vii

TABLES

Table Page

2-1 General Specifications ........................................................................................................ 2-1

2-2 Sample Motor Drive Frequency...........................................................................................2-5

2-3 General Motor Specifications.............................................................................................. 2-6

2-4 Excitation Sequence............................................................................................................ 2-8

2-5 Acceleration Steps ............................................................................................................ 2-12

2-6 Blocks and Activated Heat Element.................................................................................. 2-15

2-7 Head Resistance Ranks.................................................................................................... 2-16

2-8 Head Voltage..................................................................................................................... 2-17

2-9 Thermal Head Electrical Characteristics (at Vdd=5 V, 25°C). .......................................... 2-18

2-10 Activation Pulse Width....................................................................................................... 2-23

2-11 Temperature and Corresponding Thermistor Resistance................................................. 2-25

2-12 Absolute Maximum Ratings of the Paper Detector (at 25°C)............................................ 2-28

2-13 Paper Detector Input/Output Conditions...........................................................................2-29

3-1 Recommended Connectors................................................................................................. 3-1

3-2 Thermal Head Control Terminal Assignments................................................................... .3-3

3-3 Terminal Assignments of the Motor/Detector Connector....................................................3-4

FIGURES

Figure Page

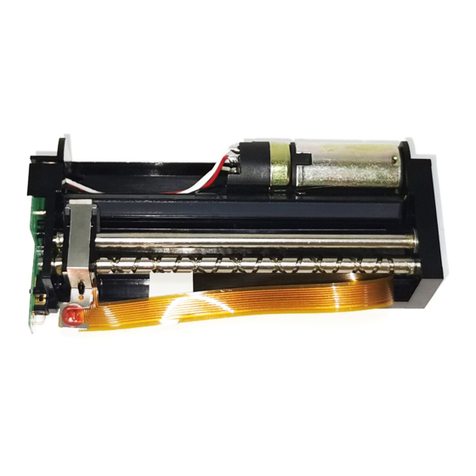

2-1 Heat Element Dimensions................................................................................................... 2-4

2-2 Print Area............................................................................................................................. 2-4

2-3 Sample Drive Circuit (Motor)............................................................................................... 2-7

2-4 Input Voltage Signals for the Sample Drive Circuit (Motor) ................................................ 2-8

2-5 Motor Start/Stop Timing ......................................................................................................2-9

2-6 Motor Drive Timing Chart.................................................................................................. 2-11

2-7 Thermal Head Block Diagram........................................................................................... 2-14

2-8 Printed Position of the Data............................................................................................... 2-15

2-9 Timing Chart...................................................................................................................... 2-19

2-10 Thermistor Resistance vs. Temperature........................................................................... 2-24

2-11 How to Drive 2-ply Thermal Paper.................................................................................... 2-26

2-12 Sample External Circuit for the Head-Up Detector ........................................................... 2-27

2-13 Sample External Circuit of the Paper Detector. ............................................................... .2-30

2-14 Flowchart for Automatic Paper Load................................................................................. 2-31

3-1 Thermal Head Control Terminals (FPW)............................................................................. 3-2

3-2 Terminals on the Motor/Detector Connector....................................................................... 3-4

4-1 Example of timing chart when executing previous line history control................................ 4-2

4-2 Example of timing chart when not executing previous line history control.......................... 4-4