6SKF TKBA 40

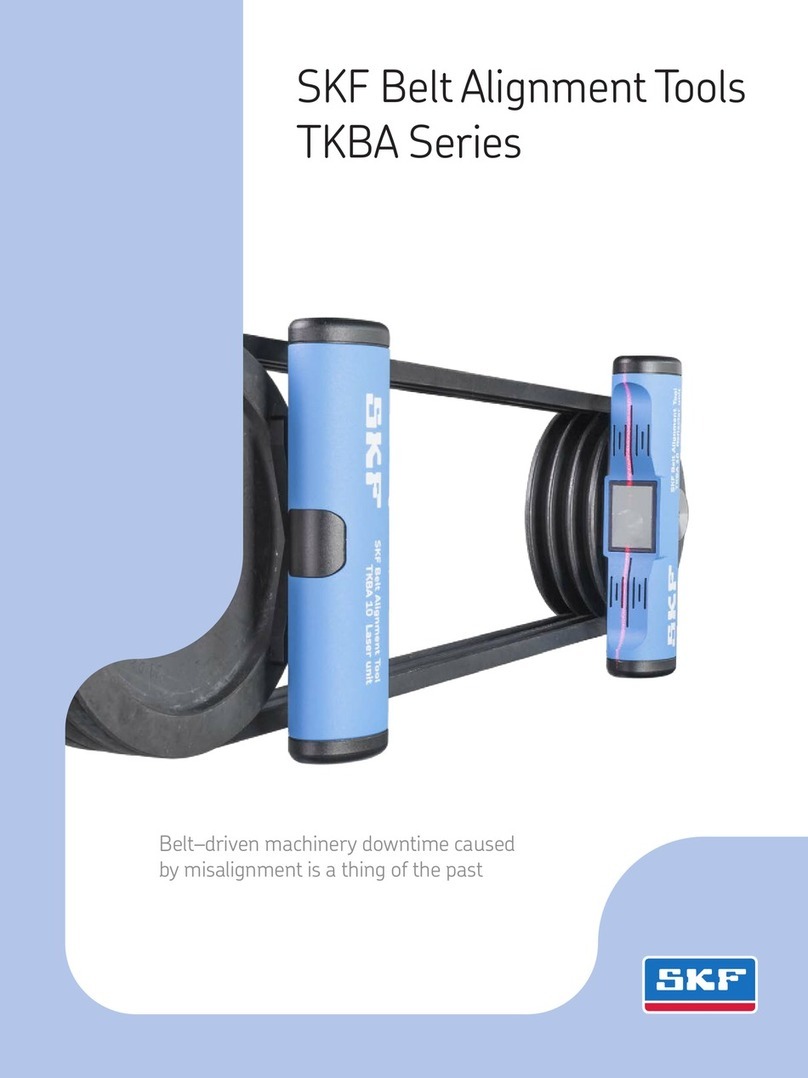

2. Belt alignment tool

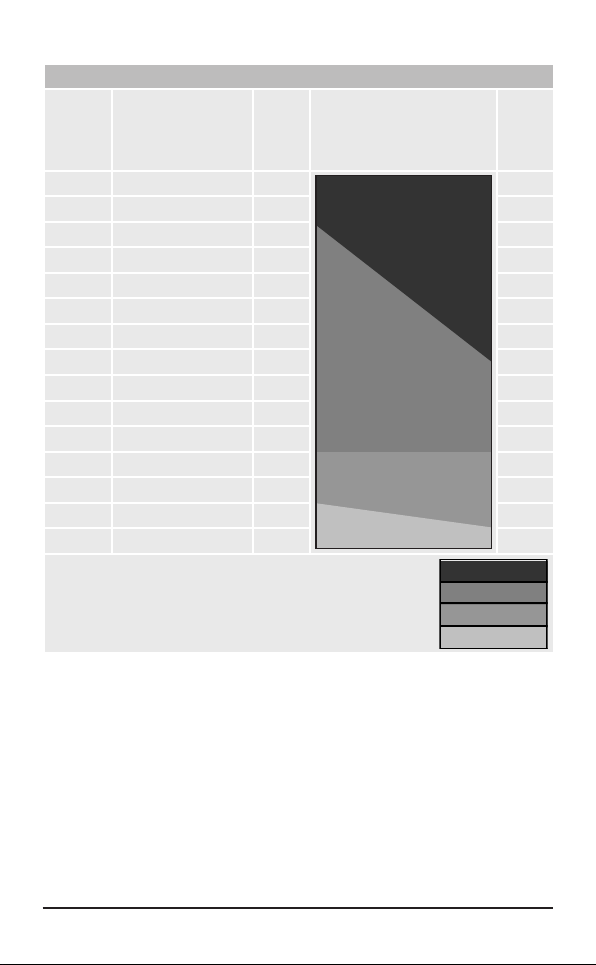

2.1 Technical data

Transmitter Unit

Type of laser Red laser diode

Laser 1™ Built-in class 2 laser, <1mW, 632nm

Laser line length 3 m at 2 m (9.8 ft at 6.6 ft)

Measurement Accuracy

Angular Better than 0,2°

Measurement Accuracy

Offset Better than 0,5 mm (0.02 in.)

Measurement distance 50 mm to 6 000 mm (2 in. to 20 ft)

Control Laser on/off switch

Housing Material Extruded aluminium

Colour Silver, blue, black

Transmitter unit dimensions 70 ™ 74 ™ 61 mm (2.8 ™ 2.9 ™ 2.4 in.)

Transmitter unit weight 320 g (0.7 lbs)

Receiver Unit

Housing Material Extruded aluminium

Colour Silver, grey, blue

Reflector dimensions N/A

Receiver unit dimensions 96 ™ 74 ™ 61 mm (3.8 ™ 2.9 ™ 2.4 in.)

Receiver unit weight 270 g (0.6 lbs)

Fixtures

Mounting “Magnetic, groove mounted

(optional side adapter TMEB A2)”

V-guides Size 1: 22 mm, short rods (3™ pairs)

Size 2: size 22 mm, long rods (3™ pairs)

Size 3: size 40 mm, short rods (3™ pairs)

Size 4: size 40 mm, long rods (3™ pairs)

Battery and Power

Battery 2™ AAA Alkaline type IEC LR03

Operation time 20 hours continuous operation