Siemens Industry, Inc.

Building Technologies Division

A6V10324655_en--_e2

SPECIAL CEILING CONSTRUCTION FACTORS

Ceiling obstructions change the natural movement of air and

combustion products. Depending on the direction of smoke

travel, joists and beams can slow the movement of heated air

and smoke, while pockets between them can contain a reduced

level of smoke. Take obstructions created by girders, joists,

beams, air conditioning ducts, or architectural design into

consideration when determining area protection. Refer to the

Initiating Devices chapter of NFPAStandard 72 for Location and

Spacing requirements for specific types of construction; e.g.

beam, suspended, level, sloped and peaked ceilings.

TEMPERATURE – HUMIDITY – PRESSURE –AIR VELOCITY

Thetemperature range for the FDOOT441detector is32°F (0°C)

to 120°F (49°C). Use the detector in environments where the

humidity does not exceed 95% (non-condensing). Normal

changes of atmospheric pressure do not affect detector

sensitivity. The air velocity range is 0-4000 ft/min for open areas

applications. Follow detector spacing and location requirements

in NFPA 72 Chapter for High Air Movement Areas and Control

of Smoke Spread. The detectors can also be installed in duct

applications between 0 and 4000 ft/min. For duct installations

follow detector installation requirements in NFPA 90A, Chapter

for Special Ceiling Construction Factors. When the detectors

employ a fixed temperature rating of 1650F or less, they are

intended for a maximum installation temperature of 1000F

(37.80C).

ULlisted with STI Mechanical ProtectionGuard Model:STI-9604

(see www.STI-USA.com for details).

LED INDICATOR OPERATION

The Model FDOOT441 contains an LED indicator capable of

flashing either one of three distinct colors: green, yellow, or red.

During each flash interval, the microprocessor-based detector

monitors the following:

• Smoke in its sensing chamber

• Smoke sensitivity is within the range indicated on the

nameplate label

• Internal sensors and electronics

Basedon the results of themonitoring, theLED indicator flashes

the following:

hsalF roloCnoitidnoC lavretnIhsalF )sdnoceS(

*neerG ekomS.noitarepoyrosivrepuslamroN .stimildetarnihtiwsiyti

vitisnes 01

wolleY sdeendnaelbuortnisirotceteD .tnemecalper 4

deRmralA1

oN *sehsalF tnemecalperro,derewoptonsiro

tceteD .dedeensi -

fonoitpircsedgnidnopserrocehtwollofesaelP.ffodenrutebnacDEL* .desulenaPeht

DETECTOR PROGRAMMING

Each detector must be programmed to respond to a unique

system address between 001 - 050 for FC2005.

• To program the detector address, use the Model DPU

Device Programming Unit. Refer to the DPU Manual, P/N

315-033260.

• Record the loop and device number (system address) for

the detector on the detector label and on the base to

prevent installing the detector in the wrong base. The

optional DPU label printer can be used for this purpose.

Each detector provides pre-programmed parameter sets which

can be selected by the panel. The FDOOT441 provides two

different alarm channels: multi-criteria (UL268) and direct in-

duct (UL268A), and heat (UL521) which can be used

simultaneously and can be configured and switched on or off

individually by the panel.Follow the description and instructions

provided in the operation manual of specific control panel used.

The FDOOT441 can be set to the FDOOT441 Selectable

Application Profiles, the FDOOT441 Selectable Fixed

Temperature Threshold Profiles and the FDOOT441 Selectable

Alarm Threshold Setting Profiles shown in the tables below and

to the right.

Additionally the detector can have another channel that can be

configured by the panel to have a low or high temperature

warning in the range from -4° to 120°F (-20° to 49°C). (Not with

FC2005.)

erutarepmeTdexiFelbatceleS144TOODF seliforPdlohserhT 531erutarepmetdexiF

0

F

541erutarepmetdexiF

0

F

551erutarepmetdexiF

0

F

561erutarepmetdexiF

0

F

571erutarepmetdexiF

0

F

531erutarepmetdexiF

0

51)RoR(esiRfoetaR+F

0

F

571erutarepmetdexiF

0

51)RoR(esiRfoetaR+F

0

F

531erutarepmetdexiF

0

02)RoR(esiRfoetaR+F

0

F

571erutarepmetdexiF

0

02)RoR(esiRfoetaR+F

0

F

seliforPgnitteSdlohserhTmralAelbatceleS144TOODF dlohserhTtf/%05.2 dlohserhTtf/%00.3 deifirev,dlohserhTtf

/%05.2 deifirev,dlohserhTtf/%00.3

ELECTRICAL

Forinformation on electricalcharacteristics ofthe detector, refer to

theFDOOT441/FDOOTC441Technical Manual,A6V10325549at

https://www.buildingtechnologies.siemens.com/extranet/ba-sp/.

Refer to the panel Installation, Operation and Maintenance

Manual for maximum line impedance of the loop driver.

WIRING

Detector bases for Model FDOOT441 should be connected as

shown in Figure 2.

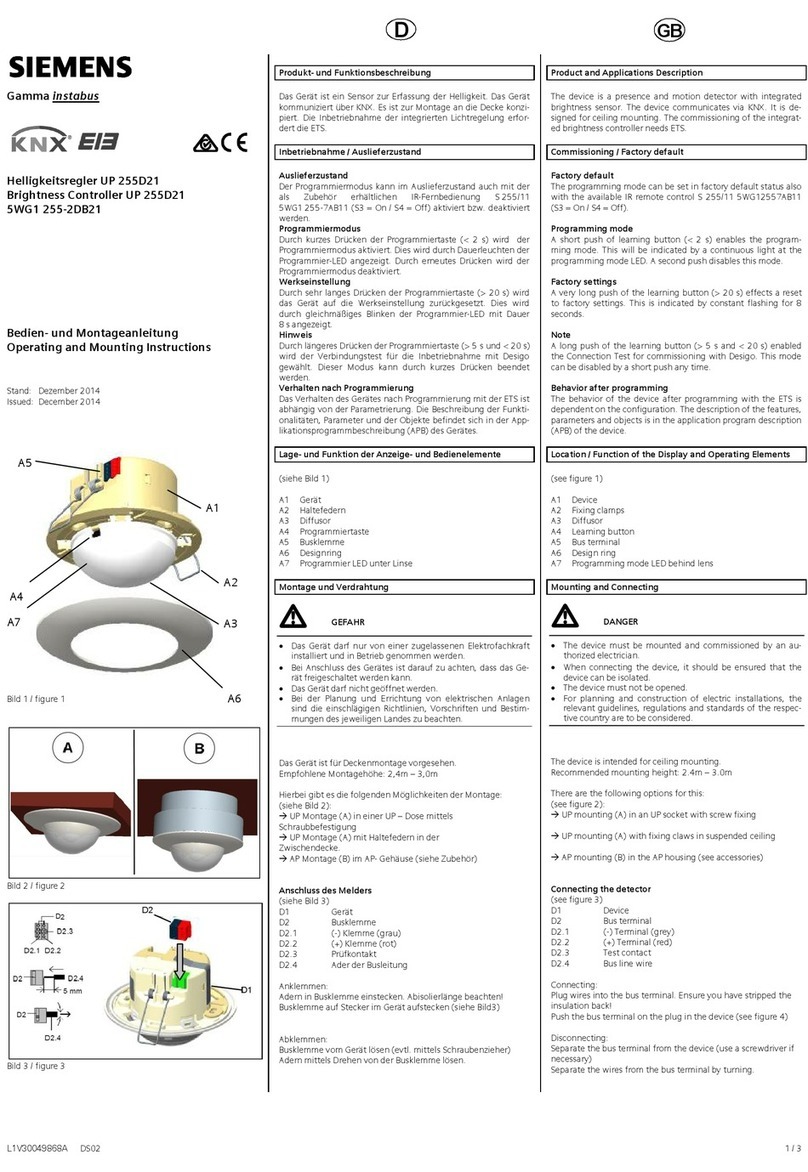

DETECTOR MOUNTING

The recommended orientation of the detector for wall mounting

isshown in Figure3. To ensureproper installationof the detector

head into the base, be sure the wires are properly dressed at

installation:

• Position all wires flat against the base.

• Take up all slack in the outlet box

• Route wires away from connector terminals.

TO INSTALL DETECTOR HEAD:

• Rotate detector counterclockwise while gently pressing on

it until the detector seats fully into base.

• Then rotate the detector clockwise until it stops and locks in

place. Insert optional locking screw (Order Model LK-11).