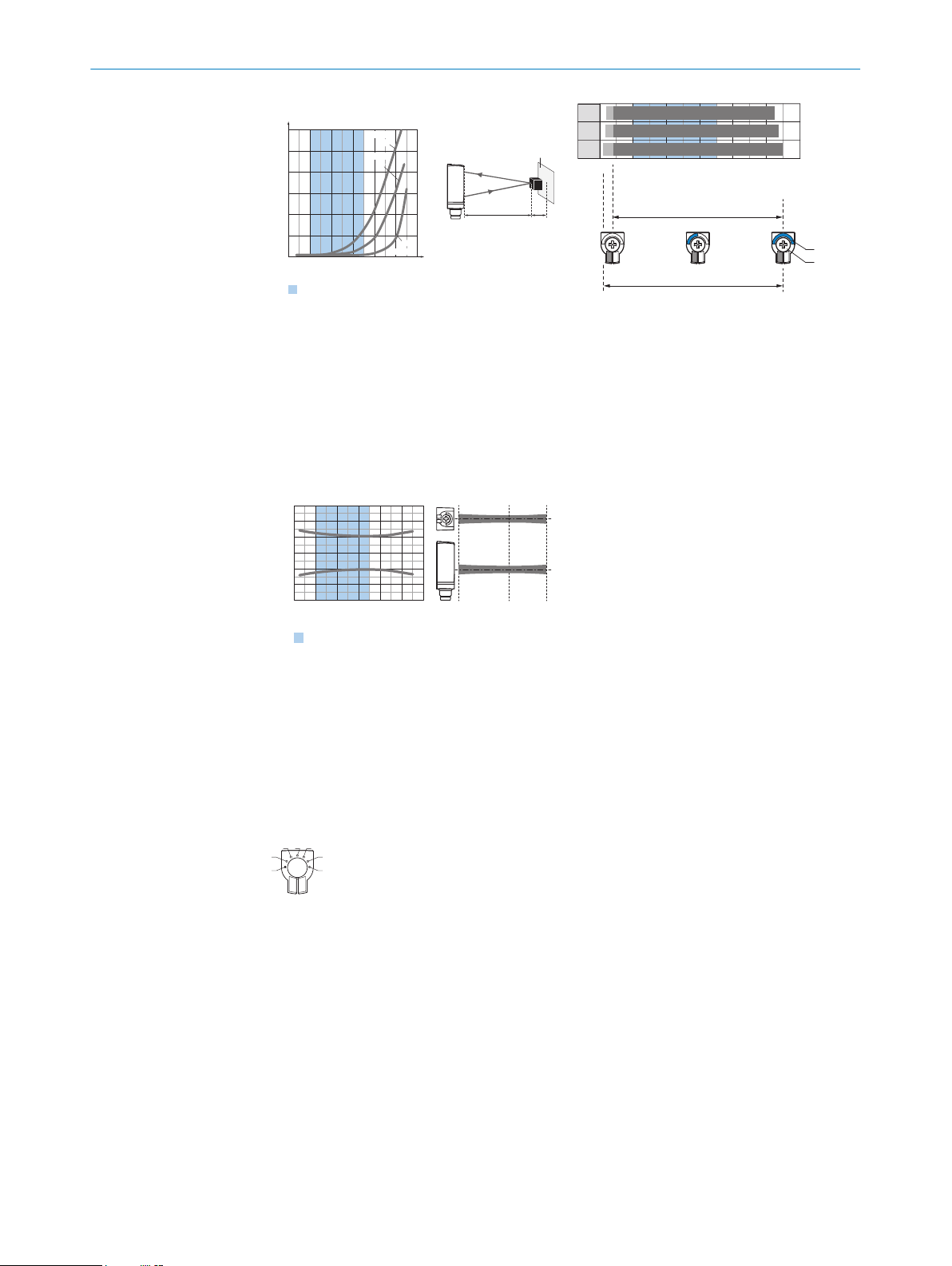

Photoelectric proximity sensor with background suppression.

1BluePilot blue: operating mode, Switching state QL1, QL2

2Teach-Button: adjusting the sensing range

3LED indicator yellow: status of received light beam

4LED indicator green: supply voltage active

GENERAL SAFETY NOTES 1

8025665 / 2020-11-13 | SICK

Subject to change without notice 5