5.7.1 PDO mapping.......................................................... 31

5.7.2 PDO data transmission.......................................... 32

5.7.3 Asynchronous or synchronous formation of the

position.................................................................... 34

5.8 Configurable functions............................................................ 34

5.8.1 EDS file.................................................................... 35

5.8.2 Scaling parameters................................................ 35

5.8.3 Preset function........................................................ 38

5.8.4 Cyclic process data................................................. 39

5.8.5 Speed measurement.............................................. 40

5.8.6 Round axis functionality......................................... 41

5.8.7 Electronic cam mechanism.................................... 42

6 Object library............................................................................................. 45

6.1 Nomenclature.......................................................................... 45

6.2 Standard objects..................................................................... 45

6.2.1 Detailed information on the standard objects...... 46

6.3 Process Data Objects.............................................................. 51

6.3.1 Basic PDO structure................................................ 52

6.3.2 Parameter of the Receive PDO.............................. 52

6.3.3 Parameter of the Transmit PDOs........................... 53

6.3.4 Transmission types................................................. 55

6.3.5 Objects and their subindices that can be map‐

ped........................................................................... 57

6.4 Encoder profile specific objects.............................................. 58

6.4.1 Encoder parameters............................................... 59

6.4.2 Objects for the electronic cam mechanism

(CAM)....................................................................... 61

6.4.3 Objects for diagnostics........................................... 64

6.5 Manufacturerspecific objects................................................. 68

6.5.1 Objects for the encoder configuration................... 69

6.5.2 Objects that provide status information................ 74

7 Commissioning......................................................................................... 83

7.1 Electrical installation............................................................... 83

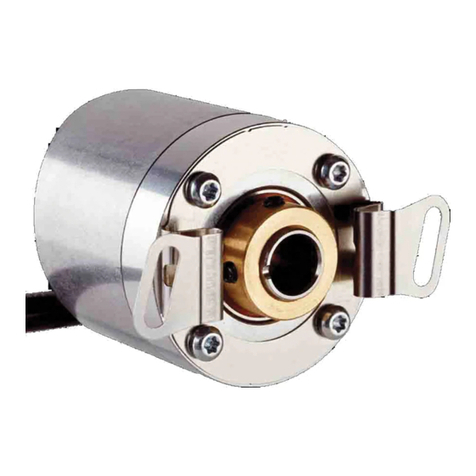

7.1.1 Connection of the AHS/AHM36 CANopen and

AHS/AHM36 CANopen Inox................................... 83

7.2 Settings on the hardware........................................................ 84

7.3 Configuration............................................................................ 84

7.3.1 Default delivery status............................................ 84

7.3.2 System configuration.............................................. 85

7.4 Tests before the initial commissioning................................... 89

8 Fault diagnosis.......................................................................................... 90

8.1 In the event of faults or errors................................................ 90

8.2 SICK-STEGMANN support....................................................... 90

8.3 Error and status indications on the LED................................ 90

8.3.1 Meaning of the LED displays.................................. 90

8.4 Diagnostics via CANopen........................................................ 91

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | AHS/AHM36 CANopen

AHS/AHM36 CANopen Inox

8016869/1B4I/2021-03-08 | SICK

Subject to change without notice