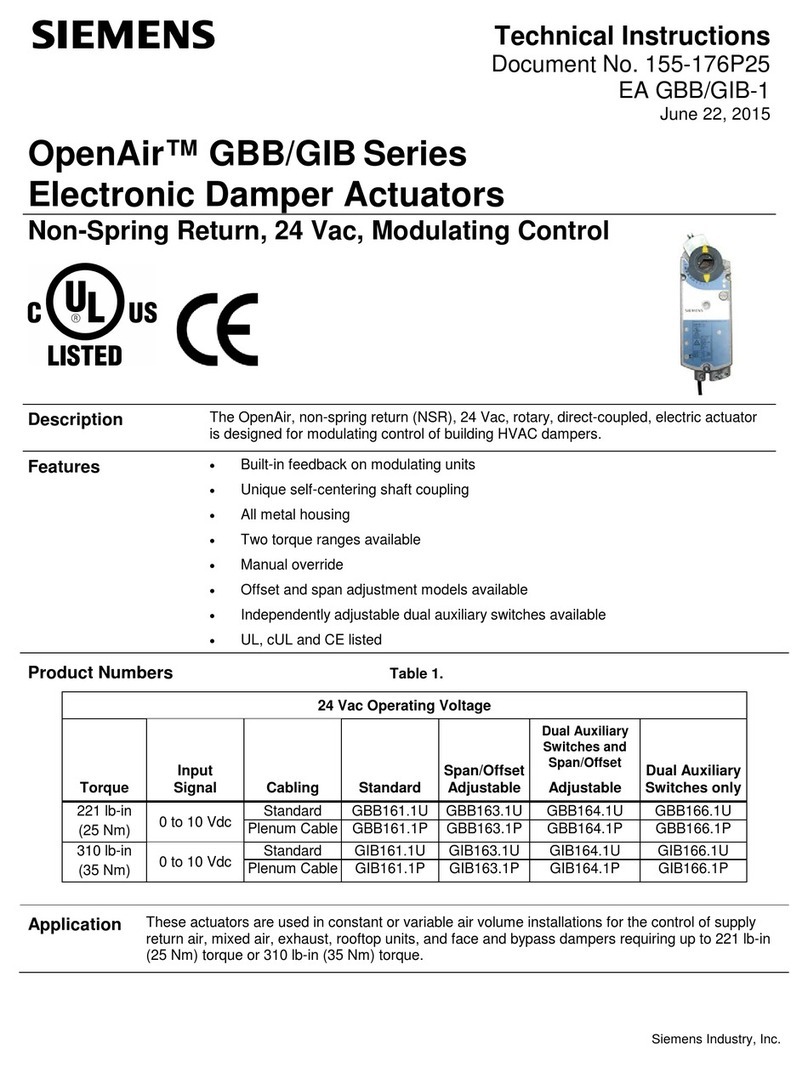

Siemens OpenAir GDE Series Owner's manual

Other Siemens Controllers manuals

Siemens

Siemens Synco 200 Operator's manual

Siemens

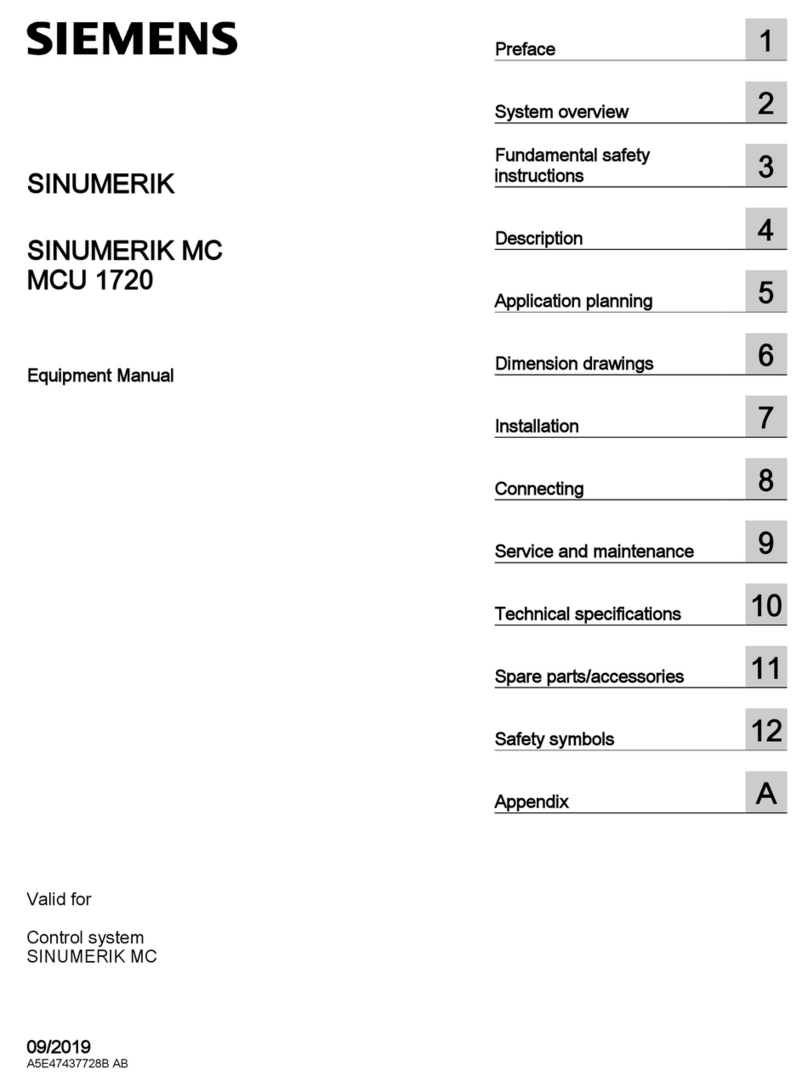

Siemens SINUMERIK MCU1720 Technical Document

Siemens

Siemens Simatic S7-1500 Instruction sheet

Siemens

Siemens SIPROTEC 5 User manual

Siemens

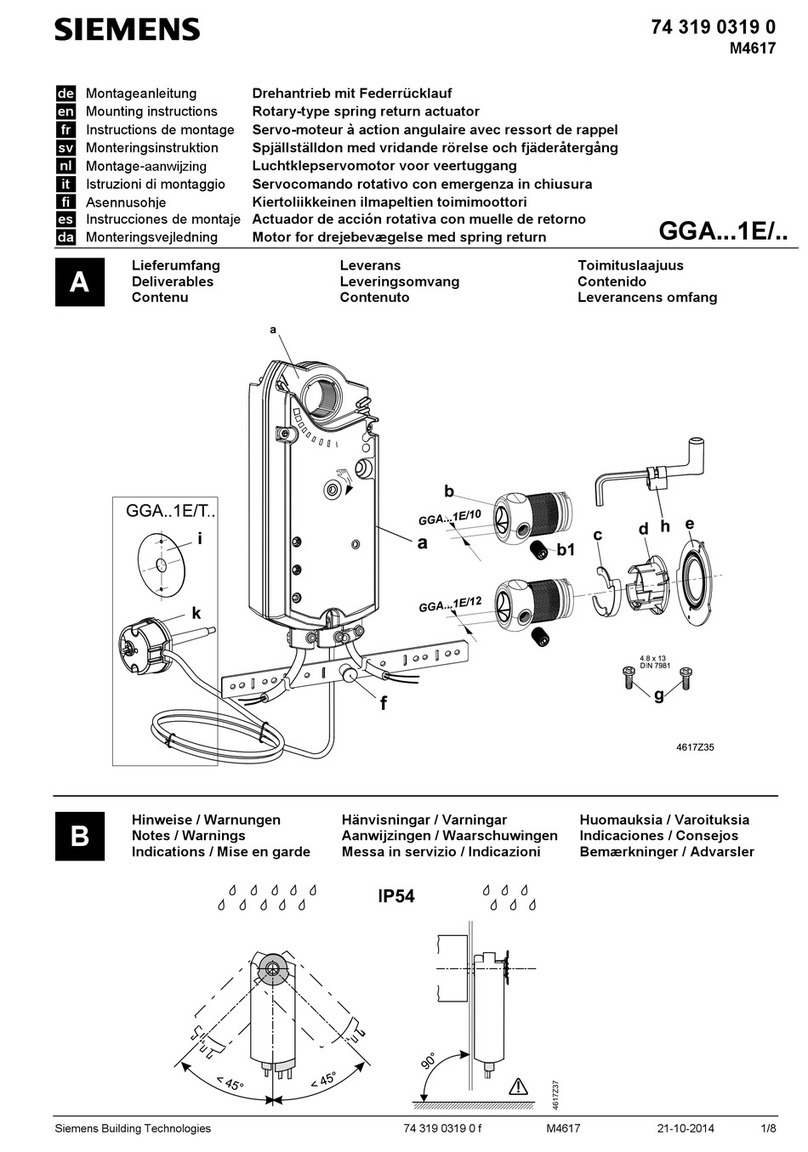

Siemens GGA 1E Series User manual

Siemens

Siemens RAJA+ Operating instructions

Siemens

Siemens RVD110 Operator's manual

Siemens

Siemens GAMMA wave GE 561/01 User manual

Siemens

Siemens 3RT2.1.-1 User manual

Siemens

Siemens acvatix SKD32 Series User manual

Siemens

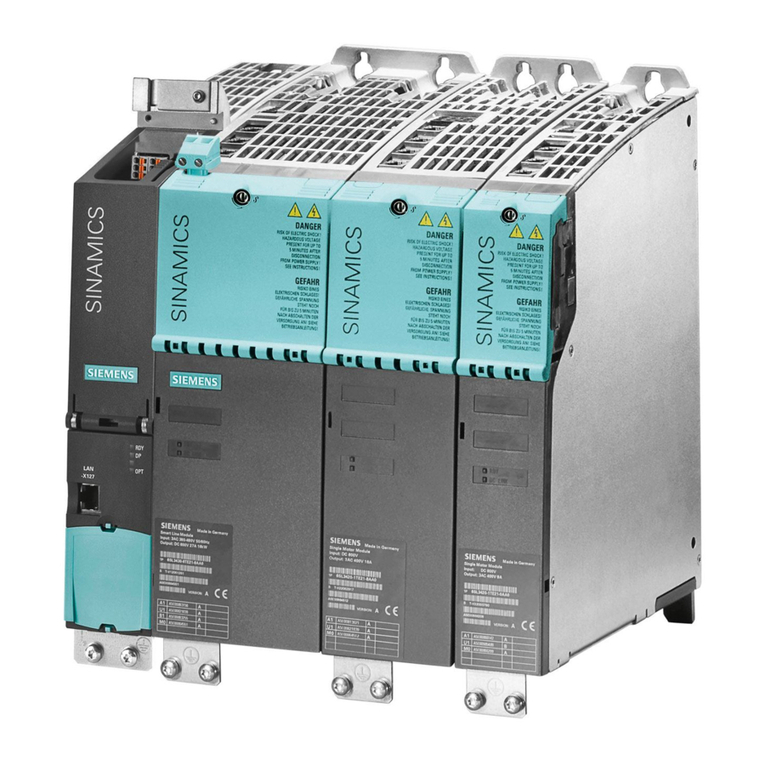

Siemens SINAMICS S120 Quick start guide

Siemens

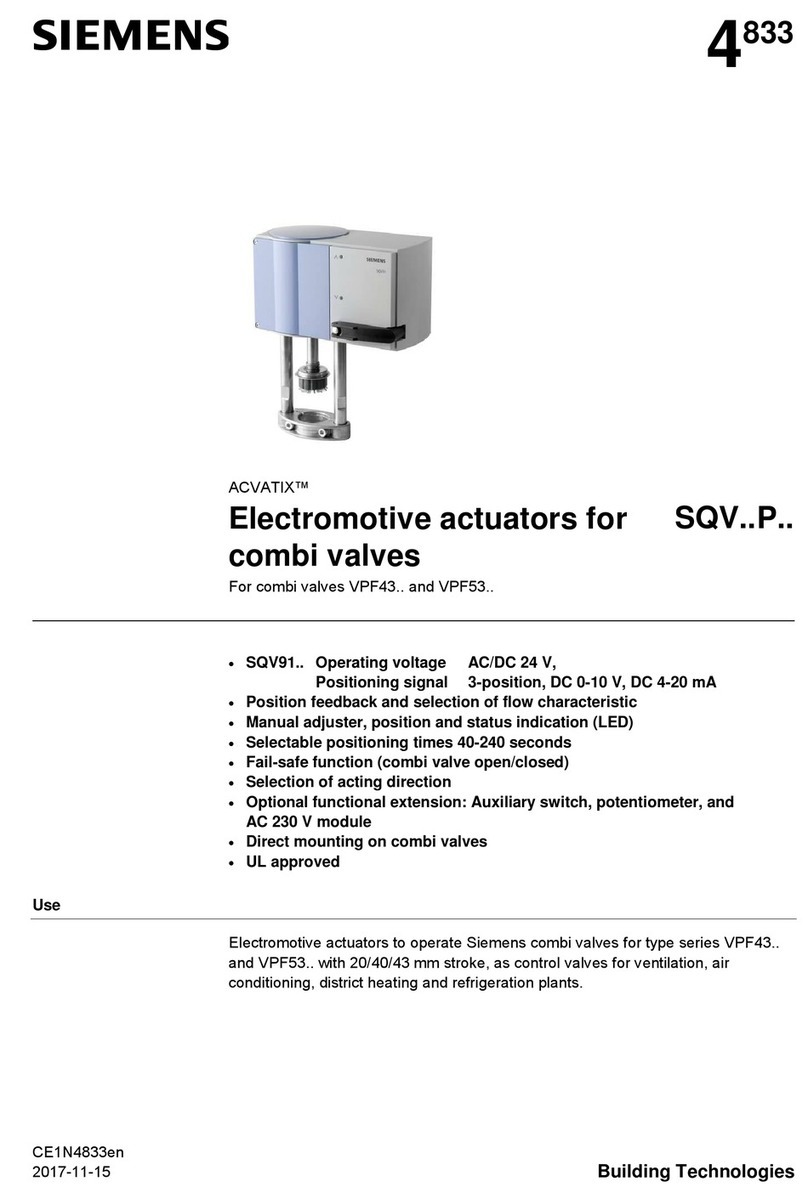

Siemens ACVATIX SQV..P Series User manual

Siemens

Siemens SINAMICS S120 Technical Document

Siemens

Siemens OpenAir GEB Series User manual

Siemens

Siemens S7-1200 TELECONTROL User guide

Siemens

Siemens SINUMERIK 840D sl User manual

Siemens

Siemens SAS61.33U Owner's manual

Siemens

Siemens Simatic S7-1500 User manual

Siemens

Siemens SPC3 Guide

Siemens

Siemens SKB32 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions