4

EN Table of contents

Table of contents

EC Declaration of incorporation following machinery directive 2006/42/

EC, annex II, part 1 B...................................................................................2

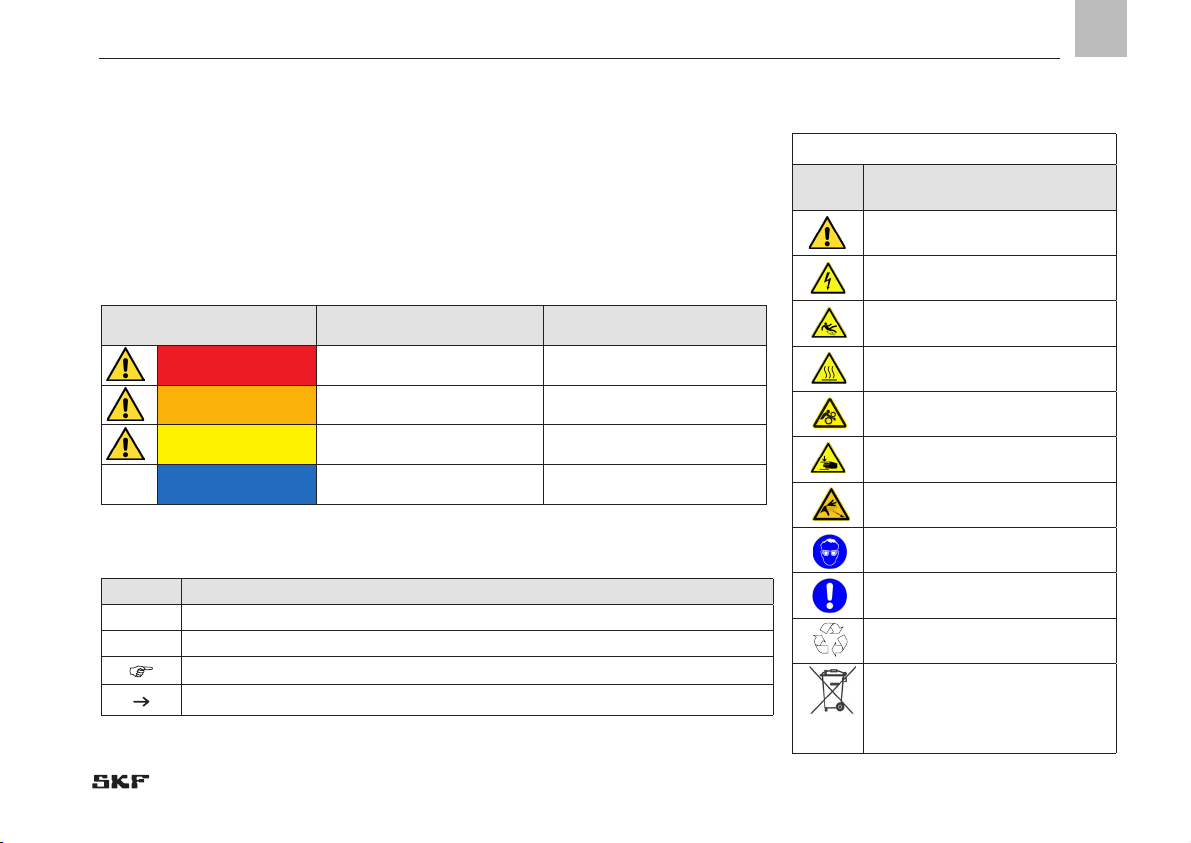

Explanation of symbols and signs ...............................................................5

1. Safety instructions.........................................................................7

1.1 General safety instructions....................................................................7

1.2 General behaviour when handling the product...................................7

1.3 Qualified technical personnel ................................................................8

1.4 Electric current hazard........................................................................... 9

1.5 System pressure hazard ........................................................................9

1.6 Operation.................................................................................................9

1.7 Assembly, maintenance, malfunctions, modification, shutdown,

disposal ..................................................................................................10

1.8 Intended use..........................................................................................10

1.9 Foreseeable misuse..............................................................................11

1.10 Disclaimer of liability.............................................................................11

1.11 Other applicable documents................................................................11

1.12 Residual risks ........................................................................................12

2. Lubricants................................................................................... 14

2.1 General information ............................................................................14

2.2 Selection of lubricants..........................................................................14

2.3 Approved lubricants..............................................................................15

2.4 Lubricants and the environment.........................................................16

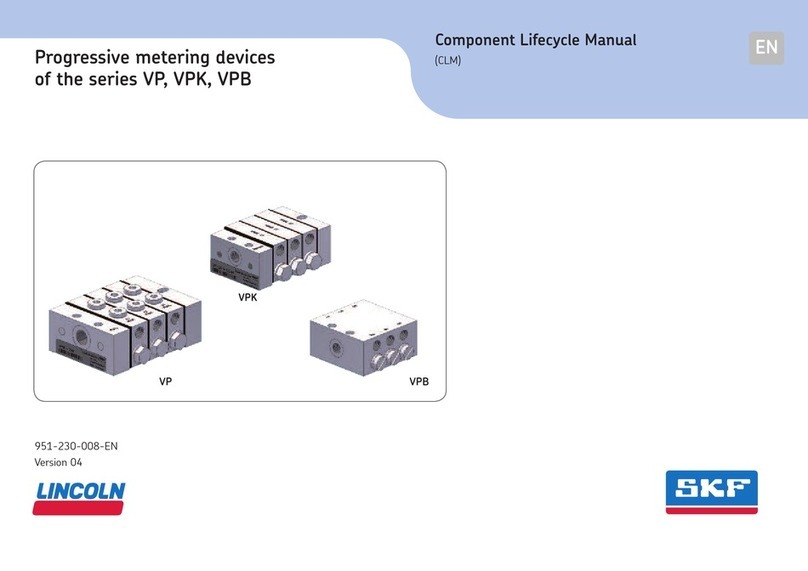

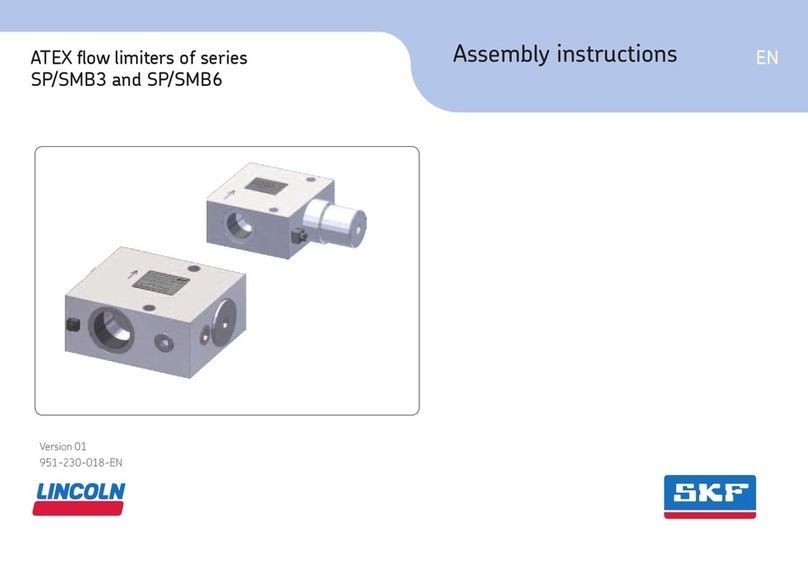

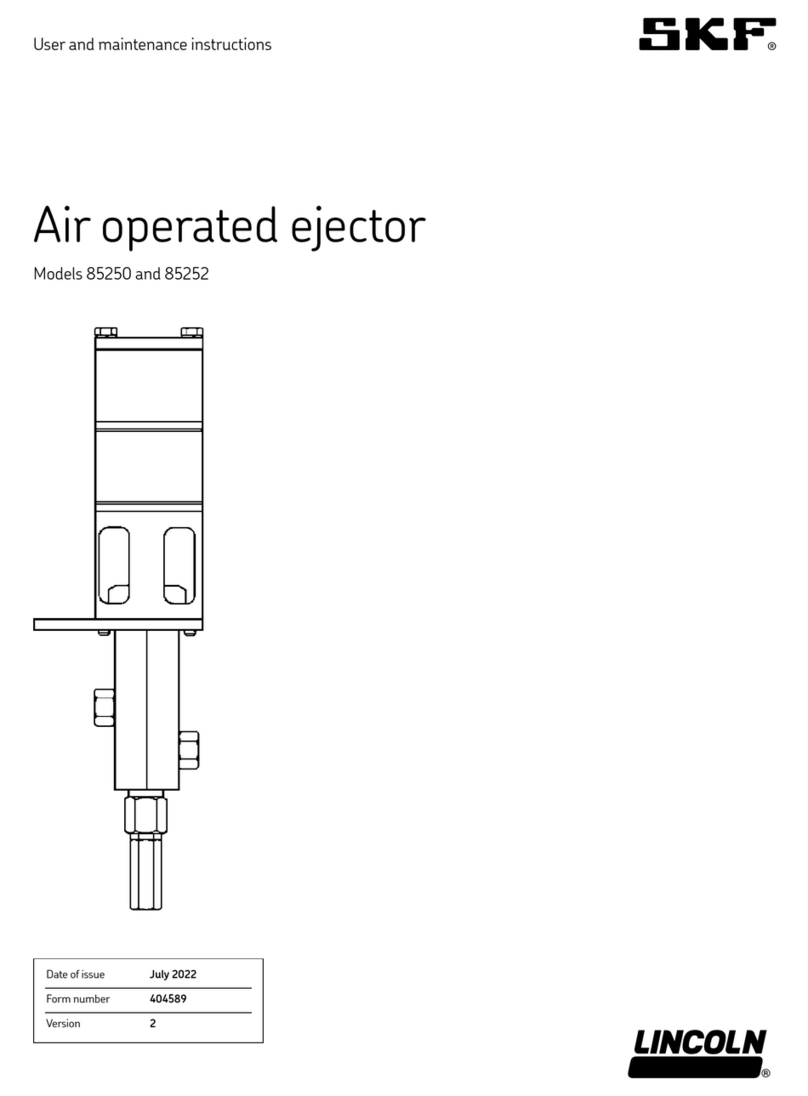

3. Overview, functional description ................................................ 17

4. Technical data ............................................................................. 20

4.1 General technical data..........................................................................20

4.2 Notes related to the type identification plate.....................................21

4.3 Notes related to the CE marking .........................................................21

4.4 Limit switch............................................................................................22

4.5 Proximity switch....................................................................................23

5. Delivery, returns, and storage .................................................... 24

5.1 Delivery..................................................................................................24

5.2 Returns .................................................................................................24

5.3 Storage...................................................................................................24

5.4 General notes related to storage.........................................................24

6. Installation.................................................................................. 25

6.1 General information .............................................................................25

6.2 Attachment............................................................................................25

6.3 Electrical connection ............................................................................26

7. Start-up...................................................................................... 27

8. Operation, shutdown and disposal ............................................. 28

8.1 Temporary shutdown ...........................................................................28

8.2 Shutdown and disposal........................................................................28

9. Maintenance, cleaning and repair .............................................. 29

9.1 General information .............................................................................29

9.2 Maintenance..........................................................................................29

9.3 Cleaning .................................................................................................29

9.4 Repair.....................................................................................................29

10. Troubleshooting.......................................................................... 30

11. Spare parts................................................................................. 31

12. Dimensional drawings ................................................................ 34