Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Explanation of symbols............................................................................ 5

1.3 Scope of delivery....................................................................................... 6

1.4 SICK service.............................................................................................. 6

1.5 Type label.................................................................................................. 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 Limitation of liability................................................................................. 7

2.4 Modifications and conversions................................................................ 7

2.5 Requirements for skilled persons and operating personnel.................. 8

2.6 Operational safety and particular hazards.............................................. 8

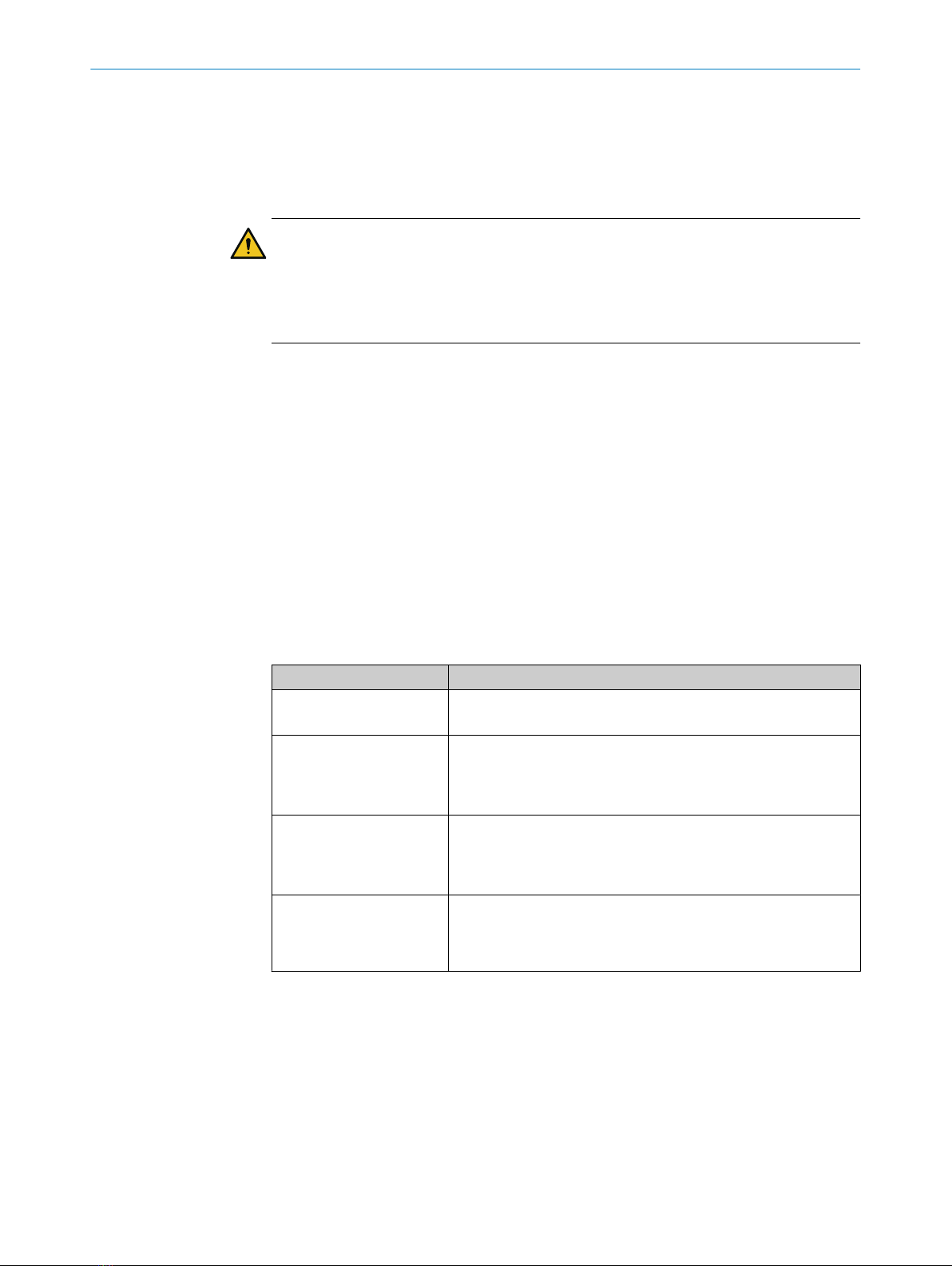

2.7 Warning signs on the device.................................................................... 9

2.8 UL conformity............................................................................................ 10

3 Transport and storage....................................................................... 11

3.1 Transport................................................................................................... 11

3.2 Transport inspection................................................................................. 11

3.3 Storage...................................................................................................... 11

4 Mounting............................................................................................. 12

4.1 Mounting instructions............................................................................... 12

4.2 Mounting the device................................................................................. 12

5 Electrical installation........................................................................ 13

5.1 Safety......................................................................................................... 13

5.2 Wiring instructions.................................................................................... 13

5.3 Connecting the sensor electrically........................................................... 15

6 Operation............................................................................................ 17

6.1 General notes............................................................................................ 17

6.2 Control elements and status indicators.................................................. 17

6.2.1 Indicator lights......................................................................... 17

6.2.2 Display...................................................................................... 18

6.3 Operating options..................................................................................... 19

6.3.1 Operation via pushbuttons and display.................................. 19

6.3.2 Operation via SOPAS ET.......................................................... 20

6.3.3 Operation via SOPASair (Wi-Fi)................................................ 21

6.3.4 Operation via IO-Link............................................................... 21

6.3.5 Operation via multifunctional input (MF)............................... 22

6.4 Description of operation........................................................................... 22

6.4.1 Switching mode for Q1 (“ModeQ1”)......................................... 22

CONTENTS

8017154/1AVV/2021-03-24 | SICK O P E R A T I N G I N S T R U C T I O N S | DT50-2 Pro 3

Subject to change without notice