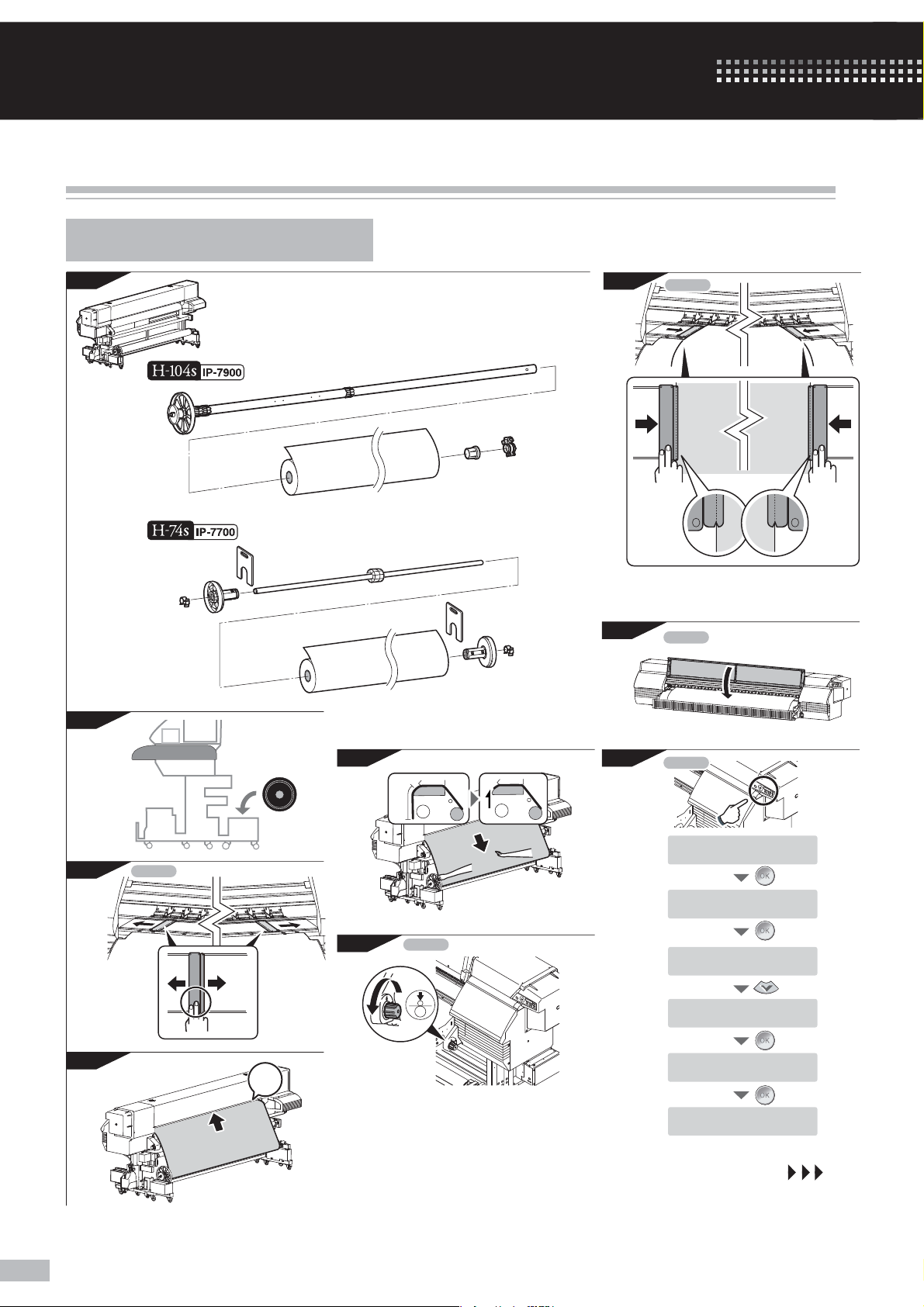

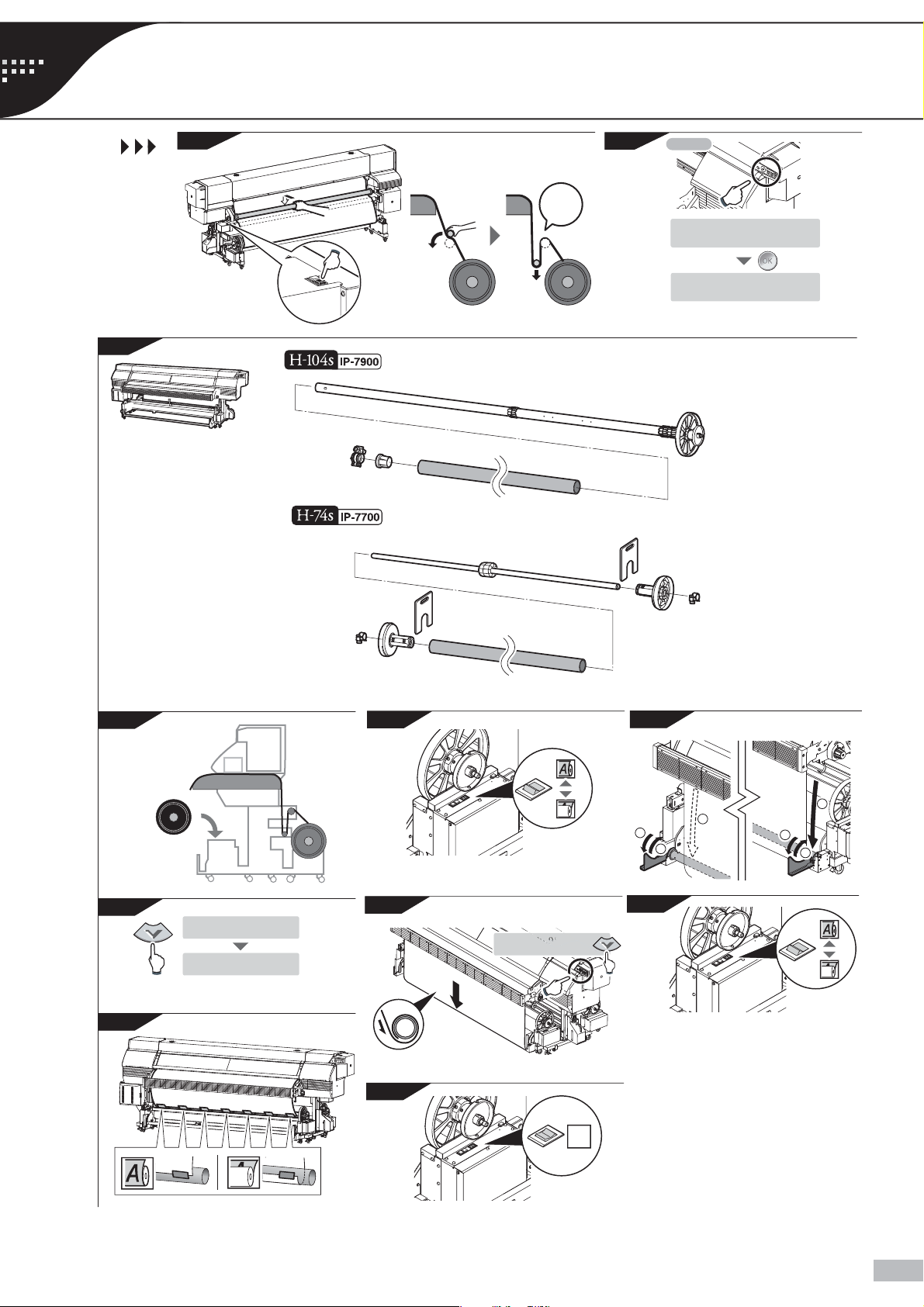

SII IP-7900 User manual

Other SII Printer manuals

SII

SII Color Painter W-64s User manual

SII

SII IP-7900-20 User manual

SII

SII RP-B10 User manual

SII

SII RP-E10 Series User manual

SII

SII DPU-30 Use and care manual

SII

SII IP-5610 User manual

SII

SII DPU-S445 SERIES Use and care manual

SII

SII IP-7700-02 User manual

SII

SII DPU-S445 SERIES User manual

SII

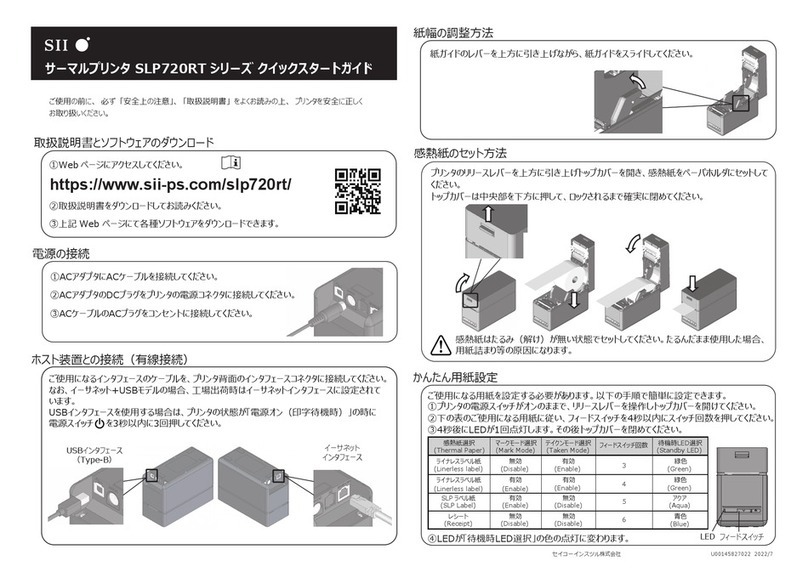

SII SLP720RT Series User manual

SII

SII IP-7700 User manual

SII

SII MTP Series Use and care manual

SII

SII DPU-S445 SERIES User manual

SII

SII IP-6900 User manual

SII

SII DPU-S245 Use and care manual

SII

SII IP-5520 User manual

SII

SII DPU-S445-00A-E User manual

SII

SII DPU-S445 SERIES User manual

SII

SII MP-A40 SERIES User manual

SII

SII DPU-3445-30A-E User manual