Siko AP10 User manual

37/22

AP10

Absolute Position Indicator with CANopen

interface

User manual

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 2 of 78

Table of contents

1General Information .................................................................................................. 5

1.1 Documentation ........................................................................................................5

1.1.1 History ................................................................................................................5

2Intended use............................................................................................................. 5

2.1 Switching on the supply voltage.................................................................................6

3Display and control keys ............................................................................................ 6

3.1 General ...................................................................................................................6

3.2 LCD display..............................................................................................................7

3.2.1 Extended display range ..........................................................................................7

3.3 LED display..............................................................................................................7

3.4 Keys .......................................................................................................................7

4Functional Description ............................................................................................... 8

4.1 Operating modes ......................................................................................................8

4.1.1 Position-bound operating modes.............................................................................9

4.1.1.1 Positioning.......................................................................................................9

4.1.1.2 Loop positioning .............................................................................................10

4.1.2 Alpha-numeric display operating mode...................................................................11

4.2 Battery buffering....................................................................................................12

4.3 Parameterization of the position indicator .................................................................12

4.3.1 Manual parameterization......................................................................................12

4.3.1.1 Starting parameterization .................................................................................12

4.3.1.2 Value input.....................................................................................................13

4.3.1.3 Value selection................................................................................................13

4.3.1.4 Adjustable parameters......................................................................................13

4.3.2 Parameterization via interface ..............................................................................13

4.4 Warnings / Errors....................................................................................................13

4.4.1 Warnings ...........................................................................................................13

4.4.2 Errors ................................................................................................................14

4.5 System commands ..................................................................................................14

4.5.1 Calibration .........................................................................................................14

4.5.2 Restore factory settings .......................................................................................15

4.5.3 Diagnosis...........................................................................................................16

5Communication via CAN bus (CANopen) .................................................................... 16

5.1 Telegram setup.......................................................................................................16

5.2 Node control..........................................................................................................18

5.2.1 Network management services (NMT) .....................................................................18

5.2.1.1 NMT communication statuses ............................................................................18

5.2.1.2 Switching between NMT communication states ....................................................19

5.2.2 Boot-Up.............................................................................................................19

5.2.3 SYNC object........................................................................................................19

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 3 of 78

5.3 Process data exchange ............................................................................................20

5.3.1 Transfer of Process Data Objects (PDO)...................................................................20

5.3.1.1 Transmit PDO (from AP10 to the master).............................................................20

5.3.1.2 Receive-PDO (from master to AP10) ...................................................................21

5.3.2 Control word ......................................................................................................21

5.3.3 Status word........................................................................................................22

5.4 Parameter data exchange.........................................................................................23

5.4.1 Transfer of Service data objects (SDO)....................................................................23

5.4.2 Error Response....................................................................................................25

5.4.3 Examples of SDO access........................................................................................25

5.5 Node monitoring ....................................................................................................26

5.5.1 Emergency Service (EMCY) ....................................................................................26

5.5.2 Node Guarding....................................................................................................27

5.5.3 Heartbeat ..........................................................................................................28

5.5.4 External heartbeat...............................................................................................28

5.5.5 Guarding Bit.......................................................................................................28

5.6 Auto functions .......................................................................................................29

5.6.1 Auto-Baud .........................................................................................................29

5.6.2 Auto-ID .............................................................................................................29

5.7 Directory of objects ................................................................................................31

5.7.1 Overview of objects .............................................................................................31

5.7.2 Description of objects..........................................................................................33

5.7.2.1 1000h: Device Type..........................................................................................33

5.7.2.2 1001h: Error Register .......................................................................................34

5.7.2.3 1002h: Manufacturer Status Register ..................................................................34

5.7.2.4 1003h: Pre-defined Error Field...........................................................................34

5.7.2.5 1005h: COB-ID SYNC message............................................................................35

5.7.2.6 1008h: Manufacturer Device Name .....................................................................36

5.7.2.7 1009h: Manufacturer Hardware Version ...............................................................36

5.7.2.8 100Ah: Manufacturer Software Version................................................................36

5.7.2.9 100Ch: Guard Time...........................................................................................37

5.7.2.10 100Dh: Life Time Factor....................................................................................37

5.7.2.11 1010h: Store Parameter....................................................................................37

5.7.2.12 1011h: Restore Parameter.................................................................................40

5.7.2.13 1014h: COB-ID Emergency Message ....................................................................42

5.7.2.14 1017h: Producer Heartbeat Time........................................................................42

5.7.2.15 1018h: Identity Object.....................................................................................42

5.7.2.16 1200h: Server SDO Parameter ............................................................................44

5.7.2.17 1400h: 1. Receive PDO Parameter ......................................................................44

5.7.2.18 1401h: 2. Receive PDO Parameter ......................................................................46

5.7.2.19 1600h: 1. Receive PDO Mapping Parameter..........................................................47

5.7.2.20 1601h: 2. Receive PDO Mapping Parameter..........................................................48

5.7.2.21 1800h: 1. Transmit PDO Parameter .....................................................................49

5.7.2.22 1801h: 2. Transmit PDO Parameter .....................................................................50

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 4 of 78

5.7.2.23 1A00h: 1. Transmit PDO Mapping Parameter ........................................................52

5.7.2.24 1A01h: 2. Transmit PDO Mapping Parameter ........................................................53

5.7.2.25 2001h: Application Offset.................................................................................54

5.7.2.26 2002h: Calibrate encoder value..........................................................................54

5.7.2.27 2003h: Calibration enable.................................................................................55

5.7.2.28 2004h: Incremental measurement enable ............................................................55

5.7.2.29 2005h: Configuration enable via keyboard and delay of start of configuration ..........55

5.7.2.30 5000h: Diagnosis of CAN bus errors ....................................................................57

5.7.2.31 5F09h: External Heartbeat timer and external Heartbeat source..............................57

5.7.2.32 5F0Ah: Node-ID, Auto-ID and Baud rate Bus CAN .................................................58

5.7.2.33 5F0Bh: Display in the 2nd row ............................................................................59

5.7.2.34 5F0Ch: Control word.........................................................................................59

5.7.2.35 5F0Dh: Differential value and difference formation...............................................60

5.7.2.36 5F10h: Target window1 (near field)....................................................................60

5.7.2.37 5F11h: Decimal places......................................................................................61

5.7.2.38 5F12h: Display orientation and LEDs ..................................................................61

5.7.2.39 5F13h: Display divisor (ADI) and ADI application .................................................64

5.7.2.40 5F14h: Loop length..........................................................................................65

5.7.2.41 5F15h: Positioning type ...................................................................................65

5.7.2.42 5F16h: Read target value..................................................................................65

5.7.2.43 5F19h: Status word..........................................................................................67

5.7.2.44 5F1Bh: Sensor type and operating mode .............................................................67

5.7.2.45 5F1Ch: Acknowledgement settings .....................................................................68

5.7.2.46 5F1Fh: Direction indicators (CW, CCW) ................................................................68

5.7.2.47 5F21h: Target window2 (far) and target window2 visualization ..............................69

5.7.2.48 6000h: Operating Parameters ............................................................................70

5.7.2.49 6001h: Measuring steps per revolution (Display per revolution = APU) ....................70

5.7.2.50 6002h: Total of measuring steps........................................................................71

5.7.2.51 6003h: Preset value (calibration value)...............................................................71

5.7.2.52 6004h: Position value ......................................................................................71

5.7.2.53 6200h: Cycle Timer ..........................................................................................72

5.7.2.54 6500h: Operating Status...................................................................................72

5.7.2.55 6501h: Single-turn resolution............................................................................72

5.7.2.56 6502h: Number of distinguishable revolutions .....................................................73

5.7.2.57 6503h: Alarms.................................................................................................73

5.7.2.58 6504h: Supported Alarms..................................................................................74

5.7.2.59 6505h: Warnings .............................................................................................74

5.7.2.60 6506h: Supported Warnings ..............................................................................75

5.7.2.61 6507h: Profile and Software Version...................................................................75

5.7.2.62 6508h: Operating Time.....................................................................................75

5.7.2.63 6509h: Encoder calibration value .......................................................................76

5.7.2.64 650Ah: Module Identification............................................................................76

5.7.2.65 650Bh: Serial Number.......................................................................................77

General Information

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 5 of 78

1General Information

1.1 Documentation

The following documents describe this product:

•The data sheet describes the technical data, the dimensions, the pin assignments, the

accessories and the order key.

•The installation instructions describe the mechanical and electrical installation including

all safety-relevant requirements and the associated technical specification.

•The user manual for commissioning and integrating the position indicator into a fieldbus

system.

•EDS file (electronic data sheet); this file enables integration and configuration in a

CANopen network by means of commercial CANopen configurators.

These documents can also be downloaded at http://www.siko-global.com/p/ap10.

1.1.1 History

Mod. status

Date

Description

037/22

28.02.2022

from firmware V3.01

Chapter 1.1.1 History new

Chapter 3.2.1 Extended display range add text

Chapter 5.3.1.1 Transmit PDO (from AP10 to the master) revised

Chapter 5.3.1.2 Receive-PDO (from master to AP10) revised

Chapter 5.3.2 Control word revised

Chapter 5.3.3 Status word revised

Chapter 1A00h: 1. Transmit PDO Mapping Parameter revised

Chapter 1A01h: 2. Transmit PDO Mapping Parameter revised

Chapter 2005h: Configuration enable via keyboard and delay of

start of configuration revised

Chapter 5F16h: Read target value revised

Chapter 5F1Ch: Acknowledgement settings sub-index 1 revised

Chapter 6002h: Total of measuring steps revised

Chapter 6502h: Number of distinguishable revolutions revised

Chapter 6507h: Profile and Software Version revised

Chapter 650Ah: Module Identification revised

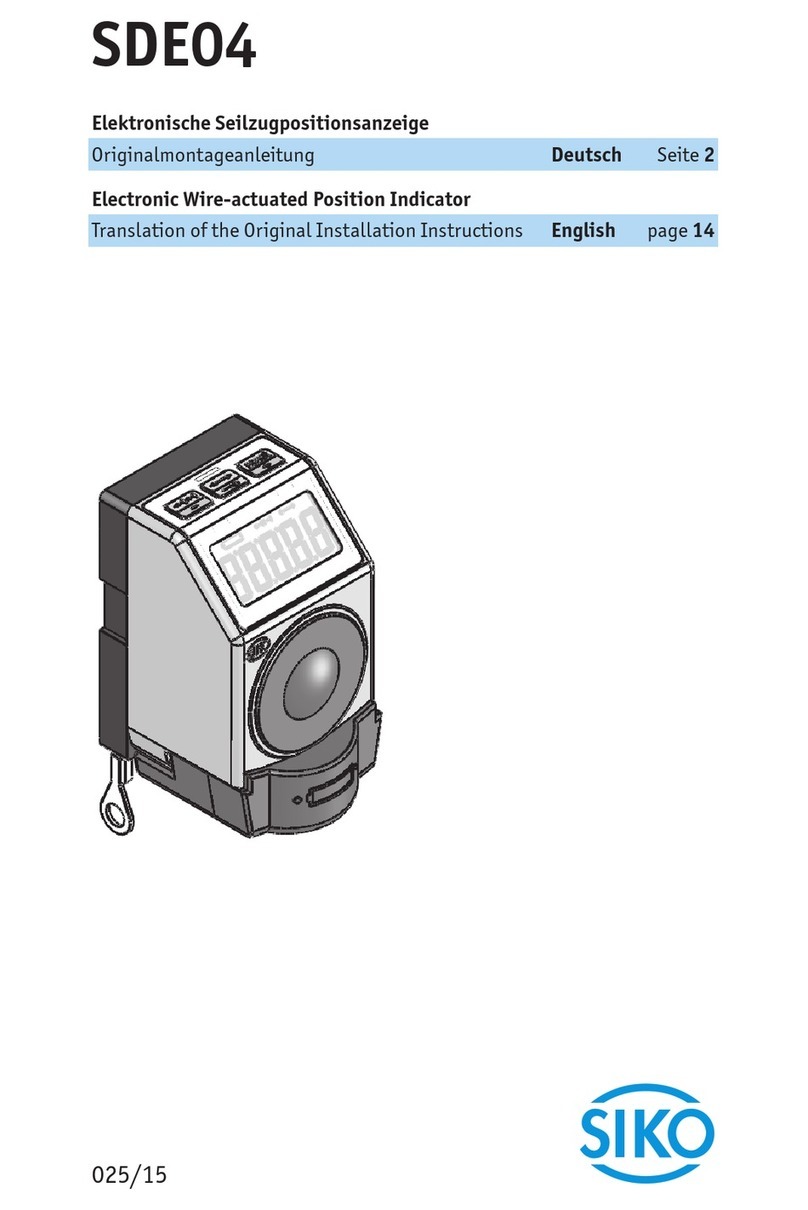

2Intended use

Absolute position indicator with hollow shaft suitable for direct shaft mounting. Actual and

target values are indicated via the backlit two-row LC display. A direction indicator (arrow) is

blended in if the actual value deviates from the target value including the adjustable target

window. The direction of the arrow indicates the direction of shaft movement necessary to

reach the target. Additionally, various visualization tasks can be realized by means of two bi-

color LEDs.

Display and control keys

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 6 of 78

The device parameters can be adjusted by means of 3 keys. You can change the set point,

output the position value and adjust all device parameters via the integrated bus interface.

Scanning is magnetically incremental. In the currentless state, scanning and saving of

changes of the position value are battery-supported.

The state of charge of the replaceable battery is monitored and signified.

Display and interface are active with external power supply only.

2.1 Switching on the supply voltage

The AP10 will be initialized after switching on the supply voltage. A display test is executed

during initialization, the LEDs are lighted consecutively and the configuration parameters are

loaded from the non-volatile memory into the RAM of the controller.

With the display still unconfigured all parameters are set to their default values. See to it that

the bus will be connected only after correct adjustment of baud rate and ID (see chapter 4.3

and chapter 5.6). The AP10 functions with the data last parameterized.

After completing the initialization procedure, the AP10 with CAN interface sends a specific

NMT command, the Boot-Up Message, which informs the system about the availability of the

display. The AP10 is now in the Pre-Operational Mode. In this state, the display can be

parameterized via SDO commands in accordance with the requirements of the application. This

applies to configuration parameters as well as to the way it makes available to the system its

position values (asynchronous or synchronous data transmission).

3Display and control keys

3.1 General

The position indicator has a two-line display with special characters and three control keys.

The keys serve for position indicator parameterization and control. Two LEDs (1) serve for

monitoring positioning.

Fig. 1: Control elements

LED3+4

LED1+2

Display and control keys

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 7 of 78

3.2 LCD display

The The display range is limited to -19999 … 99999. Values outside this

range are displayed with "".

With supply voltage applied to the position indicator with factory settings, the actual value

will be displayed in the 1st row and the set point in the 2nd row. If there is no valid set point,

"---" will be displayed in the 2nd row. The values displayed are determined by the operating

mode.

Direction indicators (arrows) support positioning.

The battery symbol is shown with a critical or insufficient battery status.

With incremental measurement function activated, the incremental measurement symbol

is shown.

If battery voltage drops to a critical value, the battery symbol on the display will flash. If it

falls below the minimum value, the symbol will glow permanently.

3.2.1 Extended display range

Values up to -999999 can be displayed by means of the control word. If the relevant bit has

been set and the value to be displayed is between -199999 and -999999, then the negative

sign and the digit of the highest order will flash alternately. If the value range drops below -

99999, "" will be displayed.

This function is not available in the alpha-numeric display mode for unacknowledged values.

3.3 LED display

In its basic state (factory setting) the LED display has different meanings depending on the

operating mode (see chapter 4.1.1 and 4.1.2).

With the basic function of the LEDs inactivated, every LED can be controlled independently via

the control word (see object 5F12h: Display orientation and LEDs and chapter 5.3.2).

3.4 Keys

Pressing the key enables or disables the incremental measurement function. With the

Auto-ID function, the new ID is adopted by actuating this key (see chapter 5.6).

Pressing the key starts calibration (see chapter 4.5.1) and acknowledges a pending error

(see chapter 4.4.2).

Pressing the key starts the parameterization mode (see chapter 4.3).

In the "Alpha-numeric display" operating mode, the set points previously received (set point1

and set point2) are acknowledged via the respective buttons depending on the

acknowledgment settings (see chapter 5.7.2.45).

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 8 of 78

4Functional Description

4.1 Operating modes

The following position-dependent operating modes are differentiated: Absolute Position,

Differential Value, Modulo and the position-independent operating mode Alpha-numeric

Display.

Operating

mode

Absolute position

Differential value

Modulo

Alpha-numeric

Display

Line 1

Actual position

Actual position

Actual position

Set point1

Line 2

Set point

Differential value

Set point

Set point2

Table 1: Display with different operating modes

Absolute position:

Linear absolute position values are displayed.

Differential value display:

With factory setting: Differential value = actual position - set point

Modulo display:

Position values ranging from 0° to 359° are displayed.

Using the "Decimal places" parameter (see object 5F11h: Decimal places) the resolution and

the modulo point of the displayed values are set.

Decimal places

Display resolution

Display range

0

1°

0° …359°

1

1/10°

0.0° …35.9°

2

1/100°

0.00° …3.59°

3

1/1000°

0.000° …0.359°

4

1/10000°

0.0000° …0.0359°

Table 2: Modulo display

Alpha-numeric display:

Both rows can be written freely. Set point1 is received via the Receive data object 1 (RPDO1),

set point2 is received correspondingly with RPDO2. The data identifier must be correctly set in

the relevant control word. The data identifier differentiates whether the data is interpreted

and displayed as figures or alpha-numeric characters (ASCII) (see chapter 5.3.2).

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 9 of 78

4.1.1 Position-bound operating modes

4.1.1.1 Positioning

(see chapter 4.1.1.2)

Arrows: (see object 5F1Fh: Direction indicators (CW, CCW))

Arrows are displayed to support the user with positioning as long as the current actual

position value is outside (see object 5F10h: Target window1 (near field)) target window1. The

direction of the arrow indicates the direction of shaft rotation in order to arrive at the set

point.

LED display: (see e. g. object 5F12h: Display orientation and LEDs)

With factory setting, the LED glows green as long as the actual position is within the

programmed window1. When leaving target window1, the LED glows red. The shaft must be

rotated in the direction of the glowing LED in order to arrive at the set point. The red glowing

LED on the right means: clockwise (cw) rotation required. Red glowing LED on the left:

counter-clockwise (ccw) rotation required.

An additional target window (target window2) and an associated visualization can also be

configured (5F21h: Target window2 (far) and target window2 visualization).

With factory settings, the LED display has the following meaning:

Operating state

LED

Status

Meaning

There is no valid set

point.

both

off

Positioning disabled.

There is a valid set

point.

LED left

off

Target window not reached!

The shaft must be rotated clockwise (cw) in

order to reach the target.

red

Target window not reached!

The shaft must be rotated counter-clockwise

(ccw) in order to reach the target.

green

Target window reached

LED right

off

Target window not reached!

The shaft must be rotated counter-clockwise

(ccw) in order to reach the target.

red

Target window not reached!

The shaft must be rotated clockwise (cw) in

order to reach the target.

green

Target window reached

Table 3: LED display

Control word (see chapter 5.3.2):

The set point is not displayed and positioning not monitored unless the set point is marked as

valid in the control word.

Status word (see chapter 5.3.3):

Upon reaching target window1, the static and dynamic target-window-reached bits are set in

the status word. The dynamic bit is deleted when leaving target window1. The user must

acknowledge the static bit.

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 10 of 78

Example Position monitoring:

Parameterization: Factory setting

Additionally: Set point = 100

Fig. 2: Positioning monitoring

Example of position monitoring with additionally activated target window2 parameter:

Parameterization: Factory setting

Additionally: Target window 2 = 15

Visualization target window 2 = 1

Set point = 100

Fig. 3: Positioning monitoring with target window2

4.1.1.2 Loop positioning

Target window1 is also applied to the loop length.

If the position indicator is operated on a spindle or an additional gear, the spindle or external

gear backlash can be compensated by means of loop positioning. Therefore, movement

towards the set point is always in the same direction. This direction of approach can be

defined.

Example:

The direction from which every target position shall be driven to is positive.

100

+

-

Target

window1

95

105

LED left

Positioning monitoring

LED right

+

-

Target

window1

Target window2

LED left

Positioning monitoring

85

115

LED right

100

95

105

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 11 of 78

•Case 1 the new position is greater than actual position:

Direct travel to the target position.

•Case 2 the new position is smaller than actual position:

The position indicator's arrows show that the set point is to be overrun by the loop length.

Afterwards, the set point is approached in positive direction.

Fig. 4: Positioning Loop+

4.1.2 Alpha-numeric display operating mode

Two 6-digit set points can be displayed in this operating mode. With factory settings, the set

points are acknowledged by pressing the asterisk key (see chapter 3.4).

LCD display:

In the absence of a valid set point, the 1st row is displayed empty (blank). " --- " appears in

the 2nd row.

A valid setpoint is displayed flashing in the factory setting until it is acknowledged.

Acknowledgement and display can be set (see object 5F1Ch: Acknowledgement settings).

LED display:

With factory settings, the LED display works according to the following table.

Operating state

LED

Status

Meaning

There is no valid set

point.

both

off

There is a valid set

point.

LED left

red

Set point1 not acknowledged

green

Set point1 acknowledged

LED right

red

Set point2 not acknowledged

green

Set point2 acknowledged

Table 4: LED display in the alpha-numeric display operating mode

Set point

+

-

Positioning in positive

direction

Positioning in negative

direction

Positioning: loop +

Loop length

Target window1

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 12 of 78

Control word:

In the control word, the relevant type (number or character string) and the validity of the set

point is transmitted to the display. As an additional option, the set point can be

acknowledged via the control word.

Status word:

Type, validity and acknowledgement status of the set points are fed back in the status word.

4.2 Battery buffering

The battery makes possible the detection of currentless displacement. Battery life is approx. 5

years depending on the duration of battery operation (including storage) and frequency of

currentless adjustments. Battery voltage is checked at intervals of approx. 5 min. If battery

voltage drops below a specified value, the battery symbol will blink on the display. If

the battery voltage continues to drop, will be displayed permanently. The battery

should be replaced within approx. three months after the first appearance of the battery

symbol. For battery replacement it is mandatory to follow the instructions of the installation

instructions. The battery can also be replaced by the SIKO distribution partners or at the SIKO

main factory.

Status word:

The charge status of the battery is signified in the status word. CANopen Emergency messages

are sent upon detection of a critical charge state and with detection of the empty state

(see chapter 5.5.1).

4.3 Parameterization of the position indicator

The position indicator can be fully parameterized via the bus interface. You can configure

manually via keyboard the most significant bus parameters (node address and baud rate).

4.3.1 Manual parameterization

4.3.1.1 Starting parameterization

After applying supply voltage and completion of initialization, the position indicator is on the

uppermost level of the menu structure (default/Factory settings).

By actuating the key, the set node address and baud rate is displayed. Parameterization

starts if it is actuated for the duration of the enable time (see object 2005h: Configuration

enable via keyboard and delay of start of configuration).

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 13 of 78

4.3.1.2 Value input

Enter values via the key and the key. Confirm values entered by pressing the key.

- decimal place selection key

- value input key

4.3.1.3 Value selection

For some parameters you can select values from a list.

Direct value input is not possible there.

Pressing the key, the value can be selected from the list. By pressing the key, the

selection is confirmed.

4.3.1.4 Adjustable parameters

The following parameters can be adjusted.

Display

Parameter

Options

ID

Node-ID

1 … 127 (see chapter 5.6.2)

KBAUD

Baud rate

Auto baud (see chapter 5.6.1)

125 kbaud

250 kbaud

500 kbaud

800 kbaud

1000 kbaud

CODE

System commands

Load factory settings (see chapter 4.5.2)

Start diagnosis (see chapter 4.5.3)

Table 5: Manually adjustable parameters

4.3.2 Parameterization via interface

The position indicator can be completely parameterized in the CANopen interface

(see chapter 5.4).

4.4 Warnings / Errors

4.4.1 Warnings

Warnings do not influence the acquisition of the absolute position value.

Warnings are deleted after removing the cause.

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 14 of 78

Possible warnings:

•Battery voltage for absolute position detection is below limit immediately exchange

battery!

This warning is displayed with a blinking battery symbol . Via status word and the

emergency service, warning messages are output via the interface (see chapter 5.3.3,

chapter 5.5.1 and chapter 4.5.3).

Display

Error code

Emergency

Bit assignment in

the status word

Error

blinking

3200h

11

Low battery voltage

4.4.2 Errors

Error states are signalled via display and interface.

To return to normal operation, the cause must be removed (see Table 7) and the fault message

acknowledged or deleted via key.

(For signaling see chapter 5.3.3, chapter 5.5.1 chapter 4.5.3)

Display

Error code

Emergency

Bit assignment in

the status word

Error

permanent

3200h

11+7

Low battery voltage

SPEED

FF12h

12

Admissible speed exceeded

Table 6: Error messages

Display

Error

Possible effect

Corrective actions

permanent

Battery empty

Position value not

reliable

Battery change +

calibration travel

SPEED

Admissible speed

exceeded (see

installation instruction)

Position value not

reliable

Reduce speed +

calibration travel

Table 7: Corrective actions

4.5 System commands

4.5.1 Calibration

Two steps are required for executing calibration:

1. Write calibration value (see object 6003h: Preset value (calibration value))

2. Execute calibration (reset) (see chapter 3.4: Keys or object 2002h: Calibrate encoder

value)

Due to the absolute measuring system, calibration is only required once during commissioning

or, if necessary, during troubleshooting.

With calibration, the calibration value is adopted for calculation of the position value. The

following equation is applied in case of calibration:

Position value = 0 + calibration value + offset value

Functional Description

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 15 of 78

Calibration value (see object 6003h: Preset value (calibration value))

Offset value (see object 2001h: Application Offset)

4.5.2 Restore factory settings

There are various options for restoring the factory settings of the device:

Access

Coding

Factory settings are restored

Manual

This is only possible if the

configuration is enabled via

the keyboard (see object

2005h: Configuration enable

via keyboard and delay of

start of configuration).

CODE

011100

all parameters

011102

all except bus parameters

011105

only bus parameters

CANopen

(see object 1011h: Restore

Parameter)

1011h

"load"

Sub-index 1

all parameters

Sub-index 2

only bus parameters

Sub-index 3

only Draft-Standard-406 parameters

Sub-index 4

only manufacturer-specific parameters

Table 8: Access to factory settings

Procedure for access via CANopen:

1. Execute object 1011h.

2. Device restart. Now all desired parameters are set to factory settings (volatile).

3. Permanent recovery: execute object 1010h: Store Parameter.

The bus parameters are:

Display

Parameter address

Parameter

ID

5F0Ah

Node-ID

KBAUD

5F0Ah

Baud rate

-

1005h

COB-ID SYNC

-

100Ch

Guard Time

-

100Dh

Life Time Factor

-

1014h

COB-ID Emergency

-

1017h

Heartbeat timer value

-

1400h Sub-index1

COB-ID RPDO1

-

1400h Sub-index2

Transmission Type RPDO1

-

1401h Sub-index1

COB-ID RPDO2

-

1401h Sub-index2

Transmission Type RPDO2

-

1800h Sub-index1

COB-ID TPDO1

-

1800h Sub-index2

Transmission Type TPDO1

-

1800h Sub-index5

Event Timer TPDO1

-

1801h Sub-index1

COB-ID TPDO2

-

1801h Sub-index2

Transmission Type TPDO2

-

5F09h Sub-index1

Ext. Heartbeat value

Communication via CAN bus (CANopen)

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 16 of 78

Display

Parameter address

Parameter

-

5F09h Sub-index2

Ext. Heartbeat source

-

1001h

Error Register

Table 9: Bus parameters

4.5.3 Diagnosis

To receive a list of all errors occurring from chapter 4.4.2 of the device, the device must be

switched to diagnosis operation. Enter CODE "200000" in parameterization (see chapter 4.3.1)

and confirm by pressing the key. Any errors occurring are output indicating the error

number and total of occurrences in the upper row. The type of error is shown in the lower row.

Error number 1 contains the latest error. The oldest error is output with the highest error

number.

5Communication via CAN bus (CANopen)

The CiA DS-301 V4.2 CANopen communication profile as well as the Device profile for Encoders

CiA DS-406 V3.2 form the basis for AP10, which supports device class C2. As this device is

beyond the scope of an encoder's functionality, communication partly differs from the above-

mentioned device profile. This document contains the details necessary for understanding the

operation of the device. If more-in-depth information is required, we recommend to consult

the pertinent specialized literature on CAN or CANopen.

5.1 Telegram setup

The data telegram of a CAN message consists of the following fields:

SOF

Identifier (COB-ID)

Control field

Data field (max. 8 byte)

CRC

ACK / EOF

SOF:

(Start of Frame) start bit of the telegram

Identifier (COB-ID):

•All bus sharing units check via identifier whether the message is relevant for them.

•The identifier sets the priority of the message. The lower the value of the identifier, the

higher the priority of the message. This results in preferential transfer of messages via the

bus.

The Identifier field contains the identifier as well as bits for the recognition of the length of

the identifierss (11 or 29 bit). Furthermore, the identifier serves for determining the device

address, the channel selection as well as the direction of data transfer.

The 11bit identifier (COB identifier) consists of a 4bit function code and a 7bit node number:

Bit no.

10

9

8

7

6

5

4

3

2

1

0

Type

Function code

Node number (node ID)

Assignment

x

x

x

x

0

0

x

x

x

x

x

Communication via CAN bus (CANopen)

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 17 of 78

The following function codes have been defined in the "Pre-defined Connection Set" (only the

function codes used in the present device are listed):

Object

Function code

Resulting COB-ID

Object

Page

Network management (NMT)

0000b

0

-

18

SYNC message

0001b

128 (80h)

1005h

35

Emergency message

0001b

128 (80h) + Node-ID

1014h

42

TPD01

0011b

384 (180h) + Node-ID

1800h

49

RPD01

0100b

512 (200h) + Node-ID

1400h

44

TPD02

0101b

640 (280h) + Node-ID

1801h

50

RPD02

0110b

768 (300h) + Node-ID

1401h

46

SDO (tx)

1011b

1408 (580h) + Node-ID

1200h

44

SDO (rx)

1100b

1536 (600h) + Node-ID

1200h

44

Heartbeat message

1110b

1792 (700h) + Node-ID

-

28

Node Guard message

1110b

1792 (700h) + Node-ID

-

27

Table 10: Overview of COB identifiers

Changes to COB-IDs are only possible in the PRE-OPERATIONAL NMT status. First, the COB-ID

must be deactivated via Bit 31 = 1b before it can be changed and reactivated.

The COB-ID of the SYNC object is an exception. There, Bit 30 must be = 0 to enable the

change of the COB-ID. The COB-ID could be changed any time because Bit 30 cannot be set to

1 in the AP10 device.

The identifier determines the priority of the message. The lower the value of the identifier,

the higher the priority of the message.

The node number (Node-ID) (see object 5F0Ah: Node-ID, Auto-ID and Baud rate Bus CAN) is

assigned in every bus system once while AP10 is being configured. Node-ID = 0 is reserved

and must not be used; thus, the node numbers are in the range of 1 to 127.

A newly set node number will only be adopted with reinitialization (see chapter 5.2.1).

The set point display is delivered with the factory-set Node-ID 125 (7Dh).

Control field:

Contains bit-by-bit information on the number of user data and decides whether a data frame

or a Remote Transmission Request (RTR) frame is concerned.

Data field:

Contains up to 8 bytes of user data. The user data has a different meaning depending on the

channel selection.

CRC:

Contains bits for error detection.

ACK/EOF:

The ACK/EOF field contains telegram acknowledgement bits as well as bits for determining the

end of telegram.

Communication via CAN bus (CANopen)

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 18 of 78

For a detailed description of the telegram refer to the relevant CAN expert literature. For

simplification, only identifier (COB-ID) and data field will be dealt with in the subsequent

telegram descriptions.

5.2 Node control

5.2.1 Network management services (NMT)

The master configures, manages and monitors network nodes via the NMT service. The device

is always in one of the four communication statuses "INITIALISATION", "PRE-OPERATIONAL",

"OPERATIONAL" or "STOPPED" (see Fig. 5).

Fig. 5: NMT status diagram

5.2.1.1 NMT communication statuses

NMT Status INITIALIZATION

The unit is not involved in the bus actions in this state. All hardware and software

components are initialised. This state is attained after switching on the device or after receipt

of the command code 81h of the own or global addresses. After receiving the command code

82h, the display is also in the initialization status. However, only the hardware and software

associated with CAN communication is reinitialized. The device automatically signifies

completion of initialization via a boot-up message. After successful transmission of the boot-

up message, the device will be in the "PRE-OPERATIONAL" status.

NMT Status PRE-OPERATIONAL

Parameterization data (SDO) can be exchanged in the Pre-Operational Mode. However, no

process data (PDO) is transferred.

Power on or software reset

Initialization

CAN-communication

BootUp Message

1

2

2

3

3

4

4

4

1

Re-initialization

CAN-card

5

5

5

Init

Communication via CAN bus (CANopen)

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 19 of 78

NMT Status OPERATIONAL

Exchange of process data is enabled as well.

NMT Status STOPPED

Communication is stopped except for Heartbeat and Node Guarding. Only NMT communication is

enabled.

5.2.1.2 Switching between NMT communication states

Telegrams with the following structures are used for switching between the communications

statuses:

Status change

Transition

in Fig. 5

COB-ID

Com.

Node-

ID

from

to

PRE-OPERATIONAL / STOPPED

OPERATIONAL

1

0h

01h

x

OPERATIONAL/ PRE-

OPERATIONAL

STOPPED

2

0h

02h

x

OPERATIONAL / STOPPED

PRE-OPERATIONAL

3

0h

80h

x

OPERATIONAL / PRE-

OPERATIONAL / STOPPED

INITIALISATION

(Reset Node)

5

0h

81h

x

OPERATIONAL / PRE-

OPERATIONAL / STOPPED

INITIALISATION

(Reset Communication)

4

0h

82h

x

Table 11: Switching between communication statuses

If transmitted as Node-ID x = 0, the message is intended for all bus subscribers.

5.2.2 Boot-Up

The COB-ID of the Boot-Up message consists of 700h and the Node-ID. The NMT-status

"Initialization" is output as data content.

COB-ID

Byte 0

700h + Node-ID

00h

Table 12: Boot-up message

5.2.3 SYNC object

CANopen makes it possible to simultaneously scan inputs and simultaneously set outputs. This

is accomplished by the synchronization message (SYNC), a high-priority CAN message. The

identifier of the SYNC object can be set via object 1005h (see 1005h: COB-ID SYNC message).

Communication via CAN bus (CANopen)

AP10 Date: 28.02.2022 Art. No. 86853 Mod. status 37/22 Page 20 of 78

5.3 Process data exchange

5.3.1 Transfer of Process Data Objects (PDO)

Process data objects (PDO) serve for quick process data exchange. A maximum of 8 bytes of

user data can be transferred in a PDO. AP10 supports the Receive-PDO services RPDO1 and

RPDO2 according to Draft Standard 301 as well as the Transmit-PDO services TPDO1 and TPDO2

according to Draft Standard 301 and Device Profile 406.

5.3.1.1 Transmit PDO (from AP10 to the master)

PDO transfer from the display to the bus master (TPDO) can be initiated as a result of various

events:

•asynchronous, controlled by an internal device timer

•synchronous as a reply to a SYNC message

•as a reply to an RTR message

TPDO1 and TPDO2 are always formed from a status word (see chapter 5.3.3) and the current

position value.

The transfer behavior of TPDO1 is determined via objects 1800h, 1A00h and 6200h and is

assigned to asynchronous transfer. TPDO2 is defined via objects 1801h and 1A01h and serves

for synchronous transfer.

The messages have the structure shown in Table 13, and mapping cannot be changed.

COB-ID

Process data in binary code

Byte 0

(LSB)

Byte 1

Byte 2

Byte 3

(MSB)

Byte 4

Byte 5

Byte 6

Byte 7

TPDO1

180h + Node-ID

Position value

Dummy 0x0000

5F19h: Status

word (see

chapter 5.3.3)

TPDO2

280h + Node-ID

Table 13: TPDO message

Asynchronous data transfer (TPDO1)

If a TPDO1 is to be sent cyclically, then the cycle time must be entered into object 1800h,

sub-index 5, in milliseconds. The TPDO1 will not be sent if the value 0 ms is written. The

function is disabled (delivery state). The minimum value to be set is 1 (= 1 ms). Alternately,

the value can also be written into the object 6200h which is permanently linked internally.

Synchronous data transfer (TPDO2)

The device is factory set to reply by output of the TPD02 message when receiving a SYNC

message. Thus it is set to the synchronous transfer type. 1 is entered in object 1801h, sub-

index 2. The device responds to every n SYNC message if a value n between 1 and 240 (=F0h)

has been entered.

Other manuals for AP10

3

Table of contents

Other Siko Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

South

South GALAXY G7 user manual

McCrometer

McCrometer Water Specialties VF28D OPERATION AND MAINTENANCE MANUAL PARTS LIST

Endress+Hauser

Endress+Hauser RID14 operating instructions

Agilent Technologies

Agilent Technologies PSA Series manual

BMR

BMR PLA44 User and service manual

YOSensi

YOSensi YO Power user guide