Siko MA10/4 User manual

User manual

Electronic display

MA10/4 Software SW02

MA10/4-SW02 Date: 06.05.2014 Page 2 of 23 Art.No. 87185 Mod. status 422/13

Table of contents

1General Information .................................................................................................................... 3

1.1 Documentation.......................................................................................................................... 3

1.2 Short Description....................................................................................................................... 3

2Key functions............................................................................................................................... 3

2.1 Operating modes....................................................................................................................... 4

3Display description ..................................................................................................................... 4

3.1 Display mode Modulo................................................................................................................ 4

3.2 Display mode 0-90-0................................................................................................................. 4

4Programming mode .................................................................................................................... 5

5Parameter description ................................................................................................................ 5

5.1 Incremental version................................................................................................................... 6

5.2 SSI version................................................................................................................................ 8

6Input mode................................................................................................................................. 11

6.1 Reset function ......................................................................................................................... 11

6.2 Incremental measurement ...................................................................................................... 11

6.3 Direct alteration of reference/offset value or calibration/offset value...................................... 12

6.4 Direct input of limiting value.................................................................................................... 12

70-90-0 Angle display.................................................................................................................. 13

7.1 Input of limit with switching output option................................................................................ 13

8Referencing / Calibration.......................................................................................................... 13

8.1 Manual referencing / calibration.............................................................................................. 14

8.2 Automatic referencing ............................................................................................................. 14

9Serial Interface........................................................................................................................... 16

9.1 Standard protocol.................................................................................................................... 16

9.2 SIKONETZ3 Protocol description ........................................................................................... 18

10 Application examples ............................................................................................................... 21

10.1 Example of Modulo display mode........................................................................................... 21

10.2 Example: Mitre-box saw (Display mode 0-90-0)..................................................................... 21

10.3 MA10/4 combined with an MSK magnetic sensor and the MR magnetic ring........................ 21

11 Trouble shooting....................................................................................................................... 22

12 Parameter list............................................................................................................................. 22

12.1 Incremental version................................................................................................................. 22

12.2 SSI version.............................................................................................................................. 23

MA10/4-SW02 Date: 06.05.2014 Page 3 of 23 Art.No. 87185 Mod. status 422/13

1 General Information

1.1 Documentation

The following documents describe this product:

The product data sheet describes the technical data, the dimensions, the pin assignments,

the accessories and the order key.

The mounting instructions describe the mechanical and electrical installation including all

safety-relevant requirements and the associated technical specifications.

The user manual of commissioning the electronic display.

These documents can also be downloaded at http://www.siko-global.com/en-de/service-

downloads.

1.2 Short Description

In combination with an incremental/SSI encoder the MA10/4 SW02 can be used for measuring

angles in three ranges of resolution (1°, 0.1°, 0.01°). After reaching the respective maximum

value, e. g., 359 (programmable modulo value), the display jumps to 0. With opposite sense of

rotation of the encoder the display jumps back from 0 to 359.

Furthermore, the MA10/4 SW02 may be used as an angle display for mitre-box saws. With the

saw blade swinging, the measured value decreases from 90° into the 0° direction.

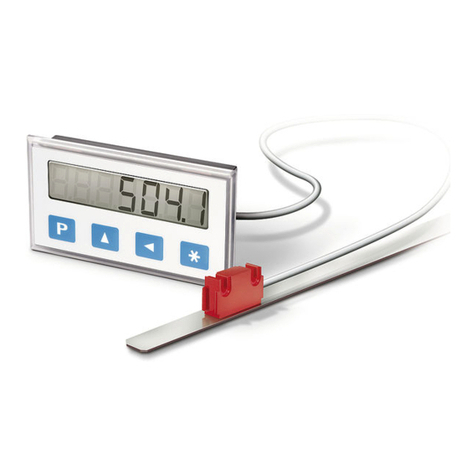

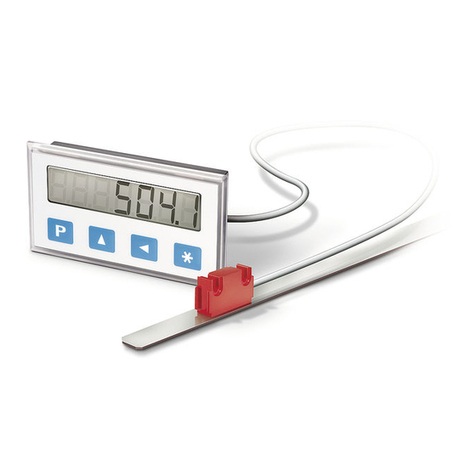

2 Key functions

The display is operated and programmed by means of the four keys of the membrane keyboard.

Depending on the operating mode the keys may have additional functions (see 'Programming

mode' and 'Input mode'). The keys are actuated individually or combined (each two of them)

and time-dependent.

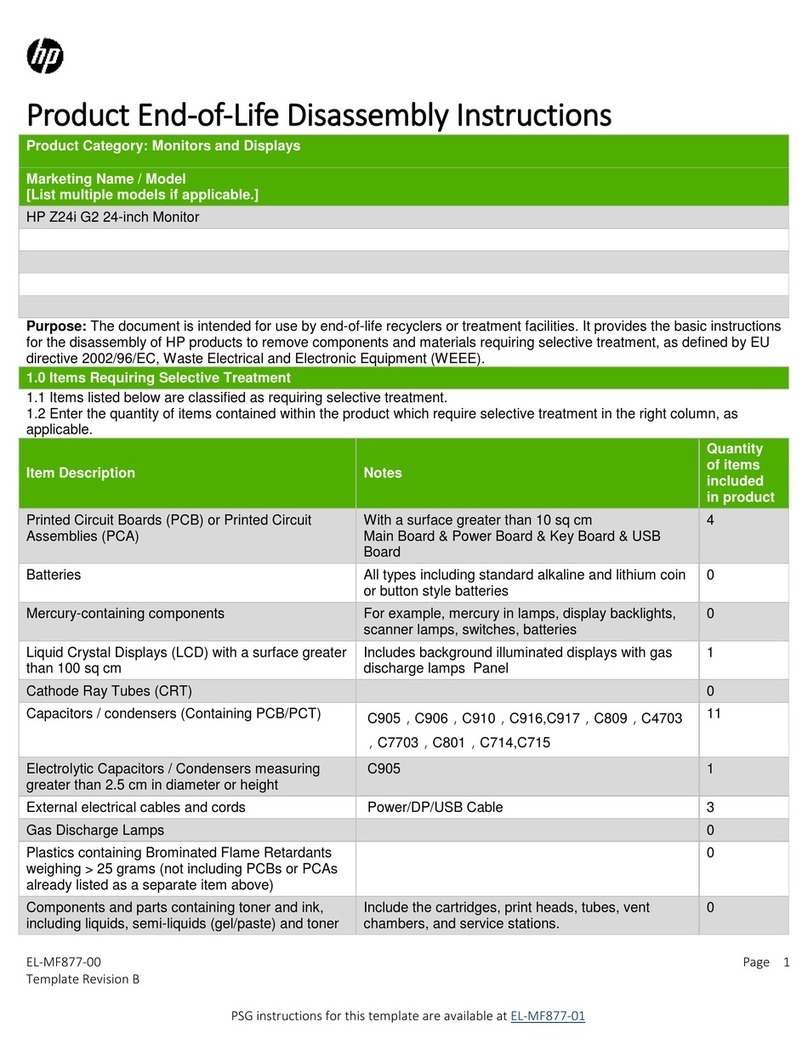

Fig. 1: Key functions

1) Programming

2) Select 'value'

3) Select 'digit'

4) Store value

1) Programming

2) Select 'value'

3) Select 'digit'

4) Store value

MA10/4-SW02 Date: 06.05.2014 Page 4 of 23 Art.No. 87185 Mod. status 422/13

2.1 Operating modes

There are two operating modes:

1. Programming mode: Single set-up of the display for the intended application.

2. Input mode: Functions required during normal application.

3 Display description

The MA10/4 has a backlighted 12-digit LC display. The display as well as the meaning of the

individual symbols is explained in the tables below. The display differs depending on the

application mode (modulo or 0-90-0):

3.1 Display mode Modulo

The display is in the input mode.

1

2

3

4

5

6

7

8

9

10

11

12

Digit

R

1

5

9

.

9

°

Angle value

Digit

Symbol

Description

1

R

Incremental measure is active.

3

Upper limiting value exceeded (only for output circuit option).

3

Lower limiting value exceeded (only for output circuit option).

5-10

Measured value

12

Unit of measure (programmable)

3.2 Display mode 0-90-0

The display is in the input mode.

1

2

3

4

5

6

7

8

9

10

11

12

Digit

3

5

.

9

0

°

Angle value

Digit

Symbol

Description

1

Position value is in the 0 quadrant.

1

Position value is at 90°.

1

Position value is in the 1 quadrant (symbol flashes).

3

Upper limiting value exceeded (only for output circuit option).

3

Lower limiting value exceeded (only for output circuit option).

4-10

Position value

12

Unit of measure (programmable)

MA10/4-SW02 Date: 06.05.2014 Page 5 of 23 Art.No. 87185 Mod. status 422/13

4 Programming mode

The display is delivered ex factory with default settings. Normally programming is only

necessary at initial installation. Parameters can be modified and checked at any time. They are

stored in a non-volatile memory. For designation, function and selectable values see chapter 5.

To change and control parameters

For parameter modification enter into programming mode.

To enter into the programming mode

Press key for at least 5 s (pre-programmed) or for the period programmed under P-KEY

delay.

To leave programming mode

Automatically, if no key has been pressed during approx. 30 s, or press key until the end of

the parameter list is reached.

To scroll parameter information

Use key .

Input of numerical values

For numerical values the smallest decade flashes first. The numerical value of the flashing digit

can be updated by pressing the key. The next digit can be accessed by pressing the key.

Changing given selection

By means of the key.

Accepting/ saving the changed value

By pressing the key, the message "speichern..." will be displayed for a short while.

5 Parameter description

At chapter 12 you will find a detailed parameter list showing all programmable parameters and

offering space for customer-specific programming values.

(in English, parameter LANGUAGE = "eng")

After entering the programming mode (see chapter 4) the parameters described below can be

configured. Depending on the settings selected, only the menu items that are relevant for the

application will be displayed.

MA10/4-SW02 Date: 06.05.2014 Page 6 of 23 Art.No. 87185 Mod. status 422/13

5.1 Incremental version

Display

Value range

Description

LANGUAGE:

ger or deu

(German)

eng (English)

Language

To choose the language in which the menu items are to

be displayed.

Attention! The term "SPRACHE" will be displayed first in

German.

WINK:

modulo, 0-90-0

Angle mode

'modulo' angle measurement, e. g., 0-360°

'0-90-0' angle measurement for mitre-box saws

DEC:

0., 0.0, 0.00

Positions after the comma

'0.' : 1° resolution

'0.0' : 0.1° resolution

'0.00' : 0.01° resolution

MOD.W:

0 ... 59999

Modulo value: Number of possible steps

Menu item is displayed only if 'WINK:' is programmed with

'modulo'

Example:

Angle measurement 0° ... 359° corresponds to a number

of 360 steps

-> MOD.W: = 00360; after reaching the maximum value

(359) the display jumps back to 0. With opposite rotational

direction of the encoder, the display jumps back from 0 to

359.

DPR:

0 ... 59999

Display after 1 revolution

Value by which the display increases/decreases after 1

revolution of the encoder. If DPR: = 0, quadruple

evaluation of the encoder signal will take place

automatically.

DIVISOR:

1, 10, 100,

1000

Display divisor

Divisor by which the display accuracy is reduced

compared to the measuring accuracy. Example: Due to an

integer value ratio, the measuring resolution is

programmed to 1/1000 mm. The display, however, needs

a resolution of 1/10 mm only. -> The display divisor is

programmed to '100'.

INCR:

0 ... 59999

Encoder pulses per revolution

If INCR: = 0, quadruple evaluation of the encoder signal

will take place automatically.

DIRECTION:

i, e

Counting direction

'i' clockwise increasing values

'e' anti-clockwise increasing values

INDEX:

I-lang, 0-lang, I-

kurz, 0-kurz

Input of logic and length of the encoder's reference signal

The encoder reference signal is output only once per

revolution.

'lang' index signal is wider than one increment; index is

linked with A and B signals.

'kurz' index signal is exactly as wide as one increment

'0' index signal with positive logic

'I' index signal with negative logic

MA10/4-SW02 Date: 06.05.2014 Page 7 of 23 Art.No. 87185 Mod. status 422/13

Display

Value range

Description

TRS:

n.open,

n.closed, hand

Reference switch

Type of reference value transmitter; can either be a

mechanical contact or a proximity switch.

'n.open' closing contact, which is normally open

'n.closed' opening contact, which is normally closed

'hand' Referencing arbitrarily via callipers independent of

A and B, index signal). The input is current-sinking and

edge-triggered.

REF:

-999999 ...

+999999

Reference point for the measuring system

Absolute datum point of the measuring system. This value

is set after system reference accord. to chapter 8.

value range modulo:

-999999...+999999

value range 0 0-90-0:

-999999...+90 (resolution 1°)

-999999...+900 (resolution 0.1°)

-999999...+9000 (resolution 0.01°)

OFF:

-999999 ...

+999999

Offset (displacement)

Menu item appears only if 'WINK:' has been programmed

with 'modulo'. Freely selectable value that influences the

display. The offset value can be used as tool correction or

offset measure for instance.

RESET:

off, on, del.1s,

del.3s

Reset via keyboard enable

'off' reset function off

'on' reset function enabled

'del.1s' reset function enabled (press key for at least

1 sec.)

'del.3s' reset function enagled (press key for at least

3 sec.)

ABS/REL:

off, on

Incremental measurement enable

Menu item will be displayed only if 'modulo' is

programmed for 'WINK:'. To switch from absolute

measurement and zero-zetting to relative measurement.

'off' function off

'on' function on

RE/OF.EN:

off, on

Reference/ offset value input enable

Menu item will be displayed only if 'modulo' is

programmed for 'WINK:'.

'off' reference/offset value correction off

'on' reference/offset value correction enabled

RE/EN:

off, on

Reference value input enable

Menu item will be displayed only if '0-90-0' is programmed

for 'WINK:'.

'off' reference value correction off

'on' reference value correction enabled

STO:

off, on

Actual value store

When switched off, the last displayed value is stored in a

non-volatile memory.

'off' Actual value memory off: when switched on, the

display must be calibrated (zeroed) (Display value is

flashing).

'on' Actual value memory on: when switched on, the last

measured value is displayed.

MA10/4-SW02 Date: 06.05.2014 Page 8 of 23 Art.No. 87185 Mod. status 422/13

Display

Value range

Description

P-KEY:

3s, 5s, 10s,

20s, 30s

Programming keys delay

Delay of key when switching from input to

programming mode.

BAUD:

2400, 4800,

9600, 19200,

SIKON.3,

SCHALT

Interface's baud rate

'SCHALT' must be programmed for switching outputs,

'SIKON.3' for SIKONETZ3.

ADR:

1 ... 31

Adress setting for SIKONETZ3

Menu item will be displayed only if 'SIKON.3' is

programmed for 'BAUD:'.

UPL:

-999999 ...

+999999

For switching output: Input of the upper switching point

Menu item will be displayed only if 'SCHALT' is

programmed for 'BAUD:'.

LOL:

-999999 ...

+999999

For switching output: Input of the lower switching point

Menu point will be displayed only if 'SCHALT' is

programmed for 'BAUD:'.

LIMIT.EN:

off, on

Enabling of modification of the limiting value

Menu item will be displayed only if 'SCHALT' is

programmed for 'BAUD:'. Possibility of input/ modification

of the upper and lower limiting values in the input mode.

'off' Modification of limiting values disabled in input mode.

'on' Modification of limiting values enabled in input mode.

UNITS:

--, °

Unit of measure

Choice of the measurement unit to be displayed on

positions 11, 12 (see chapter 3Display description).

DIS.ANGLE:

-5 ... +4

Display angle

Here, the contrast of the LC display can be set.

CODE:

00000

Code input: for service only

CONTROL:

off, on

Code input: for service only

5.2 SSI version

Display

Value range

Description

LANGUAGE:

ger or deu

(German)

eng (English)

Language

To choose the language in which the menu items are to

be displayed.

Attention! The term "SPRACHE" will be displayed first in

German.

WINK:

Modulo, 0-90-0

Angle mode

'modulo' angle measurement, e. g., 0-360°

'0-90-0' angle measurement for mitre-box saws

DEC:

0., 0.0, 0.00

Positions after the comma

'0.' : 1° resolution

'0.0' : 0.1° resolution

'0.00' : 0.01° resolution

MA10/4-SW02 Date: 06.05.2014 Page 9 of 23 Art.No. 87185 Mod. status 422/13

Display

Value range

Description

MOD.W:

0 ... 59999

Modulo value: Number of possible steps

Menu itemis displayed only if 'WINK:' is programmed with

'modulo'.

Example:

Angle measurement 0° ... 359° corresponds to a number

of 360 steps

-> MOD.W: = 00360; after reaching the maximum value

(359) the display jumps back to 0. With opposite rotational

direction of the encoder, the display jumps back from 0 to

359.

E-TYP:

multi, single

Encoder type

Determines the encoder type connected

'multi' multi-turn encoder

'single' single-turn encoder

FORMAT:

no, Tree

Data format

Menu item will be displayed only if "multi" is programmed

for 'E-TYP:'

'no' Encoder data leftjustified (MSB first)

'tree' pine-tree (12 multiturn + 13 singleturn bits data

format)

S-BITS:

5 ... 19

Input of single-turn bits for multi-turn encoder

Menu item will be displayed only if "multi" is programmed

for 'E-TYP:'.

ENCOD.BIT:

5 ... 25

Input of the total encoder bit number

DPR:

0 ... 59999

Display after 1 revolution

Menu item will be displayed only if "multi" is programmed

for 'E-TYP:' Value by which the display

increases/decreases after 1 revolution of the encoder. The

maximum possible encoder resolution is displayed if DPR:

= 0. For 10 bit single-turn: 0 ... 1023

DIVISOR:

1, 10, 100,

1000

Display divisor

Divisor by which the display accuracy is reduced

compared to the measuring accuracy. Example: Due to an

integer value ratio, the measuring resolution is

programmed to 1/1000 mm. The display, however, needs

a resolution of 1/10 mm only. -> The display divisor is

programmed to '100'.

DIRECTION:

i, e

Counting direction

'i' clockwise increasing values

'e' anti-clockwise increasing values

CAL:

-999999 ...

+999999

Calibration value for the measuring system

Absolute datum point of the measuring system. This value

is set after system calibrated accord. to chapter 8.

value range modulo:

-999999 ... +999999

value range 0-90-0:

-999999 ... +90 (resolution 1°)

-999999 ... +900 (resolution 0.1°)

-999999 ... +9000 (resolution 0.01°)

OFF:

-999999 ...

+999999

Offset (displacement)

Can be any value; used to influence the value displayed,

e. g. tool correction value.

MA10/4-SW02 Date: 06.05.2014 Page 10 of 23 Art.No. 87185 Mod. status 422/13

Display

Value range

Description

RESET:

off, on, del.1s,

del.3s

Reset via keyboard enable key

'off' reset function off

'on' reset function enabled

'del.1s' reset function enabled (press key for at least

1 sec.)

'del.3s' reset function enagled (press key for at least

3 sec.)

ABS/REL:

off, on

Incremental measurement enable

Menu item will be displayed only if 'modulo' is

programmed for 'WINK:'. To switch from absolute

measurement and zero-zetting to relative measurement.

'off' function off

'on' function on

CA/OF.EN:

off, on

Calibration/ offset value input enable

Menu item will be displayed only if 'modulo' is

programmed for 'WINK:'.

'off' calibration/offset value correction off

'on' calibration/offset value correction enabled

CA/EN:

off, on

Calibration value input enable

Menu item will be displayed only if '0-90-0' is programmed

for 'WINK:'.

'off' calibration value correction off

'on' calibration value correction enabled

OUTPUT:

gray, bin

Output code

'gray' Encoder's data in Gray code

'bin' Encoder's data in binary code

TIMEOUT:

off, on

Time-out function

'off' Cable break recognition off

'on' Cable break recognition off

P-KEY:

3s, 5s, 10s,

20s, 30s

Programming keys delay

Delay of key when switching from input to

programming mode.

BAUD:

2400, 4800,

9600, 19200,

SIKON.3,

SCHALT

Interface's baud rate

'SCHALT' must be programmed for switching outputs,

'SIKON.3' for SIKONETZ3.

ADR:

1 ... 31

Address setting for SIKONETZ3

Menu item will be displayed only if 'SIKON.3' is

programmed for 'BAUD:'.

UPL:

-999999 ...

+999999

For switching output: Input of the upper switching point

Menu item will be displayed only if 'SCHALT' is

programmed for 'BAUD:'.

LOL:

-999999 ...

+999999

For switching output: Input of the lower switching point

Menu item will be displayed only if 'SCHALT' is

programmed for 'BAUD:'.

LIMIT.EN:

off, on

Enabling of modification of the limiting value

Menu item will be displayed only if 'SCHALT' is

programmed for 'BAUD:'. Possibility of input/ modification

of the upper and lower limiting values in the input mode.

'off' Modification of limiting values disabled in input mode.

'on' Modification of limiting values enabled in input mode.

MA10/4-SW02 Date: 06.05.2014 Page 11 of 23 Art.No. 87185 Mod. status 422/13

Display

Value range

Description

UNITS:

--, °

Unit of measure

Choice of the measurement unit to be displayed on

positions 11, 12 (see chapter 3Display description).

DIS.ANGLE:

-5 ... +4

Display angle

Here, the contrast of the LC display can be set.

SET:

Encoder zeroing

Zeroing of the encoder (+offset +calibration value) in

programming mode via key.

GDAT:

Position value of the encoder

Display of the actual encoder position.

CODE:

00000

Code input: for special functions

CONTROL:

off, on

Code input: for special functions

6 Input mode

6.1 Reset function

Precondition: Parameter 'Reset enable' (RESET:) in programming mode must

be programmed to "on", "del.1s" or "del.3s" but unit must not be left in

programming mode (see chapter 4'To leave programming mode').

For "modulo" display mode

Press key to set the display to reference/calibration + offset value.

For "0-90-0" display mode

Press key to set the display to reference/calibration value.

6.2 Incremental measurement

(Not 0-90-0 display mode!)

Precondition: Menu item 'Incremental measurement enable' (ABS/REL:) in

programming mode must be programmed to "on", but unit must not be left in

programming mode (see chapter 4'To leave programming mode').

Switching on by pressing the key.

The display is zeroed and an "R" is displayed on position 1.

Switchin off by pressing the key once more. The absolute measuring value is displayed

again.

While in the incremental measurement mode the display can also be set to zero by pressing

key . This does not change the absolute measurement in the background.

MA10/4-SW02 Date: 06.05.2014 Page 12 of 23 Art.No. 87185 Mod. status 422/13

6.3 Direct alteration of reference/offset value or calibration/offset value

Precondition: In programming mode menu item 'Reference/offset value input

enable' (RE/OF.EN:) or 'calibration/offset value input enable' (CA/OF.EN:) in

display mode 'modulo', resp. reference/calibration value input enable

(RE.EN:/CA.EN:) in display mode '0-90-0' must be programmed to "on", but

unit must not be left in programming mode (see chapter 4'To leave

programming mode').

If frequent changes to the reference/calibrtation value or offset value are required in the

application, then you can call and alter these values directly in the input mode.

Input reference/calibration value

Change of reference/calibration value is enabled by pressing the key, with subsequent

pressing of the key (within 1 sec.).

The display then shows the reference/ calibration value, which can be changed via the two

arrow keys. By pressing the key, the value is saved and directly taken over in the display.

Input offset value (not at '0-90-0'!)

Change of offset value is enabled by pressing the key once again. The display then

shows the offset value, which can be changed via the two arrow keys. By pressing the

key, the value is saved and directly taken over in the display.

Finishing direct input of reference/calibration/offset value

If no key has been pressed for approx. 30 s or if you press again key , MA10/4 will return

to display mode.

6.4 Direct input of limiting value

(Only for switching output option!)

Precondition: In programming mode menu item enabling of modification of

the limiting value (LIMIT.EN:) must be programmed to "on", but unit must not

be left in programming mode (see chapter 4'To leave programming mode').

If the limiting values must be chanded frequently in the application, there is the possibility to

directly call up the input of limiting values in the input mode.

Change of the limit values is enabled by pressing the key, with subsequent pressing of

the key (within 1 sec.).

The display then shows the upper limit value, which can be changed via the two arrow keys.

By pressing the key, the changed value is saved.

After pressing key once again, the display shows the lower limit value, which also can be

changed via the two arrow keys. By pressing the key, the changed value is saved.

If no key has been pressed for approx. 30 s or if you press again key , MA10/4 will return

to display mode.

MA10/4-SW02 Date: 06.05.2014 Page 13 of 23 Art.No. 87185 Mod. status 422/13

7 0-90-0 Angle display

If the encoder value is smaller than 90 (or 90.0 or 90.00, resp.), it is immediately displayed.

However, if it exceeds the above limits, it is calculated according to the following formula:

Displayed value = 180-encoder value

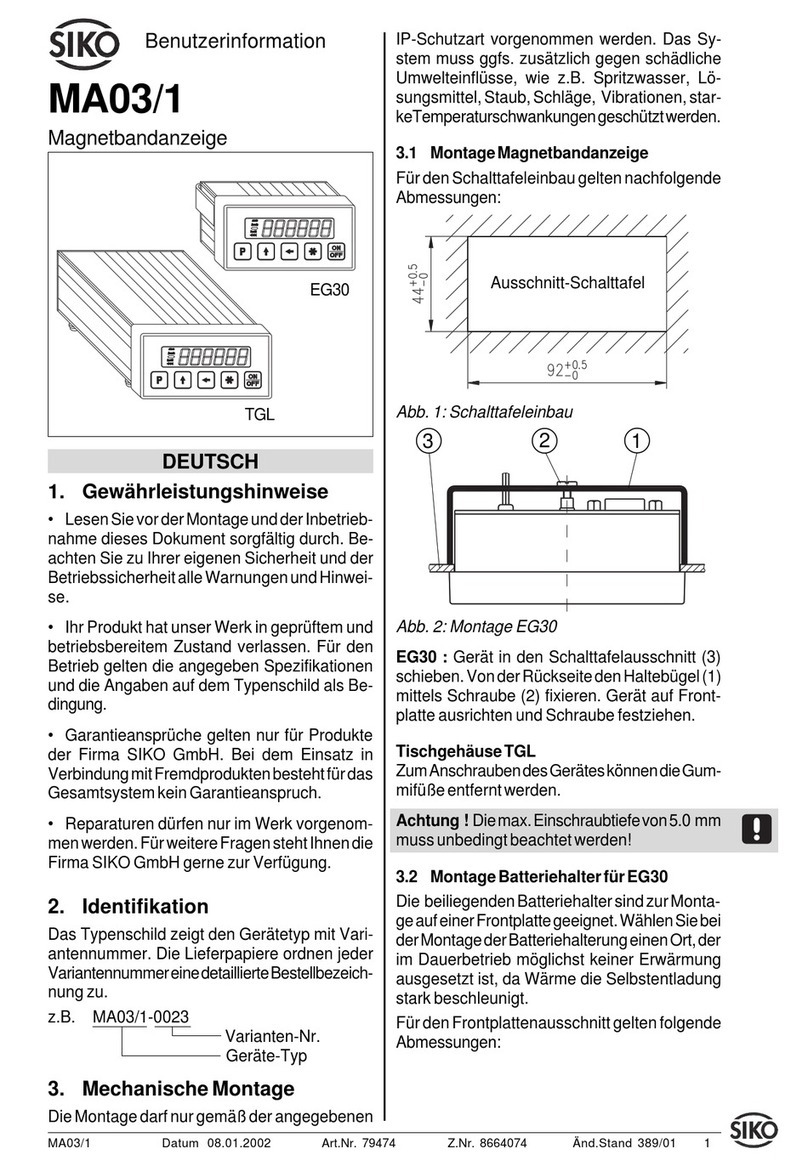

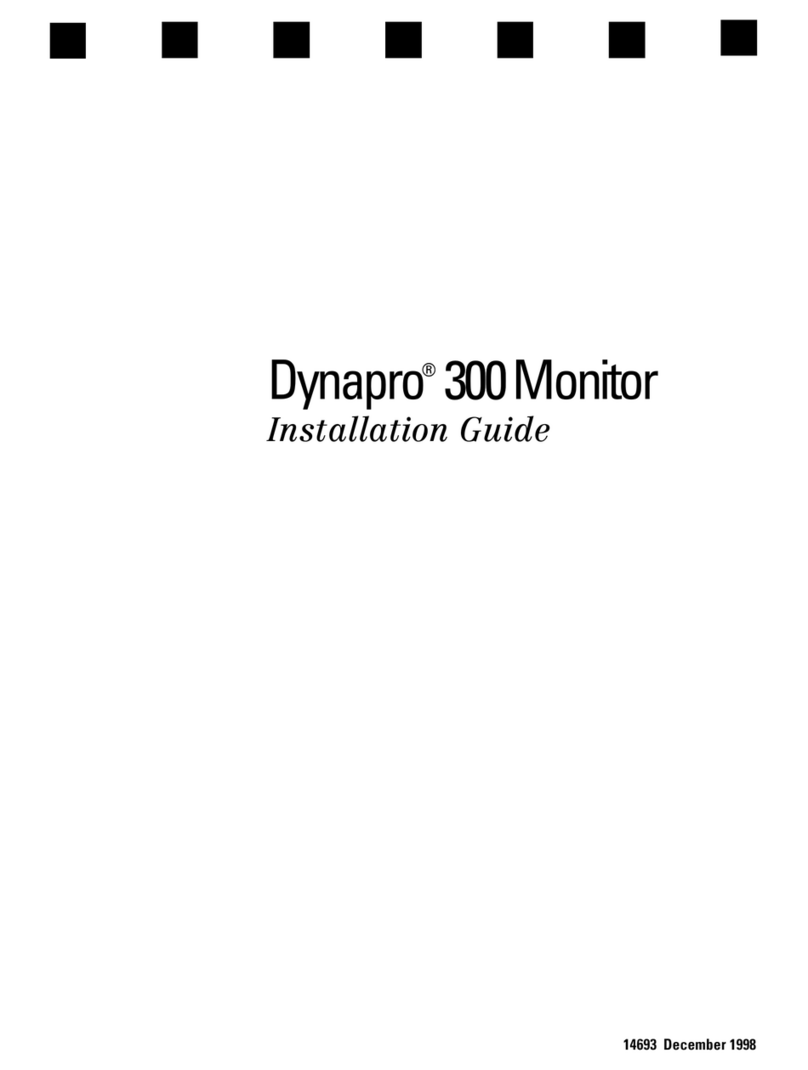

Fig. 2: Angle display

A flashing angle sign (display position 1) symbolises, that one is in the first quadrant. In this

position no referencing/calibration must be conducted. If, however, referencing/calibration is

required on this position (angle symbol flashes), it can be done by inverting the sense of

rotation.

7.1 Input of limit with switching output option

When entering the limits that are in the quadrant 1, please note that they cannot be entered

directly as with quadrant 0, but must be calculated according to the following formula:

Limiting value = 180 - display value

Example:

The lower limit is in quadrant 0 at 40°, the upper limit in quadrant 1 at 40°.

-> LOL: = 40

Calculation of the input value for the upper limit:

Upper limit = 180 - 40 = 140

-> UPL: = 140

8 Referencing / Calibration

The display must always be referenced/calibrated:

before the first use of the measuring system.

if the actual value memory (STO:) was programmed to 'off'.

in case of a displacement during power failure.

Encoder value

Display value

90

Quadrant 0

Quadrant 1

Encoder path/

angle

Display value =

encoder value

Display value = 180 –encoder value

Angle symbol flashes (digit 1)

Display

MA10/4-SW02 Date: 06.05.2014 Page 14 of 23 Art.No. 87185 Mod. status 422/13

During reference/calibration the counter is set to the programmed reference/calibration value (+

offset value when display mode modulo). The display can thus be zeroed, if

reference/calibration and offset value were previously programmed to 0.

8.1 Manual referencing / calibration

Manual reference/calibration can either be made by:

activating a reference/calibration switch according to its function, i. e. RFS/CAL to ground.

Menu item 'TRS:' must be programmed to "hand".

or by pressing key . Therefore menu item 'RESET:' must be programmed to "on", "del.1s"

or "del.3s".

During reference/calibration the counter is set to the programmed reference/calibration value

(+ offset value when display mode modulo) The display can thus be zeroed, if

reference/calibration and offset value were previously programmed to 0.

8.2 Automatic referencing

(Only incremental!)

Automatic referencing is always made via a reference point transmitter, which is automatically

approached at a defined position (reference value). Suitable reference point transmitters are:

mechanical cam switches.

proximity switches with NPN-output (connected to earth).

Referencing condition: (for opening/ closing contact)

Index "lang": Signal_A + signal_B + index signal + reference switch

Index "kurz": Index signal + reference switch

General information on automatic reference

Electronic linking of the signals from a reference point transmitter (e. g. cam switch or limit

switch) with the index pulse (index marker) of the connected encoder will calibrate the

measuring display, ie. a start position is defined. During mounting of the reference point

transmitter, please adjust the incremental encoder in such a way that the index pulse appears

when the reference point switch is activated.

The contact of the reference point transmitter must only be active for less than one revolution of

the encoder (see Fig. 3).

MA10/4-SW02 Date: 06.05.2014 Page 15 of 23 Art.No. 87185 Mod. status 422/13

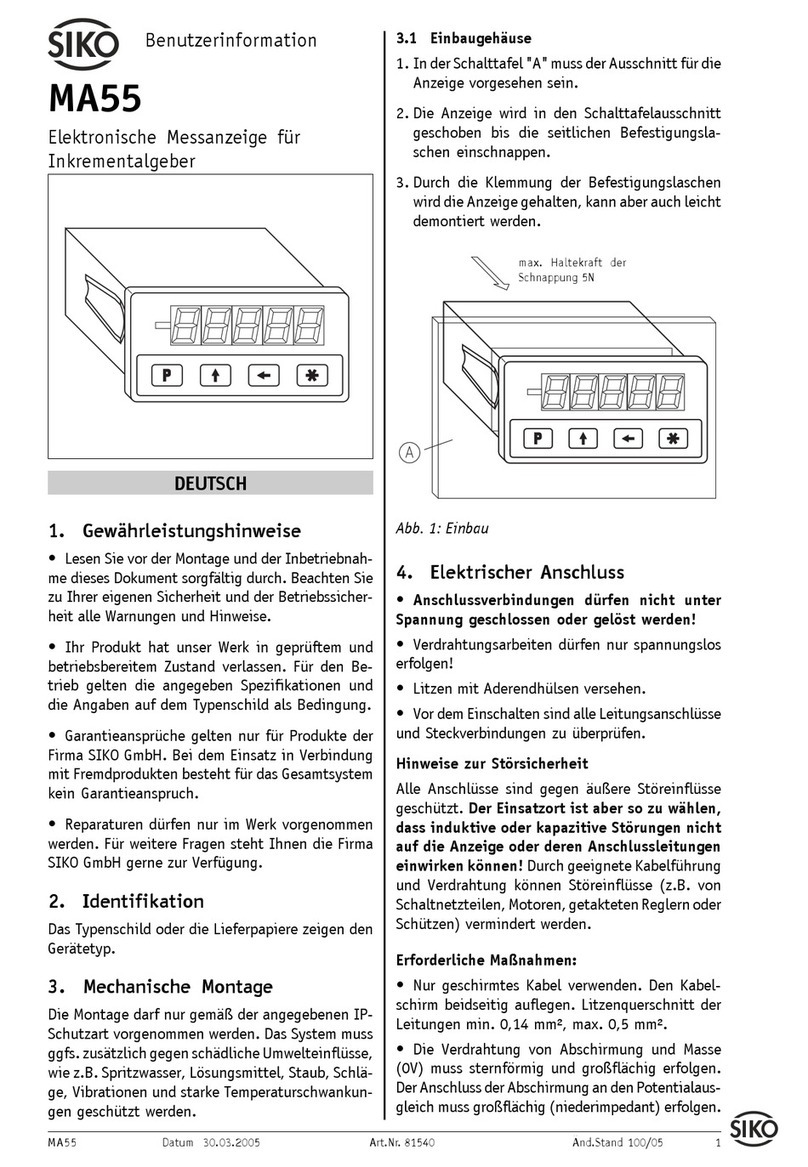

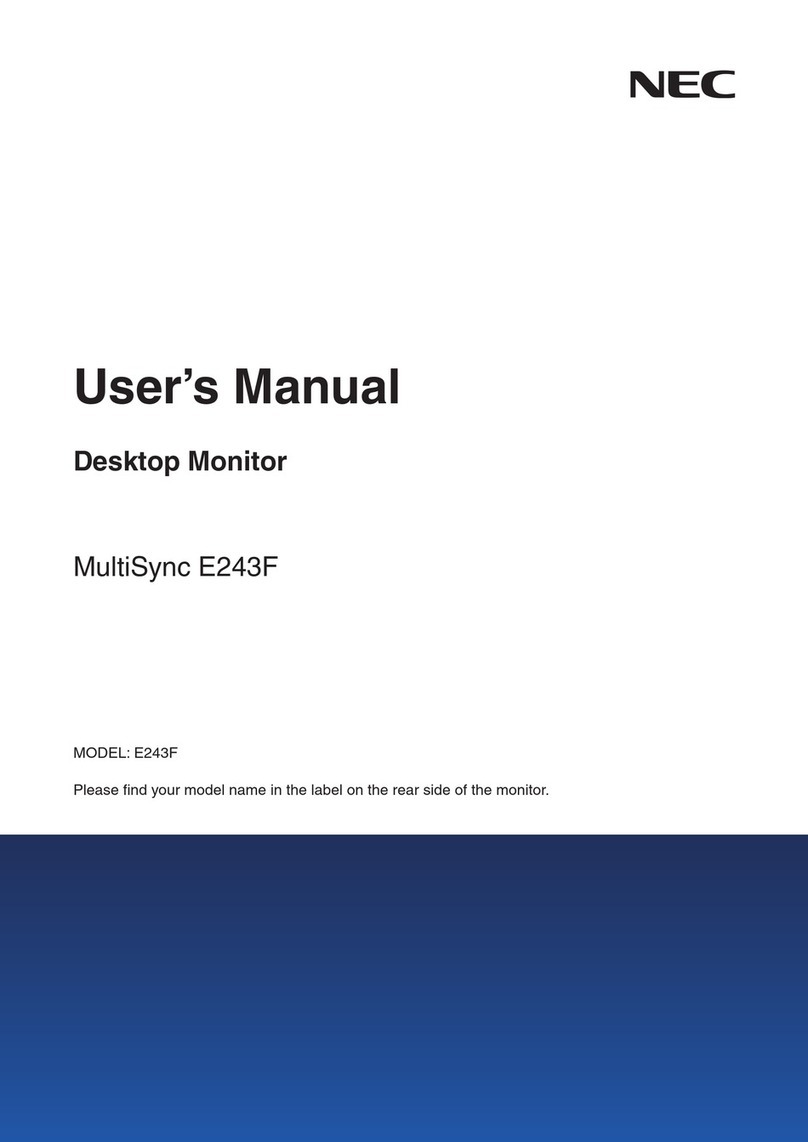

Fig. 3: Signal types for referencing

Information concerning the setting of the reference point

Move the spindle exactly to the position which corresponds to the reference value programmed

before accord. to chapter 6. The mechanically mounted reference point transmitter must now be

definitely active (see Fig. 3).

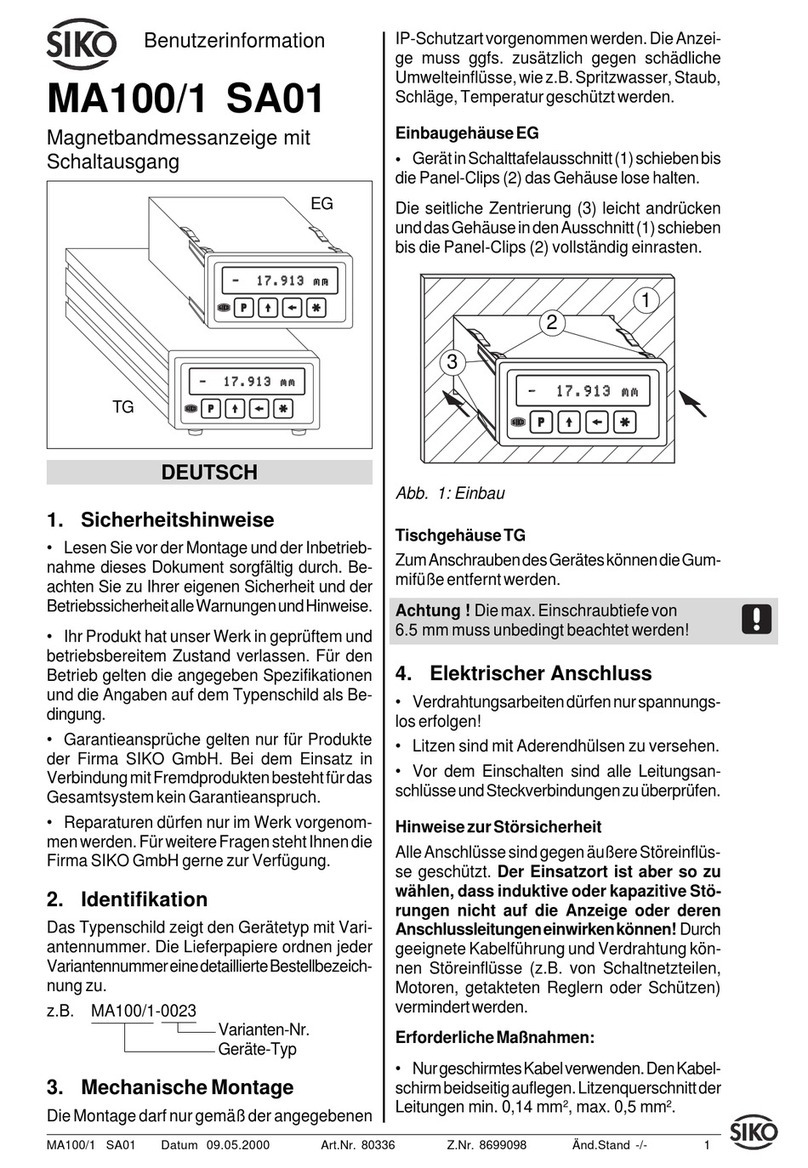

The encoder can be turned without causing any movement of the driving spindle, if you

untighten the clamping ring or coupling. You can now search the index signal of the encoder

(voltage change) by using for example a voltmeter and carry out the adjustment of the reference

point. When the index and reference point transmitter signals are positioned as described in Fig.

4, the clamping ring and the coupling of the incremental encoder are retightened.

Fig. 4: Referencing setup

Drive

Driving spindle

ref. point

transmitter

Incremental card of the MA10/4

Incremental

encoder

Signal A

Signal B

Index signal

ref. point

transmitter signal

definetely

passive

definetely

passive

definetely

aktive

one

revolution

Type 0

Type I

MA10/4-SW02 Date: 06.05.2014 Page 16 of 23 Art.No. 87185 Mod. status 422/13

9 Serial Interface

(Only interface option!)

Data can be exchanged with a PC via the serial interface of the MA10/4: Two different protocols

are used depending on the MA10/4 version (standard protocol or SIKONETZ3).

9.1 Standard protocol

Menu item 'BAUD:' must be programmed on "2400", "4800", "9600" or "19200".

The MA10/4 can be operated directly on a PC or terminal via the serial interface.

Parameter: 2400 ... 19200 baud, no parity, 8 bits, 1 Stop bit, no handshake

Data code: ASCII

Value range: 2/3 Byte: 0 ... 65536 / 0 ... ±223

The transmission functions generally so, that the PC (or terminal) sends Capital Letters, if

necessary with additional parameters. The MA10/4 transmits its answer with automatic Carriage

Return <CR>.

Input: Lower and upper cases are accepted (ASCII).

Output: All response telegrams are completed with a CR (hex 13), except for the 'W' and "K"

commands.

Command

Length

Reply

Description

Ax

2/8

2/14

2/8

"xxxxxx>"

"xxxxxxxxxxxx>"

"xxxxxx>"

Unit type/software version

x=0: hardware version

x=1: software version

x=2: unit type (INC, SSI...)

B

1/10

"±xxxxxxx>"

Binary counter value

Ey

2/10

"±xxxxxxx>"

Transmit 3-byte value

y = address (1 ... 5)

xxxxxxx = decimal value

y=1: position value

y=2: reference/calibration value

y=3: offset value

y=4: offset value of incremental measure

y=5: disc value at the moment of zeroing (SSI

only!)

Fy±xxxxxx

9/2

">"

Enter 3-byte value

y = address (2 ... 6)

xxxxxxx = decimal value

y=2: reference/calibration value

y=3: offset value

y=4: offset value of incremental measure

y=5: SSI zeroing value (SSI only!)

y=6: factor (SSI only!)

MA10/4-SW02 Date: 06.05.2014 Page 17 of 23 Art.No. 87185 Mod. status 422/13

Command

Length

Reply

Description

Gy

2/7

"xxxxx>"

Transmit 2-byte value

y = address (0 ... 7)

xxxxx = decimal value

y=0: display value after 1 revolution

y=1: number of pulses (incremental only!)

y=2: positions after the comma

y=3: baud rate

y=4: encoder bits (SSI only!)

y=5: singleturn bits (SSI only!)

y=6: modulo value

y=7: DIVISOR

Hyxxxxx

7/2

">"

Enter 2-byte-value

y = address (0 ... 6)

xxxxx = decimal value

y=0: display value after 1 revolution

y=1: number of pulses

y=2: positions after the comma

y=4: encoder bits (SSI only!)

y=5: singleturn bits (SSI only!)

y=6: modulo value

Iabc

4/2

">"

Release frontal keys

a: reset via keyboard

0 = off

1 = on

2 = 1 sec. delay

3 = 3 secs. delay

b: enable incremental measure (not 0-90-0!)

0 = off

1 = on

c: input reference (calibration)/ offset value

0 = off

1 = on

Jy

2/2

">"

y: language

0 = German

1 = English

K

1/0

" "

Software RESET

L

1/1

">"

Zero-zetting (referencing/calibration)

Mabc

4/1

">"

Enter SSI format (SSI only!)

a: Format

0 = no

1 = tree

b: output

0 = gray

1 = binary

c: Time-out

0 = off

1 = on

N

1/4

"xx>"

Issue flag register

xx: flag register 0 (HEX)

yy: flag register 1 (HEX)

Ox

2/2

">"

Actual value store (incremental only!)

x=0: actual value store off

x=1: actual value store on

MA10/4-SW02 Date: 06.05.2014 Page 18 of 23 Art.No. 87185 Mod. status 422/13

Command

Length

Reply

Description

Px

2/2

">"

Input encoder type (SSI only!)

x=0: Multiturn encoder

x=1: Singleturn encoder

S

1/2

">"

Reset device to standasrd programming (default

values)

Tx

2/1

">"

Counting direction

x=0: counting direction 'i'

x=1: counting direction 'e'

Ux

2/1

">"

Input index type (incremental only!)

x=0: Index I-lang

x=1: Index 0-lang

x=2: Index I-kurz

x=3: Index 0-kurz

Vx

2/2

">"

Type of reference switch (incremental only!)

x=0: reference switch 'closing contact'

x=1: reference switch 'opening contact'

x=2: manual reset

W

1/3

"xyz"

Binary position value

xyz = 3 bytes in two's complement MSB ... LSB

Xy

2/2

">"

Enter unit of measure

y: number

y=0: no

y=1: " ° " (angle degree)

Yx

2/2

">"

Enter display divisor (incremental and SSI only!)

x= number

x=0: ADI = 1

x=1: ADI = 10

x=2: ADI = 100

x=3: ADI = 1000

Z

1/10

"±xxxxxxx>"

Issue position value

9.2 SIKONETZ3 Protocol description

(Only interface option!)

Precondition: Menu item "BAUD:" must be programmed to "SIKON.3".

The SIKONETZ3 protocol is a bus-capable protocol based on RS485 interface.

Parameter: 19200 baud, 8 bits, no Parity, 1 Start bit, 1 Stop bit

The protocol setup follows the Master-Slave-System; the MA10/4 only has the slave function.

There are 2 telegram lengths:

3 Byte:

Address

Byte

Command

Check

Byte

6 Byte:

Address

Byte

Command

Data

Byte

Low

Data

Byte

Middle

Data

Byte

High

Check

Byte

MA10/4-SW02 Date: 06.05.2014 Page 19 of 23 Art.No. 87185 Mod. status 422/13

The address byte is composed as follows:

1

0

A0

A1

A2

A3

A4

0

RR

L

1

Start

Stopp

The check byte results from an EXOR-interconnection of the remaining two or five bytes of the

telegram.

A0 ... A4: binary coded address 1 ... 31, address 0 defined for master

RR: broadcast bit: 1 = command valid for all devices, devices do not reply

L: length bit: 1 = short telegram (3 bytes), 0 = long telegram (6 bytes)

List of commands SIKONETZ3 protocol

Parameter: 19200 baud, no Parity, 8 Bit, 1 Start bit, 1 Stop bit

Column

Signification

Hex

Hexadecimal value of the command

TX

Length of telegram from master to MA10/4

RX

Length of telegram from MA10/4 to master

S

Transmitted parameter is permanently stored in the sensor

P

For this command programming mode has to be activated (command 0x32; 0x33)

R

This command can be broadcasted

Hex

TX

RX

S

P

R

Function

0x16

3

6

-

-

-

Read out position value

0x18

3

6

-

-

-

Read out reference/calibration value

0x19

3

6

-

-

-

Read out offset value

0x1b

3

6

-

-

-

Read out device's characteristics

Low Byte: identifier = 21

Middle Byte: software version

High Byte: hardware version

0x1c

3

6

-

-

-

Read out address/positions after the comma

Low Byte: address

Middle Byte: positions after the comma

0x1d

3

6

-

-

-

Read out counting direction

Low Byte = 0: counting direction i

Low Byte = 1: counting direction e

0x1e

3

6

-

-

-

Read out display after 1 revolution

0x1f

3

6

-

-

-

Read out encoder pulses per revolution

0x28

6

6

S

P

-

Program reference/ calibration value

0x29

6

6

S

P

-

Program offset value

0x2c

6

6

S

P

-

Program positions after the comma

Value must be in data byte Middle

0x2d

6

6

S

P

-

Program counting direction (see command 0x1d)

0x2e

6

6

S

P

-

Program display after 1 revolution

Value range 0 ... 59999

0x2f

6

6

S

P

-

Program encoder pulses per revolution

Value range 0 ... 59999

0x32

3

3

-

-

-

Programming mode "on"

MA10/4-SW02 Date: 06.05.2014 Page 20 of 23 Art.No. 87185 Mod. status 422/13

Hex

TX

RX

S

P

R

Function

0x33

3

3

-

-

-

Programming mode "off"

0x38

3

6

-

-

-

Read out display divisor

Low Byte = 0: ADI 1

Low Byte = 1: ADI 10

Low Byte = 2: ADI 100

Low Byte = 3: ADI 1000

0x39

6

6

S

P

-

Program display divisor (see command 0x38)

0x3a

3

6

-

-

-

Send system status

0x3b

3

3

-

-

-

Cancel system status

0x48

3

3

S

P

-

Zero-zetting

Position value is set to reference/calibration value + offset

value

0x4f

3

3

-

-

R

Freeze measured value (position, number of pieces

number), measured value is frozen. Deactivated when

positional value is read out. Used for synchronizing the

read out of several devices.

0x6c

3

6

-

-

-

Output index type (only incremental!)

Low Byte = 0: I-lang

Low Byte = 1: 0-Lang

Low Byte = 2: I-kurz

Low Byte = 3: 0-kurz

0x6d

6

6

S

P

-

Program index type (only incremental!) (see command

0x6c)

0x72

3

6

-

-

-

Output configuration bits

0x73

6

6

S

P

-

Program configuration bits

0x7e

3

6

-

-

-

Send type of reference switch (only incremental!)

0x7f

6

6

S

P

-

Program type of reference switch (only incremental!)

Error messages

The slave (MA10/4) recognizes transmission or input errors and then issues the following error

messages:

Hex

TX

RX

S

P

R

Function

82 Hex

-

3

-

-

-

Check sum data transmission error

83 Hex

-

3

-

-

-

Invalid or unknown command

85 Hex

-

3

-

-

-

Invalid value (parameter programming)

Synchronisation

Byte/telegram synchronisation is made via "timeout": the distance between each byte of a

telegram must not exceed 10 ms. If a device does not respond, the master may only send

another telegram after 30 ms at the earliest.

Telegram example

Master requests position value from device 7

Master sends (hex): 87 16 91

Short telegram to address 7 (87h); read out position value (16h); check byte (91h)

MA10/4 replies (hex): 07 16 03 02 00 10

Other manuals for MA10/4

2

Table of contents

Other Siko Monitor manuals