Sinexcel ROLECEV ULTRACHARGE 160 User manual

Stocked in

the UK by

MAINTENANCE MANUAL

ULTR ACHARGE 160

Intelligent ultra-rapid EV charging station

Product Support

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 1of 21 January 2023

Amendments

Amendment

Number Details Date

Ver 1, Rev 0 New Document. Jan 2023

Product: UltraCharge 160 DC Charger

Models: EVDC2010 – 60kW EVDC2030 – 120kW

EVDC2020 – 80kW EVDC2040 – 160kW

Document Type: Maintenance Manual

Document Code: EVUCMM-V01R0

Language: UK English (Original)

Date Published: January 2023

Rolec Services Ltd are the publishers of this document and own the rights to use the text, images and all technical

content contained within. Content supplied by third parties / partner organisations remains the property of that

organisation and is used by agreement with the supplier.

Rolec Services Ltd exercise care to ensure content is as accurate as possible at the time of publication. However, no

guarantee of accuracy should be inferred.

Rolec Services Ltd, Ralphs Lane, Boston, Lincolnshire PE20 1QU. United Kingdom.

+44 (0) 1205 724754

enquiries@rolecserv.co.uk

Product Support

Updates to this manual will be made available on the Rolec website at

https://www.rolecserv.com/downloads-ev-charging

Check the document date, and the Version and Revision number shown at the

end of the Document Code (V01-R0, V01-R2, V02-R0, etc).

For installation assistance and advice, contact your preferred electrical

installer.

Product Support

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 2of 21

Contents

Product Support 1

Safety 3

Safety Advice Within this Manual 3

Disclaimer 4

Equipment Warnings 5

Maintenance 7

Maintenance of Inactive Charging Stations 7

Charger Checks and Maintenance Cycle 7

Replacement of Common Devices 9

Electric Meter 9

Main circuit breaker 10

Cooling fan 11

AC contactor 12

Current transformer 13

DC contactor 14

Replacement of Dust Screen (Guidance) 15

Common Troubleshooting 18

Emergency Unlock 20

Tools 20

Procedure 20

Detailed View 21

Safety

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 3of 21 January 2023

Safety

This manual is specifically applicable to the UltraCharge 160 DC Charger and is provided

as a guide to its maintenance.

IMPORTANT: Engineers must read and understand the content of this manual

before installation and/or use of the product.

Engineers must be properly qualified and competent to do work on the equipment in

accordance with the current legislation applicable in the geographical region of the

installation.

xRolec Services Ltd cannot accept any responsibility for improper actions performed

by engineers or end users.

xThe information provided in this manual must ONLY be used with the model(s) listed on

page 1 of this manual.

xThe information provided in this manual must NOT be used with any other product.

xThe content of this manual may be updated by the manufacturer as required.

xDo NOT use the equipment for anything other than its intended purpose.

xDo NOT modify the equipment unless specifically instructed to do so by the

manufacturer.

xDo NOT attempt to repair the equipment unless specifically instructed to do so by the

manufacturer.

xTo maintain electrical safety, the body enclosure of the product (access covers) must

be secured in their correct location using the supplied fasteners and the seal must be

sufficient to maintain the IP rating of the enclosure.

xFasteners used to mount the product in its working location must be sufficient for the

task and the specific mounting point.

xDamage to the product may render it unsafe. The product must be electrically

isolated and NOT used until appropriate remedial action has been performed.

Safety Advice Within this Manual

Rolec manuals use a system of warnings, cautions and notes.

xWARNINGS concern the safety of installers/end user and will be given before the

detail/instructions in the manual.

xCAUTIONS concern the potential for damage to the equipment and will be given

before the detail/instructions in the manual.

xNOTES are given to provide additional information and/or to highlight information of

importance. They will be given either before or after the detail/instructions as

appropriate and may use different wording (such as IMPORTANT) where emphasis is

required.

Warnings, Cautions and Notes may be repeated several times as appropriate and may

be preceded by a hazard symbol where appropriate.

Disclaimer

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 4of 21

Disclaimer

Rolec shall not be liable for personal injury, product damage, failure or defects in

scenarios such as but not limited to:

xUnlicensed maintenance personnel or operators to maintain the product without

authorization.

xThe product is not maintained regularly and properly according to the requirements of

the maintenance manual.

xThe product is not maintained in accordance with local specifications and standards.

xMaintenance activities are not filed or reported to the equipment supplier.

xIn the process of maintenance, the original design of the product is changed without

authorization.

xProduct damage or failure is caused intentionally or by negligence in the process of

maintenance.

xProduct damage or failure is due to force majeure (such as a bad weather, natural

disasters, etc.).

xMaintenance personnel not wearing appropriate protective equipment.

xThe front-end power supply of the equipment has not been stopped before

maintenance, resulting in personal injury and/or equipment damage.

xMaintenance while the failure of equipment is not identified, or the circuit is changed

without consulting the supplier resulting in equipment damage.

xAfter maintenance, the door lock is not closed as required, resulting in damage to the

insulation of the equipment caused by water or other foreign matters in the

equipment.

xAfter maintenance, the device with a failure is not marked clearly and sent back to

the supplier for analysis.

xAfter maintenance, the device with a failure is discarded carelessly, resulting in the

absence of cause of failure.

WARNING: Personal Injury and Equipment Damage

xBefore maintenance, make sure the power supply to the charger has been

switched OFF.

xMake sure any faults have been eliminated and the electric circuit has been

connected properly before initiating a power on test.

xPersonnel who maintain the equipment, including operators, trained personnel

and professionals, should possess the local national required qualifications in

special operations such as high-voltage operations, working at heights, and

operations of special equipment.

Equipment Warnings

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 5of 21 January 2023

Equipment Warnings

Symbol Meaning Description

DANGER

Parts of the system are at High Power during operation.

Direct or indirect contact with these components can be

fatal.

DANGER

High voltage area may cause fire or electric shock.

The construction of the area and conduits for cables must

comply with national legislation.

Only staff authorised to work with high AC and DC voltages

can work in these areas.

DANGER It is forbidden to do maintenance work in bad weather.

DANGER It is forbidden to do maintenance work when the

equipment is live.

WARNING Special tools must be used when working with high AC and

DC voltages.

WARNING Wear the appropriate personal protective equipment (PPE).

CAUTION Read and understand the manual.

CAUTION

Protective equipment and tools must be used.

Make sure all protective items are removed from the

equipment before applying power.

CAUTION Always follow national legislation.

xThis product is high-power and high-voltage equipment. Construction and

maintenance personnel shall work with the operation certificate.

xIn the maintenance of the equipment, the relevant construction standards and safety

regulations in different places and states shall be strictly followed.

xThe equipment is developed, manufactured, checked, filed and certified in

accordance with the relevant safety standards. Therefore, the product will not cause

property damage or endanger human health under normal circumstances if the

instructions for the specified use and technical instructions for safety are followed.

xThe instructions contained in this manual must be strictly observed. Otherwise, there

may be a safety hazard or failure of the safety device. Although this manual explains

the relevant safety instructions, note that safety specifications and accident

prevention specifications for the corresponding usage must be complied with.

xIn case of any problems and failures in the process of use, the user shall directly

consult the supplier. In the warranty period, if he/she asks a third party or non-

professional to maintain without authorization any safety consequences shall be

borne by the user.

xPlease strictly comply with the specifications formulated in this manual or by the

station for regular and correct maintenance of the charger.

Equipment Warnings

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 6of 21

xEach maintenance shall be recorded, components with a failure shall be identified

and, the failure description shall be prepared, and they shall be sent back to the

manufacturer for analysis. Do not discard carelessly.

xDo not change the original design of the product without authorization during

maintenance.

xMaintenance personnel shall properly wear protective equipment before entering the

field to avoid personal electric shock and equipment damage.

xAfter maintenance, close and lock the door properly so that the insulation of the

equipment will not be damaged due to water ingress or other foreign matters.

xThere is no lamp inside the charger. The installation and maintenance personnel must

bring their own lighting equipment.

xCharger is high-power and high-current equipment with a fatal dangerous voltage.

Do not repair and maintain it when it is running.

xEven when all the switches of the charger have been disconnected, the copper bar

of the charging line still has a dangerous voltage. During the maintenance of the

equipment, it is necessary to turn off the upper switch of the charger, hang the repair

sign, and check whether there is a dangerous voltage with an instrument to ensure

that the charger is completely disconnected from the power grid.

xIt is strictly forbidden to do the maintenance work in a bad weather such as

thunderstorms.

xIt is strictly forbidden to do the power-on test before troubleshooting.

xMaintenance personnel shall wear professional protective tools, such as protective

clothing, insulation boots and insulation gloves, to avoid injuries in the process of

maintenance.

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 7of 21 January 2023

Maintenance

Maintenance of Inactive Charging Stations

xWhen the charger is not in use, the charger should be in a power-off state.

xTo maintain the service life of the charger, unnecessary load should be reduced,

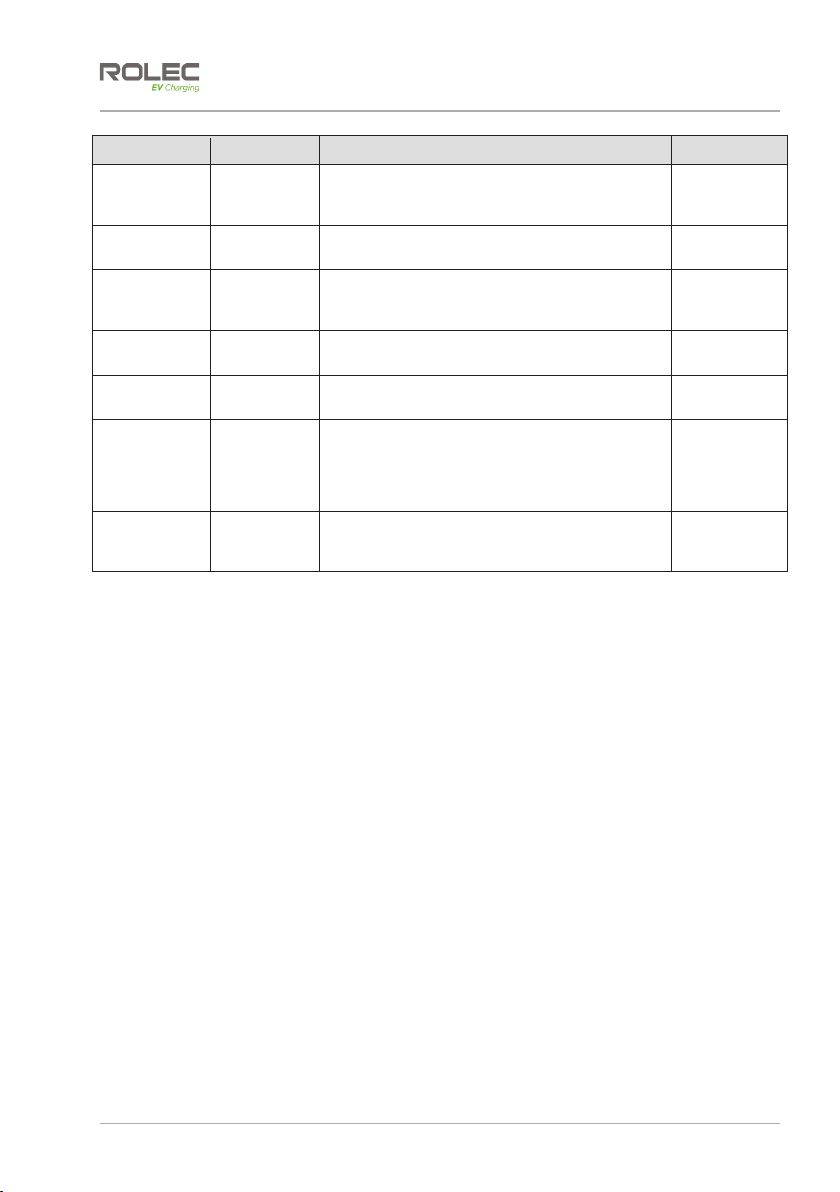

Charger Checks and Maintenance Cycle

Item Period Details Action

Front-end

distribution box Every 3 months

Each item is checked in accordance with the

maintenance manual of the distribution box. (Note:

The maintenance manual of the distribution box is

provided by the supplier of distribution box.)

Maintenance

and repairing

Appearance Every 12

months

Check the appearance of the cabinet for any stains.

Check whether the cabinet shell has any rust, scratch,

deformation, paint damage and other defects.

Cleaning and

paint repair

Interior Every 12

months

Check if the interior of the cabinet is clean and tidy.

Check whether the air inlet and outlet of the power

module are filled with dust or not. The dust shall be

timely removed to prevent the failure of the power

module.

Cleaning

Lightning

protector

Every 12

months

Check whether the module is securely connected, and

the status indicator is normal. If the status indicator

changes to red, the dry contact NC-COM of alarm

becomes open or the NC-COM becomes short-

circuited, the surge protector has failed.

Replacement

Fan Every 6 months Whether the fan is working properly. Maintenance

and repairing

Signal lamp Every 6 months Check whether the signal lamp is burned out. Make

sure it is fixed tightly and in a normal state.

Maintenance

and repairing

Components Every 6 months

Check whether components of the electric circuit

have discoloration, deformation, and other defects,

whether the fixation is loose, and whether the

connection of the components is burned out. If any

abnormality is found, parts shall be replaced in a

timely manner.

Maintenance

and repairing

Charging

connector Every 6 months

Check whether the fixing clasp of the charging

connector is damaged, whether the needle of the

charging connector is oxidized and discoloured or

obviously worn and deformed, whether any foreign

body has entered the hole on the head of the

connector, and whether the charging connector

cable is damaged.

Cleaning and

repairing

Power module Every 6 months Check that the power module is normal and there is a

trouble-free display on the module screen.

Maintenance

and repairing

Human machine

interface Every 6 months Check the display screen to see if it is cracked or not

functioning properly.

Maintenance

and repairing

Maintenance

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 8of 21

Item Period Details Action

Emergency stop

function Every 6 months

Press the emergency stop button to check whether the

emergency stop button is working normally, and reset

the emergency stop button after normal check.

Maintenance

and repairing

Equipment

grounding Every 6 months Check whether the ground wire of the equipment

housing is tightened and connected.

Maintenance

and repairing

System

grounding Every 6 months

Check whether the grounding cable inside the cabinet

is loose or detached. And check if the grounding sign is

complete and obvious.

Maintenance

and repairing

Slot Every 12

months

Check whether the slot is fixed firmly, whether the

cover plate is complete and tight.

Maintenance

and repairing

Breaker Monthly Press the TEST button of the circuit breaker to see

whether the circuit breaker can trip properly.

Maintenance

and repairing

Electric cable Every 12

months

Check whether the cable and switch are connected

closely, whether the grounding is reliable, whether the

power cable is normal, and whether the sealing

measures at the incoming cable of the cabinet are

intact.

Repairing and

replacement

of cables

Force majeure

factor Immediately

In case of flood, earthquake, impact, switch trip and

other events, the whole machine should be checked

immediately.

Maintenance

and repairing

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 9of 21 January 2023

Replacement of Common Devices

Danger: Personal Injury

Do not perform maintenance when the charger is on!

Electric Meter

Items required: xScrewdriver.

xNew electric meter.

Replacement steps: 1. Remove the screw on the protective cover at the

lower end of the electric meter,

2. Open the protective cover and remove the

connecting cable of the electric meter.

3. Remove the fixing screws at both ends of the

connection area of the electric meter and the screws

at the upper end of the electric meter.

4. Remove the electric meter.

5. Replace with a new meter in an opposite sequence of

disassembly.

6. Refit the screw on the protective cover at the lower

end of the electric meter.

Maintenance

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 10 of 21

Main circuit breaker

Items required: xHex wrench.

xScrewdriver.

xSocket wrench.

Replacement steps: 1. Remove the screws in the fixed bus bar of the circuit

breaker by using a hex wrench.

2. Remove the input and output bus bar with a socket

wrench.

3. Remove the main circuit breaker by removing the

fixing screw at the upper, middle and lower ends of

the main circuit breaker with a screwdriver.

4. Replace with a new main circuit breaker in an

opposite sequence of disassembly.

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 11 of 21 January 2023

Cooling fan

Items required: Screwdriver.

Replacement steps: 1. Remove the connecting terminals of the cooling fan;

2. Use a screwdriver to remove the four fixing screws of

the fan. And then the fan can be removed.

3. Replace with a new cooling fan in an opposite

sequence of disassembly.

Maintenance

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 12 of 21

AC contactor

Items required: Screwdriver.

Replacement step: 1. Use a screwdriver to unscrew the six screws fixing the

bus bar in the AC contactor. Note that these screws

cannot be taken out and can only be unscrewed.

2. Use a screwdriver to remove the fixing screw between

the bus bar and the insulation column.

3. Remove the bus bar from the AC contactor.

4. Use a screwdriver to remove the fixing screws in the

upper right and lower left corners of the AC contactor.

5. Remove the AC contactor.

6. Replace with a new AC contactor in an opposite

sequence of disassembly.

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 13 of 21 January 2023

Current transformer

Items required: Screwdriver.

Replacement step: 1. Use a screwdriver to remove the protective cover on

the transformer then remove the connecting cable.

2. Use the screwdriver to remove the four screws of the

fixed plate at the bottom of the current transformer.

Then the current transformer can be removed

3. Remove the cable crossing through the current

transformer from the bus bar. Then pass the transformer

through the cable to take out.

4. Replace with the new transformer in an opposite

sequence of disassembling it.

Maintenance

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 14 of 21

DC contactor

Items required: xScrewdriver.

xSocket wrench.

Replacement steps: 1. Use a socket wrench to remove the bus bar on the DC

contactor.

2. Remove the white signal line terminal on the side of

the DC contactor.

3. Use the screwdriver to remove the fixing screw in the

upper right corner and lower left corner of the DC

contactor. And then the DC contactor can be

removed.

4. Replace with a new DC contactor in an opposite

sequence of disassembling it.

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 15 of 21 January 2023

Replacement of Dust Screen (Guidance)

Items required: xScrewdriver.

xNew dust screen.

Replacement

steps: 1. Turn off the power supply, then open the left and right doors of

the cabinet.

2. Remove the left and right cover plates and their installation

screws (M4×16) with an electric screwdriver.

NOTE: The left cover plate shall be lifted up for about 20mm, and then

taken out. Do not lose the cover plate and installation screw. They will

be used in the installation later.

Maintenance

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 16 of 21

3. Use the pull ring of dust screen to draw out the old dust screen

which will be scrapped;

4. Insert the new dust screen with the same technical parameters

into the left and right-side door respectively;

Note: One end of the pull ring shall be kept outside for the next

change.

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 17 of 21 January 2023

5. Install the side cover plate and secure the (M4×16) screw to a torque

of 16kgf. Cm (1.6 Nm).

NOTE: The top of the cover plate should be hung first for installation of the

left cover plate, as shown in the figure, after which the screws are

tightened.

Maintenance

EVUCMM-V01R0 Maintenance Manual UltraCharge 160 DC Charger

January 2023 Page 18 of 21

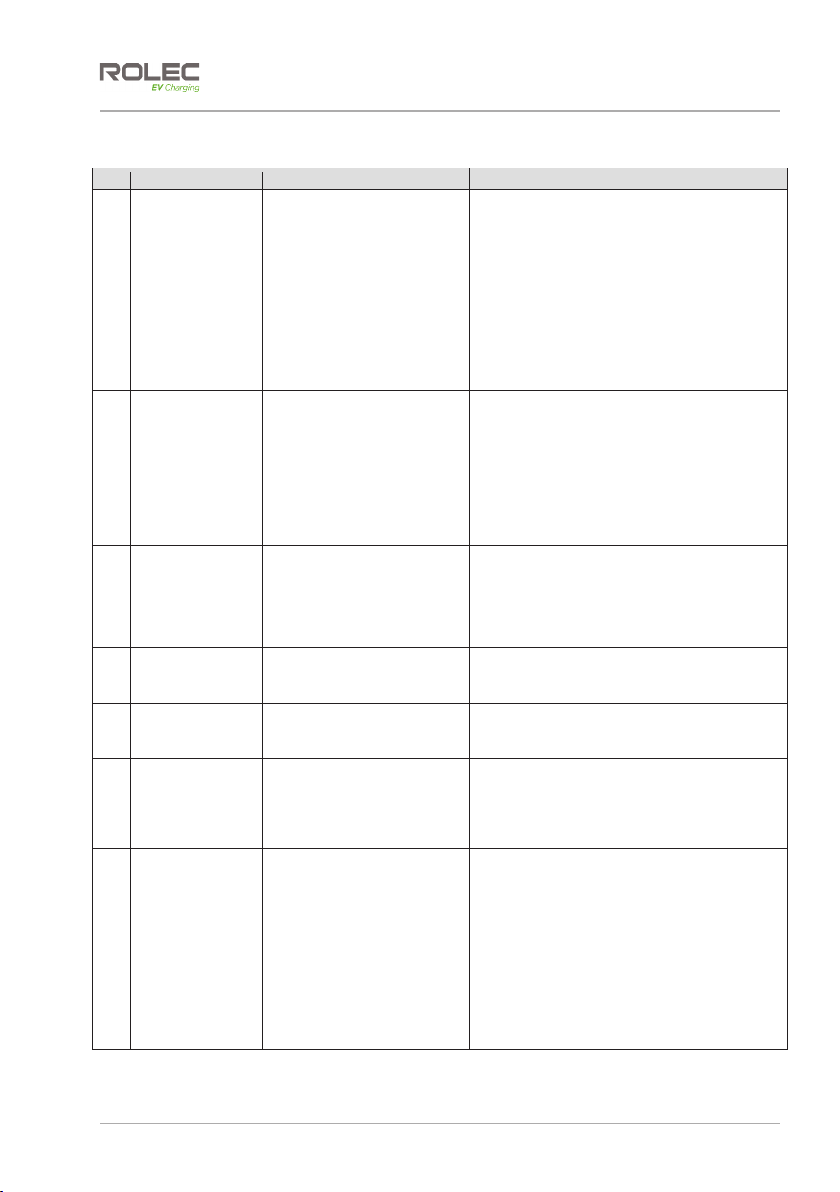

Common Troubleshooting

No. Failure Cause Correction

1 Abnormal

communication

of control panel.

1. The CAN bus wiring

between the MCU and

the charging station is

loose.

2. Error of CCU address

setting.

3. The anti-interference

ability of CAN bus is not

good, or the bus

resistance has a

problem.

1. Use a multi-meter to check whether the

CAN communication line between MCU

and the charging controller is connected

correctly, whether the build-out

resistance is connected reliably, and

whether the shield layer of the

communication line is effectively

grounded.

2. Check CCU address, dial No. 4 for No. 1

CCU, and dial No. 3 for No. 2 CCU.

3. Testing with a replaced component.

Change if MCU is damaged.

2 Electric meter

communication

failure.

1. The connection

between CCU and

electric meter is loose.

2. The electric meter

address, baud rate,

check bit, stop bit and

other settings are

incorrect.

3. Electric meter failure.

1. Check whether the connection between

CCU and electric meter is loose.

2. Check whether the electric meter

address, baud rate, check bit and stop

bit are set correctly.

3. Testing with a replaced component. If it

has a failure, the electric meter shall be

replaced.

3 Action failure of

emergency stop

button.

1. The emergency stop

button of the charging

station is pressed in the

normal state, and the

button does not restore

after being pressed.

1. Turn the emergency stop button

clockwise to return to normal.

2. Testing with a replaced component. The

damaged emergency stop button shall

be replaced.

4 Lightning

protector failure.

1. The lightning protector

is damaged.

1. Testing with a replaced component. The

damaged lightning protector shall be

replaced.

5 DC lightning

protector failure.

1. The lightning protector

is damaged.

1. Testing with a replaced component. The

damaged lightning protector shall be

replaced.

6 Access control

failure.

1. The door is not closed.

2. The wire to the micro

switch is wrongly

connected or

damaged.

1. Close and lock the door again.

2. Check whether the wire to the micro

switch is connected correctly and the

spring status is normal.

7 Off-line. 1. Check whether the

router has network, or

the signal of the station

is weak.

2. Check whether the

MCU network setting is

correct (local IP,

subnet mask, gateway,

pile number, domain

name address).

3. Network back-end is

abnormal.

1. Check whether there is a network with a

router directly connected to a laptop.

Contact the local operator if not.

2. Re-set the correct parameters if the MCU

network settings are wrong.

3. Check the back-end status in back-end.

Maintenance

UltraCharge 160 DC Charger EVUCMM-V01R0 Maintenance Manual

Page 19 of 21 January 2023

No. Failure Cause Correction

8 Black screen. 1. Whether the power

supply of MCU is lower

than 12V.

2. The power supply wire

between the MCU and

the display screen is

loose.

3. The display screen is

damaged.

1. The auxiliary power supply is damaged,

or the connection is wrong. Check the

wiring. If the wiring is correct, replace the

auxiliary power supply with a new one..

2. Tighten the power supply wire between

the MCU and the display screen.

3. If it is damaged, replace the display

screen.

9 Over-temperature

failure of charging

station.

1. There is dust

accumulation on the

dust screen at the air

outlet.

2. The internal temperature

of the charging station is

too high.

1. Remove the dust on the dust screen.

2. Check whether the fan at the air outlet

fails and whether there is dust

accumulation at the air inlet.

10 DC contactor

failure.

1. DC contactor is sticking.

2. The DC contactor do not

react or react

incorrectly.

1. Replace the DC contactor.

11 Output fuse

failure.

1. The fuse is damaged. 1. Replace the fuse.

12 Incoming circuit

breaker status

failure/ Electric

leakage failure of

incoming circuit

breaker.

1. The circuit breaker

leakage protection

device trips.

1. Check whether the leakage current of the

charging station exceeds the threshold of

the circuit breaker. If so, contact the

manufacturer.

13 Input overvoltage

failure.

1. The grid voltage

fluctuates, and the input

voltage exceeds the

protection threshold of

input voltage of the

charging station.

2. Sampling error of

charging pile.

1. Use a multi-meter to measure whether the

input three-phase voltage exceeds the

protection threshold of input voltage of the

charging pile. If so, contact the local

power grid or temporarily raise the input

voltage protection threshold of the

charging pile.

2. Contact the manufacturer for handling.

14 Input

undervoltage

failure.

1. The grid voltage

fluctuates, and the input

voltage is lower than the

input voltage protection

threshold of the charging

pile.

2. Sampling error of the

charging pile.

1. Use a multi-meter to measure whether the

three-phase voltage input is lower than the

protection threshold of input voltage of the

charging station. If so, contact the local

power grid or temporarily reduce the input

voltage protection threshold of the

charging station.

2. Contact the manufacturer for handling.

Other manuals for ROLECEV ULTRACHARGE 160

1

This manual suits for next models

4

Table of contents

Other Sinexcel Batteries Charger manuals